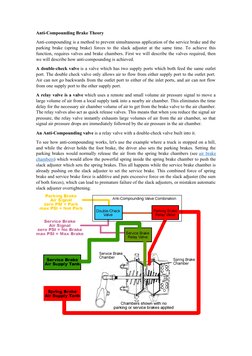

Anti-Compounding Brake Theory

Anti-compounding is a method to prevent simultaneous application of the service brake and the

parking brake (spring brake) forces to the slack adjuster at the same time. To achieve this

function, requires valves and brake chambers. First we will describe the valves required, then

we will describe how anti-compounding is achieved.

A double-check valve is a valve which has two supply ports which both feed the same outlet

port. The double check valve only allows air to flow from either supply port to the outlet port.

Air can not go backwards from the outlet port to either of the inlet ports, and air can not flow

from one supply port to the other supply port.

A relay valve is a valve which uses a remote and small volume air pressure signal to move a

large volume of air from a local supply tank into a nearby air chamber. This eliminates the time

delay for the necessary air chamber volume of air to get from the brake valve to the air chamber.

The relay valves also act as quick release valves. This means that when you reduce the signal air

pressure, the relay valve instantly exhausts large volumes of air from the air chamber, so that

signal air pressure drops are immediately followed by the air pressure in the air chamber.

An Anti-Compounding valve is a relay valve with a double-check valve built into it.

To see how anti-compounding works, let's use the example where a truck is stopped on a hill,

and while the driver holds the foot brake, the driver also sets the parking brakes. Setting the

parking brakes would normally release the air from the spring brake chambers (see air brake

chambers) which would allow the powerful spring inside the spring brake chamber to push the

slack adjuster which sets the spring brakes. This all happens while the service brake chamber is

already pushing on the slack adjuster to set the service brake. This combined force of spring

brake and service brake force is additive and puts excessive force on the slack adjuster (the sum

of both forces), which can lead to premature failure of the slack adjusters, or mistaken automatic

slack adjuster overtightening.

�One supply port of the anti-compounding valve is connected to the parking brake valve, and the

other supply port of the anti-compounding valve is connected to the rear axle service brake

pressure signal. Pressure from either source will activate the spring brake relay valve and fill the

spring brake chambers, thereby releasing the spring brake.

Therefore, in the above situation, the driver holding the service brakes on the hill, places service

brake air pressure into the service brake chambers which sets the service brakes. When the

driver now sets the parking brakes, the anti-compounding valve still holds pressure in the spring

brake chambers, from the foot brake pedal service brake supply port; even while the parking

brake valve supply port has purged all air pressure to the parking anti-compounding supply port.

This air pressure into the spring brake chamber, holds off the spring force from the spring brake

chamber as long as the service brakes are applied, and only the service brake air chamber force

is applied to the slack adjuster. This is anti-compounding, when the spring force is delayed

while the service brake force exists.

After setting the parking brakes, and when the driver then lets up on the foot brake pedal, the

service brake supply port of the anti-compounding valve looses air pressure, and the parking

brake supply port still has no air pressure. Since the spring brake relay valve now sees no signal

air pressure from either supply port, it quickly vents the spring brake chambers which sets the

spring brake force on the slack adjuster. So the service brakes stopped holding force on the

slack adjuster at the same time that the spring brakes commenced to hold force on the slack

adjuster. This is continued anti-compounding control of the brakes.

If the driver were to later step on the foot pedal after the parking brakes were on, the service

brake pressure signal would go to the service brake supply port of the anti-compounding valve,

and fill the spring brake chambers to release the spring brake force, at the same time as the

service brake air chamber applies more brake force on the slack adjuster. So now, as the service

brake force increases, the spring brake force decreases. This is also anti-compounding, when the

force from the spring brake chamber is reduced to compensate for the additional force being

applied by the service brake chamber.

This concludes the anti-compounding description. By controlling the forces being applied to the

slack adjusters, we have reduced the stress placed on the slack adjuster parts, and we have also

eliminated the potential of overflexing the automatic slack adjusters enough to the point of over

adjustment by the automatic slack adjusters.

Before anti-compounding valves, automatic slack adjusters could be flexed by the compounding

forces upon the automatic slack adjuster, and this would allow the automatic adjuster to catch

the next adjustment notch, even though it wasn't really needed. This resulted in automatic slack

adjuster over-tightening, which was a real problem, until anti-compounding valves came to the

rescue.