Professional Documents

Culture Documents

01 Genetal Index PDF

01 Genetal Index PDF

Uploaded by

Javier Aguilera0 ratings0% found this document useful (0 votes)

10 views4 pagesOriginal Title

01 Genetal Index.pdf

Copyright

© © All Rights Reserved

Available Formats

PDF or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

© All Rights Reserved

Available Formats

Download as PDF or read online from Scribd

0 ratings0% found this document useful (0 votes)

10 views4 pages01 Genetal Index PDF

01 Genetal Index PDF

Uploaded by

Javier AguileraCopyright:

© All Rights Reserved

Available Formats

Download as PDF or read online from Scribd

You are on page 1of 4

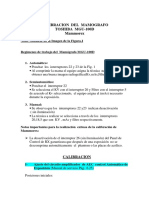

GENERAL INDEX

PREFACE SECTION .

SECTION INDEX ..

PREFACE, 7

INSTRUCTION MANUAL...

PURPOSE OF THIS MANUAL

STRUCTURE OF THIS MANUAL .....

ADDITIONAL DOCUMENTATION...

SAFETY

PERSONNEL QUALIFICATIONS

SYMBOLS USED .

WARNINGS...

CONDITIONS TO UPHOLD THE WARRANTY

WARRANTY TERMS..... 7

MANUAL DELIVERY COUPON,

GENERAL INFORMATION - SECTION 1 ..

SECTION INDEX .. 7

Ll GENERAL INFORMATION ..

1.1.1 INFORMATION IDENTIFYING THE MANUFACTURER

1.1.2 INFORMATION IDENTIFYING THE CUSTOMER/USER

1.13 INFORMATION ABOUT MAINTENANCE SERVICE ....

1.1.4 INFORMATION ABOUT THE USER/MANUFACTURER

RELATIONSHIP

1.2 GENERAL SAFETY...

12.1 SAFETY WARNINGS FOR THE MACHINE.

1.22 REQUIRED PERSONNEL. TRARINGIQUALIFICATIONS

13 INFORMATION ABOUT THE MACHINE ..

13,1 GENERAL NOTES

1.32 UNIT DIMENSIONG..... Se

133 MAIN COMPONENTS OF THE UNIT...

14 INTENDED USE

uae RAL

INSTRUCTION FOR INSTALLATION - SECTION

SECTION INDEX

21 RECEIVING...

2.1.1 LIFTING AND MOVING THE PACKED MACHINE.

2.12 FORBIDDEN LIFTING MEANS

22 STORING THE MACHINE .....

2.3 DISPOSING OF PACKING MATERIALS.

24 FEATURES OF THE PACKING

2.5 OPENING THE PACKING :

2.5.1 REMOVING THE MACHINE FROM THE BASE

2.5.2_CHECKING THE CONTENTS OF THE PACKAGE

2.6 POSITIONING THE MACHINE

26.1 CLEANING

27 INSTALLATION...

28 UTILITY HOOK-UPS Fs

29 TECHNICAL SPECIFICATIONS

2.10 MACHINE INSPECTION

OPERATING INSTRUCTION - SECTION3...

SECTION INDEX...

3.1 GENERAL SAFETY WARNINGS -

3.11 INTRODUCTION

3.12. MANUFACTURER'S RESPONSIBILITY

3.13 PROTECTION AGAINST RADIATION

3.14 ELECTRICAL SAFETY DEVICES

3.1.3 MECHANICAL SAFETY DEVICES

3.16 RISK OF EXPLOSION won reese

32 AREA NECESSARY IN ORDER TO USE THE MACHINE

GIOTTO HI-TECH

IME tit GIOTTO OE Preface Section Rev. 198

GIOTTO HL-TECH

33. GENERAL FEATURES OF THE MACHINE 6

33.1 MACHINE CONFIGURATION 6

34 DESCRIPTION OF THE CONTROLS 7

3.4.1 GANTRY MOVEMENT REMOTE CONTROL UNIT 17

8

9

9

342 CENTERING DEVICE

343 PEDALS FOR COMPRESSOR MOTOR DRIVE

3.44 MANUAL COMPRESSION HANDLE ..

345 CONTROL CONSOLE

3.46 AUTOMATIC CONTROL KEYPAD (OPTIONAL) vnncoen B

3.5 SAFETY SYSTEMS ON THE MACHINE.... Le eae

3.5.1 GENERAL SAFETY INFORMATION .. so ld

3.52 CONTROLS AND SIGNALS el

3.53 EMERGENCY STOP ‘i 14

3.6 PRELIMINARY OPERATIONS jen

3.6.1 TURNING THE EQUIPMENT ON 7 " tt

3.62 POTTER INSERTION er

3.6.3 CASSETTE INSERTION

3.64 DIAPHRAGM INSERTION, acct eG

3.6.5 LIGHTED COLLIMATOR 7 sn 16

3.66 SELECTING THE OPERATING MODE. ceased?

3.6.7 SELECTING THE TYPE OF FIELD vexrsnsnnunsnnn seen

3.6.8 SELECTING THE SCREEN eels 18

3.6.9 SELECTING THE DENSITY OF THE FILM. 18

3.6.10 SELECTING THE TUBE FOCUS S.F/L..

3.6.11 GANTRY MANUAL POSITIONING item

3.6.12 SEMIAUTOMATIC GANTRY POSITIONING 21

3.6.13, AUTOMATIC GANTRY POSITIONING ..

3.6.14 POSITIONING THE PATIENT plete

3.6.15 COMPRESSION. oa 24

3.6.16 ENLARGEMENT... BS

3.6.17 MARKERS eon lol BS

3.6.18 RAY EMISSION..... nai 26

STARTING THE MACHINE - SECTION 4

SECTION INDEX... =

4.1 GENERAL SAFETY WARNINGS......

4.1.1 INTRODUCTION

4.12 MANUFACTURER'S RESPONSIBILITY -

4.13 PROTECTION AGAINST RADIATION

42 PRELIMINARY OPERATIONS

43 STARTING THE EQUIPMENT .

SAFETY AND CONTROL DEVICES - SECTION 5.

SECTION INDEX 2

5.1 GENERAL SAFETY WARNINGS

5.1.1 INTRODUCTION...

5.12 MANUFACTURER'S RESPONSIBILITY

5.13. PROTECTION AGAINST RADIATION

5.14 ELECTRICAL SAFETY DEVICES

5.1.5 MECHANICAL SAFETY DEVICES

5.1.6 RISK OF EXPLOSION

52 SAFETY AND CONTROL SYSTEMS ON THE MACHINE

5.2.1 GENERAL SAFETY INFORMATION

5.2.2 CONTROL DEVICES...

523. SAFETY DEVICES

GIOTTOO-E Preface Section Rev 98 | == IM

GIOTTO HI-TECH

CHECKS AND ADJUSMENTS - SECTION 7

SECTION INDEX

7.1 GENERAL SAFETY,

7.1.1 SAFETY WARNINGS FOR THE MACHINE... :

7.1.2 REQUIRED PERSONNEL: TRAININGIQUALTFICATIONS

72 MONTHLY CHECKS Saal

73. PERIODIC MECHANICAL CHECKS

7.4 PERIODIC ELECTRICAL/ELECTRONIC CHECKS

7.5 LUBRICATION cease ati

7.6 MECHANICAL CONTROLS FOR SETTING DRG SWINGING MOVEMENT

FOR STEREOTAXIA weve

7.6.1 SETTING THE CYTOGUIDE.

DETERMINING RAY-TUBE 0°...

CENTERING THE X-RAY TUBE

SETTING THE #24° STOP LIMIT

ESTABLISHING THE CHORDS ...

7.7 PRELIMINARY BASIC CHECKS.

7.7.1 VISUAL MECHANICAL CHECKS ..

77.1.1 COMMAND SWITCH-BOARD/WINDOW .

7.7.1.2 CIRCULAR ARM

77.13 STAND 7

7.8 _ CHECK POWER SUPPLY, CONTROL SIGNAL, ELECTRICAL

~ ADJUSTEMENT.

7.8.1 POWER SUPPLY a

78.2 PWM MOTOR DRIVING (FOR ALL MOTOR)

783 ADJUSTMENT/REPLACEMENT OF THE VERTICAL AXIS

POTENTIOMETER sal

784 ADJUSTMENT/REPLACEMENT OF THE ROTATION AXIS

POTENTIOMETER nnn

785 ADIUSTMENT/REPLACEMENT OF THE INCLINED AXIS

POTENTIOMETER 15

78.6 MECHANICAL ADJUSTMENT OF GRID MOVEMENT 16

18.7 TUBE PENDULAR MOVEMENT SETTING # 24° 17

78.8 COMPRESSION FORCE SETTING .. AT

7.9 XRAY ADIUSTEMENT. 18

79.1 FILAMENT CURRENT 18

7.9.2 HT. INVERTER SIGNAL CHECKS «... 1B

79.3 CHECK AND SETTINGS OF HIGH VOLTAGE KVP... 19

7.94 ANODIC CURRENT CHECKS AND SETTING, oven 19)

79.5 IONIZATION CHAMBER SIGNAL CHECK AND SETTING 19

7.10 FIELD SIGNAL

7.0.AINPUT ($243) / OUTPUT (sii

INPUT 7

OUTPUT seen

7.11. CALIBRATION SCHEDULE MAIMAS/CVP (3000).

7.12, CALIBRATION SCHEDULE MA/MAS/KVP (9000)

20

20

20

21

2

23

7.13, VALUE TABLE GRID SPEED SMALL FOCUS/MANUAL TECNIQUE 23

7.14 VALUE TABLE GRID SPEED LARGE FOCUS/MANUAL TECNIQUE ........24

7.15 VALUE TABLE GRID SPEED SMALL FOCUS

SEMIAUTOMATIC - AUTOMATIC TECHNIQUE... noe 5

7.16 VALUE TABLE GRID SPEED LARGE FOCUS

SEMIAUTOMATIC - AUTOMATIC TECHNIQUE.

7.17 VOLTAGE OF MOTORS... ee

INSTRUCTION FOR CLEANING AND MAINTENANCE - SECTION 8.

SECTION INDEX

8.1 GENERAL SAFETY

8.1.1 SAFETY WARNINGS FOR THE MACHINE

8.12 REQUIRED PERSONNEL: TTRAININGIQUALIFICATIONS

82 CLEANING : a

83 ROUTINE MAINTENANCE,

84 PREVENTIVE MAINTENANCE were

85 SAFETY COMPONENTS TO BE USED AS SPARES.

IM fee GIOTTOO-E Preface Section Rev. 198

‘TROUBLE SHOOTING

ECTION 9, 1

SECTION INDEX . 2

BLL ERROR SIGNALS warn Bg 3

9.1.1 ERROR MESSAGES ON THE DISPLAY 3

DEDICATED SOFTWARE AND SETTING METHOD - SECTION 10. 1

SECTION INDEX end

10 CONFIGURATION SOFTWARE weed

10.1. INTRODUCTION 3

10.2 FEATURES... 4

103. X-RAY EXECUTION |

10.4 OPERATIONS 6

10.4.1 MAIN AXIS MOTORS. a

10.4.2 PRESSER FORCE 8

10.4.3 GRID SPEED. 9

10.4.4 TUBE KV 10

10.4.5 TUBE MA... 2 ened

10.46 MO/MO - MO/RH FILTER THRESHOLD cmaccamemennl]

10.4.7 RAY SENSOR MANAGEMENT wssoossnnnmnne sone 12,

10:48 AUTOMATIC EXPOSURE METER

10.4.8.1 SEMIAUTOMATIC TABLES “A”

10.4.8.2 SEMIAUTOMATIC TABLES “B”

10.4,8.3 AUTOMATIC TABLES “A”

10.4.8.4 AUTOMATIC TABLES "B" san

10.4.8.5 OPTIC DENSITY

105 UTILITIES

10.5.1 BACKUP MACHINE CONFIGURATION.

10.5.2 RESTORE MACHINE CONFIGURATION

10.5.4 CONFIGURE PROGRAM.

10.5.3 LIST CONFIGURATIONS «0.

10.5.5 APPENDIX A : ERROR MESSAGES

ELETRICAL AND ELECTRONIC BOARDS - SECTION 11

IONIZING CHAMBER - SECTION 114...

PWM MOTOR DRIVER - SECTION 1B wn

OVERALL MACHINE ELETRICAL DIAGRAM - SECTION 11

‘TECHNICAL DESCRIPTION OF H-T. TRASFORMER AND INVERTER ..

MECHANICAL DIAGRAMS - SECTION 13 wen

SPARE PARTS - SECTION 14

X-RAY TUBE - SECTION 15...

ACCESSORIES - SECTION 16...

You might also like

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5814)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1092)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (845)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (590)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (897)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (540)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (348)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (822)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (122)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (401)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- Manual de Servicio Iluma Imtec CBCTDocument77 pagesManual de Servicio Iluma Imtec CBCTGriselda Maria Pinto Sanchez100% (2)

- Error MessagesDocument32 pagesError MessagesGriselda Maria Pinto Sanchez100% (5)

- Link para Descargar Diagramas de TVDocument1 pageLink para Descargar Diagramas de TVGriselda Maria Pinto Sanchez100% (1)

- Gigantos 1000Document16 pagesGigantos 1000Griselda Maria Pinto Sanchez100% (1)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- Siemens Mammomat G2020Document37 pagesSiemens Mammomat G2020Griselda Maria Pinto Sanchez100% (1)

- Heliophos 5E PDFDocument25 pagesHeliophos 5E PDFGriselda Maria Pinto Sanchez100% (1)

- 2d621-092en - B Mgu-1000a Service MDocument130 pages2d621-092en - B Mgu-1000a Service MGriselda Maria Pinto Sanchez100% (4)

- 2b621-657en - C Mgu-1000a Operation MDocument166 pages2b621-657en - C Mgu-1000a Operation MGriselda Maria Pinto Sanchez100% (1)

- Siemens Klinograph EDocument17 pagesSiemens Klinograph EGriselda Maria Pinto Sanchez100% (2)

- Heliophos 5EDocument25 pagesHeliophos 5EGriselda Maria Pinto Sanchez100% (1)

- Start Up InstructionsDocument22 pagesStart Up InstructionsGriselda Maria Pinto SanchezNo ratings yet

- Siemens Polymat Plus SDocument2 pagesSiemens Polymat Plus SGriselda Maria Pinto Sanchez100% (1)

- Manual de Usuario Iluma Imtec CBCTDocument70 pagesManual de Usuario Iluma Imtec CBCTGriselda Maria Pinto SanchezNo ratings yet

- Gehc Mict ProductDocument1 pageGehc Mict ProductGriselda Maria Pinto SanchezNo ratings yet

- Siremobil 2000 DiagramasDocument195 pagesSiremobil 2000 DiagramasGriselda Maria Pinto Sanchez100% (1)

- 4.2. - Start-Up Instructions From Serial N°03000Document39 pages4.2. - Start-Up Instructions From Serial N°03000Griselda Maria Pinto SanchezNo ratings yet

- Calibracion de Angulo MGU-100DDocument2 pagesCalibracion de Angulo MGU-100DGriselda Maria Pinto Sanchez100% (1)

- System Data (MGU-1000A)Document12 pagesSystem Data (MGU-1000A)Griselda Maria Pinto SanchezNo ratings yet

- Calibracion Del Mamografo Mgu-100dDocument14 pagesCalibracion Del Mamografo Mgu-100dGriselda Maria Pinto Sanchez0% (1)

- Schematics: EVA-HF325/525 GeneratorDocument25 pagesSchematics: EVA-HF325/525 GeneratorGriselda Maria Pinto Sanchez100% (1)

- TSH4130C-Satellite C645D-SP4130L PDFDocument3 pagesTSH4130C-Satellite C645D-SP4130L PDFGriselda Maria Pinto SanchezNo ratings yet

- Requisitos de Pre-InstalaciónDocument2 pagesRequisitos de Pre-InstalaciónGriselda Maria Pinto SanchezNo ratings yet

- Calibration: EVA-HF325/525 GeneratorDocument9 pagesCalibration: EVA-HF325/525 GeneratorGriselda Maria Pinto SanchezNo ratings yet