Professional Documents

Culture Documents

Table 5: Requirements For Drill Pipe Inspection Reporting

Uploaded by

Josue Fish0 ratings0% found this document useful (0 votes)

27 views1 pageOriginal Title

T5-Requirements-for-Drill-Pipe-Inspection-Reporting-NS2

Copyright

© © All Rights Reserved

Available Formats

PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

0 ratings0% found this document useful (0 votes)

27 views1 pageTable 5: Requirements For Drill Pipe Inspection Reporting

Uploaded by

Josue FishCopyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

You are on page 1of 1

Drillstring Inspection Standard

Once printed this specification becomes an uncontrolled copy of the online version.

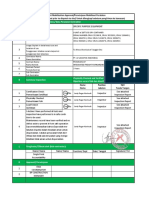

Table 5: Requirements for Drill Pipe Inspection Reporting

Revision 0

Number:

Effectivity Date: 01/03/2013

Rev Date Description Change Note

0 01/03/13 First online publication

Requirements for Drill Pipe Inspection Reporting

Traceability: The permanently assigned identification number unique to each individual component

Classification: The final classification of all pieces inspected, including any repair conducted

Markings: The type, colour, and location of the classification identification markings which have been

applied to each piece

Identification: The pipe OD, ID, grade, weight, length, thread type, MIU length, Hardbanding type and

application i.e. flush/proud Internal Plastic coating condition. Manufacturer (when possible) and

identification number

Defects: The location and severity of all defects. Identify defects using terms described in API Bulletin

5T1, ISO 10407-2

Personnel: The name, job classification(s), and certification of all Inspection Company personnel

performing inspections at the work location

Responsibility: The signature of the designated Inspection Company representative who is responsible

for the service provided

Work Order: The customer purchase order number, work order number, or shop job number(s)

Location: The name of the drilling rig and well site or pipe yard location where the inspection work was

performed

Date: The date of inspection work

Agency Standard Operating Procedure(s): The types of calibration standards and methods used

Specification: Standard used to qualify equipment e.g. NS-2™

Thread Compound: Details of the thread compound used to protect the threads on completion of the

inspection

Photocopying or reproducing this page in any way constitutes as an infringement of the license

agreement for the continued supply of the NS-2™ Service

NS-2™ Page 1

You might also like

- Jis Z2352-2010 PDFDocument32 pagesJis Z2352-2010 PDFJosue Fish50% (2)

- Ultrasonic Test Report: Before AfterDocument7 pagesUltrasonic Test Report: Before AfterMenad SalahNo ratings yet

- NORSOK M-506 CO2 corrosion rate modelDocument59 pagesNORSOK M-506 CO2 corrosion rate modelYosmar GuzmanNo ratings yet

- EMMARDocument5 pagesEMMARNisar DeenNo ratings yet

- Aws A5.3Document28 pagesAws A5.3ahmedNo ratings yet

- Aws A5.3Document28 pagesAws A5.3ahmedNo ratings yet

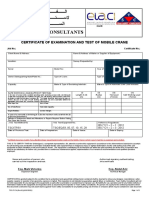

- SGS Egypt Certificate for Mobile Telescopic Crane InspectionDocument2 pagesSGS Egypt Certificate for Mobile Telescopic Crane Inspectionمحمد الديبNo ratings yet

- Method Statement Fencing Fabrication and InstalationDocument22 pagesMethod Statement Fencing Fabrication and InstalationigamamruNo ratings yet

- NCDOT WPS for Double Bevel Groove WeldsDocument3 pagesNCDOT WPS for Double Bevel Groove Weldsfarshid KarpasandNo ratings yet

- NDTSNTDocument20 pagesNDTSNTEugenia Le FosseNo ratings yet

- A-Star Testing & Inspection (S) Pte LTD: Magnetic Particle Testing ReportDocument4 pagesA-Star Testing & Inspection (S) Pte LTD: Magnetic Particle Testing ReportHari KarthickNo ratings yet

- 3576 Erbil MergedDocument4 pages3576 Erbil MergedAli AlahmaNo ratings yet

- Paint Thickness Measurement ProcedureDocument2 pagesPaint Thickness Measurement ProcedurenathgsurendraNo ratings yet

- FM Global Property Loss Prevention Data Sheets: Paper Machines and Pulp DryersDocument37 pagesFM Global Property Loss Prevention Data Sheets: Paper Machines and Pulp DryersDiego MarquinaNo ratings yet

- Forklift Safety CertificateDocument2 pagesForklift Safety CertificateSHARAFUDHEEN TKNo ratings yet

- BP 42 Guidance On The Safe Use of Container Lifting LugsDocument7 pagesBP 42 Guidance On The Safe Use of Container Lifting LugsGaniyuNo ratings yet

- 75914199-2 - Fu-10-Pad - Eyes-Mpi, 20-May-2024Document1 page75914199-2 - Fu-10-Pad - Eyes-Mpi, 20-May-2024Mohamed El-SawahNo ratings yet

- Mobile Crane Checklist EssentialsDocument6 pagesMobile Crane Checklist EssentialsBanesco TemplarisNo ratings yet

- Classification of Drilling EquipmentDocument32 pagesClassification of Drilling EquipmentJose BarreroNo ratings yet

- Procedure for Working at HeightsDocument41 pagesProcedure for Working at HeightsShahla100% (1)

- Formulas Well ControlDocument6 pagesFormulas Well ControlJosue FishNo ratings yet

- TB0022 Lifting Equipment Load Test + Visual + MpiDocument1 pageTB0022 Lifting Equipment Load Test + Visual + MpikhalilNo ratings yet

- Mobile Crane Test Procedure.Document4 pagesMobile Crane Test Procedure.Deepak GehlotNo ratings yet

- Writing Task 1 Band DescriptorsDocument1 pageWriting Task 1 Band DescriptorsIbrahim Babatunde OladapoNo ratings yet

- CA-40-02 Rev.03E UT Procedure Fer AWS D1.1-2015Document24 pagesCA-40-02 Rev.03E UT Procedure Fer AWS D1.1-2015hoangdiep phanNo ratings yet

- Joining Instruction - Rigger Level-3 TrainingDocument2 pagesJoining Instruction - Rigger Level-3 TrainingahmadNo ratings yet

- DOE Std.1090 07 Forklift TrucksDocument35 pagesDOE Std.1090 07 Forklift TrucksjoseritoNo ratings yet

- BT Lifter HPT Brochure 0614Document12 pagesBT Lifter HPT Brochure 0614Ram ReddyNo ratings yet

- RM 1ehsapprovedcosforliftingequippressvessels250914Document9 pagesRM 1ehsapprovedcosforliftingequippressvessels250914wholenumberNo ratings yet

- EX - 12.7MM - PLATE 01 PAUT Report TrainingDocument4 pagesEX - 12.7MM - PLATE 01 PAUT Report Trainingagung akbarNo ratings yet

- Pressure Vessel Inspection Record: in Accordance With API 510, 10th EditionDocument2 pagesPressure Vessel Inspection Record: in Accordance With API 510, 10th Editionbgonzalez1981No ratings yet

- Piping Thickness Measurement ReportDocument1 pagePiping Thickness Measurement ReportTevriyudha MardikaNo ratings yet

- Mobile Crane Certification and Inspection ReportDocument2 pagesMobile Crane Certification and Inspection ReportRafael LecuNo ratings yet

- Summary TER of 13 Unit 20FT ISO Dry ContainerDocument219 pagesSummary TER of 13 Unit 20FT ISO Dry ContainerGhilman0529No ratings yet

- Almansoori Inspection Services: Lifting Equipment Thorough Examination ReportDocument2 pagesAlmansoori Inspection Services: Lifting Equipment Thorough Examination ReportRanjithNo ratings yet

- Procedure For UtDocument12 pagesProcedure For UtMohammad SyeduzzamanNo ratings yet

- REPORT-MT 21.10.2022 (Test)Document2 pagesREPORT-MT 21.10.2022 (Test)Nhien ManNo ratings yet

- Ultrasonic Examination Report: Dac DetailsDocument2 pagesUltrasonic Examination Report: Dac DetailsBalkishan DyavanapellyNo ratings yet

- INSPECTION RESULTS AND RECOMMENDATIONSDocument5 pagesINSPECTION RESULTS AND RECOMMENDATIONSBayu Aringga putra100% (1)

- Rigging Platform 25-05-2022-1Document1 pageRigging Platform 25-05-2022-1dele jimohNo ratings yet

- Wheel Loader Forklift Thorough Exam ReportDocument2 pagesWheel Loader Forklift Thorough Exam ReportRanjithNo ratings yet

- NDT Report TestDocument10 pagesNDT Report TestAnjas FarizqiNo ratings yet

- Crane Inspection Check List HSE. STDDocument1 pageCrane Inspection Check List HSE. STDEdy ElfianNo ratings yet

- Mobile CraneDocument2 pagesMobile CraneSHARAFUDHEEN TKNo ratings yet

- 16" MFL-DMR Vers.15.15: ILI Tool Data SheetDocument3 pages16" MFL-DMR Vers.15.15: ILI Tool Data SheetJudo HardiantoNo ratings yet

- Almansoori Inspection Services: Travelling Block AssemblyDocument2 pagesAlmansoori Inspection Services: Travelling Block AssemblyRanjithNo ratings yet

- Obite TC & Ogbogu Cluster - Ultrasonic Examination Procedure For Steel StructureDocument22 pagesObite TC & Ogbogu Cluster - Ultrasonic Examination Procedure For Steel StructureeetuaNo ratings yet

- Techno NDT Services: Ultrasonic Flaw Detection ReportDocument1 pageTechno NDT Services: Ultrasonic Flaw Detection Reportram dreamsNo ratings yet

- MPI Reports for ROMFOR Oilfield EquipmentDocument21 pagesMPI Reports for ROMFOR Oilfield EquipmentMehmet SoysalNo ratings yet

- Dokumen - Tips Wqt-FormatDocument2 pagesDokumen - Tips Wqt-FormatMr Pie100% (1)

- T4 Drill Pipe Colour Code Classification Chart NS2Document1 pageT4 Drill Pipe Colour Code Classification Chart NS2Josue Fish100% (1)

- Derrick Sample Report PDFDocument11 pagesDerrick Sample Report PDFRajesh ThorweNo ratings yet

- Result of Inspection: ConclusionDocument5 pagesResult of Inspection: ConclusionBayu Aringga putraNo ratings yet

- Sn. Kim Ear 196 Chain Sling WLL 7.5 T Grade 80: Report of A Thorough Examination of Lifting EquipmentDocument1 pageSn. Kim Ear 196 Chain Sling WLL 7.5 T Grade 80: Report of A Thorough Examination of Lifting Equipmentoriza100% (1)

- REPORT Model of Wire RopesDocument32 pagesREPORT Model of Wire RopesalexremNo ratings yet

- NullDocument9 pagesNullMichael OkwuwaNo ratings yet

- Catalogo 511Document4 pagesCatalogo 511Luis Oswaldo R PNo ratings yet

- Bore TrackingDocument2 pagesBore TrackingLuis Adrián ElguézabalNo ratings yet

- Krulex Services Limited: InternationalDocument5 pagesKrulex Services Limited: InternationalikponmwonsaNo ratings yet

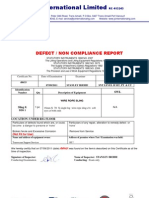

- Defect / Non Compliance ReportDocument12 pagesDefect / Non Compliance ReportMichael OkwuwaNo ratings yet

- 8689-2018 Sixco Chain SlingDocument2 pages8689-2018 Sixco Chain SlingAnonymous wuugFvOBjZNo ratings yet

- International Limited: Certificate of Visual Examination and MpiDocument2 pagesInternational Limited: Certificate of Visual Examination and MpiMichael OkwuwaNo ratings yet

- API 510 Corr. Rate & Rem Life Cal.Document1 pageAPI 510 Corr. Rate & Rem Life Cal.Ejaz Ahmed RanaNo ratings yet

- Oil India Tender for Supply of Drill PipesDocument13 pagesOil India Tender for Supply of Drill Pipesifebrian100% (1)

- RADIANT NDT SERVICES REPORT PROVIDES ULTRASONIC TESTING RESULTSDocument1 pageRADIANT NDT SERVICES REPORT PROVIDES ULTRASONIC TESTING RESULTSGoutam Kumar Deb100% (1)

- Inspected Equipment Detail: Inspection Certificate of NDTDocument1 pageInspected Equipment Detail: Inspection Certificate of NDTSpectex dubaiNo ratings yet

- Metric Conversions: To Convert From TO Multiply by Symbol Unit Symbol Unit LengthDocument1 pageMetric Conversions: To Convert From TO Multiply by Symbol Unit Symbol Unit LengthJosué Emmanuel Blásquez ContrerasNo ratings yet

- IELTS Daily Planner PDFDocument1 pageIELTS Daily Planner PDFJosue FishNo ratings yet

- What's New in PERFORM 7.50!: Worst-Case Discharge Scenario Report For Offshore WellsDocument6 pagesWhat's New in PERFORM 7.50!: Worst-Case Discharge Scenario Report For Offshore WellsrafaelNo ratings yet

- Writing Academic Essays @ieltsieltsDocument23 pagesWriting Academic Essays @ieltsieltsJosue FishNo ratings yet

- Routine IeltsDocument2 pagesRoutine IeltsJosue FishNo ratings yet

- IEC 584-2-1989, Thermocouples, Tolerances PDFDocument18 pagesIEC 584-2-1989, Thermocouples, Tolerances PDFJosue FishNo ratings yet

- Sub-Spec 023 - Tenaris DSTJ, WT™Document4 pagesSub-Spec 023 - Tenaris DSTJ, WT™Josue FishNo ratings yet

- IELTS Writing band descriptors overviewDocument2 pagesIELTS Writing band descriptors overviewIrfan PrabowoNo ratings yet

- Sub-Spec 021 - Grant Prideco GPDS™, HT™, XT™, XT-M™, TT™, TT-M™Document4 pagesSub-Spec 021 - Grant Prideco GPDS™, HT™, XT™, XT-M™, TT™, TT-M™Josue FishNo ratings yet

- SS025 Inspection of Installed Unused IntelliCoils NS2 PDFDocument1 pageSS025 Inspection of Installed Unused IntelliCoils NS2 PDFJosue FishNo ratings yet

- Table 12b: Used HWDP Dimensional Acceptance Criteria - Grant Prideco DSDocument1 pageTable 12b: Used HWDP Dimensional Acceptance Criteria - Grant Prideco DSJosue FishNo ratings yet

- Sub-Spec 022 - Vam CDS, EIS, VAM Express: Visual InspectionDocument3 pagesSub-Spec 022 - Vam CDS, EIS, VAM Express: Visual InspectionJosue FishNo ratings yet

- SS025 Inspection of Installed Unused IntelliCoils NS2 PDFDocument1 pageSS025 Inspection of Installed Unused IntelliCoils NS2 PDFJosue FishNo ratings yet

- Sub-Spec 023 - Tenaris DSTJ, WT™Document4 pagesSub-Spec 023 - Tenaris DSTJ, WT™Josue FishNo ratings yet

- SS026 Wired Drill String Electrical Inspection NS2 PDFDocument1 pageSS026 Wired Drill String Electrical Inspection NS2 PDFJosue FishNo ratings yet

- Table 13a: Bevel Diameters On BHA Bit Box ConnectionsDocument1 pageTable 13a: Bevel Diameters On BHA Bit Box ConnectionsJosue FishNo ratings yet

- T12 Rev1 Used HWDP and Connection Dimensional Acceptance Criteria NS2Document1 pageT12 Rev1 Used HWDP and Connection Dimensional Acceptance Criteria NS2Josue FishNo ratings yet

- Table 12a: Used HWDP Dimensional Acceptance Criteria - Grant Prideco XTDocument1 pageTable 12a: Used HWDP Dimensional Acceptance Criteria - Grant Prideco XTJosue FishNo ratings yet

- Table 2: Inspection Equipment Calibration FrequencyDocument1 pageTable 2: Inspection Equipment Calibration FrequencyJosue FishNo ratings yet

- Table 12c: Used HWDP Dimensional Acceptance Criteria - Grant Prideco TTDocument1 pageTable 12c: Used HWDP Dimensional Acceptance Criteria - Grant Prideco TTJosue FishNo ratings yet

- Sub-Spec 027 - DP Master DS, MT and High Torque PAC: Visual InspectionDocument3 pagesSub-Spec 027 - DP Master DS, MT and High Torque PAC: Visual InspectionJosue FishNo ratings yet

- T4 Drill Pipe Colour Code Classification Chart NS2Document1 pageT4 Drill Pipe Colour Code Classification Chart NS2Josue Fish100% (1)

- T3 Bottomhole Assembly Colour Code Classification Chart NS2Document1 pageT3 Bottomhole Assembly Colour Code Classification Chart NS2Josue FishNo ratings yet

- Table 1: Requirement For Qualification of Inspection PersonnelDocument1 pageTable 1: Requirement For Qualification of Inspection PersonnelJosue FishNo ratings yet