Professional Documents

Culture Documents

Tut Sheet-1 PDF

Uploaded by

Priyanshu SharmaOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Tut Sheet-1 PDF

Uploaded by

Priyanshu SharmaCopyright:

Available Formats

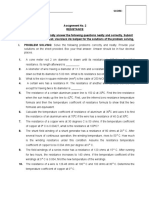

MM: 10

Tutorial Sheet-I

Write down your name, college no./faculty no. and enrolment no. on first page of the sheet.

Answer all the questions.

Assume suitable data if missing.

Notations used have their usual meaning.

Draw neat sketches to support your answers.

Q1. Two different pairs of sheets of the same material have to be spot welded. In one pair, there are

25 bridges per cm2 and the average radius of each bridge is 0.1 mm. The other pair of sheets contains

20 bridges per cm2 with the same average radius of each bridge. Determine the ratio of the voltages

to be applied in these two cases in order to generate the same rate of heating per unit area.

Q2. Two flat copper sheets of 1.2 mm thickness each are spot welded. The process parameters are:

current = 5000A, current flow time = 0.20 s, and diameter of electrodes = 6mm. Estimate the heat

generated in the welding zone.

Q3. In a resistance welding of a lap joint or two mild steel sheets of 1.5 mm thick, a current of 10,000

A is passed for a period of 0.1 seconds. The effective resistance of the joint is 120 micro ohms.

Density of steel is 0.00786 g/mm3 and heat required to melt is 1381 J/g. The joint can be considered

as a cylinder of 5 mm diameter and 2.25 mm in height. Calculate the percentage of heat distributed

to the surroundings.

Q4. For spot welding of two steel sheets (base metal) each of 3 mm thickness, welding current of

10000 A is applied for 0.2 seconds. The heat dissipated to the base metal is 1000 J. Assuming that

the heat required for melting 1 mm3 volume of steel is 20 J and interfacial contact resistance between

sheets is 0.0002 Ω, calculate the volume (in mm3) of weld nugget.

Q5. Spot welding of two 1 mm thick sheets of steel (density=8000 kg/m3) is carried out successfully

by passing a certain amount of current for 0.1 second through the electrodes. The resultant weld

nugget formed is 5 mm in diameter and 1.5 mm thick. If the latent heat of fusion of steel is 1400 kJ/kg

and the effective resistance in the welding operation in 200Ω, obtain the current passing through the

electrodes.

Q6. Two metallic sheets, each of 2.5 mm thickness, are welded in a lap joint configuration by

resistance spot welding at a welding current of 8000 A and welding time of 15 milli-second. A

spherical fusion zone extending up to the full thickness of each sheet is formed. The properties of the

metallic sheets are given as:

Density =7500 kg/ , Latent heat of fusion=350 kJ/kg

Assume: (i) contact resistance along sheet-sheet interface is 300 micro-ohm and along electrode-sheet

interface is zero; (ii) a spherical spot is formed to the full thickness, and (iii) the complete weld fusion

zone is at the melting temperature.

Calculate:

i. Amount of conductive heat loss through the bulk sheet material

ii. Melting efficiency of the process

Q7. What is 'Friction Welding'? What are the various types of friction welding processes? Discuss

them briefly.

Q8. Explain the following welding techniques:

i Explosive welding

ii Diffusion welding

iii Resistance spot welding and Resistance seam welding

iv Laser beam welding

You might also like

- Solutions Manual to accompany Engineering Materials ScienceFrom EverandSolutions Manual to accompany Engineering Materials ScienceRating: 4 out of 5 stars4/5 (1)

- HER201 Flex Tiles Set 01 - VehiclesDocument3 pagesHER201 Flex Tiles Set 01 - VehiclesDouglas Mears100% (2)

- Resistance and Special WeldingDocument24 pagesResistance and Special WeldingKBSMANITNo ratings yet

- Conduction Problems & Solutions Conduction Problems & SolutionsDocument30 pagesConduction Problems & Solutions Conduction Problems & SolutionsRoronoaNo ratings yet

- Babu Banarasi Das: Practice QuestionsDocument7 pagesBabu Banarasi Das: Practice QuestionsNeeraj KshatriyaNo ratings yet

- Tutorial Sheets SOMDocument20 pagesTutorial Sheets SOMPriyanshu Sharma100% (1)

- Ass#4 - Fall 2017 (Q)Document3 pagesAss#4 - Fall 2017 (Q)Omar BahgatNo ratings yet

- Welding - GATE QuestionsDocument1 pageWelding - GATE QuestionsJo75% (4)

- Resistance and Special Welding.0001Document100 pagesResistance and Special Welding.0001KKNo ratings yet

- SheetDocument3 pagesSheetBarun BeheraNo ratings yet

- Welding Casting Main 2021Document26 pagesWelding Casting Main 2021mohitNo ratings yet

- 1 2 Resistance and Special Welding Q A For StudentsDocument10 pages1 2 Resistance and Special Welding Q A For StudentsRavinder AntilNo ratings yet

- Welding Assignment QuestionsDocument1 pageWelding Assignment QuestionsVidhya NairNo ratings yet

- Production Technology - II: Tutorial Sheet 7Document1 pageProduction Technology - II: Tutorial Sheet 7Shravan PagrutNo ratings yet

- HMTDocument3 pagesHMTRuby SmithNo ratings yet

- Arc Length Characteristics and Calculations in Welding ProcessesDocument2 pagesArc Length Characteristics and Calculations in Welding ProcessesBhupendra Verma0% (1)

- Welding Technology Unit 6008Document10 pagesWelding Technology Unit 6008loganathanNo ratings yet

- Performance and Analysis of Weld Joint by Using Two Dissimilar Electrodes E6010 and E7018Document5 pagesPerformance and Analysis of Weld Joint by Using Two Dissimilar Electrodes E6010 and E7018Editor IJTSRDNo ratings yet

- 1.2 Resistance and Special WeldingDocument14 pages1.2 Resistance and Special WeldingnikhilbathamNo ratings yet

- Heat Transfer Equations and Critical Insulation RadiusDocument18 pagesHeat Transfer Equations and Critical Insulation RadiusPon ShanmugakumarNo ratings yet

- Embry-Riddle Aeronautical University: Engineering ScienceDocument1 pageEmbry-Riddle Aeronautical University: Engineering ScienceKãrîm KåhlìNo ratings yet

- Welding Lab Report #1: SMAW of Similar MetalsDocument6 pagesWelding Lab Report #1: SMAW of Similar MetalsAbrar HassanNo ratings yet

- The Wire Drawing Mechanics of Near-Equiatomic Niti SmaDocument5 pagesThe Wire Drawing Mechanics of Near-Equiatomic Niti SmayuhardesNo ratings yet

- HT ProblemsDocument2 pagesHT ProblemsNipun SharmaNo ratings yet

- 4.1 Prob Sheet S S C With Heat GenerationDocument2 pages4.1 Prob Sheet S S C With Heat GenerationAnonymous mXicTi8hBNo ratings yet

- Resistance ProblemsDocument3 pagesResistance ProblemsRolan PaduaNo ratings yet

- Solve The Following Problems CompletelyDocument1 pageSolve The Following Problems CompletelyReeze Vreena TamarayNo ratings yet

- HT Assignment-1Document1 pageHT Assignment-1Karthikeya Kvs0223No ratings yet

- 3.thermal Aspects - Problems AssignmentDocument1 page3.thermal Aspects - Problems AssignmentUsama HamidNo ratings yet

- HMT Question Bank-1Document10 pagesHMT Question Bank-1parasuramanNo ratings yet

- Adv - Design of Weldments Seme1 2004Document4 pagesAdv - Design of Weldments Seme1 2004mukesh3021No ratings yet

- Tính chất Vật liệu Bài tậpDocument26 pagesTính chất Vật liệu Bài tậpHoàng BeeNo ratings yet

- Assignment 2Document1 pageAssignment 2Saptarshi MajiNo ratings yet

- Electrical Arc Welding Lap Joint: PreparationDocument5 pagesElectrical Arc Welding Lap Joint: PreparationTejesh MannemNo ratings yet

- Assignment 1 - Lasers in MFGDocument2 pagesAssignment 1 - Lasers in MFGvipul mishraNo ratings yet

- Heat Transfer Assignment 10 - 22 - 20Document1 pageHeat Transfer Assignment 10 - 22 - 20Adrian Ray AyamNo ratings yet

- Heat & Mass Transfer Tutorial ProblemsDocument2 pagesHeat & Mass Transfer Tutorial ProblemsSaifullah AhmadNo ratings yet

- Continental Institute of Engineering & Technology: Welding ShopDocument8 pagesContinental Institute of Engineering & Technology: Welding ShopAjay RanaNo ratings yet

- Conventional Casting WeldingDocument190 pagesConventional Casting WeldingprabhjotbhangalNo ratings yet

- ME6502Document10 pagesME6502Thulasi RamNo ratings yet

- SM Coaching QuestionDocument3 pagesSM Coaching QuestionSelvaraj GNo ratings yet

- Sheet 4Document3 pagesSheet 4Yasmin RedaNo ratings yet

- Sheet 2 2Document2 pagesSheet 2 2Fatma AbdoNo ratings yet

- Advanced Manufacturing ScienceDocument3 pagesAdvanced Manufacturing Sciencemukesh3021No ratings yet

- Quiz Model A Time 30 MinDocument4 pagesQuiz Model A Time 30 MinYahya Abdelhameed AamerNo ratings yet

- Government College of Engineering, Jalgoan: Instructions To CandidatesDocument3 pagesGovernment College of Engineering, Jalgoan: Instructions To CandidateschupchapNo ratings yet

- Strain energy stored in stretched cables and wiresDocument2 pagesStrain energy stored in stretched cables and wiresLiuJiewChuan100% (1)

- Heat Transfer Homework SolutionsDocument1 pageHeat Transfer Homework SolutionsChemical EngineeringNo ratings yet

- SOLUDocument6 pagesSOLUVishnu JangidNo ratings yet

- HMT16 MarksDocument12 pagesHMT16 MarkstagoreboopathyNo ratings yet

- Mehcanics of Solids May2004 RR 220304Document8 pagesMehcanics of Solids May2004 RR 220304Nizam Institute of Engineering and Technology LibraryNo ratings yet

- MIN-305 Heat & Mass Transfer Tutorial - 2Document2 pagesMIN-305 Heat & Mass Transfer Tutorial - 2Ashutosh SinghNo ratings yet

- Assignment ProcessDocument2 pagesAssignment ProcessMuhammad Nazmul Hassan KhanNo ratings yet

- Heat Transfer Assignment 1Document3 pagesHeat Transfer Assignment 1Yehia Raef0% (1)

- Holman 1Document4 pagesHolman 1Kumar SamyanaikNo ratings yet

- 386 1282 1 PB PDFDocument5 pages386 1282 1 PB PDFAhmedNo ratings yet

- The Study of Elementary Electricity and Magnetism by Experiment: Containing Two Hundred ExperimentsFrom EverandThe Study of Elementary Electricity and Magnetism by Experiment: Containing Two Hundred ExperimentsNo ratings yet

- The Study of Elementary Electricity and Magnetism by Experiment: Containing Two Hundred Experiments Performed with Simple, Home-made ApparatusFrom EverandThe Study of Elementary Electricity and Magnetism by Experiment: Containing Two Hundred Experiments Performed with Simple, Home-made ApparatusNo ratings yet

- Experimental Sheet (EDM Process)Document6 pagesExperimental Sheet (EDM Process)Priyanshu SharmaNo ratings yet

- Laboratory Manual: Heat Transfer and Solar Energy LaboratoryDocument2 pagesLaboratory Manual: Heat Transfer and Solar Energy LaboratoryPriyanshu SharmaNo ratings yet

- 2 and 4 Stroke EnginesDocument2 pages2 and 4 Stroke EnginesPriyanshu SharmaNo ratings yet

- Prof. M. N. Farooqui Computer Centre: D NO: ............ New Registration Dated: ............Document2 pagesProf. M. N. Farooqui Computer Centre: D NO: ............ New Registration Dated: ............Priyanshu SharmaNo ratings yet

- Future Developments in Management AccountingDocument4 pagesFuture Developments in Management AccountingAmar narayanNo ratings yet

- ANR causes and solutionsDocument2 pagesANR causes and solutionsPRAKHAR SRIVASTAVANo ratings yet

- Final Class 8 Science 20230828084415550Document5 pagesFinal Class 8 Science 20230828084415550aryantomar5112No ratings yet

- Fire and Ice by Robert FrostDocument2 pagesFire and Ice by Robert Frostapi-561976496No ratings yet

- Icarus & DaedalusDocument2 pagesIcarus & DaedalusIsrael AsinasNo ratings yet

- Lab Manual Ds&BdalDocument100 pagesLab Manual Ds&BdalSEA110 Kshitij BhosaleNo ratings yet

- Daniel Fast Recipes A Couple CooksDocument12 pagesDaniel Fast Recipes A Couple CooksmariamNo ratings yet

- Bahan Belajar Ujian Akhir SekolahDocument13 pagesBahan Belajar Ujian Akhir SekolahArga AnggaraNo ratings yet

- Solution:: Ex 3.3 Consider The Following Parallelograms. Find The Values of The Unknowns X, Y, ZDocument9 pagesSolution:: Ex 3.3 Consider The Following Parallelograms. Find The Values of The Unknowns X, Y, ZpadmaNo ratings yet

- Master Gardener Home Vegetable Guide: Chapter 1 - Gardening BasicsDocument30 pagesMaster Gardener Home Vegetable Guide: Chapter 1 - Gardening BasicsAmr M. SaidNo ratings yet

- PEC ReviewerDocument17 pagesPEC ReviewerJunallyn ManigbasNo ratings yet

- Build Pulse Oximeter InstructionsDocument3 pagesBuild Pulse Oximeter InstructionsPrabhuDevNo ratings yet

- Buffy RPG - The Dragon and The Phoenix - 4 Identity CrisisDocument26 pagesBuffy RPG - The Dragon and The Phoenix - 4 Identity CrisisTimothy BrannanNo ratings yet

- Cissp NotesDocument83 pagesCissp NotesRobert Mota HawksNo ratings yet

- Quality Control and Assurance Processes for Coffee ProductionDocument5 pagesQuality Control and Assurance Processes for Coffee ProductionSharifah NuruljannahNo ratings yet

- Ideas For Income Generating Projects PDFDocument29 pagesIdeas For Income Generating Projects PDFheart AquinoNo ratings yet

- Cleaning Validation Master Plan PDFDocument9 pagesCleaning Validation Master Plan PDFBREWSKINo ratings yet

- VsamDocument24 pagesVsamRodrigoNo ratings yet

- 4 - Microsoft PowerPoint - JDC Company ProfileDocument12 pages4 - Microsoft PowerPoint - JDC Company ProfileBill LiNo ratings yet

- VKS INFRA DPR Submission for NHAI Bihar ProjectDocument1 pageVKS INFRA DPR Submission for NHAI Bihar ProjectamirNo ratings yet

- Detector Balance Induccion.Document11 pagesDetector Balance Induccion.Jesus OrtizNo ratings yet

- TENSION PNEUMOTHORAX (Malav Shah)Document66 pagesTENSION PNEUMOTHORAX (Malav Shah)Sharath PsNo ratings yet

- Presented by - Aniket Ghosh Dastidar Construction Engg. 4 Year Jadavpur UniversityDocument20 pagesPresented by - Aniket Ghosh Dastidar Construction Engg. 4 Year Jadavpur UniversitySaurabh AgrawalNo ratings yet

- 2020 FMGT 1013 - Financial Management RevisedDocument9 pages2020 FMGT 1013 - Financial Management RevisedYANIII12345No ratings yet

- Calculating production costs and selling pricesDocument2 pagesCalculating production costs and selling pricesMitch BelmonteNo ratings yet

- School Annual Data For Financial YearDocument3 pagesSchool Annual Data For Financial YearRamesh Singh100% (1)

- Full Download Test Bank For Positive Psychology 4th Edition Lopez PDF Full ChapterDocument36 pagesFull Download Test Bank For Positive Psychology 4th Edition Lopez PDF Full Chaptershaps.tortillayf3th100% (21)

- Unit 4 FSQCDocument28 pagesUnit 4 FSQCvaralakshmi KNo ratings yet

- Labview ProgrammingDocument20 pagesLabview ProgrammingJames WoodNo ratings yet