Professional Documents

Culture Documents

CS & Chrome Flange Torque Values By Size and Class

Uploaded by

Wilmer FigueraOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

CS & Chrome Flange Torque Values By Size and Class

Uploaded by

Wilmer FigueraCopyright:

Available Formats

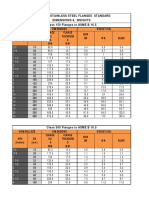

CS & Chrome RF Torque Values in Foot Pounds By Flange Size and CS & Chrome RTJ Torque Values in Foot

J Torque Values in Foot Pounds By Flange Size Wrench

Class and Class B7 Studs Size

Class

Nominal Class 150# Full Class Class Class Class Class Nominal Class Class Class Class Class Class

Pipe Size 150# Face 300# 600# 900# 1500# 2500# Pipe Size 150# 300# 600# 900# 1500# 2500# 1/4 1/2

1/2 30 65 25 20 40 40 1/2 20 25 75 85 5/16 9/16

3/4 40 65 50 30 60 60 3/4 35 40 95 105 3/8 11/16

1 55 65 40 40 Not made. 95 100 1 30 55 55 Not made. 125 150 7/16 3/4

1 1/4 60 65 65 75 Use 1500 160 200 1 1/4 45 75 90 Use 1500 160 260 1/2 7/8

class class

1 1/2 60 65 95 110 235 275 1 1/2 60 105 125 200 340 9/16 15/16

flanges flanges

2 120 130 55 75 150 200 2 100 60 85 150 200 5/8 1-1/16

2 1/2 120 130 90 110 200 275 2 1/2 125 110 135 200 300 3/4 1-1/4

3 130 130 140 150 210 340 525 3 125 160 165 200 300 530 7/8 1-7/16

3 1/2 130 130 165 245 3 1/2 105 175 210 1 1-5/8

4 120 130 200 275 375 700 925 4 125 200 240 325 615 1,075 1-1/8 1-13/16

5 200 225 225 410 795 1,125 1,500 5 165 250 345 625 865 1,900 1-1/4 2

6 225 225 210 375 465 925 2,300 6 200 200 275 350 710 2,725 1-3/8 2-3/16

8 225 225 365 700 1,020 1,640 2,300 8 225 300 420 775 1,450 2,650 1-1/2 2-3/8

10 300 375 485 965 965 2,600 3,850 10 250 300 600 775 2,175 4,900 1-5/8 2-9/16

12 320 375 685 970 1,110 2,650 6,200 12 325 425 600 775 2,700 7,200 1-3/4 2-3/4

14 420 565 500 1,225 1,580 3,100 14 400 400 800 1,300 3,800 1-7/8 2-15/16

16 360 565 935 1,580 2,070 5,000 16 350 675 1,000 1,700 5,300 2 3-1/8

18 720 825 1,015 2,430 3,350 7,000 18 450 650 1,300 2,700 6,900 2-1/4 3-1/2

20 690 825 1,170 2,300 3,715 8,850 20 400 850 1,400 3,200 9,000 2-1/2 3-7/8

24 1,375 1,550 1,750 4,000 6,200 14,000 24 725 1,600 2,400 5,800 14,000 2-3/4 4-1/4

3 4-5/8

Notes: Use Hydraulic torque equipment on stud loads over 1,000 foot pounds (Yellow shaded cells)! 3-1/2 5-3/8

304SS RTJ Torque Value in Foot Pounds By Flange Size and

304SS RF Torque Value in Foot Pounds By Flange Size and Class

Class

Class

Nominal Class 150# Full Class Class Class Class Class Nominal Class Class Class Class Class Class

Pipe Size 150# Face 300# 600# 900# 1500# 2500# Pipe Size 150# 300# 600# 900# 1500# 2500#

1/2 10 65 15 15 40 40 1/2 15 20 60 85

3/4 15 65 25 25 60 60 3/4 30 30 90 105

1 20 65 35 35 Not made. 95 100 1 25 40 40 Not made. 125 150

1 1/4 30 65 50 60 Use 1500 140 200 1 1/4 35 60 70 Use 1500 160 260

class class

1 1/2 40 65 75 85 215 275 1 1/2 45 80 100 200 340

flanges flanges

2 70 130 40 60 115 200 2 75 50 65 145 200

2 1/2 100 130 70 90 165 275 2 1/2 125 85 110 195 300

3 130 130 110 135 170 310 525 3 125 140 165 200 300 530

3 1/2 70 130 130 190 3 1/2 80 150 210

4 80 130 160 215 310 670 925 4 100 190 240 325 615 1,075

5 120 225 205 320 620 1,125 1,500 5 130 250 345 625 865 1,900

6 175 225 160 300 365 925 2,300 6 160 200 275 350 710 2,725

8 225 225 280 550 800 1,640 2,300 8 225 300 420 775 1,450 2,650

10 230 375 380 755 755 2,600 3,850 10 235 300 600 775 2,175 4,900

12 250 375 535 755 860 2,650 6,200 12 325 425 600 775 2,700 7,200

14 325 565 390 950 1,230 3,100 14 325 400 800 1,300 3,800

16 280 565 725 1,250 1,620 5,000 16 300 675 1,000 1,700 5,300

18 550 825 790 1,900 2,630 7,000 18 450 650 1,300 2,700 6,900

20 530 825 915 1,800 3,275 8,850 20 400 850 1,400 3,200 9,000

24 1,065 1,555 1,375 3,100 6,200 14,000 24 725 1,600 2,400 5,800 14,000

Notes: Use Hydraulic torque equipment on stud loads over 1,000 foot pounds (Yellow shaded cells)!

488945738.xls, Torque Summary David W. Reeves, 2/7/05

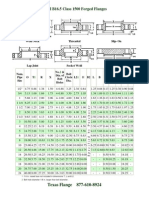

CS & Chrome RF Torque Values By Flange Size and Class CS & Chrome RTJ Torque Values By Flange Size and Class

Torque in Torque in Torque in Torque in Torque in Torque in Torque in Torque in Torque in Torque in

Torque in FP's, Stud Size FP's, Stud Size FP's, Stud Size FP's, Stud Size FP's, Stud Size FP's, Stud Size Torque in Torque in Stud Size FP's, Stud Size FP's, Stud Size FP's, Stud Size FP's,

FP's, Stud Size Class Class Torque Torque Torque Torque Torque Torque Torque Torque Torque Torque FP's, Stud Size FP's, Torque Torque Torque Torque Torque Torque Torque Torque

Nominal Class Class 150# Full 150# Full Class Class Class Class Class Class Class Class Class Class Nominal Class Class Class Class Class Class Class Class Class Class Class

Pipe Size 150# 150# Face Face 300# 300# 600# 600# 900# 900# 1500# 1500# 2500# 2500# Pipe Size 150# 150# 300# 300# 600# 600# 900# 900# 1500# 1500# 2500#

1/2 30 1/2 65 1/2 25 1/2 20 1/2 35 3/4 40 3/4 40 3/4 1/2 20 1/2 25 1/2 75 3/4 85

3/4 40 1/2 65 1/2 50 5/8 30 5/8 50 3/4 60 3/4 60 3/4 3/4 35 5/8 40 5/8 95 3/4 105

1 55 1/2 65 1/2 40 5/8 40 5/8 80 7/8 95 7/8 100 7/8 1 30 1/2 55 5/8 55 5/8 125 7/8 150

1 1/4 60 1/2 65 1/2 65 5/8 75 5/8 140 7/8 160 7/8 200 1 1 1/4 45 1/2 75 5/8 90 5/8 Not made. Use 1500 160 7/8 260

class flanges

1 1/2 60 1/2 65 1/2 95 3/4 110 3/4 200 1 235 1 275 1 1/8 1 1/2 60 1/2 105 3/4 125 3/4 200 1 340

2 120 5/8 130 5/8 55 5/8 75 5/8 140 7/8 150 7/8 200 1 2 100 5/8 60 5/8 85 5/8 150 7/8 200

2 1/2 120 5/8 130 5/8 90 3/4 110 3/4 200 1 200 1 275 1 1/8 2 1/2 125 5/8 110 3/4 135 3/4 200 1 300

3 130 5/8 130 5/8 140 3/4 150 3/4 210 7/8 340 1 1/8 525 1 1/4 3 125 5/8 160 3/4 165 3/4 200 7/8 300 1 1/8 530

3 1/2 130 5/8 130 5/8 165 3/4 245 7/8 3 1/2 105 5/8 175 3/4 210 7/8

4 120 5/8 130 5/8 200 3/4 275 7/8 375 1 1/8 700 1 1/4 925 1 1/2 4 125 5/8 200 3/4 240 7/8 325 1 1/8 615 1 1/4 1,075

5 200 3/4 225 3/4 225 3/4 410 1 795 1 1/4 1,125 1 1/2 1,500 1 3/4 5 165 3/4 250 3/4 345 1 625 1 1/4 865 1 1/2 1,900

6 225 3/4 225 3/4 210 3/4 375 1 465 1 1/8 925 1 3/8 2,300 2 6 200 3/4 200 3/4 275 1 350 1 1/8 710 1 3/8 2,725

8 225 3/4 225 3/4 365 7/8 700 1 1/8 1,020 1 3/8 1,640 1 5/8 2,300 2 8 225 3/4 300 7/8 420 1 1/8 775 1 3/8 1,450 1 5/8 2,650

10 300 7/8 375 7/8 485 1 965 1 1/4 965 1 3/8 2,600 1 7/8 3,850 2 1/2 10 250 7/8 300 1 600 1 1/4 775 1 3/8 2,175 1 7/8 4,900

12 320 7/8 375 7/8 685 1 1/8 970 1 1/4 1,110 1 3/8 2,650 2 6,200 2 3/4 12 325 7/8 425 1 1/8 600 1 1/4 775 1 3/8 2,700 2 7,200

14 420 1 565 1 500 1 1/8 1,225 1 3/8 1,580 1 1/2 3,100 2 1/4 14 400 1 400 1 1/8 800 1 3/8 1,300 1 1/2 3,800 2 1/4

16 360 1 565 1 935 1 1/4 1,580 1 1/2 2,070 1 5/8 5,000 2 1/2 16 350 1 675 1 1/4 1,000 1 1/2 1,700 1 5/8 5,300 2 1/2

18 720 1 1/8 825 1 1/8 1,015 1 1/4 2,430 1 5/8 3,350 1 7/8 7,000 2 3/4 18 450 1 1/8 650 1 1/4 1,300 1 5/8 2,700 1 7/8 6,900 2 3/4

20 690 1 1/8 825 1 1/8 1,170 1 1/4 2,300 1 5/8 3,715 2 8,850 3 20 400 1 1/8 850 1 1/4 1,400 1 5/8 3,200 2 9,000 3

24 1,375 1 1/4 1,550 1 1/4 1,750 1 1/2 4,000 1 7/8 6,200 2 1/2 14,000 3 1/2 24 725 1 1/4 1,600 1 1/2 2,400 1 7/8 5,800 2 1/2 14,000 3 1/2

304SS RF Torque Value By Flange Size and Class 304SS RTJ Torque Value By Flange Size and Class

Torque in Torque in Torque in Torque in Torque in Torque in Torque in Torque in Torque in Torque in

Torque in FP's, Stud Size FP's, Stud Size FP's, Stud Size FP's, Stud Size FP's, Stud Size FP's, Stud Size Stud Size FP's, Stud Size FP's, Stud Size FP's, Stud Size FP's,

FP's, Stud Size Class Class Torque Torque Torque Torque Torque Torque Torque Torque Torque Torque Stud Size Torque Torque Torque Torque Torque Torque Torque Torque

Nominal Class Class 150# Full 150# Full Class Class Class Class Class Class Class Class Class Class Nominal Class Class Class Class Class Class Class Class Class Class Class

Pipe Size 150# 150# Face Face 300# 300# 600# 600# 900# 900# 1500# 1500# 2500# 2500# Pipe Size 150# 150# 300# 300# 600# 600# 900# 900# 1500# 1500# 2500#

1/2 10 1/2 65 1/2 15 1/2 15 1/2 35 3/4 40 3/4 40 3/4 1/2 15 1/2 20 1/2 60 3/4 85

3/4 15 1/2 65 1/2 25 5/8 25 5/8 50 3/4 60 3/4 60 3/4 3/4 30 5/8 30 5/8 90 3/4 105

1 20 1/2 65 1/2 35 5/8 35 5/8 80 7/8 95 7/8 100 7/8 1 25 1/2 40 5/8 40 5/8 125 7/8 150

1 1/4 30 1/2 65 1/2 50 5/8 60 5/8 140 7/8 140 7/8 200 1 1 1/4 35 1/2 60 5/8 70 5/8 Not made. Use 1500 160 7/8 260

class flanges

1 1/2 40 1/2 65 1/2 75 3/4 85 3/4 200 1 215 1 275 1 1/8 1 1/2 45 1/2 80 3/4 100 3/4 200 1 340

2 70 5/8 130 5/8 40 5/8 60 5/8 115 7/8 115 7/8 200 1 2 75 5/8 50 5/8 65 5/8 145 7/8 200

2 1/2 100 5/8 130 5/8 70 3/4 90 3/4 160 1 165 1 275 1 1/8 2 1/2 125 5/8 85 3/4 110 3/4 195 1 300

3 130 5/8 130 5/8 110 3/4 135 3/4 170 7/8 310 1 1/8 525 1 1/4 3 125 5/8 140 3/4 165 3/4 200 7/8 300 1 1/8 530

3 1/2 70 5/8 130 5/8 130 3/4 190 7/8 3 1/2 80 5/8 150 3/4 210 7/8

4 80 5/8 130 5/8 160 3/4 215 7/8 310 1 1/8 670 1 1/4 925 1 1/2 4 100 5/8 190 3/4 240 7/8 325 1 1/8 615 1 1/4 1,075

5 120 3/4 225 3/4 205 3/4 320 1 620 1 1/4 1,125 1 1/2 1,500 1 3/4 5 130 3/4 250 3/4 345 1 625 1 1/4 865 1 1/2 1,900

6 175 3/4 225 3/4 160 3/4 300 1 365 1 1/8 925 1 3/8 2,300 2 6 160 3/4 200 3/4 275 1 350 1 1/8 710 1 3/8 2,725

8 225 3/4 225 3/4 280 7/8 550 1 1/8 800 1 3/8 1,640 1 5/8 2,300 2 8 225 3/4 300 7/8 420 1 1/8 775 1 3/8 1,450 1 5/8 2,650

10 230 7/8 375 7/8 380 1 755 1 1/4 755 1 3/8 2,600 1 7/8 3,850 2 1/2 10 235 7/8 300 1 600 1 1/4 775 1 3/8 2,175 1 7/8 4,900

12 250 7/8 375 7/8 535 1 1/8 755 1 1/4 860 1 3/8 2,650 2 6,200 2 3/4 12 325 7/8 425 1 1/8 600 1 1/4 775 1 3/8 2,700 2 7,200

14 325 1 565 1 390 1 1/8 950 1 3/8 1,230 1 1/2 3,100 2 1/4 14 325 1 400 1 1/8 800 1 3/8 1,300 1 1/2 3,800 2 1/4

16 280 1 565 1 725 1 1/4 1,250 1 1/2 1,620 1 5/8 5,000 2 1/2 16 300 1 675 1 1/4 1,000 1 1/2 1,700 1 5/8 5,300 2 1/2

18 550 1 1/8 825 1 1/8 790 1 1/4 1,900 1 5/8 2,630 1 7/8 7,000 2 3/4 18 450 1 1/8 650 1 1/4 1,300 1 5/8 2,700 1 7/8 6,900 2 3/4

20 530 1 1/8 825 1 1/8 915 1 1/4 1,800 1 5/8 3,275 2 8,850 3 20 400 1 1/8 850 1 1/4 1,400 1 5/8 3,200 2 9,000 3

24 1,065 1 1/4 1,555 1 1/4 1,375 1 1/2 3,100 1 7/8 6,200 2 1/2 14,000 3 1/2 24 725 1 1/4 1,600 1 1/2 2,400 1 7/8 5,800 2 1/2 14,000 3 1/2

Notes: Use Hydraulic torque equipment on stud loads over 1,000 foot pounds (Yellow shaded cells)!

B7 Studs 1/4 5/16 3/8 7/16 1/2 9/16 5/8 3/4 7/8 1 1-1/8 1-1/4 1-3/8 1-1/2 1-5/8 1-3/4 1-7/8 2 2-1/4 2-1/2 2-3/4 3 3-1/2

Wrench

Size 1/2 9/16 11/16 3/4 7/8 15/16 1-1/16 1-1/4 1-7/16 1-5/8 1-13/16 2 2-3/16 2-3/8 2-9/16 2-3/4 2-15/16 3-1/8 3-1/2 3-7/8 4-1/4 4-5/8 5-3/8

488945738.xls, Torque Summary With Studs David W. Reeves, 2/7/05

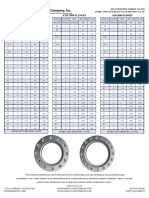

Bolt Stress vs. Gasket Stress in 150, 300, 400 and 600, 900, 1500 and 2500 class Raised Face Flanges

& Full Face (sizes listed below.)

From Calvin Gillas, Lamons Gasket Company

Bolt Stress vs. Gasket Stress in 150lb Raised Face Flanges

Calculations based on bolt root diameter

Nominal # Bolts Bolt Dia. Bolt CMG / Sheet Spiral Spiral Raised Face MAWP (PSI) Stud Load CMG / Spiral Torque Bolt Root CMG / Sheet Spiral Bolt Small Small Tongue Gasket Stess

Pipe size (In) Length Gasket ID Wound Wound OD (In) (PSI) Sheet Ring Wound Value (.15 Area in^2 Gasket Area Wound Circle Tongue Tongue Area based on

(In) (In) Gasket Gasket Gasket Gasket & .2 in^2 Gasket Diameter OD ID stud load and

Winding ID Winding Stress (PSI) Stress Friction Area in^2 pressure on

(In) OD (In) (PSI) Factors) left

1/2 4 1/2 2 1/4 0.84 0.75 1.25 1.38 285 38,000 20,278 28,679 30 0.126 0.94 0.67 2.38 1 3/8 1 0.70 27,295

3/4 4 1/2 2 1/4 1.06 1 1.56 1.69 285 51,000 18,794 26,206 40 0.126 1.36 0.98 2.75 1 11/16 1 5/16 0.88 28,943

1 4 1/2 2 1/2 1.31 1.25 1.88 2 285 70,000 19,540 25,636 55 0.126 1.79 1.37 3.12 1 7/8 1 1/2 0.99 35,261

1 1/4 4 1/2 2 1/2 1.66 1.88 2.38 2.5 285 76,000 13,827 26,310 60 0.126 2.74 1.44 3.5 2 6/25 1 7/8 1.18 32,169

1 1/2 4 1/2 2 3/4 1.91 2.13 2.75 2.88 285 76,000 10,357 17,917 60 0.126 3.65 2.11 3.88 2 1/2 2 1/8 1.36 27,745

2 4 5/8 3 2.38 2.75 3.38 3.62 285 76,000 10,354 22,372 120 0.202 5.84 2.70 4.75 3 1/4 2 7/8 1.80 33,539

2 1/2 4 5/8 3 1/4 2.88 3.25 3.88 4.12 285 76,000 8,801 19,047 120 0.202 6.82 3.15 5.5 3 3/4 3 3/8 2.10 28,591

3 4 5/8 3 1/2 3.5 4 4.75 5 285 82,390 6,446 13,760 130 0.202 10.01 4.69 6 4 5/8 4 1/4 2.61 24,693

3 1/2 8 5/8 3 1/2 4 4.5 5.25 5.5 285 82,390 11,649 24,925 130 0.202 11.19 5.23 7 5 1/8 4 3/4 2.91 44,828

4 8 5/8 3 1/2 4.5 5 5.88 6.19 285 76,000 8,402 17,164 120 0.202 14.19 6.95 7.5 5 11/16 5 3/16 4.27 27,915

5 8 3/4 3 3/4 5.56 6.13 7 7.31 285 70,500 9,313 19,877 200 0.302 17.69 8.29 8.5 6 13/16 6 5/16 5.15 31,961

6 8 3/4 3 3/4 6.62 7.19 8.25 8.5 285 79,469 8,239 15,268 225 0.302 22.33 12.05 9.5 8 7 1/2 6.09 30,220

8 8 3/4 4 8.62 9.19 10.38 10.62 285 79,469 5,879 10,285 225 0.302 30.22 17.27 11.75 10 9 3/8 9.51 18,682

10 12 7/8 4 1/2 10.75 11.31 12.5 12.75 285 65,355 8,310 14,587 300 0.420 36.91 21.03 14.25 12 11 1/4 13.70 22,399

12 12 7/8 4 1/2 12.75 13.38 14.75 15 285 69,712 6,502 11,063 320 0.420 49.04 28.82 17 14 1/4 13 1/2 16.35 19,506

14 12 1 5 14 14.63 16 16.25 285 61,000 6,725 11,452 420 0.551 53.46 31.39 18.75 15 1/2 14 3/4 17.82 20,174

16 16 1 5 1/4 16 16.63 18.25 18.5 285 52,267 5,957 9,474 360 0.551 67.74 42.59 21.25 17 5/8 16 3/4 23.62 17,081

18 16 1 1/8 5 3/4 18 18.69 20.75 21 285 70,325 8,126 12,087 720 0.728 91.89 61.78 22.75 20 1/8 19 1/4 27.06 27,594

20 20 1 1/8 6 20 20.69 22.75 23 285 67,395 8,802 13,105 690 0.728 101.32 68.05 25 22 21 33.77 26,406

24 20 1 1/4 6 3/4 24 24.75 27 27.25 285 70,990 9,105 13,413 1,375 0.930 130.82 88.80 29.5 26 1/4 25 1/4 40.45 29,447

Bolt Stress vs. Full-Face Gasket Stress in Class 150 Flat Face Flanges

Calculations based on bolt root diameter

Nominal # Bolts Bolt Dia Bolt Gasket ID Gasket OD MAWP Stud Load Full-Face Torque Bolt Root Gasket Bolt Gasket Gasket OD Outside Radial Inside Ring Gasket ID Radial MAWP Stud Load Double Rail Torque

Pipe size Length Gasket Value (.15 Area in^2 Area Circle Flange Ring ID Width of OD Width of Gasket Value

Stress & .2 Friction (in^2) Diameter Outside Inside Stress (.15 & .2

Factors) Ring Ring Friction

Factors)

1/2 4 1/2 0.84 3.50 285 82,554 5,299 65 0.126 7.84 2.38 3.500 3.500 3.005 0.2475 1.755 1.255 0.25 100 44,452 6,036 35

3/4 4 1/2 1.06 3.88 285 82,554 4,270 65 0.126 9.71 2.75 3.880 3.880 3.375 0.2525 2.125 1.625 0.25 100 44,452 5,149 35

1 4 1/2 1.31 4.25 285 82,554 3,563 65 0.126 11.61 3.12 4.250 4.250 3.750 0.25 2.495 1.995 0.25 100 44,452 4,566 35

1 1/4 4 1/2 1.66 4.63 285 82,554 3,068 65 0.126 13.45 3.50 4.630 4.625 4.125 0.25 2.875 2.375 0.25 100 44,452 4,074 35

1 1/2 4 1/2 1.91 5.00 285 82,554 2,644 65 0.126 15.54 3.88 5.000 5.005 4.505 0.25 3.255 2.755 0.25 100 44,452 3,674 35

2 4 5/8 2.38 6.00 285 82,390 2,977 130 0.202 22.06 4.75 6.000 6.000 5.500 0.25 4.000 3.500 0.25 100 41,195 4,459 65

2 1/2 4 5/8 2.88 7.00 285 82,390 2,157 130 0.202 30.20 5.50 7.000 6.750 6.250 0.25 4.750 4.250 0.25 100 41,195 3,851 65

3 4 5/8 3.50 7.50 285 82,390 1,968 130 0.202 32.79 6.00 7.500 7.250 6.750 0.25 5.250 4.750 0.25 100 41,195 3,529 65

3 1/2 8 5/8 4.00 8.50 285 82,390 3,208 130 0.202 40.64 7.00 8.500 8.250 7.750 0.25 6.250 5.750 0.25 100 41,195 6,051 65

4 8 5/8 4.50 9.00 285 82,390 2,932 130 0.202 44.18 7.50 9.000 8.750 8.250 0.25 6.750 6.250 0.25 100 41,195 5,647 65

5 8 3/4 5.56 10.00 285 79,470 3,770 225 0.302 49.45 8.50 10.000 9.875 9.375 0.25 7.625 7.125 0.25 100 30,000 5,426 85

6 8 3/4 6.62 11.00 285 79,470 3,296 225 0.302 55.80 9.50 11.000 10.875 10.375 0.25 8.625 8.125 0.25 100 30,000 4,854 85

8 8 3/4 8.62 13.50 285 79,470 2,222 225 0.302 79.97 11.75 13.500 13.125 12.625 0.25 10.875 10.375 0.25 100 35,320 4,619 100

10 12 7/8 10.75 16.00 285 81,694 3,857 375 0.420 100.87 14.25 16.000 15.750 15.250 0.25 13.250 12.750 0.25 100 30,499 6,857 140

12 12 7/8 12.75 19.00 285 81,694 2,590 375 0.420 146.43 17.00 19.000 18.500 18.000 0.25 16.000 15.500 0.25 100 30,499 5,745 140

14 12 1 14.00 21.00 285 82,030 2,762 565 0.551 180.49 18.75 21.000 20.375 19.875 0.25 17.625 16.875 0.375 100 32,667 5,973 225

16 16 1 16.00 23.50 285 82,030 3,072 565 0.551 216.77 21.25 23.500 22.875 22.375 0.25 20.125 19.375 0.375 100 32,667 7,011 225

18 16 1 1/8 18.00 25.00 285 80,586 3,996 825 0.728 216.77 22.75 25.000 24.500 24.000 0.25 21.500 20.750 0.375 100 31,744 8,409 325

20 20 1 1/8 20.00 27.50 285 80,586 4,246 825 0.728 255.25 25.00 27.500 26.750 26.250 0.25 23.750 22.750 0.5 100 31,744 8,055 325

24 20 1 1/4 24.00 32.00 285 80,025 4,219 1,550 0.930 322.16 29.50 32.000 31.375 30.875 0.25 28.125 26.875 0.625 100 30,977 7,336 600

Bolt Stress vs. Gasket Stress in 300lb Raised Face Flanges

Calculations based on bolt root diameter

Nominal # Bolts Bolt Dia. Bolt CMG / Sheet Spiral Spiral Raised Face MAWP (PSI) Stud Load CMG / Spiral Torque Bolt Root CMG / Sheet Spiral Bolt Small Small Tongue Gasket Stess

Pipe size (In) Length Gasket ID Wound Wound OD (In) (PSI) Sheet Ring Wound Value (.15 Area in^2 Gasket Area Wound Circle Tongue Tongue Area based on

(In) (In) Gasket Gasket Gasket Gasket & .2 in^2 Gasket Diameter OD ID stud load and

Winding ID Winding Stress (PSI) Stress Friction Area in^2 pressure on

(In) OD (In) (PSI) Factors) left

1/2 4 1/2 2 1/2 0.84 0.75 1.25 1.38 740 32,000 16,972 24,003 25 0.126 0.94 0.67 2.62 1 3/8 1 0.70 22,845

3/4 4 5/8 2 3/4 1.06 1 1.56 1.69 740 32,000 18,758 26,156 50 0.202 1.36 0.98 3.25 1 11/16 1 5/16 0.88 28,888

1 4 5/8 3 1.31 1.25 1.88 2 740 25,351 11,093 14,554 40 0.202 1.79 1.37 3.5 1 7/8 1 1/2 0.99 20,019

1 1/4 4 5/8 3 1.66 1.88 2.38 2.5 740 41,195 11,795 22,445 65 0.202 2.74 1.44 3.88 2 6/25 1 7/8 1.18 27,442

1 1/2 4 3/4 3 1/2 1.91 2.13 2.75 2.88 740 33,554 10,749 18,596 95 0.302 3.65 2.11 4.5 2 1/2 2 1/8 1.36 28,796

2 8 5/8 3 1/4 2.38 2.75 3.38 3.62 740 34,857 9,240 19,966 55 0.202 5.84 2.70 5 3 1/4 2 7/8 1.80 29,932

2 1/2 8 3/4 3 3/4 2.88 3.25 3.88 4.12 740 31,788 10,733 23,227 90 0.302 6.82 3.15 5.88 3 3/4 3 3/8 2.10 34,867

3 8 3/4 4 3.5 4 4.75 5 740 49,447 11,408 24,353 140 0.302 10.01 4.69 6.62 4 5/8 4 1/4 2.61 43,703

3 1/2 8 3/4 4 1/4 4 4.5 5.25 5.5 740 58,277 11,944 25,556 165 0.302 11.19 5.23 7.25 5 1/8 4 3/4 2.91 45,963

4 8 3/4 4 1/4 4.5 5 5.88 6.19 740 70,639 11,373 23,233 200 0.302 14.19 6.95 7.88 5 11/16 5 3/16 4.27 37,786

5 8 3/4 4 1/2 5.56 6.13 7 7.31 740 79,469 10,033 21,414 225 0.302 17.69 8.29 9.25 6 13/16 6 5/16 5.15 34,432

6 12 3/4 4 3/4 6.62 7.19 8.25 8.5 740 74,171 11,103 20,575 210 0.302 22.33 12.05 10.62 8 7 1/2 6.09 40,724

8 12 7/8 5 1/4 8.62 9.19 10.38 10.62 740 79,515 12,020 21,029 365 0.420 30.22 17.27 13 10 9 3/8 9.51 38,195

10 16 1 6 10.75 11.31 12.5 12.75 740 70,416 15,243 26,757 485 0.551 36.91 21.03 15.25 12 11 1/4 13.70 41,086

12 16 1 1/8 6 1/2 12.75 13.38 14.75 15 740 66,906 14,187 24,137 685 0.728 49.04 28.82 17.75 14 1/4 13 1/2 16.35 42,560

14 20 1 1/8 6 3/4 14 14.63 16 16.25 740 48,837 11,172 19,025 500 0.728 53.46 31.39 20.25 15 1/2 14 3/4 17.82 33,515

16 20 1 1/4 7 1/4 16 16.63 18.25 18.5 740 48,273 11,054 17,582 935 0.930 67.74 42.59 22.5 17 5/8 16 3/4 23.62 31,698

18 24 1 1/4 7 1/2 18 18.69 20.75 21 740 52,403 10,675 15,879 1,015 0.930 91.89 61.78 24.75 20 1/8 19 1/4 27.06 36,253

20 24 1 1/4 8 20 20.69 22.75 23 740 60,406 11,009 16,390 1,170 0.930 101.32 68.05 27 22 21 33.77 33,026

24 24 1 1/2 9 24 24.75 27 27.25 740 49,859 10,283 15,149 1,750 1.404 130.82 88.80 32 26 1/4 25 1/4 40.45 33,259

26 28 1 5/8 11 3/4 26.5 27 29 29.5 740 47,223 13,868 21,498 2,150 1.681 131.95 85.12 34.5

26 32 1 1/4 8 1/4 26 26 1/2 28 29 740 56,792 10,006 21,099 1,100 0.930 129.59 61.46 31.625

30 28 1 3/4 13 30.5 31.25 33.25 33.75 740 45,874 12,323 20,610 2,650 1.981 164.00 98.06 31.625

30 36 1 3/8 10 1/2 30.5 30 1/2 32 33.75 740 45,313 8,305 19,322 1,200 1.156 164.00 70.49 31 5/8

Bolt Stress vs. Gasket Stress in 400lb Raised Face Flanges

Calculations based on bolt root diameter

Nominal # Bolts Bolt Dia. Bolt CMG / Sheet Spiral Spiral Raised Face MAWP (PSI) Stud Load CMG / Spiral Torque Bolt Root CMG / Sheet Spiral Bolt Small Small Tongue Gasket Stess

Pipe size (In) Length Gasket ID Wound Wound OD (In) (PSI) Sheet Ring Wound Value (.15 Area in^2 Gasket Area Wound Circle Tongue Tongue Area based on

(In) (In) Gasket Gasket Gasket Gasket & .2 in^2 Gasket Diameter OD ID stud load and

Winding ID Winding Stress (PSI) Stress Friction Area in^2 pressure on

(In) OD (In) (PSI) Factors) left

1/2 4 1/2 0.84 0.75 1.25 1.38 990 38,102 20,186 28,548 30 0.126 0.94 0.67 2.62 1 3/8 1 0.70 27,171

3/4 4 5/8 1.06 1 1.56 1.69 990 35,650 20,844 29,064 56 0.202 1.36 0.98 3.25 1 11/16 1 5/16 0.88 32,100

1 4 5/8 1.31 1.25 1.88 2 990 47,525 20,970 27,513 75 0.202 1.79 1.37 3.5 1 7/8 1 1/2 0.99 37,842

1 1/4 4 5/8 1.66 1.88 2.38 2.5 990 47,525 13,547 25,777 75 0.202 2.74 1.44 3.88 2 6/25 1 7/8 1.18 31,517

1 1/2 4 3/4 1.91 2.13 2.75 2.88 990 52,979 17,059 29,511 150 0.302 3.65 2.11 4.5 2 1/2 2 1/8 1.36 45,699

2 8 5/8 2.38 2.75 3.38 3.62 990 47,525 12,609 27,244 75 0.202 5.84 2.70 5 3 1/4 2 7/8 1.80 40,842

2 1/2 8 3/4 2.88 3.25 3.88 4.12 990 39,735 13,369 28,933 113 0.302 6.82 3.15 5.88 3 3/4 3 3/8 2.10 43,432

3 8 3/4 3.5 4 4.75 5 990 59,602 13,681 29,206 169 0.302 10.01 4.69 6.62 4 5/8 4 1/4 2.61 52,413

3 1/2 8 7/8 4 4.13 5.25 5.5 990 73,524 21,206 30,668 338 0.420 11.19 7.74 7.25 5 1/8 4 3/4 2.91 81,602

4 8 7/8 4.5 4.75 5.88 6.19 990 73,524 16,521 26,458 338 0.420 14.19 8.86 7.88 5 11/16 5 3/16 4.27 54,891

5 8 7/8 5.56 5.81 7 7.31 990 73,524 12,856 20,146 338 0.420 17.69 11.29 9.25 6 13/16 6 5/16 5.15 44,123

6 12 7/8 6.62 6.88 8.25 8.5 990 73,524 15,332 22,122 338 0.420 22.33 15.47 10.62 8 7 1/2 6.09 56,235

8 12 1 8.62 8.88 10.38 10.62 990 81,668 16,221 22,619 563 0.551 30.22 21.67 13 10 9 3/8 9.51 51,547

10 16 1 1/8 10.75 10.81 12.5 12.75 990 80,580 23,322 28,971 825 0.728 36.91 29.72 15.25 12 11 1/4 13.70 62,861

12 16 1 1/4 12.75 12.88 14.75 15 990 80,025 21,992 27,557 1,550 0.930 49.04 39.13 17.75 14 1/4 13 1/2 16.35 65,975

14 20 1 1/4 14 14.25 16 16.25 990 72,281 22,291 29,783 1,400 0.930 53.46 40.01 20.25 15 1/2 14 3/4 17.82 66,874

16 20 1 3/8 16 16.25 18.25 18.5 990 79,297 24,117 31,175 2,100 1.156 67.74 52.40 22.5 17 5/8 16 3/4 23.62 69,156

18 24 1 3/8 18 18.5 20.75 21 990 79,297 21,192 28,924 2,100 1.156 91.89 67.33 24.75 20 1/8 19 1/4 27.06 71,966

20 24 1 1/2 20 20.5 22.75 23 990 79,775 23,461 32,036 2,800 1.404 101.32 74.20 27 22 21 33.77 70,383

24 24 1 3/4 24 24.75 27 27.25 990 69,244 21,737 32,022 4,000 1.981 130.82 88.80 32 26 1/4 25 1/4 40.45 70,302

Bolt Stress vs. Gasket Stress in 600lb Raised Face Flanges

Calculations based on bolt root diameter

Nominal # Bolts Bolt Dia. Bolt CMG / Sheet Spiral Spiral Raised Face MAWP (PSI) Stud Load CMG / Spiral Torque Bolt Root CMG / Sheet Spiral Bolt Small Small Tongue Gasket Stess

Pipe size (In) Length Gasket ID Wound Wound OD (In) (PSI) Sheet Ring Wound Value (.15 Area in^2 Gasket Area Wound Circle Tongue Tongue Area based on

(In) (In) Gasket Gasket Gasket Gasket & .2 in^2 Gasket Diameter OD ID stud load and

Winding ID Winding Stress (PSI) Stress Friction Area in^2 pressure on

(In) OD (In) (PSI) Factors) left

1/2 4 1/2 3 0.84 0.75 1.25 1.38 1,480 25,401 13,286 18,790 20 0.126 0.94 0.67 2.62 1 3/8 1 0.70 17,883

3/4 4 5/8 3 1/4 1.06 1 1.56 1.69 1,480 19,000 10,800 15,059 30 0.202 1.36 0.98 3.25 1 11/16 1 5/16 0.88 16,632

1 4 5/8 3 1/2 1.31 1.25 1.88 2 1,480 25,351 10,769 14,129 40 0.202 1.79 1.37 3.5 1 7/8 1 1/2 0.99 19,434

1 1/4 4 5/8 3 3/4 1.66 1.88 2.38 2.5 1,480 47,533 13,330 25,365 75 0.202 2.74 1.44 3.88 2 6/25 1 7/8 1.18 31,013

1 1/2 4 3/4 4 1.91 2.13 2.75 2.88 1,480 38,852 12,145 21,010 110 0.302 3.65 2.11 4.5 2 1/2 2 1/8 1.36 32,535

2 8 5/8 4 1/4 2.38 2.75 3.38 3.62 1,480 47,533 12,347 26,679 75 0.202 5.84 2.70 5 3 1/4 2 7/8 1.80 39,996

2 1/2 8 3/4 4 3/4 2.88 3.25 3.88 4.12 1,480 38,852 12,703 27,492 110 0.302 6.82 3.15 5.88 3 3/4 3 3/8 2.10 41,269

3 8 3/4 5 3.5 4 4.75 5 1,480 52,980 11,738 25,057 150 0.302 10.01 4.69 6.62 4 5/8 4 1/4 2.61 44,968

3 1/2 8 7/8 5 1/2 4 4.13 5.25 5.5 1,480 53,373 14,739 21,316 245 0.420 11.19 7.74 7.25 5 1/8 4 3/4 2.91 56,718

4 8 7/8 5 3/4 4.5 4.75 5.88 6.19 1,480 59,909 12,865 20,603 275 0.420 14.19 8.86 8.5 5 11/16 5 3/16 4.27 42,745

5 8 1 6 1/2 5.56 5.81 7 7.31 1,480 59,527 13,191 20,671 410 0.551 17.69 11.29 10.5 6 13/16 6 5/16 5.15 45,272

6 12 1 6 3/4 6.62 6.88 8.25 8.5 1,480 54,445 14,251 20,562 375 0.551 22.33 15.47 11.5 8 7 1/2 6.09 52,269

8 12 1 1/8 7 3/4 8.62 8.88 10.38 10.62 1,480 68,371 17,303 24,127 700 0.728 30.22 21.67 13.75 10 9 3/8 9.51 54,985

10 16 1 1/4 8 1/2 10.75 10.81 12.5 12.75 1,480 49,822 16,928 21,029 965 0.930 36.91 29.72 17 12 11 1/4 13.70 45,627

12 20 1 1/4 8 3/4 12.75 12.88 14.75 15 1,480 50,080 15,576 19,518 970 0.930 49.04 39.13 19.25 14 1/4 13 1/2 16.35 46,728

14 20 1 3/8 9 1/4 14 14.25 16 16.25 1,480 46,257 15,738 21,027 1,225 1.156 53.46 40.01 20.75 15 1/2 14 3/4 17.82 47,213

16 20 1 1/2 10 16 16.25 18.25 18.5 1,480 45,016 14,267 18,442 1,580 1.404 67.74 52.40 23.75 17 5/8 16 3/4 23.62 40,910

18 20 1 5/8 10 3/4 18 18.5 20.75 21 1,480 53,373 15,430 21,059 2,430 1.681 91.89 67.33 25.75 20 1/8 19 1/4 27.06 52,398

20 24 1 5/8 11 1/2 20 20.5 22.75 23 1,480 50,518 15,528 21,203 2,300 1.681 101.32 74.20 28.5 22 21 33.77 46,583

24 24 1 7/8 13 1/4 24 24.75 27 27.25 1,480 55,540 18,365 27,054 4,000 2.305 130.82 88.80 33 26 1/4 25 1/4 40.45 59,397

Bolt Stress vs. Gasket Stress in 900lb Raised Face Flanges

Calculations based on bolt root diameter

Nominal # Bolts Bolt Dia. Bolt CMG / Sheet Spiral Spiral Raised Face MAWP (PSI) Stud Load CMG / Spiral Torque Bolt Root CMG / Sheet Spiral Bolt Flange

Pipe size (In) Length Gasket ID Wound Wound OD (In) (PSI) Sheet Ring Wound Value (.15 Area in^2 Gasket Area Wound Circle Thickness

(In) (In) Gasket Gasket Gasket Gasket & .2 in^2 Gasket Diameter

Winding ID Winding Stress (PSI) Stress Friction Area in^2

(In) OD (In) (PSI) Factors)

1/2 4 3/4 4 1/2 0.84 3/4 1 1/4 1 3/8 2,220 12,362 15,577 21,776 35 0.302 0.93 0.67 3 1/4 7/8

3/4 4 3/4 4 3/4 1.06 1 1 9/16 1 11/16 2,220 17,660 15,031 20,731 50 0.302 1.35 0.98 3 1/2 1

1 4 7/8 5 1/4 1.31 1 1/4 1 7/8 2 2,220 17,428 15,338 20,336 80 0.420 1.79 1.35 4 1 1/8

1 1/4 4 7/8 5 1/4 1.66 1 9/16 2 3/8 2 1/2 2,220 30,499 17,663 21,237 140 0.420 2.74 2.28 4 3/8 1 1/8

1 1/2 4 1 6 1.91 1 7/8 2 3/4 2 7/8 2,220 29,037 16,566 20,634 200 0.551 3.63 2.91 4 7/8 1 1/4

2 8 7/8 6 2.38 2 5/16 3 3/8 3 5/8 2,220 30,499 16,252 21,600 140 0.420 5.87 4.42 6 1/2 1 1/2

2 1/2 8 1 6 3/4 2.88 2 3/4 3 7/8 4 1/8 2,220 29,037 17,096 21,384 200 0.551 6.85 5.48 7 1/2 1 5/8

3 8 7/8 6 3.5 3 3/4 4 3/4 5 2,220 45,748 13,772 22,198 210 0.420 10.01 6.21 7 1/2 1 1/2

4 8 1 1/8 7 1/4 4.5 4 3/4 5 7/8 6 3/16 2,220 36,627 13,091 21,038 375 0.728 14.16 8.81 9 1/4 1 3/4

5 8 1 1/4 8 5.56 5 3/16 7 7 5/16 2,220 41,045 14,770 15,703 795 0.930 17.72 16.67 11 2

6 12 1 1/8 8 6.62 6 7/8 8 1/4 8 1/2 2,220 45,418 14,962 21,513 465 0.728 22.33 15.53 12 1/2 2 3/16

8 12 1 3/8 9 1/4 8.62 8 3/4 10 1/8 10 5/8 2,220 38,500 13,935 21,777 1,020 1.156 30.31 19.39 15 1/2 2 1/2

10 16 1 3/8 9 3/4 10.75 10 7/8 12 1/4 12 3/4 2,220 36,439 13,529 21,006 965 1.156 36.91 23.77 18 1/2 2 3/4

12 20 1 3/8 10 1/2 12.75 12 3/4 14 1/2 15 2,220 41,914 14,635 19,917 1,110 1.156 49.04 36.03 21 3 1/8

488945738.xls, CS Raised Face Gasket Stresses David W. Reeves, 7/7/04

14 20 1 1/2 11 1/4 14 14 15 3/4 16 1/4 2,220 45,016 17,253 23,440 1,580 1.404 53.46 39.35 22 3 3/8

16 20 1 5/8 11 3/4 16 16 1/4 18 18 1/2 2,220 45,466 15,977 23,886 2,070 1.681 67.74 45.31 24 1/4 3 1/2

18 20 1 7/8 13 1/2 18 18 1/4 20 1/2 21 2,220 46,515 17,184 23,757 3,350 2.305 91.89 66.47 27 4

20 20 2 14 1/2 20 20 1/2 22 1/2 23 2,220 42,000 15,114 23,437 3,715 2.653 101.32 65.34 29 1/2 4 1/4

24 20 2 1/2 18 24 24 3/4 26 3/4 27 1/4 2,220 34,660 15,072 25,190 6,200 4.293 130.82 78.27 35 1/2 5 1/2

Bolt Stress vs. Gasket Stress in 1500lb Raised Face Flanges

MAWP 50,000

Calculations based on bolt root diameter

Nominal # Bolts Bolt Dia. Bolt CMG / Sheet Spiral Spiral Raised Face MAWP (PSI) Stud Load CMG / Spiral Torque Bolt Root CMG / Sheet Spiral Bolt Flange

Pipe size (In) Length Gasket ID Wound Wound OD (In) (PSI) Sheet Ring Wound Value (.15 Area in^2 Gasket Area Wound Circle Thickness

(In) (In) Gasket Gasket Gasket Gasket & .2 in^2 Gasket Diameter

Winding ID Winding Stress (PSI) Stress Friction Area in^2

(In) OD (In) (PSI) Factors)

1/2 4 3/4 4 1/2 0.84 3/4 1 1/4 1 3/8 3,705 14,128 17,556 24,543 40 0.302 0.93 0.67 3 1/4 7/8

3/4 4 3/4 4 3/4 1.06 1 1 9/16 1 11/16 3,705 21,192 17,697 24,409 60 0.302 1.35 0.98 3 1/2 1

1 4 7/8 5 1/4 1.31 1 1/4 1 7/8 2 3,705 20,696 17,746 23,528 95 0.420 1.79 1.35 4 1 1/8

1 1/4 4 7/8 5 1/4 1.66 1 9/16 2 3/8 2 1/2 3,705 34,856 19,664 23,643 160 0.420 2.74 2.28 4 3/8 1 1/8

1 1/2 4 1 6 1.91 1 7/8 2 3/4 2 7/8 3,705 34,119 18,930 23,580 235 0.551 3.63 2.91 4 7/8 1 1/4

2 8 7/8 6 2.38 2 5/16 3 3/8 3 5/8 3,705 32,677 16,703 22,200 150 0.420 5.87 4.42 6 1/2 1 1/2

2 1/2 8 1 6 3/4 2.88 2 3/4 3 7/8 4 1/8 3,705 29,037 16,032 20,053 200 0.551 6.85 5.48 7 1/2 1 5/8

3 8 1 1/8 7 1/2 3.5 3 5/8 4 3/4 5 3,705 33,209 16,700 24,109 340 0.728 10.01 6.94 8 1 7/8

4 8 1 1/4 8 1/4 4.5 4 5/8 5 7/8 6 3/16 3,705 36,140 15,690 22,830 700 0.930 14.16 9.73 9 1/2 2 1/8

5 8 1 1/2 10 1/4 5.56 5 5/8 7 7 5/16 3,705 32,052 16,213 22,182 1,125 1.404 17.72 12.95 11 1/2 2 7/8

6 12 1 3/8 10 3/4 6.62 6 3/4 8 1/4 8 1/2 3,705 34,928 17,004 22,509 925 1.156 22.33 16.86 12 1/2 3 1/4

8 12 1 5/8 12 8.62 8 1/2 10 1/8 10 5/8 3,705 36,022 17,832 23,724 1,640 1.681 30.31 22.78 15 1/2 3 5/8

10 12 1 7/8 14 10.75 10 1/2 12 1/4 12 3/4 3,705 36,101 19,164 23,526 2,600 2.305 36.91 30.07 19 4 1/4

12 16 2 15 1/2 12.75 12 3/4 14 1/2 15 3,705 29,963 17,394 23,672 2,650 2.653 49.04 36.03 22 1/2 4 7/8

14 16 2 1/4 16 3/4 14 14 1/4 15 3/4 16 1/4 3,705 24,142 14,074 22,259 3,100 3.424 53.46 33.80 25 5 1/4

16 16 2 1/2 18 1/2 16 16 18 18 1/2 3,705 27,951 17,347 22,754 5,000 4.293 67.74 51.64 27 3/4 5 3/4

18 16 2 3/4 20 1/4 18 18 1/4 20 1/2 21 3,705 29,033 16,333 22,580 7,000 5.260 91.89 66.47 30 1/2 6 3/8

20 16 3 22 1/4 20 20 1/4 22 1/2 23 3,705 27,981 16,464 22,745 8,850 6.326 101.32 73.34 32 3/4 7

24 16 3 1/2 25 1/4 24 24 1/4 26 3/4 27 1/4 3,705 27,425 16,542 22,191 14,000 8.751 130.82 97.52 39 8

Bolt Stress vs. Gasket Stress in 2500lb Raised Face Flanges

MAWP 35,000

Calculations based on bolt root diameter

Nominal # Bolts Bolt Dia. Bolt CMG / Sheet Spiral Spiral Raised Face MAWP (PSI) Stud Load CMG / Spiral Torque Bolt Root CMG / Sheet Spiral Bolt Flange

Pipe size (In) Length Gasket ID Wound Wound OD (In) (PSI) Sheet Ring Wound Value (.15 Area in^2 Gasket Area Wound Circle Thickness

(In) (In) Gasket Gasket Gasket Gasket & .2 in^2 Gasket Diameter

Winding ID Winding Stress (PSI) Stress Friction Area in^2

(In) OD (In) (PSI) Factors)

1/2 4 3/4 5 0.84 3/4 1 1/4 1 3/8 6,170 14,128 17,036 23,816 40 0.302 0.93 0.67 3 1/2 1 3/16

3/4 4 3/4 5 1/4 1.06 1 1 9/16 1 11/16 6,170 21,192 16,893 23,300 60 0.302 1.35 0.98 3 3/4 1 1/4

1 4 7/8 5 3/4 1.31 1 1/4 1 7/8 2 6,170 21,785 17,687 23,449 100 0.420 1.79 1.35 4 1/4 1 3/8

1 1/4 4 1 6 1/2 1.66 1 9/16 2 3/8 2 1/2 6,170 29,037 20,561 24,722 200 0.551 2.74 2.28 5 1/8 1 1/2

1 1/2 4 1 1/8 7 1/4 1.91 1 7/8 2 3/4 2 7/8 6,170 26,860 18,563 23,122 275 0.728 3.63 2.91 5 3/4 1 3/4

2 8 1 7 1/2 2.38 2 5/16 3 3/8 3 5/8 6,170 29,037 18,498 24,586 200 0.551 5.87 4.42 6 3/4 2

2 1/2 8 1 1/8 8 1/4 2.88 2 3/4 3 7/8 4 1/8 6,170 26,860 18,418 23,037 275 0.728 6.85 5.48 7 3/4 2 1/4

3 8 1 1/4 9 1/4 3.5 3 5/8 4 3/4 5 6,170 27,105 15,777 22,776 525 0.930 10.01 6.94 9 2 5/8

4 8 1 1/2 10 1/2 4.5 4 5/8 5 7/8 6 3/16 6,170 26,354 15,423 22,442 925 1.404 14.16 9.73 10 3/4 3

5 8 1 3/4 12 1/2 5.56 5 5/8 7 7 5/16 6,170 25,967 16,384 22,416 1,500 1.981 17.72 12.95 12 3/4 3 5/8

6 8 2 14 1/4 6.62 6 3/4 8 1/4 8 1/2 6,170 26,006 16,911 22,387 2,300 2.653 22.33 16.86 14 1/2 4 1/4

8 12 2 15 3/4 8.62 8 1/2 10 1/8 10 5/8 6,170 26,006 17,088 22,734 2,300 2.653 30.31 22.78 17 1/4 5

10 12 2 1/2 20 10.75 10 5/8 12 1/4 12 3/4 6,170 21,523 16,910 22,298 3,850 4.293 36.91 28.00 21 1/4 6 1/2

12 12 2 3/4 22 12.75 12 1/2 14 1/2 15 6,170 25,715 18,873 22,578 6,200 5.260 49.04 40.99 24 3/8 7 1/4

488945738.xls, CS Raised Face Gasket Stresses David W. Reeves, 7/7/04

Bolt Stress vs. Gasket Stress in 150, 300, 400 and 600, 900, 1500 and 2500 class Raised Face Flanges

& Full Face (sizes listed below.)

From Calvin Gillas, Lamons Gasket Company

Bolt Stress vs. Gasket Stress in 150lb Raised Face Flanges

Calculations based on bolt root diameter

Nominal # Bolts Bolt Dia. Bolt CMG / Sheet Spiral Spiral Raised Face MAWP (PSI) Stud Load CMG / Spiral Torque Bolt Root CMG / Sheet Spiral Bolt

Pipe size (In) Length Gasket ID Wound Wound OD (In) (PSI) Sheet Ring Wound Value (.15 Area in^2 Gasket Area Wound Circle

(In) (In) Gasket Gasket Gasket Gasket & .2 in^2 Gasket Diameter

Winding ID Winding Stress (PSI) Stress Friction Area in^2

(In) OD (In) (PSI) Factors)

1/2 4 1/2 2 1/4 0.84 0.75 1.25 1.38 285 12,701 6,738 9,529 10 0.126 0.94 0.67 2.38

3/4 4 1/2 2 1/4 1.06 1 1.56 1.69 285 19,051 6,963 9,708 15 0.126 1.36 0.98 2.75

1 4 1/2 2 1/2 1.31 1.25 1.88 2 285 25,401 7,011 9,198 20 0.126 1.79 1.37 3.12

1 1/4 4 1/2 2 1/2 1.66 1.88 2.38 2.5 285 38,102 6,868 13,070 30 0.126 2.74 1.44 3.5

1 1/2 4 1/2 2 3/4 1.91 2.13 2.75 2.88 285 50,802 6,877 11,897 40 0.126 3.65 2.11 3.88

2 4 5/8 3 2.38 2.75 3.38 3.62 285 44,364 5,980 12,922 70 0.202 5.84 2.70 4.75

2 1/2 4 5/8 3 1/4 2.88 3.25 3.88 4.12 285 63,377 7,305 15,809 100 0.202 6.82 3.15 5.5

3 4 5/8 3 1/2 3.5 4 4.75 5 285 82,390 6,446 13,760 130 0.202 10.01 4.69 6

3 1/2 8 5/8 3 1/2 4 4.5 5.25 5.5 285 44,364 6,160 13,179 70 0.202 11.19 5.23 7

4 8 5/8 3 1/2 4.5 5 5.88 6.19 285 50,500 5,498 11,232 80 0.202 14.19 6.95 7.5

5 8 3/4 3 3/4 5.56 6.13 7 7.31 285 42,383 5,473 11,681 120 0.302 17.69 8.29 8.5

6 8 3/4 3 3/4 6.62 7.19 8.25 8.5 285 61,809 6,328 11,727 175 0.302 22.33 12.05 9.5

8 8 3/4 4 8.62 9.19 10.38 10.62 285 79,469 5,879 10,285 225 0.302 30.22 17.27 11.75

10 12 7/8 4 1/2 10.75 11.31 12.5 12.75 285 50,105 6,230 10,935 230 0.420 36.91 21.03 14.25

12 12 7/8 4 1/2 12.75 13.38 14.75 15 285 54,500 4,940 8,405 250 0.420 49.04 28.82 17

14 12 1 5 14 14.63 16 16.25 285 47,186 5,016 8,542 325 0.551 53.46 31.39 18.75

16 16 1 5 1/4 16 16.63 18.25 18.5 285 40,652 4,445 7,070 280 0.551 67.74 42.59 21.25

18 16 1 1/8 5 3/4 18 18.69 20.75 21 285 53,720 6,021 8,956 550 0.728 91.89 61.78 22.75

20 20 1 1/8 6 20 20.69 22.75 23 285 51,767 6,556 9,761 530 0.728 101.32 68.05 25

24 20 1 1/4 6 3/4 24 24.75 27 27.25 285 54,985 6,830 10,061 1,065 0.930 130.82 88.80 29.5

Bolt Stress vs. Full-Face Gasket Stress in Class 150 Flat Face Flanges

Calculations based on bolt root diameter

Nominal # Bolts Bolt Dia Bolt Gasket ID Gasket OD MAWP Stud Load Full-Face Torque Bolt Root Gasket Bolt

Pipe size Length Gasket Value (.15 Area in^2 Area Circle

Stress & .2 Friction (in^2) Diameter

Factors)

1/2 4 1/2 0.84 3.50 285 82,554 5,299 65 0.126 7.84 2.38

3/4 4 1/2 1.06 3.88 285 82,554 4,270 65 0.126 9.71 2.75

1 4 1/2 1.31 4.25 285 82,554 3,563 65 0.126 11.61 3.12

1 1/4 4 1/2 1.66 4.63 285 82,554 3,068 65 0.126 13.45 3.50

1 1/2 4 1/2 1.91 5.00 285 82,554 2,644 65 0.126 15.54 3.88

2 4 5/8 2.38 6.00 285 82,390 2,977 130 0.202 22.06 4.75

2 1/2 4 5/8 2.88 7.00 285 82,390 2,157 130 0.202 30.20 5.50

3 4 5/8 3.50 7.50 285 82,390 1,968 130 0.202 32.79 6.00

3 1/2 8 5/8 4.00 8.50 285 82,390 3,208 130 0.202 40.64 7.00

4 8 5/8 4.50 9.00 285 82,390 2,932 130 0.202 44.18 7.50

5 8 3/4 5.56 10.00 285 79,470 3,770 225 0.302 49.45 8.50

6 8 3/4 6.62 11.00 285 79,470 3,296 225 0.302 55.80 9.50

8 8 3/4 8.62 13.50 285 79,470 2,222 225 0.302 79.97 11.75

10 12 7/8 10.75 16.00 285 81,694 3,857 375 0.420 100.87 14.25

12 12 7/8 12.75 19.00 285 81,694 2,590 375 0.420 146.43 17.00

14 12 1 14.00 21.00 285 82,030 2,762 565 0.551 180.49 18.75

16 16 1 16.00 23.50 285 82,030 3,072 565 0.551 216.77 21.25

18 16 1 1/8 18.00 25.00 285 80,586 3,996 825 0.728 216.77 22.75

20 20 1 1/8 20.00 27.50 285 80,586 4,246 825 0.728 255.25 25.00

24 20 1 1/4 24.00 32.00 285 80,283 4,234 1,555 0.930 322.16 29.50

Bolt Stress vs. Gasket Stress in 300lb Raised Face Flanges

Calculations based on bolt root diameter

Nominal # Bolts Bolt Dia. Bolt CMG / Sheet Spiral Spiral Raised Face MAWP (PSI) Stud Load CMG / Spiral Torque Bolt Root CMG / Sheet Spiral Bolt

Pipe size (In) Length Gasket ID Wound Wound OD (In) (PSI) Sheet Ring Wound Value (.15 Area in^2 Gasket Area Wound Circle

(In) (In) Gasket Gasket Gasket Gasket & .2 in^2 Gasket Diameter

Winding ID Winding Stress (PSI) Stress Friction Area in^2

(In) OD (In) (PSI) Factors)

1/2 4 1/2 2 1/2 0.84 0.75 1.25 1.38 740 19,051 10,042 14,202 15 0.126 0.94 0.67 2.62

3/4 4 5/8 2 3/4 1.06 1 1.56 1.69 740 15,844 9,167 12,782 25 0.202 1.36 0.98 3.25

1 4 5/8 3 1.31 1.25 1.88 2 740 22,182 9,666 12,682 35 0.202 1.79 1.37 3.5

1 1/4 4 5/8 3 1.66 1.88 2.38 2.5 740 31,689 8,997 17,120 50 0.202 2.74 1.44 3.88

1 1/2 4 3/4 3 1/2 1.91 2.13 2.75 2.88 740 26,490 8,411 14,550 75 0.302 3.65 2.11 4.5

2 8 5/8 3 1/4 2.38 2.75 3.38 3.62 740 25,351 6,612 14,286 40 0.202 5.84 2.70 5

2 1/2 8 3/4 3 3/4 2.88 3.25 3.88 4.12 740 24,724 8,229 17,809 70 0.302 6.82 3.15 5.88

3 8 3/4 4 3.5 4 4.75 5 740 38,852 8,851 18,895 110 0.302 10.01 4.69 6.62

3 1/2 8 3/4 4 1/4 4 4.5 5.25 5.5 740 45,915 9,276 19,846 130 0.302 11.19 5.23 7.25

4 8 3/4 4 1/4 4.5 5 5.88 6.19 740 56,511 8,967 18,319 160 0.302 14.19 6.95 7.88

5 8 3/4 4 1/2 5.56 6.13 7 7.31 740 72,405 9,068 19,355 205 0.302 17.69 8.29 9.25

6 12 3/4 4 3/4 6.62 7.19 8.25 8.5 740 56,511 8,236 15,263 160 0.302 22.33 12.05 10.62

8 12 7/8 5 1/4 8.62 9.19 10.38 10.62 740 60,998 8,934 15,630 280 0.420 30.22 17.27 13

10 16 1 6 10.75 11.31 12.5 12.75 740 55,171 11,602 20,366 380 0.551 36.91 21.03 15.25

12 16 1 1/8 6 1/2 12.75 13.38 14.75 15 740 52,255 10,706 18,216 535 0.728 49.04 28.82 17.75

14 20 1 1/8 6 3/4 14 14.63 16 16.25 740 38,093 8,245 14,041 390 0.728 53.46 31.39 20.25

16 20 1 1/4 7 1/4 16 16.63 18.25 18.5 740 37,431 8,078 12,848 725 0.930 67.74 42.59 22.5

18 24 1 1/4 7 1/2 18 18.69 20.75 21 740 40,787 7,855 11,684 790 0.930 91.89 61.78 24.75

20 24 1 1/4 8 20 20.69 22.75 23 740 47,241 8,109 12,073 915 0.930 101.32 68.05 27

24 24 1 1/2 9 24 24.75 27 27.25 740 39,175 7,531 11,095 1,375 1.404 130.82 88.80 32

26 28 1 5/8 11 3/4 26.5 27 29 29.5 740 39,975 11,283 17,490 1,820 1.681 131.95 85.12 34.5

26 32 1 1/4 8 1/4 26 26 1/2 28 29 740 50,080 8,465 17,850 970 0.930 129.59 61.46 31.625

30 28 1 3/4 13 30.5 31.25 33.25 33.75 740 45,000 12,027 20,116 2,600 1.981 164.00 98.06 31.625

30 36 1 3/8 10 1/2 30.5 30 1/2 32 33.75 740 45,313 8,305 19,322 1,200 1.156 164.00 70.49 31 5/8

Bolt Stress vs. Gasket Stress in 400lb Raised Face Flanges

Calculations based on bolt root diameter

Nominal # Bolts Bolt Dia. Bolt CMG / Sheet Spiral Spiral Raised Face MAWP (PSI) Stud Load CMG / Spiral Torque Bolt Root CMG / Sheet Spiral Bolt

Pipe size (In) Length Gasket ID Wound Wound OD (In) (PSI) Sheet Ring Wound Value (.15 Area in^2 Gasket Area Wound Circle

(In) (In) Gasket Gasket Gasket Gasket & .2 in^2 Gasket Diameter

Winding ID Winding Stress (PSI) Stress Friction Area in^2

(In) OD (In) (PSI) Factors)

1/2 4 1/2 0.84 0.75 1.25 1.38 990 38,102 20,186 28,548 30 0.126 0.94 0.67 2.62

3/4 4 5/8 1.06 1 1.56 1.69 990 35,650 20,844 29,064 56 0.202 1.36 0.98 3.25

1 4 5/8 1.31 1.25 1.88 2 990 47,525 20,970 27,513 75 0.202 1.79 1.37 3.5

1 1/4 4 5/8 1.66 1.88 2.38 2.5 990 47,525 13,547 25,777 75 0.202 2.74 1.44 3.88

1 1/2 4 3/4 1.91 2.13 2.75 2.88 990 52,979 17,059 29,511 150 0.302 3.65 2.11 4.5

2 8 5/8 2.38 2.75 3.38 3.62 990 47,525 12,609 27,244 75 0.202 5.84 2.70 5

2 1/2 8 3/4 2.88 3.25 3.88 4.12 990 39,735 13,369 28,933 113 0.302 6.82 3.15 5.88

3 8 3/4 3.5 4 4.75 5 990 59,602 13,681 29,206 169 0.302 10.01 4.69 6.62

3 1/2 8 7/8 4 4.13 5.25 5.5 990 73,524 21,206 30,668 338 0.420 11.19 7.74 7.25

4 8 7/8 4.5 4.75 5.88 6.19 990 73,524 16,521 26,458 338 0.420 14.19 8.86 7.88

5 8 7/8 5.56 5.81 7 7.31 990 73,524 12,856 20,146 338 0.420 17.69 11.29 9.25

6 12 7/8 6.62 6.88 8.25 8.5 990 73,524 15,332 22,122 338 0.420 22.33 15.47 10.62

8 12 1 8.62 8.88 10.38 10.62 990 81,668 16,221 22,619 563 0.551 30.22 21.67 13

10 16 1 1/8 10.75 10.81 12.5 12.75 990 80,580 23,322 28,971 825 0.728 36.91 29.72 15.25

12 16 1 1/4 12.75 12.88 14.75 15 990 80,025 21,992 27,557 1,550 0.930 49.04 39.13 17.75

14 20 1 1/4 14 14.25 16 16.25 990 72,281 22,291 29,783 1,400 0.930 53.46 40.01 20.25

16 20 1 3/8 16 16.25 18.25 18.5 990 79,297 24,117 31,175 2,100 1.156 67.74 52.40 22.5

18 24 1 3/8 18 18.5 20.75 21 990 79,297 21,192 28,924 2,100 1.156 91.89 67.33 24.75

20 24 1 1/2 20 20.5 22.75 23 990 79,775 23,461 32,036 2,800 1.404 101.32 74.20 27

24 24 1 3/4 24 24.75 27 27.25 990 69,244 21,737 32,022 4,000 1.981 130.82 88.80 32

Bolt Stress vs. Gasket Stress in 600lb Raised Face Flanges

Calculations based on bolt root diameter

Nominal # Bolts Bolt Dia. Bolt CMG / Sheet Spiral Spiral Raised Face MAWP (PSI) Stud Load CMG / Spiral Torque Bolt Root CMG / Sheet Spiral Bolt

Pipe size (In) Length Gasket ID Wound Wound OD (In) (PSI) Sheet Ring Wound Value (.15 Area in^2 Gasket Area Wound Circle

(In) (In) Gasket Gasket Gasket Gasket & .2 in^2 Gasket Diameter

Winding ID Winding Stress (PSI) Stress Friction Area in^2

(In) OD (In) (PSI) Factors)

488945738.xls, SS Raised Face Gasket Stresses David W. Reeves, 7/7/04

1/2 4 1/2 3 0.84 0.75 1.25 1.38 1,480 19,051 9,887 13,983 15 0.126 0.94 0.67 2.62

3/4 4 5/8 3 1/4 1.06 1 1.56 1.69 1,480 15,844 8,926 12,447 25 0.202 1.36 0.98 3.25

1 4 5/8 3 1/2 1.31 1.25 1.88 2 1,480 22,182 9,342 12,257 35 0.202 1.79 1.37 3.5

1 1/4 4 5/8 3 3/4 1.66 1.88 2.38 2.5 1,480 38,026 10,532 20,040 60 0.202 2.74 1.44 3.88

1 1/2 4 3/4 4 1.91 2.13 2.75 2.88 1,480 30,022 9,222 15,953 85 0.302 3.65 2.11 4.5

2 8 5/8 4 1/4 2.38 2.75 3.38 3.62 1,480 38,026 9,719 21,000 60 0.202 5.84 2.70 5

2 1/2 8 3/4 4 3/4 2.88 3.25 3.88 4.12 1,480 31,788 10,200 22,074 90 0.302 6.82 3.15 5.88

3 8 3/4 5 3.5 4 4.75 5 1,480 47,681 10,459 22,328 135 0.302 10.01 4.69 6.62

3 1/2 8 7/8 5 1/2 4 4.13 5.25 5.5 1,480 41,500 11,177 16,165 190 0.420 11.19 7.74 7.25

4 8 7/8 5 3/4 4.5 4.75 5.88 6.19 1,480 46,838 9,772 15,650 215 0.420 14.19 8.86 8.5

5 8 1 6 1/2 5.56 5.81 7 7.31 1,480 46,500 9,945 15,584 320 0.551 17.69 11.29 10.5

6 12 1 6 3/4 6.62 6.88 8.25 8.5 1,480 43,556 11,026 15,909 300 0.551 22.33 15.47 11.5

8 12 1 1/8 7 3/4 8.62 8.88 10.38 10.62 1,480 53,720 13,068 18,222 550 0.728 30.22 21.67 13.75

10 16 1 1/4 8 1/2 10.75 10.81 12.5 12.75 1,480 39,000 12,567 15,611 755 0.930 36.91 29.72 17

12 20 1 1/4 8 3/4 12.75 12.88 14.75 15 1,480 39,000 11,375 14,253 755 0.930 49.04 39.13 19.25

14 20 1 3/8 9 1/4 14 14.25 16 16.25 1,480 35,872 11,248 15,028 950 1.156 53.46 40.01 20.75

16 20 1 1/2 10 16 16.25 18.25 18.5 1,480 35,614 10,370 13,404 1,250 1.404 67.74 52.40 23.75

18 20 1 5/8 10 3/4 18 18.5 20.75 21 1,480 41,732 11,170 15,246 1,900 1.681 91.89 67.33 25.75

20 24 1 5/8 11 1/2 20 20.5 22.75 23 1,480 39,536 11,155 15,231 1,800 1.681 101.32 74.20 28.5

24 24 1 7/8 13 1/4 24 24.75 27 27.25 1,480 43,043 13,081 19,271 3,100 2.305 130.82 88.80 33

Bolt Stress vs. Gasket Stress in 900lb Raised Face Flanges

Calculations based on bolt root diameter

Nominal # Bolts Bolt Dia. Bolt CMG / Sheet Spiral Spiral Raised Face MAWP (PSI) Stud Load CMG / Spiral Torque Bolt Root CMG / Sheet Spiral Bolt Flange

Pipe size (In) Length Gasket ID Wound Wound OD (In) (PSI) Sheet Ring Wound Value (.15 Area in^2 Gasket Area Wound Circle Thickness

(In) (In) Gasket Gasket Gasket Gasket & .2 in^2 Gasket Diameter

Winding ID Winding Stress (PSI) Stress Friction Area in^2

(In) OD (In) (PSI) Factors)

1/2 4 3/4 4 1/2 0.84 3/4 1 1/4 1 3/8 2,220 12,362 15,577 21,776 35 0.302 0.93 0.67 3 1/4 7/8

3/4 4 3/4 4 3/4 1.06 1 1 9/16 1 11/16 2,220 17,660 15,031 20,731 50 0.302 1.35 0.98 3 1/2 1

1 4 7/8 5 1/4 1.31 1 1/4 1 7/8 2 2,220 17,428 15,338 20,336 80 0.420 1.79 1.35 4 1 1/8

1 1/4 4 7/8 5 1/4 1.66 1 9/16 2 3/8 2 1/2 2,220 30,499 17,663 21,237 140 0.420 2.74 2.28 4 3/8 1 1/8

1 1/2 4 1 6 1.91 1 7/8 2 3/4 2 7/8 2,220 29,037 16,566 20,634 200 0.551 3.63 2.91 4 7/8 1 1/4

2 8 7/8 6 2.38 2 5/16 3 3/8 3 5/8 2,220 25,000 13,107 17,421 115 0.420 5.87 4.42 6 1/2 1 1/2

2 1/2 8 1 6 3/4 2.88 2 3/4 3 7/8 4 1/8 2,220 23,230 13,359 16,709 160 0.551 6.85 5.48 7 1/2 1 5/8

3 8 7/8 6 3.5 3 3/4 4 3/4 5 2,220 37,034 10,850 17,489 170 0.420 10.01 6.21 7 1/2 1 1/2

4 8 1 1/8 7 1/4 4.5 4 3/4 5 7/8 6 3/16 2,220 30,279 10,481 16,843 310 0.728 14.16 8.81 9 1/4 1 3/4

5 8 1 1/4 8 5.56 5 3/16 7 7 5/16 2,220 32,000 10,973 11,666 620 0.930 17.72 16.67 11 2

6 12 1 1/8 8 6.62 6 7/8 8 1/4 8 1/2 2,220 35,651 11,140 16,017 365 0.728 22.33 15.53 12 1/2 2 3/16

8 12 1 3/8 9 1/4 8.62 8 3/4 10 1/8 10 5/8 2,220 30,208 10,141 15,847 800 1.156 30.31 19.39 15 1/2 2 1/2

10 16 1 3/8 9 3/4 10.75 10 7/8 12 1/4 12 3/4 2,220 28,500 9,552 14,832 755 1.156 36.91 23.77 18 1/2 2 3/4

12 20 1 3/8 10 1/2 12.75 12 3/4 14 1/2 15 2,220 32,474 10,185 13,862 860 1.156 49.04 36.03 21 3 1/8

14 20 1 1/2 11 1/4 14 14 15 3/4 16 1/4 2,220 35,044 12,015 16,323 1,230 1.404 53.46 39.35 22 3 3/8

16 20 1 5/8 11 3/4 16 16 1/4 18 18 1/2 2,220 35,582 11,071 16,552 1,620 1.681 67.74 45.31 24 1/4 3 1/2

18 20 1 7/8 13 1/2 18 18 1/4 20 1/2 21 2,220 36,518 12,170 16,825 2,630 2.305 91.89 66.47 27 4

20 20 2 14 1/2 20 20 1/2 22 1/2 23 2,220 37,030 12,511 19,400 3,275 2.653 101.32 65.34 29 1/2 4 1/4

24 20 2 1/2 18 24 24 3/4 26 3/4 27 1/4 2,220 34,660 15,072 25,190 6,200 4.293 130.82 78.27 35 1/2 5 1/2

Bolt Stress vs. Gasket Stress in 1500lb Raised Face Flanges

MAWP 50,000

Calculations based on bolt root diameter

Nominal # Bolts Bolt Dia. Bolt CMG / Sheet Spiral Spiral Raised Face MAWP (PSI) Stud Load CMG / Spiral Torque Bolt Root CMG / Sheet Spiral Bolt Flange

Pipe size (In) Length Gasket ID Wound Wound OD (In) (PSI) Sheet Ring Wound Value (.15 Area in^2 Gasket Area Wound Circle Thickness

(In) (In) Gasket Gasket Gasket Gasket & .2 in^2 Gasket Diameter

Winding ID Winding Stress (PSI) Stress Friction Area in^2

(In) OD (In) (PSI) Factors)

1/2 4 3/4 4 1/2 0.84 3/4 1 1/4 1 3/8 3,705 14,128 17,556 24,543 40 0.302 0.93 0.67 3 1/4 7/8

3/4 4 3/4 4 3/4 1.06 1 1 9/16 1 11/16 3,705 21,192 17,697 24,409 60 0.302 1.35 0.98 3 1/2 1

1 4 7/8 5 1/4 1.31 1 1/4 1 7/8 2 3,705 20,696 17,746 23,528 95 0.420 1.79 1.35 4 1 1/8

1 1/4 4 7/8 5 1/4 1.66 1 9/16 2 3/8 2 1/2 3,705 30,499 16,999 20,439 140 0.420 2.74 2.28 4 3/8 1 1/8

1 1/2 4 1 6 1.91 1 7/8 2 3/4 2 7/8 3,705 31,215 17,166 21,382 215 0.551 3.63 2.91 4 7/8 1 1/4

2 8 7/8 6 2.38 2 5/16 3 3/8 3 5/8 3,705 25,000 12,313 16,365 115 0.420 5.87 4.42 6 1/2 1 1/2

2 1/2 8 1 6 3/4 2.88 2 3/4 3 7/8 4 1/8 3,705 23,956 12,762 15,962 165 0.551 6.85 5.48 7 1/2 1 5/8

3 8 1 1/8 7 1/2 3.5 3 5/8 4 3/4 5 3,705 30,279 14,996 21,648 310 0.728 10.01 6.94 8 1 7/8

4 8 1 1/4 8 1/4 4.5 4 5/8 5 7/8 6 3/16 3,705 34,591 14,877 21,647 670 0.930 14.16 9.73 9 1/2 2 1/8

5 8 1 1/2 10 1/4 5.56 5 5/8 7 7 5/16 3,705 32,052 16,213 22,182 1,125 1.404 17.72 12.95 11 1/2 2 7/8

6 12 1 3/8 10 3/4 6.62 6 3/4 8 1/4 8 1/2 3,705 34,928 17,004 22,509 925 1.156 22.33 16.86 12 1/2 3 1/4

8 12 1 5/8 12 8.62 8 1/2 10 1/8 10 5/8 3,705 36,022 17,832 23,724 1,640 1.681 30.31 22.78 15 1/2 3 5/8

10 12 1 7/8 14 10.75 10 1/2 12 1/4 12 3/4 3,705 36,101 19,164 23,526 2,600 2.305 36.91 30.07 19 4 1/4

12 16 2 15 1/2 12.75 12 3/4 14 1/2 15 3,705 29,963 17,394 23,672 2,650 2.653 49.04 36.03 22 1/2 4 7/8

14 16 2 1/4 16 3/4 14 14 1/4 15 3/4 16 1/4 3,705 24,142 14,074 22,259 3,100 3.424 53.46 33.80 25 5 1/4

16 16 2 1/2 18 1/2 16 16 18 18 1/2 3,705 27,951 17,347 22,754 5,000 4.293 67.74 51.64 27 3/4 5 3/4

18 16 2 3/4 20 1/4 18 18 1/4 20 1/2 21 3,705 29,033 16,333 22,580 7,000 5.260 91.89 66.47 30 1/2 6 3/8

20 16 3 22 1/4 20 20 1/4 22 1/2 23 3,705 27,981 16,464 22,745 8,850 6.326 101.32 73.34 32 3/4 7

24 16 3 1/2 25 1/4 24 24 1/4 26 3/4 27 1/4 3,705 27,425 16,542 22,191 14,000 8.751 130.82 97.52 39 8

Bolt Stress vs. Gasket Stress in 2500lb Raised Face Flanges

MAWP 35,000

Calculations based on bolt root diameter

Nominal # Bolts Bolt Dia. Bolt CMG / Sheet Spiral Spiral Raised Face MAWP (PSI) Stud Load CMG / Spiral Torque Bolt Root CMG / Sheet Spiral Bolt Flange

Pipe size (In) Length Gasket ID Wound Wound OD (In) (PSI) Sheet Ring Wound Value (.15 Area in^2 Gasket Area Wound Circle Thickness

(In) (In) Gasket Gasket Gasket Gasket & .2 in^2 Gasket Diameter

Winding ID Winding Stress (PSI) Stress Friction Area in^2

(In) OD (In) (PSI) Factors)

1/2 4 3/4 5 0.84 3/4 1 1/4 1 3/8 6,170 14,128 17,036 23,816 40 0.302 0.93 0.67 3 1/2 1 3/16

3/4 4 3/4 5 1/4 1.06 1 1 9/16 1 11/16 6,170 21,192 16,893 23,300 60 0.302 1.35 0.98 3 3/4 1 1/4

1 4 7/8 5 3/4 1.31 1 1/4 1 7/8 2 6,170 21,785 17,687 23,449 100 0.420 1.79 1.35 4 1/4 1 3/8

1 1/4 4 1 6 1/2 1.66 1 9/16 2 3/8 2 1/2 6,170 29,037 20,561 24,722 200 0.551 2.74 2.28 5 1/8 1 1/2

1 1/2 4 1 1/8 7 1/4 1.91 1 7/8 2 3/4 2 7/8 6,170 26,860 18,563 23,122 275 0.728 3.63 2.91 5 3/4 1 3/4

2 8 1 7 1/2 2.38 2 5/16 3 3/8 3 5/8 6,170 29,037 18,498 24,586 200 0.551 5.87 4.42 6 3/4 2

2 1/2 8 1 1/8 8 1/4 2.88 2 3/4 3 7/8 4 1/8 6,170 26,860 18,418 23,037 275 0.728 6.85 5.48 7 3/4 2 1/4

3 8 1 1/4 9 1/4 3.5 3 5/8 4 3/4 5 6,170 27,105 15,777 22,776 525 0.930 10.01 6.94 9 2 5/8

4 8 1 1/2 10 1/2 4.5 4 5/8 5 7/8 6 3/16 6,170 26,354 15,423 22,442 925 1.404 14.16 9.73 10 3/4 3

5 8 1 3/4 12 1/2 5.56 5 5/8 7 7 5/16 6,170 25,967 16,384 22,416 1,500 1.981 17.72 12.95 12 3/4 3 5/8

6 8 2 14 1/4 6.62 6 3/4 8 1/4 8 1/2 6,170 26,006 16,911 22,387 2,300 2.653 22.33 16.86 14 1/2 4 1/4

8 12 2 15 3/4 8.62 8 1/2 10 1/8 10 5/8 6,170 26,006 17,088 22,734 2,300 2.653 30.31 22.78 17 1/4 5

10 12 2 1/2 20 10.75 10 5/8 12 1/4 12 3/4 6,170 21,523 16,910 22,298 3,850 4.293 36.91 28.00 21 1/4 6 1/2

12 12 2 3/4 22 12.75 12 1/2 14 1/2 15 6,170 25,715 18,873 22,578 6,200 5.260 49.04 40.99 24 3/8 7 1/4

488945738.xls, SS Raised Face Gasket Stresses David W. Reeves, 7/7/04

Bolt Stress vs. Gasket Stress in 150, 300, 400 and

600, 900, 1500 and 2500 class RTJ Flanges

From Calvin Gillas, Lamons Gasket Company

Bolt Stress vs. Gasket Stress in 150lb RTJ Flanges

Calculations based on bolt root diameter

Nominal Ring Joint # Bolts Bolt Dia Bolt MAWP Stud Load RTJ Gasket Torque Stud Load @ Torque Bolt Root RTJ Gasket Bolt

Pipe size "R" Number Length Stress (PSI) Value (.15 25,000 PSI Value (.2 Area in^2 Area in^2 Circle

& .2 Gasket Friction Diameter

Friction Stress Factor) Gasket

Factors) Gasket ID OD

1 R-15 4 1/2 2 1/2 285 38,102 11,764 30 80,469 84 0.126 1.613 3.12 1.562 2.188

1 1/4 R-17 4 1/2 2 1/2 285 57,153 14,698 45 96,723 102 0.126 1.936 3.5 1.937 2.563

1 1/2 R-19 4 1/2 2 3/4 285 76,500 17,255 60 110,388 116 0.126 2.205 3.88 2.25 2.876

2 R-22 4 5/8 3 285 63,377 17,992 100 87,630 184 0.202 2.796 4.75 2.937 3.563

2 1/2 R-25 4 5/8 3 1/4 285 79,221 18,192 125 108,219 228 0.202 3.441 5.5 3.687 4.313

3 R-29 4 5/8 3 1/2 285 79,221 16,012 125 122,292 257 0.202 3.871 6 4.187 4.813

3 1/2 R-33 8 5/8 3 1/2 285 66,546 23,477 105 70,754 149 0.202 4.463 7 4.875 5.501

4 R-36 8 5/8 3 1/2 285 79,221 24,617 125 80,418 169 0.202 5.054 7.5 5.562 6.188

5 R-40 8 3/4 3 3/4 285 58,277 23,284 165 62,403 236 0.302 5.807 8.5 6.437 7.063

6 R-43 8 3/4 3 3/4 285 70,639 24,789 200 71,211 269 0.302 6.560 9.5 7.312 7.938

8 R-48 8 3/4 4 285 79,469 21,183 225 92,721 350 0.302 8.388 11.75 9.437 10.063

10 R-52 12 7/8 4 1/2 285 54,462 24,401 250 55,689 341 0.420 10.323 14.25 11.687 12.313

12 R-56 12 7/8 4 1/2 285 70,801 25,135 325 70,456 431 0.420 12.904 17 14.687 15.313

14 R-59 12 1 5 285 58,075 25,304 400 57,457 528 0.551 13.442 18.75 15.312 15.938

16 R-64 16 1 5 1/4 285 50,815 25,891 350 49,290 453 0.551 15.090 21.25 17.562 18.188

18 R-68 16 1 1/8 5 3/4 285 43,953 25,073 450 43,843 599 0.728 17.528 22.75 20.062 20.688

20 R-72 20 1 1/8 6 285 39,069 25,328 400 38,643 528 0.728 18.926 25 21.687 22.313

24 R-76 20 1 1/4 6 3/4 285 37,431 24,875 725 37,585 728 0.930 22.797 29.5 26.187 26.813

Bolt Stress vs. Gasket Stress in 300lb RTJ Flanges

Calculations based on bolt root diameter

Nominal Ring Joint # Bolts Bolt Dia Bolt MAWP Stud Load RTJ Gasket Torque Stud Load @ Torque Bolt Root RTJ Gasket Bolt

Pipe size "R" Number Length Stress (PSI) Value (.15 25,000 PSI Value (.2 Area in^2 Area in^2 Circle

& .2 Gasket Friction Diameter

Friction Stress Factor) Gasket

Factors) Gasket ID OD

1/2 R-11 4 1/2 2 1/2 740 25,401 14,639 20 43,175 45 0.126 0.864 2.62 1.094 1.594

3/4 R-13 4 5/8 2 3/4 740 22,182 12,115 35 45,342 95 0.202 1.452 3.25 1.375 2.001

1 R-16 4 5/8 3 740 34,857 16,029 55 53,963 114 0.202 1.721 3.5 1.687 2.313

1 1/4 R-18 4 5/8 3 740 47,533 18,350 75 64,351 135 0.202 2.043 3.88 2.062 2.688

1 1/2 R-20 4 3/4 3 1/2 740 37,086 18,808 105 48,938 185 0.302 2.312 4.5 2.375 3.001

2 R-23 8 5/8 3 1/4 740 38,026 17,010 60 55,211 116 0.202 3.475 5 2.812 3.688

2 1/2 R-26 8 3/4 3 3/4 740 39,000 21,180 110 45,762 173 0.302 4.277 5.88 3.562 4.438

3 R-31 8 3/4 4 740 56,511 25,188 160 56,106 212 0.302 5.213 6.62 4.437 5.313

3 1/2 R-34 8 3/4 4 1/4 740 61,809 25,635 175 60,351 228 0.302 5.548 7.25 4.75 5.626

4 R-37 8 3/4 4 1/4 740 70,639 25,686 200 68,854 260 0.302 6.282 7.88 5.437 6.313

5 R-41 8 3/4 4 1/2 740 88,299 26,094 250 84,850 320 0.302 7.619 9.25 6.687 7.563

6 R-45 12 3/4 4 3/4 740 70,639 26,445 200 67,094 253 0.302 8.889 10.62 7.875 8.751

8 R-49 12 7/8 5 1/4 740 65,355 25,696 300 63,784 390 0.420 11.361 13 10.187 11.063

10 R-53 16 1 6 740 43,556 23,903 300 45,253 416 0.551 13.634 15.25 12.312 13.188

12 R-57 16 1 1/8 6 1/2 740 41,511 24,930 425 41,608 568 0.728 16.040 17.75 14.562 15.438

14 R-61 20 1 1/8 6 3/4 740 39,069 25,787 400 38,116 520 0.728 17.644 20.25 16.062 16.938

16 R-65 20 1 1/4 7 1/4 740 34,850 25,236 675 34,599 670 0.930 19.782 22.5 18.062 18.938

18 R-69 24 1 1/4 7 1/2 740 33,559 24,960 650 33,599 651 0.930 22.456 24.75 20.562 21.438

488945738.xls, CS RTJ Gasket Stresses David W. Reeves, 7/7/04

Nominal Ring Joint # Bolts Bolt Dia Bolt MAWP Stud Load RTJ Gasket Torque Stud Load @ Torque Bolt Root RTJ Gasket Bolt

Pipe size "R" Number Length Stress (PSI) Value (.15 25,000 PSI Value (.2 Area in^2 Area in^2 Circle

& .2 Gasket Friction Diameter

Friction Stress Factor) Gasket

Factors) Gasket ID OD

20 R-73 24 1 1/4 8 740 43,885 25,397 850 43,361 840 0.930 29.402 27 22.5 23.5

24 R-77 24 1 1/2 9 740 45,586 25,863 1,600 44,396 1,558 1.404 46.447 32 26.625 27.875

Isomax Reactors

20 R-73 24 1 1/4 8 176 36,140 25,546 700 35,421 686 0.930 29.402 27 E-410 Bottom 20" Nozzle

CCR Furnace Header Inspection

34,843

20 R-73 24 1 1/4 8 135 34,843 25,000 675 675 0.930 29.402 27 Ports, B8M Studs (304SS)

24 R-77 24 1 1/2 9 165 37,038 25,262 1,300 36,676 1,287 1.404 46.447 32 R-410/20/30/40 Manways

30 R-94 36 1 9 5/8 165 90,742 25,083 625 90,463 831 0.551 67.113 Isomax R-410 Manway/Nozzel

30 R-95 28 1 3/4 135 34,622 25,374 2,000 34,137 1,972 1.981 71.907 CCR Furnace Header (no washers)

30 R-95 28 1 3/4 176 34,622 24,971 2,000 34,660 2,002 1.981 71.907 E-410 Top Head

36 R-98 32 2 176 30,528 25,535 2,700 29,933 2,647 2.653 94.493 E-410 Bottom Elbow

53.653 SP-1 68 1 1/8 15 1/2 165 73,255 25,416 750 72,178 985 0.728 128.013 58.78 Isomax R-410 Top Head

74.984 SP-2 76 1 3/8 20 1/2 150 64,193 25,531 1,700 63,015 1,669 1.156 194.879 80.315 Isomax R-430 Top Head

34.750 R-103 48 1 3/4 13 1/2 500 34,622 26,236 2,000 33,226 1,919 1.981 107.381 80.315 SLC R-3500

Bolt Stress vs. Gasket Stress in 600lb RTJ Flanges

Calculations based on bolt root diameter

Nominal Ring Joint # Bolts Bolt Dia Bolt MAWP Stud Load RTJ Gasket Torque Stud Load @ Torque Bolt Root RTJ Gasket Bolt

Pipe size "R" Number Length Stress (PSI) Value (.15 30,000 PSI Value (.2 Area in^2 Area in^2 Circle

& .2 Gasket Friction Diameter

Friction Stress Factor) Gasket

Factors) Gasket ID OD

1/2 R-11 4 1/2 3 1,480 31,752 18,173 25 43,464 46 0.126 0.864 2.62 1.094 1.594

3/4 R-13 4 5/8 3 1/4 1,480 25,351 13,653 40 45,747 96 0.202 1.452 3.25 1.375 2.001

1 R-16 4 5/8 3 1/2 1,480 34,857 15,691 55 54,683 115 0.202 1.721 3.5 1.687 2.313

1 1/4 R-18 4 5/8 3 3/4 1,480 57,039 21,665 90 65,475 138 0.202 2.043 3.88 2.062 2.688

1 1/2 R-20 4 3/4 4 1,480 44,000 21,855 125 50,021 189 0.302 2.312 4.5 2.375 3.001

2 R-23 8 5/8 4 1/4 1,480 53,871 23,708 85 56,650 119 0.202 3.475 5 2.812 3.688

2 1/2 R-26 8 3/4 4 3/4 1,480 47,681 25,235 135 47,266 178 0.302 4.277 5.88 3.562 4.438

3 R-31 8 3/4 5 1,480 58,270 25,000 165 58,270 220 0.302 5.213 6.62 4.437 5.313

3 1/2 R-34 8 7/8 5 1/2 1,480 45,748 25,121 210 45,548 279 0.420 5.548 7.25 4.75 5.626

4 R-37 8 7/8 5 3/4 1,480 52,317 25,000 240 52,317 320 0.420 6.282 8.5 5.437 6.313

5 R-41 8 1 6 1/2 1,480 50,089 25,167 345 49,801 457 0.551 7.619 10.5 6.687 7.563

6 R-45 12 1 6 3/4 1,480 39,938 25,000 275 39,938 367 0.551 8.889 11.5 7.875 8.751

8 R-49 12 1 1/8 7 3/4 1,480 41,026 25,000 420 41,026 560 0.728 11.361 13.75 10.187 11.063

10 R-53 16 1 1/4 8 1/2 1,480 30,977 25,273 600 30,727 595 0.930 13.634 17 12.312 13.188

12 R-57 20 1 1/4 8 3/4 1,480 30,977 25,476 600 30,567 592 0.930 16.040 19.25 14.562 15.438

14 R-61 20 1 3/8 9 1/4 1,480 30,208 26,659 800 28,942 766 1.156 17.644 20.75 16.062 16.938

16 R-65 20 1 1/2 10 1,480 28,491 25,398 1,000 28,210 990 1.404 19.782 23.75 18.062 18.938

18 R-69 20 1 5/8 10 3/4 1,480 28,554 25,980 1,300 27,899 1,270 1.681 22.456 25.75 20.562 21.438

20 R-73 24 1 5/8 11 1/2 1,480 30,750 26,382 1,400 29,743 1,354 1.681 29.402 28.5 22.5 23.5

24 R-77 24 1 7/8 13 1/4 1,480 33,324 25,269 2,400 33,098 2,384 2.305 46.447 33 26.625 27.875

30 R-95 28 1 7/8 15 1,480 44,069 25,000 3,174 44,069 3,174 2.305 71.907 33 33 34.5

36 R-98 28 2 600 40,019 25,000 3,539 40,019 3,539 2.653 94.493 33 39.375 41.125

Bolt Stress vs. Gasket Stress in 900lb RTJ Flanges

Calculations based on bolt root diameter

488945738.xls, CS RTJ Gasket Stresses David W. Reeves, 7/7/04

Nominal Ring Joint # Bolts Bolt Dia Bolt MAWP Stud Load RTJ Gasket Torque Stud Load @ Torque Bolt Root RTJ Gasket Bolt

Pipe size "R" Number Length Stress (PSI) Value (.15 25,000 PSI Value (.2 Area in^2 Area in^2 Circle

& .2 Gasket Friction Diameter

Friction Stress Factor) Gasket

Factors) Gasket ID OD

Nominal Ring Joint # Bolts Bolt Dia Bolt MAWP Stud Load RTJ Gasket Torque Stud Load @ Torque Bolt Root RTJ Gasket Bolt Flange Thickness

Pipe size "R" Number Length Stress (PSI) Value (.15 25,000 PSI Value (.2 Area in^2 Area in^2 Circle

& .2 Gasket Friction Diameter

Friction Stress Factor) Gasket

Factors) Gasket ID OD

1/2 R-12 4 3/4 4 1/2 2,220 30,000 26,628 85 28,188 106 0.302 1.345 3 1/4 7/8 1.25 1.876

3/4 R-14 4 3/4 4 3/4 2,220 35,320 27,689 100 31,968 121 0.302 1.505 3 1/2 1 1.437 2.063

1 R-16 4 7/8 5 1/4 2,220 27,231 25,556 125 26,661 163 0.420 1.721 4 1 1/8 1.687 2.313

1 1/4 R-18 4 7/8 5 1/4 2,220 34,856 27,306 160 32,050 196 0.420 2.043 4 3/8 1 1/8 2.062 2.688

1 1/2 R-20 4 1 6 2,220 29,037 25,980 200 28,009 257 0.551 2.312 4 7/8 1 1/4 2.375 3.001

2 R-24 8 7/8 6 2,220 32,677 25,622 150 31,935 195 0.420 4.010 6 1/2 1 1/2 3.312 4.188

2 1/2 R-27 8 1 6 3/4 2,220 29,037 25,768 200 28,246 259 0.551 4.545 7 1/2 1 5/8 3.812 4.688

3 R-31 8 7/8 6 2,220 43,570 25,052 200 43,489 266 0.420 5.213 7 1/2 1 1/2 4.437 5.313

4 R-37 8 1 1/8 7 1/4 2,220 31,744 24,990 325 31,755 433 0.728 6.282 9 1/4 1 3/4 5.437 6.313

5 R-41 8 1 1/4 8 2,220 32,268 25,780 625 31,469 610 0.930 7.619 11 2 6.687 7.563

6 R-45 12 1 1/8 8 2,220 34,186 26,538 350 32,621 445 0.728 8.889 12 1/2 2 3/16 7.875 8.751

8 R-49 12 1 3/8 9 1/4 2,220 29,264 25,897 775 28,529 756 1.156 11.361 15 1/2 2 1/2 10.187 11.063

10 R-53 16 1 3/8 9 3/4 2,220 29,264 26,899 775 27,864 738 1.156 13.634 18 1/2 2 3/4 12.312 13.188

12 R-57 20 1 3/8 10 1/2 2,220 29,264 26,515 775 28,213 747 1.156 16.040 21 3 1/8 14.562 15.438

14 R-62 20 1 1/2 11 1/4 2,220 37,038 24,828 1,300 37,210 1,306 1.404 28.124 22 3 3/8 15.875 17.125

16 R-66 20 1 5/8 11 3/4 2,220 37,339 25,657 1,700 36,723 1,672 1.681 31.533 24 1/4 3 1/2 17.875 19.125

18 R-70 20 1 7/8 13 1/2 2,220 37,489 25,995 2,700 36,523 2,630 2.305 44.742 27 4 20.25 21.75

20 R-74 20 2 14 1/2 2,220 36,182 24,949 3,200 36,229 3,204 2.653 49.003 29 1/2 4 1/4 22.25 23.75

24 R-78 20 2 1/2 18 2,220 32,424 25,465 5,800 32,045 5,732 4.293 69.889 35 1/2 5 1/2 26.25 28.25

28 R-94 28 1 1/2 18 850 56,982 25,578 2,000 55,995 1,965 1.404 67.113 35 1/2 5 1/2 30.75 32.25

30 R-102 20 3 ?? 2,000 31,067 25,000 9,826 31,067 9,826 6.326 100.670 35 1/2 5 1/2 32.5 35

Bolt Stress vs. Gasket Stress in 1500lb RTJ Flanges

Calculations based on bolt root diameter

Nominal Ring Joint # Bolts Bolt Dia Bolt MAWP Stud Load RTJ Gasket Torque Stud Load @ Torque Bolt Root RTJ Gasket Bolt Flange Thickness

Pipe size "R" Number Length Stress (PSI) Value (.15 25,000 PSI Value (.2 Area in^2 Area in^2 Circle

& .2 Gasket Friction Diameter

Friction Stress Factor) Gasket

Factors) Gasket ID OD

1/2 R-12 4 3/4 4 1/2 3,705 26,490 23,258 75 28,429 107 0.302 1.345 3 1/4 7/8 1.25 1.876

3/4 R-14 4 3/4 4 3/4 3,705 33,554 25,837 95 32,511 123 0.302 1.505 3 1/2 1 1.437 2.063

1 R-16 4 7/8 5 1/4 3,705 27,231 24,878 125 27,356 167 0.420 1.721 4 1 1/8 1.687 2.313

1 1/4 R-18 4 7/8 5 1/4 3,705 34,856 26,414 160 33,135 203 0.420 2.043 4 3/8 1 1/8 2.062 2.688

1 1/2 R-20 4 1 6 3,705 29,037 24,845 200 29,200 268 0.551 2.312 4 7/8 1 1/4 2.375 3.001

2 R-24 8 7/8 6 3,705 32,677 24,458 150 33,325 204 0.420 4.010 6 1/2 1 1/2 3.312 4.188

2 1/2 R-27 8 1 6 3/4 3,705 29,037 24,164 200 29,900 275 0.551 4.545 7 1/2 1 5/8 3.812 4.688

3 R-35 8 1 1/8 7 1/2 3,705 29,302 25,137 300 29,166 398 0.728 5.748 8 1 7/8 4.937 5.813

4 R-39 8 1 1/4 8 1/4 3,705 31,744 27,805 615 29,173 565 0.930 6.817 9 1/2 2 1/8 5.937 6.813

5 R-44 8 1 1/2 10 1/4 3,705 24,645 25,027 865 24,625 864 1.404 8.154 11 1/2 2 7/8 7.187 8.063

6 R-46 12 1 3/8 10 3/4 3,705 26,810 25,128 710 26,712 707 1.156 10.627 12 1/2 3 1/4 7.813 8.813

8 R-50 12 1 5/8 12 3,705 31,848 25,192 1,450 31,676 1,442 1.681 18.110 15 1/2 3 5/8 10 11.25

10 R-54 12 1 7/8 14 3,705 30,200 25,042 2,175 30,167 2,173 2.305 21.732 19 4 1/4 12.125 13.375

12 R-58 16 2 15 1/2 3,705 30,528 24,904 2,700 30,608 2,707 2.653 35.215 22 1/2 4 7/8 14.125 15.875

14 R-63 16 2 1/4 16 3/4 3,705 29,594 24,836 3,800 29,721 3,816 3.424 42.318 25 5 1/4 15.5 17.5

16 R-67 16 2 1/2 18 1/2 3,705 29,628 25,144 5,300 29,520 5,281 4.293 51.315 27 3/4 5 3/4 17.375 19.625

18 R-71 16 2 3/4 20 1/4 3,705 28,619 25,167 6,900 28,503 6,872 5.260 58.249 30 1/2 6 3/8 19.875 22.125

20 R-75 16 3 22 1/4 3,705 28,455 25,014 9,000 28,446 8,997 6.326 68.605 32 3/4 7 21.75 24.25

488945738.xls, CS RTJ Gasket Stresses David W. Reeves, 7/7/04

Nominal Ring Joint # Bolts Bolt Dia Bolt MAWP Stud Load RTJ Gasket Torque Stud Load @ Torque Bolt Root RTJ Gasket Bolt

Pipe size "R" Number Length Stress (PSI) Value (.15 25,000 PSI Value (.2 Area in^2 Area in^2 Circle

& .2 Gasket Friction Diameter

Friction Stress Factor) Gasket

Factors) Gasket ID OD

24 R-79 16 3 1/2 25 1/4 3,705 27,425 24,817 14,000 27,539 14,058 8.751 87.197 39 8 25.875 28.625

24 R-79 20 2 1/2 25 1/4 1,780 35,000 25,230 6,261 34,766 6,219 4.293 87.197 39 El Segundo Isomax/JHP R-110 25.875 28.625

Bolt Stress vs. Gasket Stress in 2500lb RTJ Flanges

Calculations based on bolt root diameter

Nominal Ring Joint # Bolts Bolt Dia Bolt MAWP Stud Load RTJ Gasket Torque Stud Load @ Torque Bolt Root RTJ Gasket Bolt Flange Thickness

Pipe size "R" Number Length Stress (PSI) Value (.15 25,000 PSI Value (.2 Area in^2 Area in^2 Circle

& .2 Gasket Friction Diameter

Friction Stress Factor) Gasket

Factors) Gasket ID OD

1/2 R-13 4 3/4 5 6,170 30,022 24,140 85 31,055 117 0.302 1.452 3 1/2 1 3/16 1.375 2.001

3/4 R-16 4 3/4 5 1/4 6,170 37,086 24,454 105 37,863 143 0.302 1.721 3 3/4 1 1/4 1.687 2.313

1 R-18 4 7/8 5 3/4 6,170 32,677 24,478 150 33,313 204 0.420 2.043 4 1/4 1 3/8 2.062 2.688

1 1/4 R-21 4 1 6 1/2 6,170 37,749 24,869 260 37,930 348 0.551 3.041 5 1/8 1 1/2 2.406 3.282

1 1/2 R-23 4 1 1/8 7 1/4 6,170 33,209 24,691 340 33,577 458 0.728 3.475 5 3/4 1 3/4 2.812 3.688

2 R-26 8 1 7 1/2 6,170 29,037 25,394 200 28,655 263 0.551 4.277 6 3/4 2 3.562 4.438

2 1/2 R-28 8 1 1/8 8 1/4 6,170 29,302 25,100 300 29,206 399 0.728 5.593 7 3/4 2 1/4 3.875 4.875

3 R-32 8 1 1/4 9 1/4 6,170 27,348 25,000 530 27,348 530 0.930 6.392 9 2 5/8 4.5 5.5

4 R-38 8 1 1/2 10 1/2 6,170 30,628 25,264 1,075 30,380 1,066 1.404 10.547 10 3/4 3 5.563 6.813

5 R-42 8 1 3/4 12 1/2 6,170 32,891 25,032 1,900 32,858 1,898 1.981 15.979 12 3/4 3 5/8 6.75 8.25

6 R-47 8 2 14 1/4 6,170 30,811 25,009 2,725 30,803 2,724 2.653 19.175 14 1/2 4 1/4 8.25 9.75

8 R-51 12 2 15 3/4 6,170 29,963 24,933 2,650 30,018 2,655 2.653 25.824 17 1/4 5 10.125 11.875

10 R-55 12 2 1/2 20 6,170 27,392 24,746 4,900 27,577 4,933 4.293 37.446 21 1/4 6 1/2 12.375 14.625

12 R-60 12 2 3/4 22 6,170 29,863 24,878 7,200 29,955 7,222 5.260 47.725 24 3/8 7 1/4 14.75 17.25

488945738.xls, CS RTJ Gasket Stresses David W. Reeves, 7/7/04

Bolt Stress vs. Gasket Stress in 150, 300, 400 and

600, 900, 1500 and 2500 class RTJ Flanges

From Calvin Gillas, Lamons Gasket Company

Bolt Stress vs. Gasket Stress in 150lb RTJ Flanges

Calculations based on bolt root diameter

Nominal Ring Joint # Bolts Bolt Dia Bolt MAWP Stud Load RTJ Gasket Torque Stud Load @ Torque Bolt Root RTJ Gasket Bolt

Pipe size "R" Number Length Stress (PSI) Value (.15 25,000 PSI Value (.2 Area in^2 Area in^2 Circle

& .2 Gasket Friction Diameter

Friction Stress Factor) Gasket

Factors) Gasket ID OD

1 R-15 4 1/2 2 1/2 285 31,752 9,781 25 80,469 84 0.126 1.613 3.12 1.562 2.188

1 1/4 R-17 4 1/2 2 1/2 285 44,452 11,392 35 96,723 102 0.126 1.936 3.5 1.937 2.563

1 1/2 R-19 4 1/2 2 3/4 285 57,153 12,834 45 110,388 116 0.126 2.205 3.88 2.25 2.876

2 R-22 4 5/8 3 285 47,533 13,414 75 87,630 184 0.202 2.796 4.75 2.937 3.563

2 1/2 R-25 4 5/8 3 1/4 285 79,221 18,192 125 108,219 228 0.202 3.441 5.5 3.687 4.313

3 R-29 4 5/8 3 1/2 285 79,221 16,012 125 122,292 257 0.202 3.871 6 4.187 4.813

3 1/2 R-33 8 5/8 3 1/2 285 50,702 17,741 80 70,754 149 0.202 4.463 7 4.875 5.501

4 R-36 8 5/8 3 1/2 285 63,500 19,591 100 80,418 169 0.202 5.054 7.5 5.562 6.188

5 R-40 8 3/4 3 3/4 285 45,915 18,140 130 62,403 236 0.302 5.807 8.5 6.437 7.063

6 R-43 8 3/4 3 3/4 285 56,511 19,586 160 71,211 269 0.302 6.560 9.5 7.312 7.938

8 R-48 8 3/4 4 285 79,469 21,183 225 92,721 350 0.302 8.388 11.75 9.437 10.063

10 R-52 12 7/8 4 1/2 285 51,195 22,807 235 55,689 341 0.420 10.323 14.25 11.687 12.313

12 R-56 12 7/8 4 1/2 285 70,801 25,135 325 70,456 431 0.420 12.904 17 14.687 15.313

14 R-59 12 1 5 285 47,186 19,947 325 57,457 528 0.551 13.442 18.75 15.312 15.938

16 R-64 16 1 5 1/4 285 43,556 21,650 300 49,290 453 0.551 15.090 21.25 17.562 18.188

18 R-68 16 1 1/8 5 3/4 285 43,953 25,073 450 43,843 599 0.728 17.528 22.75 20.062 20.688

20 R-72 20 1 1/8 6 285 39,069 25,328 400 38,643 528 0.728 18.926 25 21.687 22.313

24 R-76 20 1 1/4 6 3/4 285 37,431 24,875 725 37,585 728 0.930 22.797 29.5 26.187 26.813

Bolt Stress vs. Gasket Stress in 300lb RTJ Flanges

Calculations based on bolt root diameter

Nominal Ring Joint # Bolts Bolt Dia Bolt MAWP Stud Load RTJ Gasket Torque Stud Load @ Torque Bolt Root RTJ Gasket Bolt

Pipe size "R" Number Length Stress (PSI) Value (.15 25,000 PSI Value (.2 Area in^2 Area in^2 Circle

& .2 Gasket Friction Diameter

Friction Stress Factor) Gasket

Factors) Gasket ID OD

1/2 R-11 4 1/2 2 1/2 740 19,500 11,199 15 43,175 45 0.126 0.864 2.62 1.094 1.594

3/4 R-13 4 5/8 2 3/4 740 19,013 10,352 30 45,342 95 0.202 1.452 3.25 1.375 2.001

1 R-16 4 5/8 3 740 25,351 11,565 40 53,963 114 0.202 1.721 3.5 1.687 2.313

1 1/4 R-18 4 5/8 3 740 38,026 14,591 60 64,351 135 0.202 2.043 3.88 2.062 2.688

1 1/2 R-20 4 3/4 3 1/2 740 28,256 14,195 80 48,938 185 0.302 2.312 4.5 2.375 3.001

2 R-23 8 5/8 3 1/4 740 31,689 14,064 50 55,211 116 0.202 3.475 5 2.812 3.688

2 1/2 R-26 8 3/4 3 3/4 740 30,022 16,109 85 45,762 173 0.302 4.277 5.88 3.562 4.438

3 R-31 8 3/4 4 740 49,447 21,914 140 56,106 212 0.302 5.213 6.62 4.437 5.313

3 1/2 R-34 8 3/4 4 1/4 740 52,979 21,790 150 60,351 228 0.302 5.548 7.25 4.75 5.626

4 R-37 8 3/4 4 1/4 740 67,000 24,287 190 68,854 260 0.302 6.282 7.88 5.437 6.313

5 R-41 8 3/4 4 1/2 740 88,299 26,094 250 84,850 320 0.302 7.619 9.25 6.687 7.563

6 R-45 12 3/4 4 3/4 740 70,639 26,445 200 67,094 253 0.302 8.889 10.62 7.875 8.751

8 R-49 12 7/8 5 1/4 740 65,355 25,696 300 63,784 390 0.420 11.361 13 10.187 11.063

10 R-53 16 1 6 740 43,556 23,903 300 45,253 416 0.551 13.634 15.25 12.312 13.188

12 R-57 16 1 1/8 6 1/2 740 41,511 24,930 425 41,608 568 0.728 16.040 17.75 14.562 15.438

14 R-61 20 1 1/8 6 3/4 740 39,069 25,787 400 38,116 520 0.728 17.644 20.25 16.062 16.938

16 R-65 20 1 1/4 7 1/4 740 34,850 25,236 675 34,599 670 0.930 19.782 22.5 18.062 18.938

18 R-69 24 1 1/4 7 1/2 740 33,559 24,960 650 33,599 651 0.930 22.456 24.75 20.562 21.438

20 R-73 24 1 1/4 8 740 43,885 25,397 850 43,361 840 0.930 29.402 27 22.5 23.5

24 R-77 24 1 1/2 9 740 45,586 25,863 1,600 44,396 1,558 1.404 46.447 32 26.625 27.875

Isomax Reactors

20 R-73 24 1 1/4 8 176 41,303 29,464 800 35,421 686 0.930 29.402 27 E-410 Bottom 20" Nozzle

CCR Furnace Header Inspection

34,843

20 R-73 24 1 1/4 8 135 46,466 33,820 900 675 0.930 29.402 27 Ports, B8M Studs (304SS)

24 R-77 24 1 1/2 9 165 42,736 29,396 1,500 36,676 1,287 1.404 46.447 32 R-410/20/30/40 Manways

30 R-94 36 1 9 5/8 165 78,945 21,596 544 90,463 831 0.551 67.113 Isomax R-410 Manway/Nozzel

30 R-95 28 1 3/4 135 48,471 36,054 2,800 34,137 1,972 1.981 71.907 CCR Furnace Header (no washers)

30 R-95 28 1 3/4 176 41,546 30,311 2,400 34,660 2,002 1.981 71.907 E-410 Top Head

36 R-98 32 2 176 35,051 29,598 3,100 29,933 2,647 2.653 94.493 E-410 Bottom Elbow

53.653 SP-1 44 1 7/8 15 1/2 165 76,918 58,016 4,155 35,239 2,538 2.305 128.013 58.78 Isomax R-410 Top Head

53.653 SP-1 44 1 7/8 20 1/2 1,058 55,148 25,000 3,972 55,148 3,972 2.305 128.013 80.315 Isomax R-430 Top Head

53.653 SP-1 44 1 7/8 20 1/2 290 55,148 38,563 3,972 38,026 2,739 2.305 128.013 80.315 Isomax R-430 Top Head

53.653 SP-1 44 1 7/8 20 1/2 150 67,969 51,192 4,895 34,904 2,514 2.305 128.013 80.315 Isomax R-430 Top Head

44.000 R-104 32 1 5/8 20 1/2 150 30,000 11,396 1,175 60,751 2,766 1.681 121.596 PAS

48.000 R-104 28 1 7/8 20 1/2 150 30,000 13,689 2,161 51,314 3,696 2.305 121.596 PAS

Bolt Stress vs. Gasket Stress in 600lb RTJ Flanges

Calculations based on bolt root diameter

Nominal Ring Joint # Bolts Bolt Dia Bolt MAWP Stud Load RTJ Gasket Torque Stud Load @ Torque Bolt Root RTJ Gasket Bolt

Pipe size "R" Number Length Stress (PSI) Value (.15 25,000 PSI Value (.2 Area in^2 Area in^2 Circle

& .2 Gasket Friction Diameter

Friction Stress Factor) Gasket

Factors) Gasket ID OD

1/2 R-11 4 1/2 3 1,480 25,401 14,471 20 43,464 46 0.126 0.864 2.62 1.094 1.594

3/4 R-13 4 5/8 3 1/4 1,480 19,013 10,127 30 45,747 96 0.202 1.452 3.25 1.375 2.001

1 R-16 4 5/8 3 1/2 1,480 25,351 11,228 40 54,683 115 0.202 1.721 3.5 1.687 2.313

1 1/4 R-18 4 5/8 3 3/4 1,480 44,364 16,653 70 65,475 138 0.202 2.043 3.88 2.062 2.688

1 1/2 R-20 4 3/4 4 1,480 35,320 17,320 100 50,021 189 0.302 2.312 4.5 2.375 3.001

2 R-23 8 5/8 4 1/4 1,480 41,000 17,724 65 56,650 119 0.202 3.475 5 2.812 3.688

2 1/2 R-26 8 3/4 4 3/4 1,480 38,852 20,247 110 47,266 178 0.302 4.277 5.88 3.562 4.438

3 R-31 8 3/4 5 1,480 58,270 25,000 165 58,270 220 0.302 5.213 6.62 4.437 5.313

3 1/2 R-34 8 7/8 5 1/2 1,480 45,748 25,121 210 45,548 279 0.420 5.548 7.25 4.75 5.626

4 R-37 8 7/8 5 3/4 1,480 52,317 25,000 240 52,317 320 0.420 6.282 8.5 5.437 6.313

5 R-41 8 1 6 1/2 1,480 50,089 25,167 345 49,801 457 0.551 7.619 10.5 6.687 7.563

6 R-45 12 1 6 3/4 1,480 39,938 25,000 275 39,938 367 0.551 8.889 11.5 7.875 8.751

8 R-49 12 1 1/8 7 3/4 1,480 41,026 25,000 420 41,026 560 0.728 11.361 13.75 10.187 11.063

10 R-53 16 1 1/4 8 1/2 1,480 30,977 25,273 600 30,727 595 0.930 13.634 17 12.312 13.188

12 R-57 20 1 1/4 8 3/4 1,480 30,977 25,476 600 30,567 592 0.930 16.040 19.25 14.562 15.438

14 R-61 20 1 3/8 9 1/4 1,480 30,208 26,659 800 28,942 766 1.156 17.644 20.75 16.062 16.938

16 R-65 20 1 1/2 10 1,480 28,491 25,398 1,000 28,210 990 1.404 19.782 23.75 18.062 18.938

18 R-69 20 1 5/8 10 3/4 1,480 28,554 25,980 1,300 27,899 1,270 1.681 22.456 25.75 20.562 21.438

20 R-73 24 1 5/8 11 1/2 1,480 30,750 26,382 1,400 29,743 1,354 1.681 29.402 28.5 22.5 23.5

24 R-77 24 1 7/8 13 1/4 1,480 33,324 25,269 2,400 33,098 2,384 2.305 46.447 33 26.625 27.875

Bolt Stress vs. Gasket Stress in 900lb RTJ Flanges

Calculations based on bolt root diameter

Nominal Ring Joint # Bolts Bolt Dia Bolt MAWP Stud Load RTJ Gasket Torque Stud Load @ Torque Bolt Root RTJ Gasket Bolt Flange Thickness

Pipe size "R" Number Length Stress (PSI) Value (.15 25,000 PSI Value (.2 Area in^2 Area in^2 Circle

& .2 Gasket Friction Diameter

Friction Stress Factor) Gasket

Factors) Gasket ID OD

1/2 R-12 4 3/4 4 1/2 2,220 22,958 20,301 65 28,188 106 0.302 1.345 3 1/4 7/8 1.25 1.876

3/4 R-14 4 3/4 4 3/4 2,220 35,320 27,689 100 31,968 121 0.302 1.505 3 1/2 1 1.437 2.063

1 R-16 4 7/8 5 1/4 2,220 27,231 25,556 125 26,661 163 0.420 1.721 4 1 1/8 1.687 2.313

1 1/4 R-18 4 7/8 5 1/4 2,220 34,856 27,306 160 32,050 196 0.420 2.043 4 3/8 1 1/8 2.062 2.688

1 1/2 R-20 4 1 6 2,220 29,037 25,980 200 28,009 257 0.551 2.312 4 7/8 1 1/4 2.375 3.001

2 R-24 8 7/8 6 2,220 32,677 25,622 150 31,935 195 0.420 4.010 6 1/2 1 1/2 3.312 4.188

2 1/2 R-27 8 1 6 3/4 2,220 29,037 25,768 200 28,246 259 0.551 4.545 7 1/2 1 5/8 3.812 4.688

3 R-31 8 7/8 6 2,220 43,570 25,052 200 43,489 266 0.420 5.213 7 1/2 1 1/2 4.437 5.313

4 R-37 8 1 1/8 7 1/4 2,220 31,744 24,990 325 31,755 433 0.728 6.282 9 1/4 1 3/4 5.437 6.313

5 R-41 8 1 1/4 8 2,220 32,268 25,780 625 31,469 610 0.930 7.619 11 2 6.687 7.563

6 R-45 12 1 1/8 8 2,220 34,186 26,538 350 32,621 445 0.728 8.889 12 1/2 2 3/16 7.875 8.751

8 R-49 12 1 3/8 9 1/4 2,220 29,264 25,897 775 28,529 756 1.156 11.361 15 1/2 2 1/2 10.187 11.063

10 R-53 16 1 3/8 9 3/4 2,220 29,264 26,899 775 27,864 738 1.156 13.634 18 1/2 2 3/4 12.312 13.188

12 R-57 20 1 3/8 10 1/2 2,220 29,264 26,515 775 28,213 747 1.156 16.040 21 3 1/8 14.562 15.438

488945738.xls, SS RTJ Gasket Stresses David W. Reeves, 7/7/04

Nominal Ring Joint # Bolts Bolt Dia Bolt MAWP Stud Load RTJ Gasket Torque Stud Load @ Torque Bolt Root RTJ Gasket Bolt

Pipe size "R" Number Length Stress (PSI) Value (.15 25,000 PSI Value (.2 Area in^2 Area in^2 Circle

& .2 Gasket Friction Diameter

Friction Stress Factor) Gasket

Factors) Gasket ID OD

14 R-62 20 1 1/2 11 1/4 2,220 37,038 24,828 1,300 37,210 1,306 1.404 28.124 22 3 3/8 15.875 17.125

16 R-66 20 1 5/8 11 3/4 2,220 37,339 25,657 1,700 36,723 1,672 1.681 31.533 24 1/4 3 1/2 17.875 19.125

18 R-70 20 1 7/8 13 1/2 2,220 37,489 25,995 2,700 36,523 2,630 2.305 44.742 27 4 20.25 21.75

20 R-74 20 2 14 1/2 2,220 36,182 24,949 3,200 36,229 3,204 2.653 49.003 29 1/2 4 1/4 22.25 23.75

24 R-78 20 2 1/2 18 2,220 32,424 25,465 5,800 32,045 5,732 4.293 69.889 35 1/2 5 1/2 26.25 28.25

Bolt Stress vs. Gasket Stress in 1500lb RTJ Flanges

Calculations based on bolt root diameter

Nominal Ring Joint # Bolts Bolt Dia Bolt MAWP Stud Load RTJ Gasket Torque Stud Load @ Torque Bolt Root RTJ Gasket Bolt Flange Thickness

Pipe size "R" Number Length Stress (PSI) Value (.15 25,000 PSI Value (.2 Area in^2 Area in^2 Circle