Professional Documents

Culture Documents

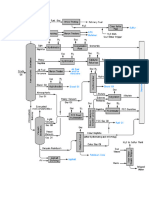

Raw Meal Conversion Requirements for Chemical Kiln Process

Uploaded by

jagrutOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Raw Meal Conversion Requirements for Chemical Kiln Process

Uploaded by

jagrutCopyright:

Available Formats

Process Requirements For Kiln System

The kiln system has to be able to allow a chemical process to take place, which converts raw meal into clinker. Since

this process as a whole is endothermic and takes place at temperatures up to 1450 ºC, it is also referred to as

preprocess.

Type of reaction and temperature development is compiled in the table below.

Temperature ranges (ºC) Type of reaction

Heating Up

20 - 100 Evaporation of free H2O

100 - 300 Loss of physically absorbed water

Removal of structural H2O (H2O and OH groups) from

400 - 900

clay minerals

> 500 Structural changes in silicate minerals

600 - 900 Dissociation of carbonates (CO2 driven out)

Formation of belite, intermediate products, aluminate and

> 800

ferrite

> 1250 Formation of liquid phase (aluminate and ferrite melt)

Completion of reaction and re-crystallization of alite and

approx. 1450

belite

Cooling

Crystallization of liquid phase into mainly aluminate and

1300 - 1240

ferrite

Kiln Process

You might also like

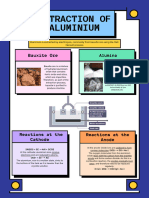

- AluminiumDocument32 pagesAluminiumNanda Rizky50% (2)

- Empty Mill & High Mill KWDocument2 pagesEmpty Mill & High Mill KWjagrut100% (2)

- Method for Determining Acid Insoluble Sieve ResiduesDocument2 pagesMethod for Determining Acid Insoluble Sieve ResiduesjagrutNo ratings yet

- MERTEC Refactory Castables & Anchors - Binder 2011Document100 pagesMERTEC Refactory Castables & Anchors - Binder 2011jagrutNo ratings yet

- Temperature Events in CeramicDocument3 pagesTemperature Events in CeramicjamenI100% (2)

- ILC SLC-D Kiln SystemDocument45 pagesILC SLC-D Kiln SystemAndris Risyat100% (1)

- 4 - Silica in BoilerDocument3 pages4 - Silica in BoilerKrishnan ManiNo ratings yet

- BurnningDocument2 pagesBurnningAhmed Nasr ElbehairyNo ratings yet

- Introductory Of: UtilityDocument49 pagesIntroductory Of: UtilitynugrohoNo ratings yet

- Chemistry of Lime1Document3 pagesChemistry of Lime1raenbulaNo ratings yet

- Clinker Formation ConceptsDocument28 pagesClinker Formation ConceptspashaNo ratings yet

- C Clliinnkkeerr:: Rreeaaccttiioonnss Iinn Tthhee KkiillnnDocument3 pagesC Clliinnkkeerr:: Rreeaaccttiioonnss Iinn Tthhee KkiillnnFamiloni LayoNo ratings yet

- Annealing Process BasicsDocument30 pagesAnnealing Process Basicsleebrown21082003No ratings yet

- Fundamentals of Solidification in Aluminum Castings: Geoffrey K. SigworthDocument14 pagesFundamentals of Solidification in Aluminum Castings: Geoffrey K. SigworthMohmal AhmedNo ratings yet

- Precipitating Impurities from Molten MetalsDocument18 pagesPrecipitating Impurities from Molten MetalsMarcellus NascimentoNo ratings yet

- Extraction of AluminiumDocument1 pageExtraction of Aluminiumchkim26No ratings yet

- BOILER FEEDWATER REQUIREMENTSDocument4 pagesBOILER FEEDWATER REQUIREMENTSanghel_florin82No ratings yet

- Calculation BFWDocument22 pagesCalculation BFWDavid Lambert100% (1)

- Appunti AlbaneseDocument192 pagesAppunti Albanesej77wn7j9yvNo ratings yet

- Ferritic Hot Rolling for Low Carbon SteelsDocument10 pagesFerritic Hot Rolling for Low Carbon SteelsKetnipha SukwannawitNo ratings yet

- Boiler Feed Water CalculationDocument4 pagesBoiler Feed Water Calculationamit_kt1973No ratings yet

- 24 A Rabia FiazDocument6 pages24 A Rabia FiazRabbia FayyazNo ratings yet

- Temperature ThresholdDocument4 pagesTemperature Thresholdkenny_1983_lfyNo ratings yet

- Enhancing Calcium Recovery by Introducti PDFDocument9 pagesEnhancing Calcium Recovery by Introducti PDFMohit GhoshNo ratings yet

- Raw Material of Cement: LimeDocument6 pagesRaw Material of Cement: LimeAyaz AhmadNo ratings yet

- Boiler Feed Water Requirements and Conditioning MethodsDocument22 pagesBoiler Feed Water Requirements and Conditioning MethodsManivannanVenkatesan100% (1)

- CLE 513 - Advanced Concrete Technology: Cement ProductionDocument17 pagesCLE 513 - Advanced Concrete Technology: Cement ProductionrajasekharNo ratings yet

- MetalDocument57 pagesMetalPrashant PuriNo ratings yet

- 17.4 Boiler and Feed-Water TreatmentDocument28 pages17.4 Boiler and Feed-Water Treatmentnomeacuerdo1No ratings yet

- Water TreatDocument15 pagesWater TreatbjosufNo ratings yet

- ULSD Production - Improved Feed Stream QualityDocument6 pagesULSD Production - Improved Feed Stream Qualitysaleh4060No ratings yet

- Pretreatment (Ahmad Irwiyan Haq)Document53 pagesPretreatment (Ahmad Irwiyan Haq)Ferdik 69No ratings yet

- Fcccatalystdesignmorphphysiooptimization 150107212315 Conversion Gate01Document91 pagesFcccatalystdesignmorphphysiooptimization 150107212315 Conversion Gate01swaggeroni yololoNo ratings yet

- Power Plant Chemistry For BoeDocument22 pagesPower Plant Chemistry For BoeRamakrishna ChiliveryNo ratings yet

- Lesson 5 - Fe-C Diagram - Rev. 0Document11 pagesLesson 5 - Fe-C Diagram - Rev. 0Arga SetyaNo ratings yet

- BF 03355657Document4 pagesBF 03355657m.j.hemmati72No ratings yet

- Refractories Selectionforfor Cement Kiln IREFCON2012Document6 pagesRefractories Selectionforfor Cement Kiln IREFCON2012Saravana KumarNo ratings yet

- Demineralisation Plant: BY RAVIKUMAR G/ CM/Chemical Tps I ExpansionDocument37 pagesDemineralisation Plant: BY RAVIKUMAR G/ CM/Chemical Tps I Expansionarul mNo ratings yet

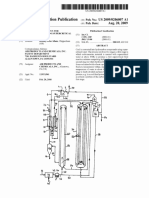

- Patent Application Publication (10) Pub. No.: US 2009/0206007 A1Document13 pagesPatent Application Publication (10) Pub. No.: US 2009/0206007 A1Tree SilviaNo ratings yet

- AlterationDocument3 pagesAlterationirfan fadhilNo ratings yet

- 0 0 1211812181211ManufacturingProcessDocument17 pages0 0 1211812181211ManufacturingProcessLUISNo ratings yet

- Geo ThermometryDocument4 pagesGeo ThermometryIrwan EPNo ratings yet

- Hydrothermal alteration minerals and stylesDocument26 pagesHydrothermal alteration minerals and stylessafasfasfasNo ratings yet

- Boiling: 1. Neutralization of Magma Gas in Host Rock at Deep LocationDocument68 pagesBoiling: 1. Neutralization of Magma Gas in Host Rock at Deep LocationNurlia AduNo ratings yet

- Boilers Water Treatment: Chemist / Mustafa Ateia MustafaDocument38 pagesBoilers Water Treatment: Chemist / Mustafa Ateia MustafaMakhdoom Ibad HashmiNo ratings yet

- SumitDocument15 pagesSumitrahulthapa403No ratings yet

- Diagrama de FlujoDocument2 pagesDiagrama de FlujoMariana PadillaNo ratings yet

- 6035 L2u203 PPT Outcome2Document22 pages6035 L2u203 PPT Outcome2shahin.noktehdan4102No ratings yet

- BOILERS WATER TREATMENT CHEMISTRYDocument38 pagesBOILERS WATER TREATMENT CHEMISTRYMahmoud MahmoudmNo ratings yet

- Manufacture Of Portland CementDocument4 pagesManufacture Of Portland CementArif SajjadNo ratings yet

- OJT 6 - Boiler ProblemsDocument27 pagesOJT 6 - Boiler ProblemsAzizul IshakNo ratings yet

- 2 Materials of Construction Portland CementDocument103 pages2 Materials of Construction Portland CementEnes YavuzNo ratings yet

- Boiler Water Chemistry - Cause & EffectDocument46 pagesBoiler Water Chemistry - Cause & EffectBhavesh PatelNo ratings yet

- 4 RecoveryBoiler FoulingDocument73 pages4 RecoveryBoiler Foulingmarcus vinicius silva de souzaNo ratings yet

- Feni: Formation and Reversal of Silicon: Egil J.M. Jahnsen July 4, 2007Document21 pagesFeni: Formation and Reversal of Silicon: Egil J.M. Jahnsen July 4, 2007Egil JahnsenNo ratings yet

- ZN Auhba JsiDocument5 pagesZN Auhba JsiYonda KeduaNo ratings yet

- C2 Carbon Compound Note 3 (2022) (ANSWER)Document2 pagesC2 Carbon Compound Note 3 (2022) (ANSWER)TEE LI XUAN MoeNo ratings yet

- EMM LectureDocument38 pagesEMM Lecturelatendra kumar srivastavNo ratings yet

- Synthetic Rutile PDFDocument3 pagesSynthetic Rutile PDFrazor75apNo ratings yet

- Boiler Feed Water TreatmentDocument12 pagesBoiler Feed Water TreatmentSivaprasad GanjiNo ratings yet

- What Is Lime - EN - 2xa4 - 2016 06 28 A 1Document2 pagesWhat Is Lime - EN - 2xa4 - 2016 06 28 A 1Shreyas PranavNo ratings yet

- Annual Reports in Organic Synthesis — 1971From EverandAnnual Reports in Organic Synthesis — 1971John McMurryNo ratings yet

- Bull Nose Ref FailureDocument1 pageBull Nose Ref FailurejagrutNo ratings yet

- The Magottaux Test - FeO in Clinker & Reducing CondnsDocument1 pageThe Magottaux Test - FeO in Clinker & Reducing CondnsjagrutNo ratings yet

- Determine Carbon Content in Flyash Using LECO CR-412 AnalyzerDocument3 pagesDetermine Carbon Content in Flyash Using LECO CR-412 AnalyzerjagrutNo ratings yet

- Ship Unloaders InfoDocument4 pagesShip Unloaders InfojagrutNo ratings yet

- Refractories and Itstypes - Chemicallibrary Blogspot PDFDocument23 pagesRefractories and Itstypes - Chemicallibrary Blogspot PDFjagrutNo ratings yet

- Atex Explosion GuideDocument12 pagesAtex Explosion GuidejagrutNo ratings yet

- Refra Properties1Document2 pagesRefra Properties1jagrut100% (1)

- Burner MomentumDocument2 pagesBurner MomentumjagrutNo ratings yet

- Use of Fly Ash As Alternative RAw MAtrl.Document4 pagesUse of Fly Ash As Alternative RAw MAtrl.jagrutNo ratings yet

- Hi Temp Psycro ChartDocument1 pageHi Temp Psycro ChartjagrutNo ratings yet

- Material Buildups and SolutionsDocument4 pagesMaterial Buildups and SolutionsjagrutNo ratings yet

- Cement Kiln DustDocument36 pagesCement Kiln DustjagrutNo ratings yet

- Grinding Circuit DesignDocument50 pagesGrinding Circuit Designjagrut100% (1)

- DHADocument2 pagesDHAjagrut100% (1)

- Various Forms of Cement Grinding TechnologyDocument3 pagesVarious Forms of Cement Grinding TechnologyjagrutNo ratings yet

- Bulk Materials Ch. SticsDocument3 pagesBulk Materials Ch. SticsjagrutNo ratings yet

- Close CKT Ball Mill MODELDocument1 pageClose CKT Ball Mill MODELjagrutNo ratings yet

- Low Cost Grinding AidsDocument9 pagesLow Cost Grinding AidsjagrutNo ratings yet

- Calculating Chiller and Cooling Tower Refrigeration - in TonsDocument2 pagesCalculating Chiller and Cooling Tower Refrigeration - in TonsjagrutNo ratings yet

- Material PropertiesDocument1 pageMaterial PropertiesjagrutNo ratings yet

- Water Cooling For Cement Mill PDFDocument2 pagesWater Cooling For Cement Mill PDFjagrutNo ratings yet

- Slag NoteDocument3 pagesSlag NotejagrutNo ratings yet

- Material Buildups and SolutionsDocument4 pagesMaterial Buildups and SolutionsjagrutNo ratings yet

- Mill Internals & Efficient GrindingDocument3 pagesMill Internals & Efficient GrindingjagrutNo ratings yet

- Grinding Aid Admixtures Improve Cement ProductionDocument3 pagesGrinding Aid Admixtures Improve Cement Productionjagrut100% (2)

- CA Silicate & Other Insulation - Surface Dew PointDocument5 pagesCA Silicate & Other Insulation - Surface Dew PointjagrutNo ratings yet