Professional Documents

Culture Documents

Tnnneiling in Soft Ground

Uploaded by

SajidAliKhan0 ratings0% found this document useful (0 votes)

20 views5 pagesCopyright

© © All Rights Reserved

Available Formats

DOCX, PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

© All Rights Reserved

Available Formats

Download as DOCX, PDF, TXT or read online from Scribd

0 ratings0% found this document useful (0 votes)

20 views5 pagesTnnneiling in Soft Ground

Uploaded by

SajidAliKhanCopyright:

© All Rights Reserved

Available Formats

Download as DOCX, PDF, TXT or read online from Scribd

You are on page 1of 5

4.

7 Tnnneiling in Soft Ground

in case of tunneling in soft ground the bridging period

is so short that steel supports cannot be erected.

‘I’hcrefc,re. the bridging time should be improved by

shortcreting and the excavation supported to the extent

feasible. Excavation of tunnels by drilling holes, and

biasting with explosives is normally not done in soft

~CIround. other methods are followed. Precautions

against hazards in the use of various other methods

arc given below :

a)

b)

c)

SP 70:2001

Forepo/ing — If the forepoling is done by timber,

the timber should be strong enough to take

ground pressure, and it should be securely

wedged. If the forepoling is done by steel rods,

structural etc, then the same precautions

should be observed as required for machines.

Shield Tunneling — The shield is operated

by the hydraulic system. The safety measures

for hydraulic machinery have been mentioned

in 14.6. The excavation behind the shield is

lined with cast iron or concrete segments that

are bolted together to form a rib. The handling

and erecting of these heavy segments should

be done with the help of hoists and platforms

should not be slippery.

Compressed Air Tunneling — In running

grounds or where there is a substantial quantity

of sub-soil water, tunneling is carried out by

compressed air locks. The relevant safety

measures are given in 12.

4.8 Working Through a Shaft

The use of shaft for construction purpose only or as a

permanent structure in the hydro electric tunnels 01

transport tunnels is, at times, inevitable. Working

through a shaft is an additional hazard in tunneling

and underground work. The following safety measures

should

a)

b)

c)

d)

e)

8

be observed:

Hoists, sheaves, cables and head frames should

be of adequate strength.

Shaft openings at the surface should be

protected to prevent material and men falling

into it.

The roof should be strong enough to protect

men riding in it.

Hoists should be equipped with limit switches

that give clear indication to the operator about

the position of cage, that is, bottom or top of’

the shaft.

It is essential to provide automatic brakes that

become functional in the case of elect ric:]l

power failure.

The signal system should be foolproof ad

should be operated by trained personnel only.

For sinking the shaft, all precautions that are necessary

for tunneling should be observed.

4.9 General Safety Measures

Electrical supply and installations:

a)

b)

All equipment and cables should be capable

of withstanding the damage likely to be caused

by water, dust and humid atmosphere.

Suitable notices should be displayed where the

9

SP 70:2001

c)

d)

e)

9

g)

h)

j)

k)

m)

n)

voltage is more than 220 V.

Only qualified electricians should be allowed

to work on electrical installations.

Switches and electrical installations should be

earthed and placed on high ground or platform.

The persons working in the tunnel should be

provided with suitable protective wears,

helmets, gumboots, etc.

The workers from the underground works

should be withdrawn in case of prolonged

ventilation failure or a heavy rush of ground

water.

Good housekeeping is essential for safe and

successful operations of tunneling and

underground works. All the debris, refuse,

materials, tools and equipment, etc, not

required for the operation of work should be

removed from the tunnel.

Proper and adequate drainage inside the tunnel

leads to safe working conditions. Sump pumps,

switches and crossings of the fall tracks,

transformers and installations of euipment

should be well lighted.

All equipment and machines should be maintained

in good working order.

The engineerlsupervisor should inspect the

machinery and equipment frequently and

ensure that they are in good condition.

Gears and moving parts should be protected

from dust and guarded to prevent accidental

contact by operators.

Only experienced men should be allowed to

operate the power plant.

5 ROAD MAKING

5.1 Hot Mix Plant

A Hot Mix Plant comprises of the following major

components:

a) Feed hopper,

b) Dryer drum unit,

c) Hot elevator and gradation control unit,

d) Mixing unit, and

e) Bitumen unit.

For safe operations of the plant, the following

procedure should be adopted :

a) Locate the plant in the direction of the wind.

This will carry the dust away from the

operating staff and stores.

b) Provide fire fighting equipment at the site.

Store fuel and lubricants away from the plant.

c) Do not bring open fire near the fuel tank.

d)

e)

o

g)

h)

j)

k)

Helmets, gumboots, goggles and hand gloves

should be provided to operators, mechanics and

helpers working on the plant.

Staff should not wear loose clothing.

Check guards, canopies, etc, for their proper

position and ensure that they are firmly fixed.

In the dryer drum, the flame burns at high

speed and it has high temperature. Therefore,

special precautions should be taken so that

there is no leakage of fuel in the vicinity.

Again, backfire is a very common incidence

in the dryer drum. To prevent backfire, the fuel

supply should be cut-off and heating tube

thoroughly blown out by a fan.

The platform for operation should be strong

and spacious and provided with side railings.

A ladder should be provided for climbing up

and down.

Since the temperature of the aggregate coming

out from the dryer is quite high, the operator

and helpers should take proper care to avoid

direct contact with the aggregate or the dryer

drum to avoid injuries due to bums.

The operator and helpers working at bitumen

units should wear gumboots and hand gloves

so as to avoid getting bums in the event of

leakage of hot bitumen. Further, the operator

should not lean over the mixer chamber to

avoid being hit by jumping or flying particles

of the aggregate. The mixer unit should be kept

closed from the top.

5.2 Sprayers

The sprayer should be fitted with a fire resistant screen

and an observation window. Its piping should be

adequately insulated to prevent workers from getting

bum injuries. Workers should stand in the opposite

direction of the wind. This will avoid hot bitumen

spray on their body.

5.3 Spreader and Paver

The general safety precautions and other safety

measures prescribed for operating the equipment and

starting the engine etc, hold good for the paver also.

Additional safety precautions are given below:

a)

b)

c)

d)

Before switching on the augerlconveyor, ensure

that the hopper is clear of unwanted material

and there is sufficient mix material left

in it.

Never lean on its side arms when the paver is

working.

When paver is traveling, the screed should

always be raised and secured.

Avoid over-vibration of screeds. When lighting

screed burners, keep face and hands away from

firebox. Never over-heat the screed.

10

5.4 Heating Bitumen

Tar requires heating before use. Vats, pots, drums and

other containers are used for heating it. The container

should be resistant to damage by heat and transportation.

[t should be leakproof and should have suitable

outlets which can be controlled for taking out the hot

material. The heating should be done in the presence

of a person and the cover of the container kept closed.

t3bserve temperature constantly. Avoid backfire. Use

no open light to ascertain the level of binder in the

boiler.

When bitumen is being heated in series of boilers the

distance between two boilers should be about 1% to

2 m to avoid spreading of t-l-e to the adjoining boiler

in case of any mishap. Leakage of bitumen from pipe

joints/bitumen hot boilers should be checked as far as

possible. In no case the leaked bitumen be allowed to

remain around the work place at the end of the days

work

While handling hot tar/ bitumen, workers should be

careful to prevent accidental spillage. Buckets and cans

for carrying hot material fi-om boiler should be checked

before use to ensure that they are intact and in safe

condition.

5.5 Road Maintenance

Road maintenance possesses a greater variety of safety

problems than do most other fields of heavy

constructional engineering. Since hazards normally

associated with such operations are multiplied several

times over. The process of surfacing or resurfacing of

a roadway involves the use of heavy mobile equipment

and close proximity of moving streams of road traffic

calls for a high degree of safety consciousness on the

part othfe work party as a whole.

T}le various hazards are mainly due to backing of truck

lo unload asphalt or crushed stones, hot asphalt (above

i 50’C) appl ied to road surface, fumes and dusts during

asphalting, skin contact with concrete during placing,

proximity of electric and water pipes, etc.

Responsibility of field engineer of road maintenance

is many fold — it must ensure the safety of the general

public, motorists, pedestrian, residents, workers and

construction equipment. Priorities should be assigned

to specitic hazardous areas as determined by the

locations. length of job, night time requirements, etc.

5.6 Traffic Management During Road

Construction/Repair

There are broadly two types of diversions, namely new

diversion road and portion of existing road duly

upgraded serving as diversion.

In order to minimize traffic hazards and inconvenience

SP 70:2001

to the users of the diversion roads and for safety of the

personnel working at site the standard signs and

caution boards in good and clear conditions should be

displayed as per IRC codes.

6 SITE TRANSPORT

6.1 Human Factor

Almost 90 percent of the road traffic accidents are

attributable to the human factor — the condition of

vehicles and roads being the other. Studies conducted

on the causes of accident have indicated that:

a)

b)

c)

d)

Young drivers have been increasingly involved

in motor vehicle accidents.

Elderly drivers are more susceptible to

accidents.

Age is an important factor in driving through

different areas. Younger age drivers can drive

more safely in urban/built up areas; elderly

drivers are more safe on the highways.

The in-attention time gradually increases on a

long drive on highways, thereby slowing the

reaction time in an emergency. A car radio may

help but will not improve the standard of

driving.

Fatigue is more dangerous than most medical

conditions.

6.2 Vehicles and Drivers

6.2.1 Fitness of Vehic[es

All vehicles that are used on construction site must be

in fit condition and should carry proper fitness

certificate.

6.2.2 Driving License

A driver plying vehicle for site driving should be at

least 18 years old and must hold a valid and current

driving license issued by the prescribed licensing

authority.

A driver driving vehicle of permissible weight

exceeding 7.5 tonnes in the case of engineering plants

and 3.5 tonnes in the case of dampers should be at

least 21 years of age and must hold a valid and current

driving license issued by the prescribed licensing

authority.

6.2.3 Driving Rules

The person in charge of a project or a site, as the case

may be, should impress on the drivers of vehicles under

his charge to follow the driving rules. He should do

spot checking occasionally to ensure that drivers follow

the rules. Basically, he should ensure that the drivers:

a) follow the indications given by traffic sign

You might also like

- 16th Edition IEE Wiring Regulations: Design and Verification of Electrical InstallationsFrom Everand16th Edition IEE Wiring Regulations: Design and Verification of Electrical InstallationsRating: 4 out of 5 stars4/5 (1)

- STANDART PROCEDUR1 TankDocument6 pagesSTANDART PROCEDUR1 TankvayakunNo ratings yet

- Thermal Insulation Handbook for the Oil, Gas, and Petrochemical IndustriesFrom EverandThermal Insulation Handbook for the Oil, Gas, and Petrochemical IndustriesRating: 3.5 out of 5 stars3.5/5 (3)

- Safety Plan - Nfa 2Document2 pagesSafety Plan - Nfa 2Bryan100% (1)

- 1001 Mechanical Facts Made Easy - A Handbook Of Simple Mechanical Knowledge For Everyone Interested In The Work Of The EngineerFrom Everand1001 Mechanical Facts Made Easy - A Handbook Of Simple Mechanical Knowledge For Everyone Interested In The Work Of The EngineerNo ratings yet

- METHOD of STATEMENT For Grounding SystemDocument12 pagesMETHOD of STATEMENT For Grounding SystemHamada Khamis100% (1)

- A Good Practice Guide For The Electrofusion Jointing of Larger Diameter Polyethylene Pressure PipesDocument20 pagesA Good Practice Guide For The Electrofusion Jointing of Larger Diameter Polyethylene Pressure PipesHilal Al KhuzaimiNo ratings yet

- SOP for Safe Work on Coal Stacker PilesDocument19 pagesSOP for Safe Work on Coal Stacker PilesIzaac ErenstNo ratings yet

- Method Statement Pipe JackingDocument7 pagesMethod Statement Pipe Jackingsinthian88% (8)

- RBA Code BitumenDocument6 pagesRBA Code Bitumenkhalidwy6342No ratings yet

- Method statement transmission line installation safetyDocument12 pagesMethod statement transmission line installation safetySheik Peer MohideenNo ratings yet

- 2750 - MS For Cable Crossing Under ORPIC PipelinesDocument6 pages2750 - MS For Cable Crossing Under ORPIC PipelinesGeeks PondNo ratings yet

- Method Statement For ExcavationDocument7 pagesMethod Statement For Excavationspwong99100% (3)

- ER420 - MS of G.I Pipe Crossing - r0Document12 pagesER420 - MS of G.I Pipe Crossing - r0Wr ArNo ratings yet

- JSA HCK MOC Hot Tap Drilling Rev1Document6 pagesJSA HCK MOC Hot Tap Drilling Rev1Ijaz Hussain100% (2)

- Health & Safety Plan for Electrical InstallationDocument14 pagesHealth & Safety Plan for Electrical Installationshareyhou0% (1)

- GNFC Safety Rules PDFDocument16 pagesGNFC Safety Rules PDFCawaNo ratings yet

- 01 - Aramco Exam & Interview QuestionsDocument4 pages01 - Aramco Exam & Interview QuestionsChen XinNo ratings yet

- Safety Precautions Durring Dismentling of StructresDocument83 pagesSafety Precautions Durring Dismentling of StructresshujaNo ratings yet

- Risk Assessment Method Statement Documents: April 2007Document11 pagesRisk Assessment Method Statement Documents: April 2007Tamilchelvam MurogayahNo ratings yet

- Written Work Instruction (Sheet Piles Installation)Document14 pagesWritten Work Instruction (Sheet Piles Installation)cynthia100% (1)

- HKMU Li Ka Shing School of Professional and Continuing Education OSH5002 Assessment Legislative Context in Occupational Health and SafetyDocument21 pagesHKMU Li Ka Shing School of Professional and Continuing Education OSH5002 Assessment Legislative Context in Occupational Health and SafetyWan Ching WongNo ratings yet

- Evaluation Questionnaire For Security SupervisorsDocument13 pagesEvaluation Questionnaire For Security SupervisorsScribdTranslationsNo ratings yet

- Methods and techniques for safe underpass constructionDocument15 pagesMethods and techniques for safe underpass constructionSajjad HassanNo ratings yet

- Method of Statement Natural Gas Pipeline InstallationDocument7 pagesMethod of Statement Natural Gas Pipeline InstallationFrancis DhanarajNo ratings yet

- Ce4012 09Document26 pagesCe4012 09Durga SharmaNo ratings yet

- 3 - JT262.12 General Instructions For AssemblyDocument10 pages3 - JT262.12 General Instructions For AssemblymliugongNo ratings yet

- Work Method ExhaustDocument3 pagesWork Method Exhaustaloysius akpanNo ratings yet

- Pipe Road Crossing MSDocument7 pagesPipe Road Crossing MSJeffrey WeyNo ratings yet

- Method Statement For Laboratory Compressed Air and Vacuum SystemDocument8 pagesMethod Statement For Laboratory Compressed Air and Vacuum SystemAhmed SherifNo ratings yet

- Genset Installation GuidelinesDocument16 pagesGenset Installation GuidelinesEmma NuNo ratings yet

- Example Method Statement For The Installation of Concrete Floor SlabsDocument8 pagesExample Method Statement For The Installation of Concrete Floor SlabsMohammad Ali ElhamNo ratings yet

- SC-19 Safety Code On Operation and Maintenance of Conveyor BeltsDocument10 pagesSC-19 Safety Code On Operation and Maintenance of Conveyor Beltsdcsk84No ratings yet

- Example Method Statement For The Installation of Concrete Floor SlabsDocument8 pagesExample Method Statement For The Installation of Concrete Floor SlabsLombe Paul OkparaNo ratings yet

- CABLE PULLING SAFETYDocument13 pagesCABLE PULLING SAFETYchiat mingNo ratings yet

- Ans Sheet Construction Safety 23110Document93 pagesAns Sheet Construction Safety 23110PRATIKNo ratings yet

- Method Statement For Installation of Sanitary Vent and Storm Drainage PipingDocument5 pagesMethod Statement For Installation of Sanitary Vent and Storm Drainage PipingDong VanraNo ratings yet

- Top Drive Drilling Equipment HSE ManualDocument16 pagesTop Drive Drilling Equipment HSE ManualHayLenLeeNo ratings yet

- Method Statement UG GRE R 3 PDFDocument46 pagesMethod Statement UG GRE R 3 PDFRashid Kayum50% (2)

- Construction Safety ManualDocument25 pagesConstruction Safety ManualNecklal SoniNo ratings yet

- 2.0-General Safety RulesDocument4 pages2.0-General Safety RulesouhadiNo ratings yet

- Thermal Insulation ContractorsDocument4 pagesThermal Insulation Contractorsprabuv40No ratings yet

- Electrical Safety & Accident PreventionDocument50 pagesElectrical Safety & Accident PreventionTina Surve0% (1)

- Install Sanitary Vent Storm Drain PipingDocument6 pagesInstall Sanitary Vent Storm Drain Piping721917114 47No ratings yet

- Method Statement For Concrete WallDocument7 pagesMethod Statement For Concrete WallDeo100% (2)

- BRE PilingDocument10 pagesBRE PilingRavi SalimathNo ratings yet

- Annex 2.1 - Safe Work Practices (Rev 3)Document25 pagesAnnex 2.1 - Safe Work Practices (Rev 3)Kyaw Zin WinNo ratings yet

- Safety Briefing For Sheet Piling Works and Safe Work ProcedureDocument7 pagesSafety Briefing For Sheet Piling Works and Safe Work ProcedureMin Min Soe100% (1)

- Method Statement: Project: Between 9040 & 9013 Contract Number 4400012358Document14 pagesMethod Statement: Project: Between 9040 & 9013 Contract Number 4400012358Qiddiya AlHaiderNo ratings yet

- Safe Work ProcedureDocument19 pagesSafe Work Procedureshihab67% (3)

- SG-19 Safety Guideline On Operation and Maintenance of Conveyor BeltsDocument11 pagesSG-19 Safety Guideline On Operation and Maintenance of Conveyor BeltsHIMANSHU SUTHARNo ratings yet

- Amended MS For Pipe DemolationDocument5 pagesAmended MS For Pipe DemolationahmadNo ratings yet

- Method of Statement Grounding System & Lightning ProtectionDocument7 pagesMethod of Statement Grounding System & Lightning Protectionafm0% (1)

- Cable Installation MethodDocument7 pagesCable Installation MethodAhmad Dagamseh100% (1)

- Method Statement Format (CDRIHBIBSG and Silo DC Pipe Line Cleaning by Hydrojetting MOSDocument11 pagesMethod Statement Format (CDRIHBIBSG and Silo DC Pipe Line Cleaning by Hydrojetting MOSPrem Preetham Dsouza100% (1)

- Butt Fusion Machine ManualDocument22 pagesButt Fusion Machine ManualSachin SampatNo ratings yet

- MS - Tank Cleaning and DesludgingDocument7 pagesMS - Tank Cleaning and DesludgingkoyahassanNo ratings yet

- CPI Site-Activities PDFDocument30 pagesCPI Site-Activities PDFmassive85No ratings yet

- Method of Statement-Rev1Document33 pagesMethod of Statement-Rev1Yusri Yusof100% (1)

- RA For High Pressure Cleaning Using HPCE 520-330Document3 pagesRA For High Pressure Cleaning Using HPCE 520-330George CristianNo ratings yet

- Specification For Jolting Apparatus Used For Testing CementDocument3 pagesSpecification For Jolting Apparatus Used For Testing CementSajidAliKhanNo ratings yet

- Foreword:, Pndis)Document2 pagesForeword:, Pndis)SajidAliKhanNo ratings yet

- Bleaching Powder Solution FeederDocument2 pagesBleaching Powder Solution FeederSajidAliKhanNo ratings yet

- Site Investigations For Foundation in GravelDocument2 pagesSite Investigations For Foundation in GravelSajidAliKhanNo ratings yet

- Requirements For Sludge DewateringDocument2 pagesRequirements For Sludge DewateringSajidAliKhanNo ratings yet

- Bleaching Powder Solution FeederDocument2 pagesBleaching Powder Solution FeederSajidAliKhanNo ratings yet

- Cohesionless SoilDocument2 pagesCohesionless SoilSajidAliKhanNo ratings yet

- Rectangular TankDocument2 pagesRectangular TankSajidAliKhanNo ratings yet

- Example 11: Design of A Hall Subjected To Wind Load: Solution: Design Data/ AssumptionsDocument5 pagesExample 11: Design of A Hall Subjected To Wind Load: Solution: Design Data/ AssumptionsSajidAliKhanNo ratings yet

- Bleaching Powder Solution FeederDocument2 pagesBleaching Powder Solution FeederSajidAliKhanNo ratings yet

- Example 11: Design of A Hall Subjected To Wind Load: Solution: Design Data/ AssumptionsDocument5 pagesExample 11: Design of A Hall Subjected To Wind Load: Solution: Design Data/ AssumptionsSajidAliKhanNo ratings yet

- Rectangular TankDocument2 pagesRectangular TankSajidAliKhanNo ratings yet

- 18:3370 (Partiv) - 1967: Fig. 3) - Walls Built Continuous With Their Footings Are Sometime DesignedDocument2 pages18:3370 (Partiv) - 1967: Fig. 3) - Walls Built Continuous With Their Footings Are Sometime DesignedSajidAliKhanNo ratings yet

- IS: Lo687 ? 1983 4.1.1.2: 4.1.3.1 When Sheathing Is Applied On The Top and Bottom EdgeDocument2 pagesIS: Lo687 ? 1983 4.1.1.2: 4.1.3.1 When Sheathing Is Applied On The Top and Bottom EdgeSajidAliKhanNo ratings yet

- Staggered Free WallDocument1 pageStaggered Free WallSajidAliKhanNo ratings yet

- Cohesionless SoilDocument2 pagesCohesionless SoilSajidAliKhanNo ratings yet

- Example 11: Design of A Hall Subjected To Wind Load: Solution: Design Data/ AssumptionsDocument5 pagesExample 11: Design of A Hall Subjected To Wind Load: Solution: Design Data/ AssumptionsSajidAliKhanNo ratings yet

- PrecastDocument3 pagesPrecastSajidAliKhanNo ratings yet

- Guide to Mortar Types, Properties and Mix DesignDocument3 pagesGuide to Mortar Types, Properties and Mix DesignSajidAliKhanNo ratings yet

- Example 11: Design of A Hall Subjected To Wind Load: Solution: Design Data/ AssumptionsDocument5 pagesExample 11: Design of A Hall Subjected To Wind Load: Solution: Design Data/ AssumptionsSajidAliKhanNo ratings yet

- Example 12: Design of Panel Walls: SolutionDocument2 pagesExample 12: Design of Panel Walls: SolutionSajidAliKhanNo ratings yet

- In Sewerage System The Usage of Natural or SyntheticDocument9 pagesIn Sewerage System The Usage of Natural or SyntheticSajidAliKhanNo ratings yet

- Example 10: Design of Walls of A Building With Cross Waij System of Load-Bearing Construction A 3 Storeyed Building As Shown in Fig. E-38 HasDocument7 pagesExample 10: Design of Walls of A Building With Cross Waij System of Load-Bearing Construction A 3 Storeyed Building As Shown in Fig. E-38 HasSajidAliKhanNo ratings yet

- Between 1904 and 1925Document1 pageBetween 1904 and 1925SajidAliKhanNo ratings yet

- Timber Engineering Handbook Covers Wood Properties and Structural DesignDocument8 pagesTimber Engineering Handbook Covers Wood Properties and Structural DesignSajidAliKhanNo ratings yet

- AnneDocument1 pageAnneSajidAliKhanNo ratings yet

- Wet BulbDocument7 pagesWet BulbSajidAliKhanNo ratings yet

- Indian Standard: Second Revision)Document47 pagesIndian Standard: Second Revision)SajidAliKhanNo ratings yet

- Methods For Estimation of Preservatives in Treated Timber and in Treating SolutionsDocument7 pagesMethods For Estimation of Preservatives in Treated Timber and in Treating SolutionsSajidAliKhanNo ratings yet

- Dell M1000e Install Admin TroubleshootingDocument78 pagesDell M1000e Install Admin Troubleshootingsts100No ratings yet

- Change Management HRDocument2 pagesChange Management HRahmedaliNo ratings yet

- MMRP Narrative Report FormatDocument3 pagesMMRP Narrative Report FormatClarence Dave TolentinoNo ratings yet

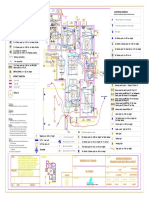

- Varun Valanjeri Electrical Layout-3Document1 pageVarun Valanjeri Electrical Layout-3ANOOP R NAIRNo ratings yet

- Ch-4 Stock Markets - OldDocument56 pagesCh-4 Stock Markets - OldYibeltal AssefaNo ratings yet

- Gateway A2 Test 1BDocument3 pagesGateway A2 Test 1BNewteacher29100% (6)

- Integrating JasperReports To PHPDocument10 pagesIntegrating JasperReports To PHPrupinder_3061463No ratings yet

- Asian Studies Vol 49 No 2 - 2013Document218 pagesAsian Studies Vol 49 No 2 - 2013Ari Dodol100% (1)

- 2010 - Octenidine Dihydrochloride, A Modern Antiseptic For Skin, Mucous Membranes and WoundsDocument15 pages2010 - Octenidine Dihydrochloride, A Modern Antiseptic For Skin, Mucous Membranes and Woundsnovia100% (2)

- 51 Power SteeringDocument72 pages51 Power Steeringlymeng porNo ratings yet

- BeadsDocument8 pagesBeadsMukesh MonuNo ratings yet

- 1 The Importance of Business ProcessesDocument17 pages1 The Importance of Business ProcessesFanny- Fan.nyNo ratings yet

- Sindhi 2020Document1 pageSindhi 2020Engr Javed AkhtarNo ratings yet

- TwistiesDocument2 pagesTwistiesHazwan Hj YusofNo ratings yet

- Name of DrugDocument2 pagesName of Drugmonique fajardo100% (1)

- Quam SingulariDocument2 pagesQuam SingulariMichael WurtzNo ratings yet

- ADL Report "Attacking" Press TVDocument20 pagesADL Report "Attacking" Press TVGordon DuffNo ratings yet

- Neco Catlog 4 FoldDocument2 pagesNeco Catlog 4 FoldSanket PhatangareNo ratings yet

- Margie's Group Travel Presents The Sparks Rebellion 1855-1857Document12 pagesMargie's Group Travel Presents The Sparks Rebellion 1855-1857fcmitcNo ratings yet

- Mil STD 1365bDocument49 pagesMil STD 1365bprakki123No ratings yet

- Paths To Mastery Lesson 17 Speaking Tips From Dale Carnegie The Quick and Easy Way To Effective SpeakingDocument10 pagesPaths To Mastery Lesson 17 Speaking Tips From Dale Carnegie The Quick and Easy Way To Effective SpeakingZelic NguyenNo ratings yet

- GasGas TXT Racing 2014 Owner's ManualDocument60 pagesGasGas TXT Racing 2014 Owner's Manualstone chouNo ratings yet

- ANCHETAAADocument79 pagesANCHETAAAGUILAY, KEVIN MARK F.No ratings yet

- Route StructureDocument3 pagesRoute StructureAndrei Gideon ReyesNo ratings yet

- 3 Demand ForecastingDocument23 pages3 Demand Forecastingnareshshendge100% (1)

- Distribution and Production of Rice in IndiaDocument6 pagesDistribution and Production of Rice in IndiaZehan SheikhNo ratings yet

- Unit 10 Conic Sections ProjectDocument8 pagesUnit 10 Conic Sections Projectapi-290873974No ratings yet

- Railways MedicalDocument73 pagesRailways MedicalGaurav KapoorNo ratings yet

- Faculty of Health and Medical Sciences: Academic Terms and Fee Schedule For 2022Document3 pagesFaculty of Health and Medical Sciences: Academic Terms and Fee Schedule For 2022Sadwi MulatsihNo ratings yet

- Royalstone ReadmeDocument2 pagesRoyalstone ReadmeAdnan BrianNo ratings yet

- Transformed: Moving to the Product Operating ModelFrom EverandTransformed: Moving to the Product Operating ModelRating: 4 out of 5 stars4/5 (1)

- Strong Is the New Beautiful: Embrace Your Natural Beauty, Eat Clean, and Harness Your PowerFrom EverandStrong Is the New Beautiful: Embrace Your Natural Beauty, Eat Clean, and Harness Your PowerRating: 4 out of 5 stars4/5 (5)

- The Darkest White: A Mountain Legend and the Avalanche That Took HimFrom EverandThe Darkest White: A Mountain Legend and the Avalanche That Took HimRating: 4 out of 5 stars4/5 (1)

- Artificial Intelligence Revolution: How AI Will Change our Society, Economy, and CultureFrom EverandArtificial Intelligence Revolution: How AI Will Change our Society, Economy, and CultureRating: 4.5 out of 5 stars4.5/5 (2)

- Design for How People Think: Using Brain Science to Build Better ProductsFrom EverandDesign for How People Think: Using Brain Science to Build Better ProductsRating: 4 out of 5 stars4/5 (8)

- Practical Troubleshooting of Electrical Equipment and Control CircuitsFrom EverandPractical Troubleshooting of Electrical Equipment and Control CircuitsRating: 4 out of 5 stars4/5 (5)

- Training for the Uphill Athlete: A Manual for Mountain Runners and Ski MountaineersFrom EverandTraining for the Uphill Athlete: A Manual for Mountain Runners and Ski MountaineersRating: 4.5 out of 5 stars4.5/5 (8)

- The User's Journey: Storymapping Products That People LoveFrom EverandThe User's Journey: Storymapping Products That People LoveRating: 3.5 out of 5 stars3.5/5 (8)

- Nir Eyal's Hooked: Proven Strategies for Getting Up to Speed Faster and Smarter SummaryFrom EverandNir Eyal's Hooked: Proven Strategies for Getting Up to Speed Faster and Smarter SummaryRating: 4 out of 5 stars4/5 (5)

- Delft Design Guide -Revised edition: Perspectives- Models - Approaches - MethodsFrom EverandDelft Design Guide -Revised edition: Perspectives- Models - Approaches - MethodsNo ratings yet

- The Maker's Field Guide: The Art & Science of Making Anything ImaginableFrom EverandThe Maker's Field Guide: The Art & Science of Making Anything ImaginableNo ratings yet

- The Art of Fear: Why Conquering Fear Won't Work and What to Do InsteadFrom EverandThe Art of Fear: Why Conquering Fear Won't Work and What to Do InsteadRating: 4 out of 5 stars4/5 (10)

- 507 Mechanical Movements: Mechanisms and DevicesFrom Everand507 Mechanical Movements: Mechanisms and DevicesRating: 4 out of 5 stars4/5 (28)

- Understanding Automotive Electronics: An Engineering PerspectiveFrom EverandUnderstanding Automotive Electronics: An Engineering PerspectiveRating: 3.5 out of 5 stars3.5/5 (16)

- Design Is The Problem: The Future of Design Must Be SustainableFrom EverandDesign Is The Problem: The Future of Design Must Be SustainableRating: 1.5 out of 5 stars1.5/5 (2)

- Training for the Uphill Athlete: A Manual for Mountain Runners and Ski MountaineersFrom EverandTraining for the Uphill Athlete: A Manual for Mountain Runners and Ski MountaineersRating: 5 out of 5 stars5/5 (13)

- The Design Thinking Playbook: Mindful Digital Transformation of Teams, Products, Services, Businesses and EcosystemsFrom EverandThe Design Thinking Playbook: Mindful Digital Transformation of Teams, Products, Services, Businesses and EcosystemsNo ratings yet

- The Art of Fear: Why Conquering Fear Won't Work and What to Do InsteadFrom EverandThe Art of Fear: Why Conquering Fear Won't Work and What to Do InsteadRating: 3 out of 5 stars3/5 (5)