Professional Documents

Culture Documents

State of Art GS in Asphalt Pavemenmts PDF

Uploaded by

VgkBharadwajOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

State of Art GS in Asphalt Pavemenmts PDF

Uploaded by

VgkBharadwajCopyright:

Available Formats

A state-of-the-art review on geosynthetics in

low-volume asphalt roadway pavements

Seth Flutcher*1 and Jonathan T. H. Wu2

A majority of the applications to incorporate geosynthetics into pavements exist in low-volume

asphalt roadways. This paper presents a state-of-the-art review of geosynthetics in pavements for

low-volume asphalt roadways. Within that realm, the use of geosynthetics is grouped into three

categories for the purpose of this review. The categories are sub-pavement reinforcement, interlayer

reinforcement, and other non-reinforcing applications; each has been found to incorporate

geosynthetics into pavements with some degree of success. In this paper, selected case studies

and major findings of each case study are summarized in the form of a table for each category. From

this review, it is clear that geogrids are especially useful as sub-pavement reinforcement. Field

experience suggests that geogrids installed into low-volume pavement sections at one-third depth

from the top of an aggregate sub-base course have had very good success. Interlayer reinforcement

with geosynthetics has been geared to reduce or retard reflective cracking in pavement overlays.

This application has been found to be valuable; however, the benefits realized are circumstantial.

Geosynthetics as interlayers should only be incorporated when a pavement’s main failure mode is

fatigue or age cracking, and should be carefully prescribed based on economics. Other uses of

geosynthetics in roadways have been focused on moisture transportation or mitigation of moisture

movement. It was found that most of these geosynthetic applications are well developed and can be

employed as needed by design engineers.

Keywords: Geosynthetics, Pavement, Asphalt roadway, Low volume, Review

Introduction involves lower quality crushed aggregate, can be placed

under the base course in order to reduce costs or to

Flexible pavements are layered pavement systems that minimize capillary action under the pavement. The

include materials with diminishing quality from the top constructed layers are placed directly onto a prepared

layer toward the bottom layer to accommodate the subgrade, which is generally graded and compacted

gradually decreasing contact stresses from top to bottom natural in situ soil (Zornberg and Gupta, 2010).

in pavements. Adherence to this principle makes possible Due to traffic loads, local differential settlement may

the use of local materials and usually results in an occur and horizontal stresses tend to be induced between

economical design (Huang, 1993). A typical flexible layers of flexible pavements, both often lead to formation

pavement system includes four distinct layers: asphalt of cracks in the pavements. A technique that involves

concrete, base course, sub-base, and subgrade (Fig. 1). embedding polymeric geosynthetics in pavement structure

The surface layer is typically asphalt concrete, which is has received considerable attention as a viable solution to

obtained by the hot mixing of aggregate and bitumen, a these problems.

heavy distillate obtained from refining crude oil. The Geosynthetics are planar synthetic products manufac-

asphalt concrete is underlain by a layer of base course, tured for soil-related applications. Many different types of

typically consisting of 0?2–0?3 m of unbound coarse geosynthetics have been developed to serve functions such

aggregate. An optional sub-base layer, which generally as reinforcement (stabilization), filtration, drainage,

separation, moisture barrier, and cushion (stress relief).

For applications in flexible pavements, geotextiles, geo-

1

Engineering Consultant, 5404 Fox Run Blvd. Frederick, CO 80504, USA grids, and geocomposites have been used most often.

2

Department of Civil Engineering, University of Colorado Denver, Denver, Use of geosynthetics in flexible pavements was first

CO 80217, USA tested in the 1960s with geotextiles (also referred to as

*Corresponding author, email sethflutcher@gmail.com ‘‘paving fabric’’). Regular testing and usage of geotextiles

ß 2013 W. S. Maney & Son Ltd

Received 10 May 2013; accepted 11 June 2013 International Journal of

DOI 10.1179/1939787913Y.0000000002 Geotechnical Engineering 2013 VOL 7 NO 4 411

Flutcher and Wu Geosynthetics in low-volume asphalt roadway pavements

1 Cross-section of flexible pavement system a higher contact stresses in top layer and b lower contact stresses in bottom

layer (Muench, 2006)

began in the mid 1970s. The test reports and numerous test and active in the research arena. Geosynthetic research in

sections conclusively proved its value. Since then usage has general has only come to the forefront of civil engineering

increased to over 100 million square yards annually in the practice over the past three decades. Many applications

United States, and approximately double the amount are still under investigation and the ideology and

worldwide according to the Industrial Fabrics Association methodology on how pavements can be improved with

International (Barazone, 2010). geosynthetics are currently evolving as new work comes to

It has been stated that the most pertinent area for light and the experience in the field matures. Secondly,

geosynthetics in pavements is centered on flexible, or neither researchers nor practitioners have come to a

asphaltic pavements, which can be considered as medium consensus on geosynthetics in pavement. Even when cost

to low volume (Al-Qadi et al., 2011). The above statement considerations are removed, opinions vary considerably

may be oversimplifying; however, rigid pavements and by those familiar in the field.

their design are such that the effects of geosynthetic The purpose of this study was to investigate both the

inclusion as reinforcement are clearly not as pronounced current state, along with historical consideration of the

as in flexible pavements. The high stiffness in rigid applications and research of geosynthetics in the field of

pavements generally makes the inclusion of subgrade pavement engineering. The literature on the subject was

reinforcement an area of less interest. A majority of the reviewed and organized to help achieve a good under-

applications to incorporate geosynthetics into pavements standing of both current state and relevant history of the

exist in low-volume asphalt roadways. Consequently, high topic at hand. At conclusion of the research, this paper

volume flexible pavements are also designed and built at was compiled to describe the review and provide relevant

very high stiffness. This stiffness comes from the increased commentary.

pavement thickness, and not because of variables in In this study, two major types of reinforcement are

material or methods. Therefore, similar to rigid pave- considered: sub-pavement reinforcement and interlayer

ments, many high volume or high load flexible pavements reinforcement, and are presented separately. In pavement

will become thick enough, or stiff enough, to reduce the engineering, these two types of reinforcement are often

interest in geosynthetic reinforcement. That does not mean treated differently. The first and most fundamental

that there is no use or benefits in these fields, but most reinforcement application is the inclusion of geosynthetic

research and highest potential for civil engineering benefit materials in sub-pavement material. The placement of

lie elsewhere. geosynthetic materials within a subgrade, sub-base (or

Therefore, weaker or lower volume flexible pavements aggregate base course, ABC, etc.), or an interface between

seem to have the most potential. Supporting that notion is pavement section layers has been done. Extensive research

the fact that early applications, and even current applica- on the location, geosynthetic type, and effectiveness are

tions, of geosynthetics are common in unpaved roadways. available and many of the ideas and conclusions are still

To simplify, the weaker the pavement section, the higher debatable in today’s engineering community. However,

the potential for a geosynthetic material to improve the general idea is to stiffen the pavement section to

performance. Since the investment in unpaved roads is enhance its performance.

far lesser than that of paved roadways, the interest in The second reinforcement type, i.e., interlayer reinforce-

geosynthetics in the former can be somewhat complex and ment, is almost exclusively used when the overlay of older

arguable. The point is that research and practice have pavement is performed. The reason for this is that the

essentially narrowed a great deal of geosynthetic interest purpose of interlayer reinforcement is to reduce or retard

to lower volume asphaltic pavements, with still some the propagation of cracks. One should understand that

interest in applying geosynthetics to certain unpaved when a geosynthetic product is applied in this manner, it is

roads. most often accompanied by a bituminous coating, which

The reason that a state-of-the-art review on the subject enables another important engineering factor. The combi-

is needed is twofold. Firstly, the subject is relatively new nation of the bituminous tack coat to the geosynthetic

412 International Journal of Geotechnical Engineering 2013 VOL 7 NO 4

Flutcher and Wu Geosynthetics in low-volume asphalt roadway pavements

(normally a geotextile) creates an impermeable layer. This pointed out by Hawkins (2012), the fact that many

impermeability is a desired effect to prolong the life of a unpaved roads will eventually become paved. If an

pavement by reducing the amount to water infiltration unpaved roadway has favorable properties, it would be

into the pavement system. suitable to be paved with minimal construction effort on

While the interest in this topic lies on reinforcement of the existing surface. Since Hawkins’ point is accurate, and

pavements, there are many other types of pavement the engineering aspect of reinforcement is equivalent in

enhancement through the use of geosynthetics. Since this sub-pavement reinforcement, the two scenarios are

is a review of geosynthetics in pavements, and because merged for purpose of discussion herein.

some of these applications are of practical importance, a The mechanism in which reinforcement should work to

section of this paper is devoted to non-reinforced uses of prolong a pavement in the methodology is far from simple.

geosynthetics in pavement engineering. Shukla (2002) offers a good summary on the effects that

In this paper, several fundamental ideas were reviewed the inclusion of reinforcement will offer a pavement. First,

first. Then, many newer concepts and conclusions drawn the overall bearing capacity is increased by the shear stress

from theory, modeling, or most often experimentation were reduction effect. This is the reduction of outward shear

evaluated and compared. Upon completion of review, the stress from soil over the reinforcement to the soil

materials gathered were categorized and organized. And underneath. Next, the slab or confinement effect is

finally, the summary of many relevant materials previously discussed. This is due to the restraint put on the soil

circulated, alongside with commentary, is included herein. section due to the reinforcement. Friction at the geosyn-

thetic introduces a countering force to lateral displace-

Geosynthetic sub-pavement ment, somewhat confining (Shukla, 2002).

Another effect commonly discussed in pavement rein-

reinforcement forcement is the effect of a deformed geosynthetic that is

This section begins with a discussion of the fundamental withstanding normal and shear stress. The deformed

method of applying geosynthetics to pavement. material will have a resisting force in the opposite

Reinforcement within the subgrade, within an aggregate direction to the displacement (like a trampoline or

base course, or at the pavement-grade interface is the most membrane). Hence, this is known as the membrane effect.

fundamental way in which reinforcement to a flexible Finally, an anchoring effect is realized in geogrid applica-

pavement can be effective. It is common knowledge, tions. Since soil or aggregate base may interlock through

especially in the realm of the moderate to low-volume the apertures of grids, a stress mobilization may occur in

flexible pavements, that the ability of a pavement to the cross direction of the grid. There is also a separation

perform is directly related to the geostructure it lies upon. effect, which will be discussed later (Shukla, 2002).

More simply stated, pavement is only as good as the Other researchers have paraphrased the reinforcing

material beneath it. benefits by stating that reinforcement can minimize

Since pavements are often built on soft subgrades, and displacements. Deterioration in a granular base will occur

also commonly include an aggregate base course layer due to the lateral displacement that may occur at the

between subgrade and pavement, the opportunities and bottom of a base course. The inclusion of reinforcement

methods to reinforce with a geosynthetic are numerous. will minimize these lateral deformations (Al-Qadi et al.,

Varieties on base course types, subgrade types, geosyn- 2011). General fatigue of materials is also combated in the

thetics types, location, and many combinations of those reinforced section (United States National Research

have been used and studied with variable results. In this Council, 1989). Additionally, intuition allows us to

application type, the inclusion of geosynthetic reinforce- understand that if a base becomes more solid through

ment has almost always shown improvement from a reinforcement, any pavement would perform better and

performance aspect (United States National Research essentially resist all of the failure modes.

Council, 1989). Although the mechanisms in which pavements become

As noted earlier in the Introduction section, moderate stronger are complex, and materials such as geogrids

to low-volume flexible pavements seem to have the receive attributes from stress reduction, anchoring, etc.,

greatest potential to successfully use geosynthetic reinfor- the enhancement of a pavement section is indisputable.

cement. This is again, because the lower volume flexible Figure 2 shows reduction of permanent deformation of

pavements are thin enough to allow stress distribution pavement sections due to reinforcement at different depths

from the traffic loading into a reinforcing material. when subject to cyclic dynamic loads. After 20 000 cycles

Furthermore, the investment in an asphalt road is high of load applications, for example, the permanent deforma-

enough to garner the added technology. In reference to the tion in the unreinforced section was 25 mm, and reduced

idea, Abu-Farsakh and Chen (2011) point out that the to 15–18 mm in the reinforced sections.

weaker the subgrade, the higher the percentage improve- Finally, it should be noted that a great majority of the

ment in relation to the rutting action in pavements. applications and the study of reinforcement in subgrade

The ideology of sub-pavement reinforcement with and sub-base have been focused on geogrids. Geotextiles

geosynthetics can also be merged with the application in have been used; however, the engineering community

unpaved roads. Similar to thinner pavement sections, seems to be convinced that for this application especially,

sometimes the environment of a dirt roadway will be such geogrids hold the highest potential. Partly the reason for

that the inclusion of geosynthetic reinforcement is this is the unique interface that occurs with a perforated

beneficial. Not only that, but one can also consider that material within soil or gravel. The apertures of the geogrid

International Journal of Geotechnical Engineering 2013 VOL 7 NO 4 413

Flutcher and Wu Geosynthetics in low-volume asphalt roadway pavements

pavement material magnify the ability, cost effectiveness,

and importance of these maintenance functions.

Often the maintenance of a pavement is required when

cracks have originated within a pavement. Cracks can be

considered a failure mode, or just an inconvenience that

requires attention. Cracks do not generally reduce the

structural capacity of a given pavement (Button and

Lytton, 2003). But, as Shukla and Yin (2004) point out,

the presence of cracks can also reduce safety, comfort,

increase degradation, and allow for water infiltration and

pumping. In essence, some cracks can cause pavement

failure to propagate through a positive feedback, and be

extremely destructive if not addressed.

Cracks come from a variety of origins. Primary sources

of cracking are fatigue, shrinkage and/or consolidation

2 Permanent deformation in unreinforced and reinforced (due to temperature cycles), construction joints, and age

pavement sections with reinforcement at different depths (Zamora-Barraza et al., 2011). In all instances, it is

of aggregate bases (modified after Abu-Farsakh and relevant that cracks most often appear prior to any other

Chen, 2011) failure mode of a flexible pavement. Therefore, if cracks

can be mitigated, the overall life of a pavement can most

likely be prolonged.

may allow for greater interlocking of base and soil, which The overlay of an existing asphalt pavement is the most

common renovation method (Shukla and Yin, 2004). In

again mobilizes stress into the reinforcement during

fact, the asphalt overlay, which can be used atop both

deformation. Also, the overall strength of the geogrid is

flexible and rigid pavements, was originally proposed in

beneficial and it is well documented that improvement in a

the 1920s (Button and Lytton, 2003). For those unfami-

pavement is proportional to the tensile modulus of

liar, overlays consist of adding a relatively thin pavement

reinforcement (Abu-Farsakh and Chen, 2011). This trend

layer to an existing pavement structure. Sometimes a

does have a point of diminishing return. In fact, some of

comparable removal is done via milling. Removals can be

the most recent theories on reinforcement of unbound

done at full width, or only at edges (where drainage points

aggregate base with geogrid clearly show that the are critical), or in some cases not at all.

mechanism in which the geogrid can reinforce is complex This overlay operation offers great opportunity to

and does not always hinge on the strength of the utilize geosynthetics. It has long been used and researched

geosynthetic (Giroud and Han, 2012). Note that in this with somewhat arguable results. Cleveland et al. (2002)

application, the geogrid has emerged as the geosynthetic of paraphrases that research on the topic ranged from

choice, and even earlier studies have found that an open ‘‘highly successful to disastrous failures.’’ This is in part

mesh geogrid within an aggregate base course would have due to the vast variable in pavements, construction

a similar reinforcing capacity to a geotextile which would material costs, environmental conditions, and the like.

exhibit a strength of 2?5 times that of the grid (United One may wonder why this stage in a pavements life is so

States National Research Council, 1989). opportunistic for geosynthetics. This is due to the

In today’s culture, it is agreed that reinforcing with engineer’s effort to eliminate or retard the propagation

geosynthetics, most often geogrids, brings a certain of cracking from the older pavement into the newer

amount of attributes. Reinforcement can serve as a overlay.

platform over soft soils, in a type of bridging mode. It The inclusion of geosynthetics directly between layers of

can extend the projected service life of pavement. A the pavement is often coined ‘‘interlayer’’ or ‘‘interlayer

reduction in base course thickness can be realized, and the reinforcement.’’ The installation of interlayer geosyn-

ultimate bearing capacity of a soil will be increased. Also, thetics is fairly straight forward. The paving surface

a delay and reduction of rutting is realistic (Al-Qadi et al., should be completely cleaned and dried prior to tack coat.

2011). It is also generally acknowledged that a more After that, the tack coat should be applied at the

favorable stress distribution will be realized (IGS, 2012). prescribed rate. This quantity is dependent on the fabric,

A summary of selected case studies of geosynthetics for surface conditions, and type of tack coat. For reference, a

sub-pavement reinforcement is given in Table 1. common application of 0?90 L m22 (0?20 gallons/yd2) can

be assumed for straight bitumen tack coats.

Geosynthetic interlayer reinforcement Immediately after tack coat is applied, the geosynthetic

should be laid down directly on top. It should be relatively

Of great importance in pavement engineering is the tight, but not stressed. Overlap between sheets should be

longevity of a given pavement. Almost any design or sufficient and wrinkles to be avoided. In any case the

application of pavement requires some maintenance in manufactures instructions should be referenced for best

order to fully reap the investment of a roadway or runway. practices. After the fabric is spread, normal paving

This is especially true in the case of asphalt pavements. It operations can commence. Low temperatures should be

should also be realized that the proponents of asphalt as a avoided for both tacking and paving operations.

414 International Journal of Geotechnical Engineering 2013 VOL 7 NO 4

Flutcher and Wu Geosynthetics in low-volume asphalt roadway pavements

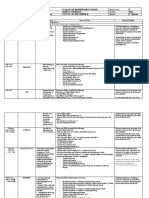

Table 1 Selected case studies of geosynthetics for sub-pavement reinforcement

Agency or authors (Year) Subject Method of study Major findings

US National Research Pull-out in geosynthetic- Laboratory testing - Pull-out is highly variable and

Council (1988) reinforced base depends on geometry, soil density,

angle of internal friction, etc.

US National Research Geosynthetic-reinforced base Repeated load tests - Optimum location of reinforcement

Council, Hass (1988) is at the bottom of base course

US National Research Geosynthetic-reinforced base Accelerated pavement tests - Reinforcement reduces deformation

Council, Barksdale (primarily with pre-stressed or rutting by 20–40%

(1989) reinforcement)

- Base course/fill can be reduced by

25–50 mm (1–2 in.) when reinforcement

is introduced

- Fatigue is reduced when

reinforcement is utilized

Duskov (1997) Reinforcement with geofoam Full-scale/in situ testing of - Geofoam is ineffective for pavement

geofoam reinforcement

Gurung (2003) Tensile response of Laboratory test using - Reinforcing yields favorable results in

reinforced base specialized ‘‘pavement sub-pavement application

tensile test box’’

- Geogrids tested show high peak stress

at low displacement, which is good

Raymond and Ismail Optimum location and number -Static and repeated - Ultimate bearing capacity is increased

(2003) of reinforcement layers load testing (lab) when reinforcement is near the surface

(effect diminishes with depth)

- Finite element analysis - Second layer of geosynthetic can be

beneficial when introduced at the base

course-subgrade interface

- Finite element analysis can successfully

predict behavior of reinforced

pavement section

Kamel et al. (2004) Optimum location of - CBR tests (lab) - Maximum strength increases at a depth

reinforcement of 72–76% (from top)

- Static and dynamic

triaxial tests (lab)

Kazimierowica- Settlement of reinforced Computer modeling - Modeling successfully predicted

Frankowska pavement settlement on reinforced section

(2007)

- Geosynthetics at subgrade interface

reduce settlement

- Little is known about two-layer system

Tang et al. (2008) Rutting in reinforced 1/3 scale accelerated - Strength, aperture size, junction strength,

pavement pavement testing and flexural rigidity are most important

in geogrids

- Pavement performance in

geogrid-reinforced sections is favorable

Al-Qadi et al. (2011) Effectiveness of geogrids in Full-scale accelerated - Any geogrid improves response

low-volume pavements and pavement testing by 23–31%

optimum placement

- Adding a second reinforcing layer has

only circumstantial benefits

- Geogrid minimizes lateral deformations

Abu-Farsakh and Chen Investigation of benefits from Cyclic load testing (lab) - Pavement performance improvement is

(2011) geogrid reinforcement proportional to increased tensile modulus

of a given geogrid

- No clear relationship between

reinforcement performance and aperture

size of the geogrid

- Performance of pavement is optimized

when reinforcement is inserted at the

upper 1/3 of the base course layer

The inclusion of a geosynthetic as interlayer reinforce- stress relieving layer, or a tensile reinforcement, or a

ment is the second largest application of geosynthetics in combination of both (Khodaii et al., 2009). In all cases,

North America reported in 1993 (Cleveland et al., 2002). the objective is for the geosynthetic layer to absorb or

In this application, the geosynthetic can act by either a redistribute stress, so the crack propagation, or reflective

International Journal of Geotechnical Engineering 2013 VOL 7 NO 4 415

Flutcher and Wu Geosynthetics in low-volume asphalt roadway pavements

have been used between the layer of existing cracked

pavement and new maintenance overlays. Surface treat-

ments, such as hot scarification are also optional, and

finally treating individual cracks is possible. This can be

done with simple rubber crack sealing methods. There are

instances where individual cracks are also given a

geosynthetic treatment, but overall the ideology of that

method is synonymous with the general discussion herein

(Cleveland et al., 2002).

While considering the reinforcement interlayer, there

are a few applicable generalizations. It is common practice

to include a liquid asphaltic layer of some type in

conjunction with the geosynthetic. In these instances, the

tack coat, or liquid asphalt is applied to the pavement

surface, and then the geosynthetic is laid down. This is

done primarily to bond the geotextile to the pavement,

3 Increase in stiffness and strength of a non-woven geotex-

however, the inclusion of this asphalt barrier can in itself

tile due to bituminous impregnation (modified after

contribute favorably to the pavement section. First, it acts

Correia and Bueno, 2011)

as a moisture barrier, which will reduce the amount of

water infiltration beneath the pavement. Second, it adds

stiffness to the interlayer. Finally, the liquid asphalt can

cracking, is minimized. Since the existing pavement is

act as a cushion, or stress absorber within the pavement.

assumed to have cracks, the discontinuity alone creates

Pavement designers should note that this procedure is

stress concentrations, which are obviously undesirable

unique and the inclusion of the bituminous tack signifi-

(Correia and Bueno, 2011).

cantly affects how the pavement section will behave. An in

Additional to the stress concentrations are the driving depth study was released in 2011 by Correia and Bueno

forces that initiated the crack. The common contributors who specifically addressed the properties of non-woven

would be the applied wheel loads from traffic, and the geotextiles after impregnation with bituminous liquid.

expansion and contraction experienced from temperature The two part material will become less permeable with

cycles (Correia and Bueno, 2011). Temperature cycles are increased tack, but more interesting is that the strength of

complex within themselves, and both daily temperature the geotextile is pronouncedly increased. Figure 3 shows

swings, as well as seasonal ones are influential (Cleveland the load deformation relationships of a non-woven

et al., 2002). Also noteworthy, moisture presence or lack geotextile due to bituminous impregnation. The increase

thereof can in many cases drive volumetric deviations in in stiffness and strength is sometimes ignored by designers

the subgrade of a soil. This cyclic type action additionally when prescribing geotextiles for interlayer reinforcement.

will promote cracking in pavement. In any case, when the Moving on, the overlay of pavement follows immedi-

stresses experienced in an overlay exceed the fracture ately after the tack coat has been applied to the fabric. The

stresses, the crack will obviously continue (Correia and method of inclusion of liquid asphalt usually eliminates

Bueno, 2011). woven geotextiles for use. This is because the woven

Although reflective cracking is normally the primary geotextiles have no interior plane, hence do not hold any

reason for an interlayer reinforcement, there may be some liquid. Also for this reason, the commonly selected

different or at least accompanying benefits. First would be geotextiles are non-woven lightweight fabrics in the range

the extension of pavement life due to reduced fatigue. of 120–200 g m22 (Shukla and Yin, 2004). The lightweight

Second is the consideration to the limitation or elimina- non-wovens are good absorbers of liquid asphalt and also

tion of deformations (Virgili et al., 2009). are preferred due to their constructability in the field

In fact, a geosynthetic’s usefulness in pavement extends (Correia and Bueno, 2011).

to the ideology of limiting deformation. Pavement rutting It should be noted that the above description applies to

is considered to be a type of failure mode. Many of the practice, and the interest of including geosynthetics within

uses of geosynthetics as reinforcement below the pavement the pavement are not limited to the methodology

layer focus on rutting or permanent deformations. This described above. In fact, many of the references used to

benefit should not be ignored, but the general ideology is create this review, expand and explore alternate methods

prevalent while discussing the subject of sub-pavement and materials for this type of application.

reinforcement (Geosynthetic sub-pavement reinforcement Some recent research studies have investigated the

section), and this discussion is focused on the interlayer optimal location of the interlayer, similar to studies on

geosynthetics as crack inhibitors. reinforcement of unbound aggregates. Khodaii et al.

In the report of Cleveland et al. (2002), it is stated that (2009) concluded that, if a leveling course of asphalt was

reflective cracking treatments are certainly not exclusive first applied, followed by the geosynthetic installation, and

to a geosynthetic interlayer. Ideas as simple as increasing finally succeeded by the remaining overlay, the best

the asphalt overlay thickness have been employed and performance was observed. Supporting data from the

researched for the purpose of reducing reflective cracking. group is shown in Fig. 4, which shows how the permanent

Also, stress-absorbing membrane interlayers (or SAMI’s) deformation and vertical crack growth are affected by

416 International Journal of Geotechnical Engineering 2013 VOL 7 NO 4

Flutcher and Wu Geosynthetics in low-volume asphalt roadway pavements

4 a Permanent deformation v. number of cycles and b vertical crack growth versus number of cycles, for overlays with

differing locations of interlayer reinforcement (modified after Khodaii et al., 2009)

different locations of interlayer reinforcement. This geosynthetics in non-reinforcing applications as they apply

recommendation also allows for an increase in smoothness to pavements are reviewed and discussed in this section.

(due to a two layered approach) and a new clean surface Most common among non-reinforcing categories in

for geotextile installation. This technique counters cynical pavement are geotextiles for drainage. The purpose of a

outlooks that point to improper application from ‘‘dirty’’ geotextile in a roadway drainage system would be to carry

surfaces, improper tack coat rates, and lack of tightness of water from the pavement section to the edge of the

geosynthetics. roadway, normally into an edge drain or to a sloped

Another common occurrence in the art of retarding embankment. This in-plane water transmissivity increases

reflective cracking is that it is not effective against all types water movement in planar directions. The promotion of

of reflective cracking. Both practitioners and engineers lateral flow is significant, because surface water will most

agree that using any method to retard or reduce reflective often enter a pavement section at a much higher rate than

cracking from the large thermal cracks is ineffective it will drain (Murty et al., 1994).

(Shukla and Yin, 2004). These cracks are normally found Another interesting drainage mechanism that geotex-

as transverse cracks (perpendicular to roadway alignment) tiles have been attributed to help mitigate is the capillary

and have developed due to large movements. rise (Meccai and Hasan, 2004). Perhaps as important as

A summary of selected case studies for pavement minimizing the surface or rainwater infiltration is the

interlayer reinforcement is given in Table 2. intentions of a geotextile to drain from an upward flow

sub-pavement path. The capillary rise of pore water in a

Non-reinforcing applications of soil in itself is not complex, but to inhibit the action with a

geotextile is certainly far from simple. In either case, it

geosynthetics to pavements should be noted that under the right conditions, the

Though the primary focus of this study is to evaluate and usefulness of a geotextile in pavement could lie solely in its

review the applications of geosynthetics as reinforcement ability to move moisture.

of a pavement structure, there are other applications of One qualification on the topic of drainage and

geosynthetics in pavements that are relevant. The use of geosynthetics that has not yet been mentioned is that

International Journal of Geotechnical Engineering 2013 VOL 7 NO 4 417

Flutcher and Wu Geosynthetics in low-volume asphalt roadway pavements

some of the best examples do not solely involve the sheet Somewhat similar to a geosynthetics use in drainage is

like structures that have been discussed thus far. Sub- their utilization as water inhibitors. Geomembranes can be

surface drainage by use of perforated pipes, or other placed in several configurations that will eliminate, or at

geocomposite drains, with and without a fabric lining, is a least minimize the ability of a pavement to take on

common utilization. In any event, one should note that the moisture from certain sources. Again, according to the

benefits of geosynthetics in drains are not only to maintain idea that water is especially detrimental to pavements, one

drainage, but also can aid in dissipation of pore water can see the benefits potentially exist with moisture

from clays to improve constructability, accelerate con- barriers. Geomembranes have also been applied in areas

solidation, or both. of swelling soils to reduce damage to pavement (Holtz,

Table 2 Selected case studies of geosynthetics for pavement interlayer reinforcement

Agency or authors Topic Method of study Major findings

US National Research Benefits of reinforcement Review/compilation - Interlayer reinforcement is not

Council (1989) interlayer recommended based on contractor’s

inexperience and cost analysis

Cleveland et al. (2002) Geosynthetics in Crack propagation tests - In place cost of geosynthetics had

pavement overlays using ‘‘overlay tester’’ improved, but economic benefits are

only marginal at the time

- Stiffer geosynthetics yield more

favorable results

Button and Lytton Guidelines for using Review of research and - Includes a discussion on the

(2003) geosynthetics with recommendation to potential for treated non-woven

HMA overlays practitioners geotextiles as moisture barriers

- The in place cost of fabric installation

is roughly equivalent to the cost of

12?5–15 mm (0?5–0?6 in.) of asphalt

- Including reinforcement has only

60–65% success rate

- When successful, interlayer

contribution is comparable to an

additional 30 mm (1?2 in.) of asphalt

James (2004) Reinforcement interlayer Presentation - Interlayer reinforcement with geogrids

leads to dramatic reduction of

reflective cracking

Shukla and Yin Reinforcement interlayer Review - Proper use of geosynthetics could

(2004) waterproof, delay reflective cracking,

and improve service life of pavements

- Including reinforcement can potentially

decrease pavements by approx.

50 mm (2 in.) for similar performance

Khodaii et al. Reflective crack Repeated load - Any geogrid inclusion can significantly

(2009) propagation testing (lab) enhances performance

- Interlayer reinforcement is less

effective at higher temperatures

- Optimum location of reinforcement is

at mid-depth of overlay

Virgili et al. (2009) Flexural strength of Four-point bending - Mathematical methods are able to

reinforced asphalt tests (lab) define pavement failure points

Correia and Bueno Effects of bituminous Lab procedures to measure - At 0?03% strain, geotextile stiffness

(2011) impregnation of asphalt retention and will increases between 500% and 2230%

geosynthetics stress/strain relation after

impregnation

- Impregnated non-woven geotextiles

had permeability comparable to

geomembranes (on the order

of 1022 cm s21)

Zamora-Barraza Crack propagation in Repeated load testing - All interlayer reinforcement leads to

et al. (2011) reinforced interlayers favorable results

- Interlayer reinforcement with

polypropylene geotextiles can offer

a 2–3 times increase in pavement

durability

- Geogrid-reinforced pavements show

increased durability and increased

bearing capacity

418 International Journal of Geotechnical Engineering 2013 VOL 7 NO 4

Flutcher and Wu Geosynthetics in low-volume asphalt roadway pavements

2004). Membrane usage may be a topic that does not well understood that under deformation a geotextile can

require extensive or technical study, but the benefits in take on stress and reinforce. But, the separation ideology

pavement functions are certainly apparent. begs the question whether the reinforcement application

While consistent with the promotion of, or mitigation might at times get credit for the benefits being provided by

of, water movement, the next common act for geosyn- separation.

thetics is filtration. Shukla (2002) defines filtration as the Since geogrids are most popular and proven to be

ability of a fabric to filter out soil fines contained in pore superior to geotextiles, and the separation effect will be

water. This of course refers to water movement in normal reduced when apertures are present, it is reasonable to

to the plane of a geosynthetic, or permittivity. The most assume that the reinforcing effect is of far greater

popular geosynthetics for filtration are non-woven needle- magnitude than separation. The marriage between separa-

punched fabrics. Slit film woven geotextiles are also tion and reinforcement, especially in a pavement section,

common, and both are less susceptible to blinding or mimics that of the sealant and reinforcement function as

clogging than the other types of geosynthetics (Black an interlayer to a pavement overlay. In summary, the

and Holtz, 1999). Key in filtration is the ability of a reinforcement is the primary function, but benefit can be

geosynthetic to not become plugged, because trapped soil realized by separation at the same time.

particles will change the way a geotextile will function over The case studies used for this literature review are

time. Designers and engineers must be cognizant and summarized in Table 3.

proceeded accordingly. Many of the difficulties (like

plugging or poor permeability) exist in other types of Issues with studies of geosynthetics

filters used in engineering, and at least one study found

that the soil–geotextile filter system could be more inclusion in flexible pavements

effective than those that are more conventional (Murty Upon completing this review of geosynthetics in flexible

et al., 1994). pavements, a few items have become apparent. While

The balance of non-reinforcing, non-drainage, uses of conducting any type of experiments or modeling, there

geotextiles lies in categories of sealing, protection, and are inevitably variables that are unaccounted for or not

separation. As for the sealing function, the primary simulated in a realistic manner. For this reason, a dis-

application of geosynthetics is in the asphalt impregnated cussion on some of the unfavorable scenarios that

pavement interlayer (Meccai and Hasan, 2004). This surround the field of pavement engineering and the

subject accompanies the reinforcement interlayer men- difficulties that may arise are discussed.

tioned earlier in the Geosynthetic interlayer reinforcement Theories, modeling, and testing of pavement perfor-

section. Also, the protection category is the one that needs mance all depend on assumptions that could be difficult

little elaboration. In short, there are situations where a to accommodate. The way stresses dissipate deep into

geosynthetic might be used to prevent damages. In pave- pavement layers, soil and other variable materials, aging

ment, a likely scenario would be to place a cheap geotextile and cracking of pavements, and random traffic patterns

over a surface that might need protection from traffic or can all affect engineering methods and theoretical

natural elements. assumptions. The following discusses a few of the most

The separation function is more difficult to analyze. apparent obstacles in the field of pavement engineering

Most often, separation with a geotextile is achieved when and the use of geosynthetics inclusions.

placed between a subgrade layer and an aggregate base One issue is with the angle at which loads disperse into

layer. If separation is achieved in this scenario, the design the pavement and sub-pavement. Even modern research

strength and thickness of the base course will be has not resolved the question about how to accurately

maintained. If not, the base course may lose some of its determine the way loads are distributed (Kazimierowicz-

bearing capacity or general strength, due to loss of Frankowska, 2007). When layered soil systems with

material, or the infiltration of fines. pavement, aggregate, in situ materials, and now geosyn-

The reason this subject is difficult is twofold. First, it is thetics are included, the load distribution becomes even

hard to quantify how much a material is affected by more complex. In computer modeling using finite element

contamination. Black and Holtz (1999) noted that limited methods of analysis, the results are often unreliable. The

information about the long-term performance of separa- reliability of finite element analysis is highly dependent

tors was available. Second, the contamination is a duplex upon the ability to characterize the constitutive relation-

system, where one material should demonstrate unfavor- ships of the materials involved in the problem. The

able contamination, and where the other should become constitutive relationships of soils have been a subject with

stronger. great uncertainties and numerous different opinions. The

Another difficulty with the subject of separation is the theory behind the finite element methods is sound, but the

fact that it is most often combined with reinforcement inability to correctly simulate the constitutive behavior

applications. It is deemed both popular and effective to under changing environmental and loading conditions

include even weaker geotextiles in subgrades and sub remains problematic.

bases of pavement structures. So, when a geosynthetic is Another issue is with complex stress distribution in

included, the separation function is achieved in combina- soils of differing densities, strengths, moistures, tempera-

tion with the function of reinforcement. Most experimental tures, etc. Considering the topic at hand, the pavement only

procedures would quantify the benefits of reduced rutting adds complexity to stress distribution. For interlayer rein-

or increased bearing capacity on the reinforcement. It is forcement, pavement cracks contribute to the complexity of

International Journal of Geotechnical Engineering 2013 VOL 7 NO 4 419

Flutcher and Wu Geosynthetics in low-volume asphalt roadway pavements

stress distributions to the already complex problem. This

is illustrated by Fig. 5, which shows how a single wheel

load might distribute stress in the longitudinal direction

of a transverse crack. Moreover, the dynamic traffic load-

ing makes the stress distribution even more difficult to

analyze.

Cracks in pavements involve other issues as well. One is

how cracking relates to aging. Pavement aging is a main

cause of asphalt cracking (Zamora-Barraza et al., 2011).

This may be due to more than one reason, however it is

well known that the bituminous binder in asphalt

pavement will oxidize over time. The oxidation results in

stiffer pavement (Jung, 2006). Neither cracking nor aging

of pavements are well understood as of today.

Many of these issues extend to a common laboratory

practice known as accelerated pavement tests, or APTs.

APTs are experiments where pavements are subjected to

numerous and intense repeated traffic loads over a short

5 Stresses from wheel over crack (Cleveland et al., 2002) period of time. The purpose of APTs is to evaluate how a

Table 3 Selected case studies for non-reinforcing applications to pavements

Agency or authors Subject Method of study Major findings

US National Research Geomembranes in Review - Geomembranes are functional for

Council, Koerner (1989) transportation frost heave mitigation and can be used

to protect materials susceptible to

weathering, such as limestone

- Geomembranes should be

well protected

US National Research Geocomposite drainage Review - Basic recommendations on

Council, Koerner and geosynthetic types and applications

Highlands (1991) provided

- Edge drains are adequately

permeable, but are not strong enough

and are too porous

- Preventing damage from drainage

issues greatly outweighs cost of

resources used to install

geocomposite drains

Murty et al. (1994) Pavement edge drains Lab tests of drainage - Non-woven geotextiles perform best

functions

- Apparent opening size is important

- Clogging resistance needs to be

considered per-soil

Black and Holtz (1999) Geosynthetics as Full-scale in situ test - Durability of geosynthetics is adequate

separators, durability

v. time

- Consolidation of subgrade is greater

when separators are utilized

- Migration of fines across geosynthetic

layers is successfully mitigated

- Clogging more likely in heat-bonded

geotextiles

- Rutting will decrease when geosynthetic

separator layer is employed

Henry and Holtz (2001) Geosynthetics as capillary Lab tests for moisture - Geotextiles containing fines are

barriers to reduce frost heave migration not effective

- Geocomposites can be an effective

capillary barrier when water level is at

or below the geosynthetic, and the

barrier is saturated

- The application of geosynthetics as

capillary barriers requires more

attention and is a complex topic

420 International Journal of Geotechnical Engineering 2013 VOL 7 NO 4

Flutcher and Wu Geosynthetics in low-volume asphalt roadway pavements

pavement would perform in its service live, in a much portrayal of field conditions is questionable, and for these

shorter amount of time, therefore enabling the experiment. reasons bending or tensile tests have been employed

However, aging (or oxidizing) that results in stiffer (Cleveland et al., 2002).

pavement over are not accounted for in these sophisticated All the discussions on asphalt stiffening over time do

laboratory exercises. Since the goal of APTs is to evaluate not necessarily create a unique situation. Not different

pavement section in a short amount of time, the aging from other engineering materials, a stiffer specimen will

process is often ignored. It can be argued that the likely have some increased strength, but perhaps at the

evaluation of the geosynthetic reinforcement can be done expense of decreased ductility. In the field of evaluating

apart from detailed analysis on this, but the pavement asphaltic pavement, a material that has stiffened, may

system in general is interactive and relationships between resist failure modes such as rutting, while it would be more

the elements are not simple. susceptible to failure modes such as cracking or breaking,

Perhaps the biggest challenge in interpreting accelerated when in a less ductile state.

pavement tests is due to the variations in traffic from While the above discussion points out some sources of

experiment. Two very sophisticated APT devices in the US potential error, oversight, or just the imperfections that

are the ATLAS full-scale-loading assembly in Illinois and are inevitable in any type of research, the discussion is not

the one-third scale MMLS3 in Pennsylvania. They both intended to discount or detract from the field. Those issues

have some shortcomings for simulation of actual traffic. In are acknowledged to provide proper perspectives of the

fact, the author who wrote on the ATLAS test notes that results obtained, and to help researchers improve their

exerted torque from vehicle axles is not simulated. studies.

Similarly, the driving gear or braking is not simulated and In most instances, modern and technical accelerated

those actions are known to drastically increase the shear pavement tests provide valuable research. Central to the

stresses experienced by pavements (Al-Qadi et al., 2011). case in point is the comparison of a pavement section

Finally, these difficulties in representative tests also with geosynthetic inclusion versus one without. For this

extend to minor nuances. Stresses in pavement, and the reoccurring theme, difficult variables such as pavement

subsequent layers that make up the pavement system, are stiffness, stress, and load distributions should be equally

affected by tire tread, speed, and inflation pressure, among

applied to both the control and the experimental

other things. Different tire configurations like super

circumstances. Not to say there would be no effect, but

singles or dual tires also will alter the stress distribution

overall the reported test results would identify a trend

(Al-Qadi et al., 2011). These state-of-the-art tests,

which would be dependent on the controlled variable and

especially those investigating rutting, have another issue.

minimally affected by others factors.

The ideology of simulating pavement ruts with the devices

This ideology has been reported by some of the research

will likely magnify the effect due to the lack of wheel path

studies that have been topical thus far. For example, Abu-

wander. When APTs are conducted, loads are usually

repeated at the exact same location. In reality, the area Farsakh and Chen (2011) state, while considering a field

affected by random traffic is wider and somewhat random, environment against the popular cyclic loading plate, the

and some of the negative effects might be washed out or at wheel loads are much more damaging. But, the research,

least reduced in true traffic settings. in a like for like scenario shows that the various sections

When considering rutting failure, two-dimensional subjected to cyclic plate testing indicate that the perfor-

permanent deformations are considered the criteria for mance is the same using either cyclic plates or wheel loads.

performance. This is clearly relevant since traffic-induced Although this section points out some of the glaring

rutting follows that pattern. On the other hand, many are difficulties in the study of pavement performance, it can be

of the opinion that longitudinal strain in pavements is said that methods utilized can be very effective on side-by-

greater than the transverse strain that results in rutting side analysis of many sorts. In the topic of pavement

(Al-Qadi et al., 2011). That begs the question as to reinforcement, especially the idea that a theory, model, or

whether another failure criterion is being missed or should APT could be used to evaluate a reinforced pavement

at least be considered. The above-mentioned stiffness versus a non-reinforced pavement, many of these obstacles

change due to oxidation may also play a role in rutting. If are less influential.

a pavement becomes stiffer over time, its resilience to Because there are however undoubted issues with

rutting may increase, hence some APT results may be almost any geotechnical testing techniques and engineer-

unfair to the pavements performance. ing, the field is dependent on intelligent and experienced

The stiffening of asphalt with age can shed light on engineers. When considering the difficult nature of the

another issue. Pavement performance can often be tied to dynamic traffic loading, it really becomes interesting. The

an asphaltic concrete’s ability to withstand flexural strain. use of accelerated pavement testing contributes greatly to

As asphalt becomes stiffer with age, it becomes more the field. The same could be said about finite element

brittle, and therefore the flexural stress–strain behavior modeling. Issues could be discussed and arguments made,

will be altered. but our modern engineering research as it applies to

Moving on, it can be said that asphalt materials can be pavements and geosynthetics is indeed state-of-the-art.

much more difficult to test using standard materials testing The methods that are available and used may not always

methods than many other materials. Typical cylindrical offer perfect answers, but the knowledge gained from

specimens, especially in the case of including a geosyn- experiments is invaluable to the pavement engineering

thetic, are difficult to create. In addition, their accurate community.

International Journal of Geotechnical Engineering 2013 VOL 7 NO 4 421

Flutcher and Wu Geosynthetics in low-volume asphalt roadway pavements

Summary and concluding remarks prior to geotextile installation. It is suggested when the

leveling layer is installed; the geosynthetic should be

Summary placed at about 1/3 depth from the bottom of the overlay.

A state-of-the-art review of geosynthetics for low-volume The two layered approach could add expense, so it also

roadways is performed. The review divides the use of must be cautiously recommended.

geosynthetics inclusion into three categories: sub-pavement Geogrids are not recommended for interlayer reinforce-

reinforcement, interlayer reinforcement, and non-reinfor- ment because they do not facilitate the bituminous tack

cing applications. Selected case studies and major findings layer. The desired water barrier and cushion effect are

are summarized in the form of a table for each category. important factors for geosynthetic interlayer applications.

Non-woven needle-punched geotextiles with desired prop-

Geosynthetic sub-pavement reinforcement erties should be utilized. When considering geotextiles, the

Geosynthetic sub-pavement reinforcement is a fundamen- condition of the fabric after bituminous impregnation is

tal use of geosynthetics as reinforcement of unbound most important. The properties of geotextiles improve

aggregate bases. Studies have evaluated materials and dramatically after impregnation (Correia and Bueno, 2011).

methods to understand how geosynthetics may improve Finally, the ability for geogrid–geotextile composites to

a roadway, and most research promotes geosynthetic both accept bituminous impregnation, along with high

utilization in one form or another. strength, means that they should be considered too. It is

Geogrids have largely dominated sub-pavement rein- foreseeable that these geocomposites will garner more

forcement. Overall strength, stiffness, and the existence of interest in both research and practice in future pavement

apertures all improve upon a geosynthetics ability to take interlayer scenarios.

on stress. Furthermore, the stress–strain behavior of the

geogrid is very favorable for pavements where large Non-reinforcing applications of geosynthetics in roadways

deformation is not tolerable. Non-reinforcing applications of geosynthetics in roadways

Large variability in soils, loading, configurations, and are most notably for the functions of separation, filtration,

geosynthetics have inspired differing opinions on depth of drainage, sealing, and/or protection. Most research topics

reinforcement. However, it is relevant that two recent have been concluded, and empirical designs are in use

studies have had similar findings (Abu-Farsakh and Chen, today. It is important to note that moisture presence in

2011; Al-Qadi et al., 2011) that support placement of pavement is of great importance; therefore, many of these

reinforcing geogrid at the upper 1/3 of the aggregate base application methods can be effectively utilized.

layer (as seen in Fig. 2). Additionally, when geosynthetics are used in reinforce-

Many have considered a second layer of geosynthetics ment applications, some of these alternate applications

at times. Most have found that this can improve incidentally come into play. Using bituminous impregnated

performance, but on a much lower magnitude than the non-woven geotextiles as an interlayer will create added

first layer. If conditions and economics dictate that a benefit as a moisture barrier. Using sub-pavement reinfor-

second geosynthetic is reasonable, it should be placed at cement can create a separation effect between fine subgrade

the bottom of the aggregate base course (or the subgrade and aggregate bases, which adds to the effectiveness.

base interface). The separation function of geosynthetics in pavement

engineering is probably the most beneficial, aside from

Geosynthetic interlayer reinforcement reinforcement. A second geosynthetic layer included as

Geosynthetic interlayer reinforcement is intended to sub-pavement reinforcement at the subgrade sub-base

reduce the propagation of reflective cracking in overlays interface is possible, and could be recommended in

of older pavements. Overall experience and recommenda- situations where very soft subgrade soils existed.

tions suggest that reinforcement for large thermal cracks is Capillary barriers were considered, but using geosyn-

not effective. However, it is effective for retardation of thetics as capillary barriers are not practical. Perhaps

crack propagation for common fatigue cracks found in future research would yield a situation more favorable, but

pavements. It has been recommended that non-woven common practitioners should direct resources elsewhere

geotextiles with the inclusion of a bituminous tack coat be for the time being.

utilized. Cost benefit analyses are necessary, because in

these applications the improvement is often marginal. Concluding remarks

When maintaining old pavements a judicious selection is For successful applications of geosynthetics in low-volume

needed by the designer. asphalt roadway pavements, assessment of the suitability

Additionally, because effectiveness of this interlayer of a project and selection of appropriate geosynthetic type

reinforcement is dependent upon crack type, the identifi- are most important. The ultimate strength of geosynthetics

cation of the failure modes is crucial and the pavement used in pavement design is only of secondary importance.

must be in a condition susceptible to maintenance. When Specifically, with respect to pavement reinforcement, the

the proper situation is identified, interlayers should be major areas for consideration are, whether geosynthetics

applied (when determined to be cost effective). are effective improvers of pavement, where the optimal

Similar to the sub-pavement reinforcement, the opti- locations are (for placing geosynthetics), and what proper-

mum location for interlayer reinforcement has been ties of geosynthetics govern their performance.

identified. It has been found that the best performance is When considering geogrids as a reinforcement material,

achieved when a leveling course of pavement is applied a possible contributor to the interaction of geogrids with

422 International Journal of Geotechnical Engineering 2013 VOL 7 NO 4

Flutcher and Wu Geosynthetics in low-volume asphalt roadway pavements

soil is geogrid aperture properties. Some agree that the Henry, K. S. and Holtz, R. D. 2001. Geocomposite capillary barriers to

reduce frost heave in soils. Can. Geotech. J., 38, (4), 678–694.

overall geogrid strength is of less importance, but also say

Holtz, R. D. 2004. Geosynthetics R&D – The ‘‘Early’’ Days (1960s to Circa

aperture stability is very influential. Opening size could be 1985). www.geosynthetica.net/tech_docs/KoernerSympBobHoltz.pdf

(and has been) evaluated for given materials when (19th Feb., 2012).

considering the interaction. However, others believe that Huang, Y. H. 1993. Pavement analysis and design, Englewood Cliff, New

the aperture stability is not relevant to the geogrid Jersey, Prentice-Hall.

IGS, (International Geosynthetic Society). 2012. Various leaflets used

performance in reinforced roads. It can reasonably be for general information. ‘‘Geosynthetics Classification’’, ‘‘Geosyn-

said that with today’s understanding, it is difficult to make thetics Functions’’, ‘‘Geosythetics in Road Engineering’’, ‘‘Geos-

definitive conclusions concerning the aperture properties ynthetics in Unpaved Roads.’’ http://www.geosyntheticssociety.org/

that affect pavement performance; however, the mere Resources.aspx (21 Jan. 2012).

presence of apertures in geogrids have been found to James, G. M. 2004. Geosynthetic Materials as Asphalt Reinforcement

Interlayers: The Southern African Experience. Proc. 8th Conference

enhance pavement strength. on ‘Asphalt Pavements for Southern Africa’, Sun City, South

A section in this paper was devoted to the issues with Africa, 1–13, Kaytech Engineered Fabircs, Pinetown.

studies of geosynthetics inclusion in flexible pavements. An Jung, S. H. 2006. The effects of asphalt binder oxidation on hot mix

important remark is that a design engineer must carefully asphalt concrete mixture rheology and fatigue performance,

Doctoral Dissertation Submitted to the Office of Graduate Studies

interpret any test results or measured data. Most of the results of Texas A&M University, 1–172.

coming out of research communities are of great value, even Kamel, M. A., Chandra, S. and Kumar, P. 2004. Behaviour of subgrade

though pavement testing is very difficult to quantify. soil reinforced with geogrid. Int. J. Pavement Eng., 5, (4), 201–209.

However, anyone in the field must continue to make good Kazimierowicz-Frankowska, K. 2007. Influence of geosynthetic reinfor-

judgments based on experience, local conditions, in addition cement on the load-settlement characteristics of two-layer subgrade.

Geotextiles Geomembr., 25, (6), 366–376.

to practices recommended in technical documents. Khodaii, A., Fallah, S. and Nejad, F. M. 2009. Effects of geosynthetics on

Although the benefits to utilizing geosynthetics in low- reduction of reflection cracking in asphalt overlays. Geotextiles

volume asphalt roadways are apparent in almost all cases, Geomembr., 27, (1), 1–8.

the technology is relatively new and prospective needs Meccai, K. and Hasan, E. A. 2004. Geotextiles in transportation

applications. Proc. 2nd Gulf Conference on ‘Roads’, 1–13; Abu

have to be always applied. New knowledge will certainly Dhabi, UAE.

come to light in the years to come, and past engineering Muench, S. (2006). http://pavementinteractive.org/ (22 Jan., 2012).

experience is invaluable. Since roadway projects are Murty, A. V. S. R., Mathur, S., Chandra, D. and Rao, K. N. 1994.

dependent on sub-soil, environmental conditions, traffic Selection of geotextile filters wrapped around pipes in pavement

loading, and other unpredictable or unquantifiable fac- edge drains. Geotextiles Geomembr., 13, (8), 519–529.

Raymond, G. and Ismail, I. 2003. The effect of geogrid reinforcement on

tors, the application of geosynthetics will always need to unbound aggregates. Geotextiles Geomembr., 21, (6), 355–380.

be evaluated judiciously. Shukla, S. K. 2002 (ed.). Geosynthetics and their applications. London,

Thomas Telford Ltd

References Shukla, S. K. and Yin, J. H. 2004. Functions and installation of paving

geosynthetics, GeoAsia 2004, Seoul Korea., 314–321. http://

Abu-Farsakh, M. Y. and Chen, Q. 2011. Evaluation of geogrid base www.geosynthetica.net/tech_docs/GeoAsia04Shukla.pdf (21 Jan.,

reinforcement in flexible pavement using cyclic plate load testing. 2012).

Int. J. Pavement Eng., 12, (3), 275–288. Tang, X., Chehab, G. R. and Palomino, A. 2008. Evaluation of geogrids

Al-Qadi, I. L., Dessouky, S., Tutumluer, E. and Kwon, J. 2011. Geogrid for stabilizing weak pavement subgrade. Int. J. Pavement Eng., 9,

mechanism in low-volume flexible pavements: accelerated testing of (6), 413–429.

full-scale heavily instrumented pavement sections. Int. J. Pavement United States National Research Council, Transportation Research Board

Eng., 12, (2), 121–135. 1988. Effects of geosynthetics on soil properties and of environment

Barazone, M. 2010. The definitive guide to paving synthetics and on pavement systems. Transportation Research Record 1188, 1–73;

installation. http://www.pavingfabric.com (5th Feb., 2012). Washington, DC, Transportation Research Board.

Black, P. J. and Holtz, R. D. 1999. Performance of geotextile separators United States National Research Council. Transportation Research

five years after installation. J. Geotech. Geoenviron. Eng., 21, (5), Board. 1989. Geosynthetics, Geomembranes, and Silt Curtains in

404–412. Transportation Facilities. Transportation Research Record 1248, 1–

Button, J. W. and Lytton, R. L. 2003. Guidelines for using geosynthetics 56; Washington, DC, Transportation Research Board.

with HMA overlays to reduce reflective cracking, 1–40; College United States National Research Council. Transportation Research

Station, TX, Information and Technology Center, Texas Board. 1989. Potential Benefits of Geosynthetics in Flexible

Transportation Institute. Pavement Systems. National Cooperative Highway Research

Cleveland, G. S., Button, J. W. and Lytton, R. L. 2002. Geosynthetics in Program Report 315, 1–62; Washington, DC, Transportation

Flexible and Rigid Pavement Overlay Systems to Reduce Reflection Research Board.

Cracking, 1–283; College Station TX, Texas Transportation Institute. United States National Research Council. Transportation Research Board.

Correia, N. D. S. and Bueno, B. D. S. 2011. Effect of bituminous 1991. Geocomposite Pavement Drain Systems. Transportation

impregnation on nonwoven geotextiles tensile and permeability Research Record 1329, 1–61; Washington, DC, Transportation

preperties. Geotextiles Geomembr., 2, (2), 92–101. Research Board.

Duskov, M. 1997. Measurements on a flexible pavement structure with an Virgili, A., Canestrari, F., Grilli, A. and Santagata, F. A. 2009. Repeated

EPS geofoam sub-base. Geotextiles Geomembr., 15, (1), 5–27. load test on bituminous systems reinforced by geosynthetics.

Giroud, J. P. and Han, J. 2012. The Giroud-Han design method for Geotextiles Geomembr., 27, (3), 187–195.

geosynthetic-reinforced unpaved roads. Geosynthetics, Vol. 30, Issue Zamora-Barraza, D., Calzada-Perez, M. A., Castro-Fresno, D. and Vega-

1, pp. 40–49. Zamanillo, A. 2011. Evaluation of anti-reflective cracking systems

Gurung, N. 2003. A laboratory study on the tensile response of unbound using geosynthetics in the interlayer zone. Geotextiles Geomembr.,

granular base road pavement model using geosynthetics. Geotextiles 29, (2), 130–136.

Geomembr., 21, (1), 59–68. Zornberg, J. G. and Gupta, R. 2010. Geosynthetics in Pavements: North

Hawkins, W. M. 2012. Geotextiles in unpaved roads: a 35-Year case American Contributions, 9th International Conference on

history. http://www.typargeotextiles.com/PDFs.TG-35yrcasehistory. Geosynthetics, Brazil, University of Texas at Austin, Austin, TX,

pdf (5th Feb., 2012). 379–398.

International Journal of Geotechnical Engineering 2013 VOL 7 NO 4 423

You might also like

- Phyto RemediationDocument11 pagesPhyto RemediationVgkBharadwajNo ratings yet

- A 3Document11 pagesA 3VgkBharadwajNo ratings yet

- Geotextiles Usage in AviationDocument62 pagesGeotextiles Usage in AviationVgkBharadwajNo ratings yet

- Studies On GS Road Pavement Structures PDFDocument12 pagesStudies On GS Road Pavement Structures PDFVgkBharadwajNo ratings yet

- Geosynthetics - For - Soil - Reinforcement PDFDocument21 pagesGeosynthetics - For - Soil - Reinforcement PDFVgkBharadwajNo ratings yet

- Reivew PaperDocument4 pagesReivew PaperVgkBharadwajNo ratings yet

- GC Sheet Drain JoiningDocument6 pagesGC Sheet Drain JoiningVgkBharadwajNo ratings yet

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5796)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (895)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (400)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (589)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (345)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1091)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (122)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- Innovation WaterDocument396 pagesInnovation WaterBrian ThomasNo ratings yet

- Community Develpoment Project: Submitted by Name:-Dipanjan Sarkar Registration Number:-12110940Document12 pagesCommunity Develpoment Project: Submitted by Name:-Dipanjan Sarkar Registration Number:-12110940DIPANJAN SARKARNo ratings yet

- Kak English Year 2 2021Document11 pagesKak English Year 2 2021June AzryNo ratings yet

- Lecture 1Document21 pagesLecture 1Dr. AnasNo ratings yet

- Writing The IntroductionDocument17 pagesWriting The IntroductionFerlyn PascuaNo ratings yet

- Swagelok® Medium-Pressure, Gaugeable Tube Fittings and Adapter Fittings 2011-3-16Document20 pagesSwagelok® Medium-Pressure, Gaugeable Tube Fittings and Adapter Fittings 2011-3-16朱向斌No ratings yet

- Topic 2 - Sampling TechniquesDocument34 pagesTopic 2 - Sampling TechniquesCarlyne Guiang FijerNo ratings yet

- English For Academic and Professional Purposes M67777Document1 pageEnglish For Academic and Professional Purposes M67777Ericka Rivera SantosNo ratings yet

- School: Grade Level: Teacher: Section Teaching Dates and Time: QuarterDocument4 pagesSchool: Grade Level: Teacher: Section Teaching Dates and Time: QuarterZeny Aquino DomingoNo ratings yet

- Question Bank UM19MB602: Introduction To Machine Learning Unit 4: Decision TreeDocument4 pagesQuestion Bank UM19MB602: Introduction To Machine Learning Unit 4: Decision TreeBharathi RajuNo ratings yet

- 1D Motion Modelling - v1.1Document10 pages1D Motion Modelling - v1.1Msindwana siyoliseNo ratings yet

- ҚМЖ 2кл - 130б-2Document72 pagesҚМЖ 2кл - 130б-2NazymNo ratings yet

- Pitch Anything NotesDocument9 pagesPitch Anything Noteskirik - scribdNo ratings yet

- Chemistry Project On Chemistry in Everyday LifeDocument25 pagesChemistry Project On Chemistry in Everyday LifeAnkit Mishra67% (27)

- Ebook Comprehensive Materials Finishing PDF Full Chapter PDFDocument67 pagesEbook Comprehensive Materials Finishing PDF Full Chapter PDFvictor.vega375100% (27)

- General Rules - APA FormattingDocument3 pagesGeneral Rules - APA FormattingSYafikFikkNo ratings yet

- 9700 w18 QP 22 PDFDocument16 pages9700 w18 QP 22 PDFعالم بوليودNo ratings yet

- KBE Main Brochure Handling Care Ventilation 334PR1000 0315 Web PDFDocument12 pagesKBE Main Brochure Handling Care Ventilation 334PR1000 0315 Web PDFJoão Paulo Fernandes MonteiroNo ratings yet

- Notre Dame of Masiag, Inc.: TopicsDocument6 pagesNotre Dame of Masiag, Inc.: TopicsMary Jean FarillonNo ratings yet