Professional Documents

Culture Documents

BBL 432: Fluid Solid Systems: Answer All Questions. Maximum Marks 60

BBL 432: Fluid Solid Systems: Answer All Questions. Maximum Marks 60

Uploaded by

Sparsh Negi0 ratings0% found this document useful (0 votes)

20 views1 pageOriginal Title

BBL432_AGP_FE (2).pdf

Copyright

© © All Rights Reserved

Available Formats

PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

0 ratings0% found this document useful (0 votes)

20 views1 pageBBL 432: Fluid Solid Systems: Answer All Questions. Maximum Marks 60

BBL 432: Fluid Solid Systems: Answer All Questions. Maximum Marks 60

Uploaded by

Sparsh NegiCopyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

You are on page 1of 1

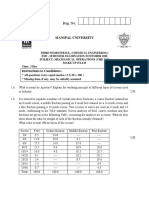

BBL 432 : Fluid Solid Systems

Final Evaluation

Answer all questions. Maximum marks 60

1. (i) Explain how one may use the data from batch sedimentation experiments to

design a continuous settler.

(ii) Theoretically, the required area of a continuous thickener can be decreased by

increasing the downward velocity. However, this may not always be desirable.

Why? [15]

2. (i) Explain the importance of different resistance factors considered in filtration

design. What is the significance of the nature of filter cake?

(ii) Show the differences and similarity between batch and continuous filtration

system designs [15]

3. A maximum flow rate of 50 litres/min was achieved for the centrifugation of

bacteria cells in a tubular centrifuge. The cells were 2.0 μm in diameter and had a

density of 1.08 g/cm3. The medium had a density of 1.01 g/cm3 and viscosity of

1.2 cp. It is desired to centrifuge yeast cells in this same centrifuge. The yeast

cells have a diameter of 5.0 μm and a density of 1.10 g/cm3. The medium has a

density of 1.02 g/cm3 and a viscosity of 1.3 cp. Estimate the maximum flow rate

that can be used to centrifuge the yeast cells. [15]

4. A bench-top centrifuge is designed to pellet material rapidly from a small amount

of sample. The unit holds six micro test tubes, each 0.8 cm in diameter and 3.0 cm

in height. The test tubes are held at a 45o angle to the axis of rotation. If the

centrifuge reaches 95000 rpm in 15 sec, how long will it take to clarify a liquid

containing protein aggregates of 0.2 µm diameter and of a density difference

0.002 g/cm3 [15]

You might also like

- Wastewater QuestionDocument18 pagesWastewater Questionth3mannnNo ratings yet

- DSP IiiDocument2 pagesDSP IiiGaurav Singh ThakurNo ratings yet

- Bioseparation Pratice QuestionsDocument1 pageBioseparation Pratice QuestionsAnkit SinghNo ratings yet

- Assignment 2 - CentrifugationDocument2 pagesAssignment 2 - CentrifugationAnanthi P bt20d203No ratings yet

- Centrifugation Homework TemplateDocument7 pagesCentrifugation Homework TemplatewldmznahNo ratings yet

- Gujarat Technological University Subject Name:Mechanical OperationDocument2 pagesGujarat Technological University Subject Name:Mechanical OperationShivam PanchalNo ratings yet

- CM 404 Fluid Particle Mechanics Jun 2020Document1 pageCM 404 Fluid Particle Mechanics Jun 2020RAHUL MATHURNo ratings yet

- T Exeter Hydrocyclonemodel2 PDFDocument7 pagesT Exeter Hydrocyclonemodel2 PDFqweNo ratings yet

- DSP RevisionDocument1 pageDSP RevisionGaurav Singh ThakurNo ratings yet

- Particulate Technology Quiz: (Questions)Document7 pagesParticulate Technology Quiz: (Questions)Yushene Sarguet100% (1)

- SS DM EX 003 Nanolive Sample Preparation ManualDocument17 pagesSS DM EX 003 Nanolive Sample Preparation ManualMariana CarvalhoNo ratings yet

- Slide Preparation of Cerebrospinal Fluid For Cytological ExaminationDocument3 pagesSlide Preparation of Cerebrospinal Fluid For Cytological ExaminationMurshed HaidarNo ratings yet

- Tank Mixing Eductors.: Features and SpecificationsDocument4 pagesTank Mixing Eductors.: Features and Specificationshoangvubui4632No ratings yet

- CHL 780 Tut 5 v2Document2 pagesCHL 780 Tut 5 v2Pratyush GoelNo ratings yet

- Final ExamDocument6 pagesFinal ExamTej ChoksiNo ratings yet

- Transport Phenomenon Question Paper (M.tech)Document3 pagesTransport Phenomenon Question Paper (M.tech)Kiran SheelavantNo ratings yet

- Merco CH38Document2 pagesMerco CH38BASICNo ratings yet

- 2023 June CHT206-EDocument3 pages2023 June CHT206-EGouri K SNo ratings yet

- Worked Out ProblemsDocument49 pagesWorked Out ProblemsPaYee Biongcog - Manalo45% (11)

- Experiment No 1Document7 pagesExperiment No 1LJ IDANE ARANASNo ratings yet

- Gujarat Technological UniversityDocument2 pagesGujarat Technological UniversityShivam PanchalNo ratings yet

- Bty543hw1Document1 pageBty543hw1bedibediNo ratings yet

- Recovery of Bio-ProductsDocument32 pagesRecovery of Bio-ProductsH.J.Prabhu67% (3)

- Laboratory Experiments Compilation: College of Engineering EducationDocument21 pagesLaboratory Experiments Compilation: College of Engineering EducationhachimanNo ratings yet

- Final Mat Oel RPTDocument14 pagesFinal Mat Oel RPTl236729No ratings yet

- Problems Collection-2018Document19 pagesProblems Collection-2018calvinNo ratings yet

- Ductility Test PDFDocument4 pagesDuctility Test PDFAshishJamadarNo ratings yet

- Sathyabama University: (Established Under Section 3 of UGC Act, 1956)Document2 pagesSathyabama University: (Established Under Section 3 of UGC Act, 1956)KRUNAL Parmar0% (1)

- Desalting, Concentration, and Buffer Exchange by Dialysis and UltrafiltrationDocument15 pagesDesalting, Concentration, and Buffer Exchange by Dialysis and UltrafiltrationAlejandraBarrónHernándezNo ratings yet

- Mechanical Operations (CHE-205) (Makeup) (EngineeringDuniya - Com)Document3 pagesMechanical Operations (CHE-205) (Makeup) (EngineeringDuniya - Com)Cester Avila Ducusin100% (1)

- Basics of CentrifugationDocument10 pagesBasics of Centrifugationramar.r.k9256No ratings yet

- SPE 144098 A New Technique To Characterize Drilling Fluid Filter CakeDocument14 pagesSPE 144098 A New Technique To Characterize Drilling Fluid Filter CakeJorge FernandoNo ratings yet

- Help - Protocols - Competent CellsDocument4 pagesHelp - Protocols - Competent CellsRaulDurandeAlbaNo ratings yet

- Basics of CentrifugationDocument7 pagesBasics of CentrifugationFauzi OkiNo ratings yet

- Centrifugal SeparationDocument7 pagesCentrifugal Separationabhinav singh yadavNo ratings yet

- Rr310801 Mechanical Unit OperationsDocument7 pagesRr310801 Mechanical Unit OperationsSrinivasa Rao GNo ratings yet

- P 1 1 Leung DDocument10 pagesP 1 1 Leung DMasha NikolovaNo ratings yet

- Penetration Test of BitumenDocument12 pagesPenetration Test of BitumenDakshraj RathodNo ratings yet

- Xampler HFDocument8 pagesXampler HFAnil ReddyNo ratings yet

- Scaffold Lab #4 HandoutDocument3 pagesScaffold Lab #4 HandoutĐinh Thị Trúc QuỳnhNo ratings yet

- Jar TestDocument4 pagesJar TestAnis NurdiniNo ratings yet

- IMO MSC Circ.670Document11 pagesIMO MSC Circ.670Mihailescu IulianNo ratings yet

- 2.3 Analytical Method 2.3.1 PH TestDocument9 pages2.3 Analytical Method 2.3.1 PH TestSusi MulyaniNo ratings yet

- Gujarat Technological UniversityDocument2 pagesGujarat Technological Universityvifaket581No ratings yet

- 03 01 DOCU Concrete ManualDocument209 pages03 01 DOCU Concrete ManualJeronimo FatimaNo ratings yet

- Noaa Methods of Analyze Sediment Bed SampleDocument6 pagesNoaa Methods of Analyze Sediment Bed SampleWadiya ApriliantiNo ratings yet

- Momentum Transfer PDFDocument5 pagesMomentum Transfer PDFonyxNo ratings yet

- Gujarat Technological UniversityDocument2 pagesGujarat Technological Universityfeyayel988No ratings yet

- ExChEL Group Study Session 28 - FiltrationDocument3 pagesExChEL Group Study Session 28 - FiltrationRochelle Louise SampagaNo ratings yet

- Development of A Prototype of A Microfluidic DeviceDocument14 pagesDevelopment of A Prototype of A Microfluidic DeviceArka SadhuNo ratings yet

- High Performance Dialysis GuideDocument28 pagesHigh Performance Dialysis GuideRoxana ElenaNo ratings yet

- Chee Lab 2 FinalDocument26 pagesChee Lab 2 FinalOLEBOGENG RATLHOGONo ratings yet

- Dowex Ion Exchange Resins LAB GUIDE LDocument9 pagesDowex Ion Exchange Resins LAB GUIDE Ltestuser01No ratings yet

- Mechanical Analysis of Extracted Aggregate: Standard Method of Test ForDocument6 pagesMechanical Analysis of Extracted Aggregate: Standard Method of Test Forclint silNo ratings yet

- Cross FlowDocument14 pagesCross FlowFoong Shiuh HaurNo ratings yet

- CE3040 Water Treatment Assignment 2Document1 pageCE3040 Water Treatment Assignment 2Anonymous Vx9KTkM8nNo ratings yet

- Water Treatment Processes and Plant Design Home-Take Exam (50%)Document2 pagesWater Treatment Processes and Plant Design Home-Take Exam (50%)awol mohammedNo ratings yet

- Bioprocessing for Cell-Based TherapiesFrom EverandBioprocessing for Cell-Based TherapiesChe J. ConnonNo ratings yet

- Technology Platforms for 3D Cell Culture: A User's GuideFrom EverandTechnology Platforms for 3D Cell Culture: A User's GuideStefan PrzyborskiNo ratings yet