Professional Documents

Culture Documents

ICF Connectors: Installation of ICFVL

ICF Connectors: Installation of ICFVL

Uploaded by

Ethan GuzmanOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

ICF Connectors: Installation of ICFVL

ICF Connectors: Installation of ICFVL

Uploaded by

Ethan GuzmanCopyright:

Available Formats

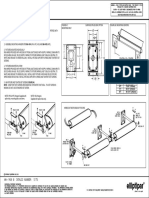

ICF Connectors

The ICF Ledger Connector System is engineered to solve the challenges of mounting

wood or steel ledgers to walls built with insulated concrete forms (ICF). This flier provides

information on the various products we have to serve the ICF market.

The ICFVL is a 14-gauge galvanized steel connector designed to provide both vertical 513⁄16"

and lateral in-plane resistance. The embedded legs are embossed for additional stiffness

and the holes allow for concrete to flow through and around the connector. The exposed

flange on the face of the ICF provides a structural surface for mounting either a wood or

steel ledger.

8"

See the current Simpson Strong-Tie® Wood Construction Connectors catalog

or strongtie.com for additional information.

Installation of ICFVL

15⁄8 6"

1. Snap a line for the bottom of the "

ledger and mark the on-center spacing

ICFVL

2. Use the ICFVL to mark the kerf Patent pending

locations in the ICF

3. Cut the kerfs as marked

4. Insert the ICFVL flush to the face 7"

of the ICF 73∕16"

5. Place concrete (min. f'c = 2,500 psi) ICFVL-W

19/16"

(for wood)

Installation tip: Use a screw through ½" to ICFVL-CW

diamond hole in face of ICFVL and into ¾" 113/16"

web to hold in place during concrete (for LVL)

pour (remove prior to ledger installation).

Attachment of Wood Ledger Attachment of Steel Ledger

ICFVL-W and ICFVL-CW

1. Slip the appropriate ledger connector

underneath the wood ledger (as shown). 1. Position bottom of the ledger level

to the chalk line and drive the

2. Install the eight ICF-D3.25 screws required number of screws through

partially into the ledger. For denser the steel ledger and into the ICFVL

wood species (specific gravity ≥ 0.50) 2. All screws (#14 x 3/4" drill point — not

such as LVL and other EWP products, provided) should be located at

predrilling may be necessary. Predrill the least 1⁄2" from the edge of the ICFVL

wood ledger only with 5/32" drill bit.

3. Space screws evenly

3. Position the bottom of the ledger level

to the chalk line and drive the screws

through the wood and into the ICFVL.

4. All screws should be located at least

1

⁄2" from the edge of the ICFVL.

Note: Do not splice at the ICFVL-W or

ICFVL-CW location.

© 2019 Simpson Strong-Tie Company Inc. F-C-ICFVL19

ICF Connectors

1 Use MAB15Z

2 Attach interior partition walls

with 1⁄4–14 #3 drill point screws

(sold separately) into ICFVL

where needed

3 Use ICFVL to attach

ledger to ICF

1

4 Use ICFVL-W for solid sawn

lumber or ICFVL-CW for LVL

Note: See drawing below for

detail on double 2x ledger

5 Use IUS hanger for

I-joist floor system 2

Typical face-mount floor truss

hangers include, but aren’t limited

to, LUS, HUS, HGUS and HHUS.

Attachment of second ledger to Alternative hanger for solid sawn Use wood-to-steel drill point screws through

be designed by others. floor joist using LUS joist hangers. wood cabinets and into the ICFVL connector.

© 2019 Simpson Strong-Tie Company Inc. F-C-ICFVL19

Plate Connections

MAB Anchor Spacing

O.C. Spacing O.C. Spacing

to Replace 1⁄2 " to Replace 5⁄8" Min.

Min.

Model Anchor Bolts Anchor Bolts Concrete C-C

No. 6' o.c. 6' o.c. End

Spacing

Distance

(160) (160)

MAB15 3'-10" 2'-8" 6 1⁄2" 13"

1. "Prescriptive" denotes designs per the IRC or conventional

provisions of the IBC for wind speeds 100 mph or less, or for

Seismic Design Category D and less (SDC E and less in IBC).

2. Spacing is based on parallel-to-plate load direction only.

3. Place anchors not more than 12" from the end of sill and splices

per code.

4. Concrete shall have a minimum compressive strength of f'c = Typical MAB15

2,500 psi. Installation into ICF

5. Grout-filled CMU (GFCMU) shall have a minimum compressive

strength of f'm = 1,500 psi.

6. Spacings apply to DF, SP and HF sill plates.

Bearing plate

Titen HD® Anchor as required

The Titen HD Anchor may be

used for sill plate applications.

Use bearing plates as required by

code. Refer to the code report

(ICC-ES ESR-2713), or use

Cracked

Concrete

Simpson Strong-Tie CODE LISTED

Anchor Designer™ software.

Download at:

strongtie.com/software 6" min.

Titen HD Anchor

Preservative-

treated lumber

Titen HD Installation into ICF

LSTA18

HDU5-SDS2.5

MTS20

(minimum

4 double stud)

LTP4

For additional corrosion information,

see the current Simpson Strong-Tie®

Wood Construction Connectors catalog LTP4 BP

Preservative-

or strongtie.com. treated lumber

LTP4

LTP4 spacing as

required for shear

and uplift

© 2019 Simpson Strong-Tie Company Inc. F-C-ICFVL19

Truss Connections

Moisture barrier

LTA Lateral Truss not shown H3 for Single

Anchor, for High Uplift Plate-to-Truss

F2 and Lateral Values, Connection

Eliminates Treated

Plate See the current

F1

Simpson Strong-Tie

Moisture

barrier not See the current Simpson Strong-Tie® Wood Construction Connectors

shown Wood Construction Connectors catalog or strongtie.com for

catalog or strongtie.com additional information on and

#5 rebar

min. for additional information other models of seismic and

on lateral truss anchors. hurricane ties.

Allowable Loads (160)1 Allowable Loads

Fasteners (in.)

Model Fasteners (160)1

Lateral Model

No. (in.) Uplift Ga.

No. To Rafter or Truss To Lateral

F1 F2 Uplift

Single Ply 2 Ply or Greater Plates F1 F2

LTA2 (10) 0.148 x 1 1⁄2 990 415 735

(4) 0.131

1. Allowable loads are for SPF/HF species wood. See the current H3 20 (4) 0.131 x 1 1⁄2 (4) 0.131 x 2 1⁄2 365 180 145

x 1 1⁄2

Simpson Strong-Tie Wood Construction Connectors catalog or

strongtie.com for additional wood and installation information. 1. Allowable loads are for SPF/HF species wood. See the current

Simpson Strong-Tie Wood Construction Connectors catalog or

strongtie.com for additional wood and installation information.

FGTR

Typical MTSM20

Installation

into ICF Installation into ICF

Reinforcement

by others Moisture barrier

not shown

4" min.

Install See the current

Titen HD Simpson Strong-Tie Wood

anchors Construction Connectors

in every

#5 rebar other hole catalog or strongtie.com for

min. on the part additional information on and

Moisture Barrier #5 rebar other models of twist straps.

not shown min.

Fasteners (in.) Fasteners (in.)

Allowable Allowable

Model Model To Rafter or Truss

To Rafters Uplift Loads L To Uplift Loads

No. To Concrete No.

or Truss (160)1 2 Ply or Concrete (160)1

Single Ply

Greater

FGTR (18) 1⁄4 x 3 SDS (2) 1⁄2 x 5 Titen HD® 3,400

(7) 0.148

1. Allowable loads are for SPF/HF species wood. See the current MTSM20 20 (7) 0.148 x 1 1⁄2 (4) 1⁄4" x 1 3⁄4" Titen® 2 715

x3

Simpson Strong-Tie Wood Construction Connectors catalog or

strongtie.com for additional wood and installation information. 1. Allowable loads are for SPF/HF species wood. See the current

Simpson Strong-Tie Wood Construction Connectors catalog or

strongtie.com for additional wood and installation information.

Moisture Moisture

barrier Moisture

barrier barrier

not shown not shown F1

not shown

F2

680 lb.

#5 rebar min. #5 rebar min. #5 rebar min.

H16S Installation into ICF HM9 Installation into ICF HGAM10 Installation into ICF

1. Allowable loads have been increased for wind or earthquake loading

Fasteners (in.) Allowable Loads4 with no further increases allowed. Reduce where other loads govern.

Model

Ga. To Rafter To 2. Minimum concrete edge distance is 1 3⁄4" when using Simpson Strong-Tie

No. Uplift F1 F2 Titen 2 screws.

or Truss Concrete

3. See the current Simpson Strong-Tie Wood Construction Connectors

H16S 18 (2) 0.148 x 1 1⁄2 (6) 1⁄4 x 1 3⁄4 Titen 2 1,180 — — catalog for additional dimensional, installation and loading information.

4. Allowable loads are for SPF/HF species wood. See the current

HM9 18 (4) 1⁄4 x 1 1⁄2 SDS (5) 1⁄4 x 1 3⁄4 Titen 2 760 670 190 Simpson Strong-Tie Wood Construction Connectors catalog or

strongtie.com for additional wood and installation information.

HGAM10 14 (4) 1⁄4 x 1 1⁄2 SDS (4) 1⁄4 x 1 3⁄4 Titen 2 585 630 795 5. The HM9KT is sold as a10-pack with the required fasteners.

The HGAM10KTA is sold as a 10-pack with the required fasteners.

© 2019 Simpson Strong-Tie Company Inc. F-C-ICFVL19

ICF Connectors

General Notes:

1. For denser wood species (specific gravity ≥ 0.50) such as LVL and other EWP products, Warning: Industry studies show that

predrilling may be necessary. Predrill the wood ledger only with 5/32" drill bit. hardened fasteners can experience

2. These products are not intended for use with preservative-treated lumber. performance problems in wet

3. Do not splice ledger at ICFVL location. environments. Accordingly, use this

4. No load duration increase is allowed. product in dry, interior applications only.

5. Minimum concrete compressive strength (f'c) is 2,500 psi.

6. Use the unity equation when applying vertical and lateral loads simultaneously.

Design Download/Allowable Download + Design Lateral Load/Allowable Lateral Load ≤1.0.

Wood Ledgers

Allowable Loads

(lb.) – ASD

Vertical Lateral Botto

of ledm

1,940 1,905 ger

1. Use (8) ICF-D3.25 screws (provided).

2. Loads apply to ICFs with foam thickness

31⁄4" or less.

3. Loads assume a minimum spruce-pine-fir ledger.

4. Loads may not be increased for short-term loading. ICFVL ICFVL on EWP

5. The top of the ICFVL must be installed 4" minimum

(see General Note above) Incorrect

below the top of the wall. For installations where the Installation

ICFVL is installed less than 4" from the top of the wall

Typical Wood Ledger Installation

(including flush), multiply the allowable loads by 0.94.

with ICFVL and ICFVL-W

(ICFVL-CW for LVL ledger similar)

ICFVL Spacing to Replace Anchor Bolts

Max.

12"

⁄2 " Diameter Bolts

1

⁄8" Diameter Bolts

5

Recommended Max.

12"

12" o.c. 24" o.c. 36" o.c. 48" o.c. 12" o.c. 24" o.c. 36" o.c. 48" o.c. Splicing

48" 48" 48" 48" 48" 48" 48" 48" Installation

(2) 5⁄8" Diameter Bolts ⁄4" Diameter Bolts

3

12" o.c. 24" o.c. 36" o.c. 48" o.c. 12" o.c. 24" o.c. 36" o.c. 48" o.c.

24" 48" 48" 48" 42" 48" 48" 48"

1. This table addresses vertical load applications only.

2. The Designer may specify different spacing based on the load requirements.

3. Spacings are based on perpendicular to grain capacity of bolt in spruce-

pine-fir wood ledger compared to tested value of ICFVL with a maximum

allowable spacing of 48".

4. Connector spacing requirements are based on a CD = 1.00 load duration. Incorrect

Contact Simpson Strong-Tie for alternate load durations. Spliced-Ledger

5. Bolt design values are based on 2015 NDS Table 12E for SPF lumber (SG = Installation

0.42), a minimum 6" anchor embedment, and concrete with f'c = 2,500 psi.

Steel Ledgers

Allowable Loads 1. Use four #14 x 3⁄4" or 1⁄4-14 x 3⁄4", #3 drill point screws (not provided).

(lb.) – ASD 2. Loads apply to ICFs with wall thickness 3 1⁄4" or less.

3. The ICFVL must be installed not less than 4" from the

Vertical Lateral top of the wall to achieve the allowable loads shown.

For installations where the ICFVL is installed less than

1,660 1,525 4" from the top of the wall (including flush applications),

multiply the allowable loads by 0.94.

Ledger ICFVL Spacing to Replace Anchor Bolts

Requires

Thickness 1

⁄2 " Diameter Bolts 5

⁄8" Diameter Bolts four screws at

(mil) 12" o.c. 24" o.c. 12" o.c. 24" o.c. each location.

68 mil (0.068") 11" 22" 9" 18" Table provides

on-center spacing. O.C.

spac

54 mil (0.054") 15" 30" 12" 24" ing

1. This table addresses vertical load applications only.

2. For steel ledgers, the ICFVL spacing is closer for 68 mil ledgers than

for 54 mil ledgers because the calculated load for the bolt is greater Typical Steel Ledger Installation with ICFVL

for a thicker member than for a thinner member. (minimum 16 gauge, 54 mil steel ledger)

3. Steel ledger values are based on steel. Fu = 60 ksi.

© 2019 Simpson Strong-Tie Company Inc. F-C-ICFVL19

ICF Connectors

The following spacing tables are an alternative to the ICFVL spacing to replace anchor bolts tables or allowable

loads on page 5. They give the spacing of the ICFVL Ledger Connectors based on the allowable vertical load

of the connector, the load on the floor and the span of the joists. The Designer must determine the design load,

the ledger design and joist design. This table is useful if the Designer already has loads and spans, but not

necessarily anchor bolt spacing.

Uniform Loads ICFVL Spacing for SPF Wood Ledger (in.)

Dead Load Live Load Joist Span (ft.)

(psf) (psf) 10 12 14 16 18 20 22 24 26 28

10 40 48 48 48 48 48 47 42 39 36 33

15 40 48 48 48 48 47 42 38 35 33 30

20 40 48 48 48 48 43 39 35 32 30 28

10 60 48 48 48 42 37 33 30 28 26 24

20 60 48 48 42 36 32 29 26 24 22 21

30 60 48 43 37 32 29 26 24 22 20 18

40 60 47 39 33 29 26 23 21 19 18 17

10 100 42 35 30 26 24 21 19 18 16 15

20 100 39 32 28 24 22 19 18 16 15 14

See notes below.

Uniform Loads ICFVL Spacing for Steel Ledger (in.) – 54 mil

Dead Load Live Load Joist Span (ft.)

(psf) (psf) 1. Spacing tables address vertical load

10 12 14 16 18 20 22 24 26 28 applications only. If the connection is

designed to resist simultaneous

10 40 48 48 48 48 44 40 36 33 31 28

lateral loads, spacing may decrease.

15 40 48 48 48 45 40 36 33 30 28 26 Contact Simpson Strong-Tie

for additional information.

20 40 48 48 47 42 37 33 30 28 26 24 2. Values shown are maximum spacing

10 60 48 47 41 36 32 28 26 24 22 20 distances (in.) based on simple span,

uniformly loaded conditions and do

20 60 48 42 36 31 28 25 23 21 19 18 not consider concentrated loads.

30 60 44 37 32 28 25 22 20 18 17 16 3. Joist and ledger are to be designed

by others.

40 60 40 33 28 25 22 20 18 17 15 14 4. Allowable loads are based on testing,

with no further increases allowed.

10 100 36 30 26 23 20 18 16 15 14 13

20 100 33 28 24 21 18 17 15 14 13 12

Alternative Retrofit Solution for Direct Attachment of Joist to Wall

The HU and HUC hangers are heavy-duty face-mount joist hangers

made from 14-gauge galvanized steel. These hangers can be directly

attached to concrete wall using 1⁄4" x 1 3⁄4" Simpson Strong-Tie® Titen® 2

hex-head screws. See strongtie.com for more information on

installation and use.

Simpson Strong-Tie offers many retrofit products for attaching wood

or steel framing members to concrete. For expanded details contact us

at (800) 999-5099 and request the current Anchoring, Fastening and

Restoration Systems for Concrete and Masonry catalog, or visit the

Simpson Strong-Tie website at strongtie.com. HUC410 Installed on Face of

Concrete in ICF

This flier is effective until June 30, 2021, and reflects information available as of May 1, 2019.

This information is updated periodically and should not be relied upon after June 30, 2021. (800) 999-5099

Contact Simpson Strong-Tie for current information and limited warranty or see strongtie.com.

strongtie.com

© 2019 Simpson Strong-Tie Company Inc. • P.O. Box 10789, Pleasanton, CA 94588 F-C-ICFVL19 5/19 exp. 6/21

You might also like

- Jet Boat, New Thrills Afloat With ThisDocument16 pagesJet Boat, New Thrills Afloat With ThisJim50% (2)

- Pocket Guide to Flanges, Fittings, and Piping DataFrom EverandPocket Guide to Flanges, Fittings, and Piping DataRating: 3.5 out of 5 stars3.5/5 (22)

- Interview QPDocument6 pagesInterview QPManasa RamananNo ratings yet

- Cell DivisionDocument70 pagesCell Divisioncandice swanepoel100% (2)

- Irreantum, Volume 13, No. 1, 2011Document136 pagesIrreantum, Volume 13, No. 1, 2011Association for Mormon LettersNo ratings yet

- 2016 - UKG - Active Starter - QPs PDFDocument40 pages2016 - UKG - Active Starter - QPs PDFKrishna Ck100% (1)

- Notes On Complexity (Neil Theise) (Z-Library)Document151 pagesNotes On Complexity (Neil Theise) (Z-Library)Nadir Khan100% (1)

- Lecture Plate Girder Intro DSS 2Document37 pagesLecture Plate Girder Intro DSS 2Amarendra KojjaNo ratings yet

- Sample Completed Performance AppraisalDocument6 pagesSample Completed Performance AppraisalMichael Bob0% (1)

- Amvic ICF Pool 10 Step Construction GuideDocument2 pagesAmvic ICF Pool 10 Step Construction GuidedanNo ratings yet

- Banana Man EssayDocument2 pagesBanana Man EssayAngelo 'alex' Beckles100% (2)

- Structure Details FOR Foundation: Practical Architectural Training-Fun Begins (For Interns and Freshers)Document37 pagesStructure Details FOR Foundation: Practical Architectural Training-Fun Begins (For Interns and Freshers)Divya Varshney100% (1)

- 190159-222685 LebusDocument28 pages190159-222685 Lebussangwoo jungNo ratings yet

- Q3.similarity of FiguresDocument4 pagesQ3.similarity of FiguresEaster Florenda Tolentino-BuenaflorNo ratings yet

- Amvic ICF ICF AccessoriesDocument2 pagesAmvic ICF ICF AccessoriesdanNo ratings yet

- CA4 CG15 Cable Suspension Install For Glass ShelvesDocument2 pagesCA4 CG15 Cable Suspension Install For Glass ShelvesRoger LandivarNo ratings yet

- Kim Lighting AFL2 Series Architectural Floodlights Brochure 1995Document32 pagesKim Lighting AFL2 Series Architectural Floodlights Brochure 1995Alan MastersNo ratings yet

- MA-1456 Elliptipar Mounting InstructionDocument1 pageMA-1456 Elliptipar Mounting InstructionJonathan BaileyNo ratings yet

- 1615 KaruzaMaulHinkley FFCinPicosatellitesDocument16 pages1615 KaruzaMaulHinkley FFCinPicosatellitesMuhammad SyafiiNo ratings yet

- Land Hang Off: Technical Information SheetDocument2 pagesLand Hang Off: Technical Information SheetPredrag MileticNo ratings yet

- Obsolete Ac Power ConnectorsDocument5 pagesObsolete Ac Power ConnectorsdavemcguireNo ratings yet

- Condulets Galco PDFDocument6 pagesCondulets Galco PDFCesar ArroyoNo ratings yet

- Extended End Plate ConnectionDocument9 pagesExtended End Plate ConnectionMoe Oo HtunNo ratings yet

- Fiber Cable Preparation, Splicing, and Termination InstructionsDocument8 pagesFiber Cable Preparation, Splicing, and Termination InstructionsHunaAdjaganNo ratings yet

- The Zl2bmi DSB Transceiver Introduction 2Document9 pagesThe Zl2bmi DSB Transceiver Introduction 2jlnlimaNo ratings yet

- Combi-Wall Systems: Connection: Pbs - F/M BBS-F/M PZ Flanges Wof/Wom Intermediate PileDocument20 pagesCombi-Wall Systems: Connection: Pbs - F/M BBS-F/M PZ Flanges Wof/Wom Intermediate Pilemevice63No ratings yet

- Crouse Hinds Industrial FittingsDocument166 pagesCrouse Hinds Industrial FittingsJonathan FerueloNo ratings yet

- F TrayDocument7 pagesF TrayprimaryrateNo ratings yet

- LH-3000 InterconnectDocument3 pagesLH-3000 InterconnecttuyenNo ratings yet

- DFK, VDFK, HDFK Feed-Through Terminal Blocks: General InformationDocument24 pagesDFK, VDFK, HDFK Feed-Through Terminal Blocks: General InformationMohammad UsmanNo ratings yet

- 1485-In001 - En-P KwikLink General Purpose DeviceNet Media Installation InstructionsDocument4 pages1485-In001 - En-P KwikLink General Purpose DeviceNet Media Installation InstructionsjoseNo ratings yet

- Datasheet - Pig Signallers: Product Description and FunctionsDocument2 pagesDatasheet - Pig Signallers: Product Description and FunctionsMurli ramchandranNo ratings yet

- The Zl2bmi DSB Transceiver Introduction 2Document9 pagesThe Zl2bmi DSB Transceiver Introduction 2NickEglezosNo ratings yet

- 110 Block Termination Instructions For Feeder Pair Cabling.Document4 pages110 Block Termination Instructions For Feeder Pair Cabling.Victor L. HartNo ratings yet

- Lap Splices and Dowels TB5 091417Document4 pagesLap Splices and Dowels TB5 091417Sathiyaseelan /Prin.Des.Mgr.No ratings yet

- Installation Instructions Power Cat 6A Data Gate Shielded Patch PanelDocument6 pagesInstallation Instructions Power Cat 6A Data Gate Shielded Patch PanelflyingcowintheskyNo ratings yet

- History of Fibre Optics ConnectorsDocument4 pagesHistory of Fibre Optics ConnectorseemirojNo ratings yet

- Flanges PDFDocument9 pagesFlanges PDFDGG2010No ratings yet

- Fiberlign Dead-End For OPGWDocument3 pagesFiberlign Dead-End For OPGWJoan Andres Coulson SanchezNo ratings yet

- Porta Fusible Canister para 34.5 KVDocument24 pagesPorta Fusible Canister para 34.5 KVjryamNo ratings yet

- K StageDocument8 pagesK Stagedeco lombNo ratings yet

- Cabinet Manufacturing TipsDocument132 pagesCabinet Manufacturing TipsTarek KhafagaNo ratings yet

- Seismic Bracing Cable TrifoldDocument2 pagesSeismic Bracing Cable TrifoldingcarlosgonzalezNo ratings yet

- Catalog LWNDocument36 pagesCatalog LWNPralhadNo ratings yet

- McCoy VFO PDFDocument17 pagesMcCoy VFO PDFFrancisco J. Aguilera HiguereyNo ratings yet

- McCoy VFODocument17 pagesMcCoy VFOFrancisco J. Aguilera HiguereyNo ratings yet

- Chapter 10 PDFDocument56 pagesChapter 10 PDFAdolfo ElizondoNo ratings yet

- WincroDocument20 pagesWincromdavies20No ratings yet

- Sylvania Twist-Pak Post Top Decorator Models Spec SheetDocument2 pagesSylvania Twist-Pak Post Top Decorator Models Spec SheetAlan MastersNo ratings yet

- Manual Cartão VickersDocument7 pagesManual Cartão VickersWesley SilvaNo ratings yet

- Composite Steel Formwork System: Outline of Live-End Anchorage PocketDocument30 pagesComposite Steel Formwork System: Outline of Live-End Anchorage PocketJames MizziNo ratings yet

- JVC GR Sxm38u Manual de UsuarioDocument24 pagesJVC GR Sxm38u Manual de UsuarioerikvidalagNo ratings yet

- Optical Fiber Fusion Splicer: NoriyukiDocument5 pagesOptical Fiber Fusion Splicer: NoriyukiPrince JoseNo ratings yet

- ADSS Tab 3 - HDWR Assembly InstructionsDocument9 pagesADSS Tab 3 - HDWR Assembly InstructionsramsesiNo ratings yet

- 04 - WindpostsDocument1 page04 - WindpostsPauloRobertoLiñanFigueiredoNo ratings yet

- Quickfit Coupling Adaptors IOM-GB IT 06-2017Document8 pagesQuickfit Coupling Adaptors IOM-GB IT 06-2017PawelNo ratings yet

- KF750F SpecificacionesDocument2 pagesKF750F SpecificacionesMarcus VinicyusNo ratings yet

- Module 1 Topic 3Document28 pagesModule 1 Topic 3Salt PapiNo ratings yet

- 2-Flange Tunnel Liner Plate Design Guide: 2nd EditionDocument20 pages2-Flange Tunnel Liner Plate Design Guide: 2nd Editionjuancaf773557No ratings yet

- Crouse Hinds LCC Cable Tray Clamps Catalog PageDocument1 pageCrouse Hinds LCC Cable Tray Clamps Catalog Pageadibella77No ratings yet

- Manual EAW KF750FDocument20 pagesManual EAW KF750FMarcus VinicyusNo ratings yet

- Product Data Sheet Lighting Fixture Hangers Accessories Appleton en 6573280Document16 pagesProduct Data Sheet Lighting Fixture Hangers Accessories Appleton en 6573280pablo ignacio cancino molinaNo ratings yet

- SFA6 (SS) Slipfitter Adapter IF 1251: Installation & Maintenance InformationDocument6 pagesSFA6 (SS) Slipfitter Adapter IF 1251: Installation & Maintenance Informationbeimar_nalNo ratings yet

- Design 50 - AtAGlance2020 - DOWNLOADDocument2 pagesDesign 50 - AtAGlance2020 - DOWNLOADlizukyNo ratings yet

- Eurobase: Shallow Bases and AccessoriesDocument4 pagesEurobase: Shallow Bases and AccessoriesFranciscoVicenteNo ratings yet

- Lapp LeRoy Catalog C-1 12-01-2017 PDFDocument14 pagesLapp LeRoy Catalog C-1 12-01-2017 PDFdeltaNo ratings yet

- 5 Inch "Ultra Light" FSL Antenna: Maximum Am-Dxing Performance From A Minimal PackageDocument12 pages5 Inch "Ultra Light" FSL Antenna: Maximum Am-Dxing Performance From A Minimal PackageTariq MahmoodNo ratings yet

- Legal Theory IIDocument6 pagesLegal Theory IIDaniyal sirajNo ratings yet

- MM2 Assignment Group1Document14 pagesMM2 Assignment Group1Abhijit RoyNo ratings yet

- Quality of Work LifeDocument10 pagesQuality of Work LifeAzula AzulaNo ratings yet

- Wilhelmine Schröder-Devrient: A Woman of Bravery and CourageDocument5 pagesWilhelmine Schröder-Devrient: A Woman of Bravery and CourageAndres Felipe LosadaNo ratings yet

- Approximate Calculation of U-Shaped BellowsDocument5 pagesApproximate Calculation of U-Shaped BellowsGicuNo ratings yet

- Mutoh PhotoPrintDX10 SpectoVue ProfilingDocument12 pagesMutoh PhotoPrintDX10 SpectoVue ProfilingДенис ЛобачевскийNo ratings yet

- Effectiveness of Model (Latest) PDFDocument9 pagesEffectiveness of Model (Latest) PDFDhani Shanker ChaubeyNo ratings yet

- Amy LowellDocument4 pagesAmy LowellRatnakar KoliNo ratings yet

- Human Nature 060522Document39 pagesHuman Nature 060522Милена МиленаNo ratings yet

- 2021 CGV LPU REM 2 THQ No. 4Document2 pages2021 CGV LPU REM 2 THQ No. 4Susannie AcainNo ratings yet

- PetrifiedDocument13 pagesPetrifiedMarta GortNo ratings yet

- Annotated BibliographyDocument7 pagesAnnotated Bibliographyjenicaq820No ratings yet

- If at Faust You Don't Succeed - Roger ZelaznyDocument4 pagesIf at Faust You Don't Succeed - Roger ZelaznyВекослав СтефановскиNo ratings yet

- Daily Lesson Log in Science Grade 9 THIRD QUARTER S.Y. 2019-2020 November 6, 2019 / WEDNESDAY Bernadette L. MacadangdangDocument1 pageDaily Lesson Log in Science Grade 9 THIRD QUARTER S.Y. 2019-2020 November 6, 2019 / WEDNESDAY Bernadette L. MacadangdangBernadette L. MacadangdangNo ratings yet

- Science Module 2Document6 pagesScience Module 2Christian Lazatin SabadistoNo ratings yet

- Test Bank For Understanding Management 11th EditionDocument35 pagesTest Bank For Understanding Management 11th Editiondidym.moate.i4f28100% (31)

- ColleyDocument8 pagesColleyPetra KarmelićNo ratings yet

- 5late Childhood Development PowerPoint PresentationDocument13 pages5late Childhood Development PowerPoint PresentationDanilo BrutasNo ratings yet

- 07 - Convective Heat TransferDocument75 pages07 - Convective Heat TransferMerazka FaroukNo ratings yet

- Johari WindowDocument5 pagesJohari WindowNikita OjhaNo ratings yet

- Lecture 10 Parts of A PlantDocument6 pagesLecture 10 Parts of A PlantkedeshiaNo ratings yet

- 830-00990-13 Configuration Guide For Software Version 1.14.1Document396 pages830-00990-13 Configuration Guide For Software Version 1.14.1gglaze1No ratings yet