Professional Documents

Culture Documents

Apply The E.C.R.S. Technique and Identify Improvement Actions: Mechanise Some Movements

Uploaded by

Rahul RawatOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Apply The E.C.R.S. Technique and Identify Improvement Actions: Mechanise Some Movements

Uploaded by

Rahul RawatCopyright:

Available Formats

Apply the E.C.R.S.

technique and identify improvement

actions: mechanise some movements

Plant:

One Point Lesson (OPL) WCOM™

Basic Knowledge Problem Improvement N°

Filled by: Date:

ISW ISW

Before E C R S After

OSW OSW

Problem: Difficulty in changing the drum height Improvement: Pneumatic system to lift the drum up

Results: It is possible to change the drum height rapidly and without physical efforts

Training date - - - - - - - -

Trainer - - - - - - - -

Trainee - - - - - - - -

Opl ECRS_S Solving Efeso © 1999 -1-

Apply the E.C.R.S. technique and identify improvement

actions: rapid clamps

Plant:

One Point Lesson (OPL) WCOM™

Basic Knowledge Problem Improvement N°

Filled by: Date:

Before E C R S After

stop

stop

mould

Pressure

closing

system

Reduction of the number of parts for a single screw-less mould

change

Problem: the mould change requires unscrewing 6 bolts Improvement: two stops and a pressure closing system simplify

the operation

Results: the mould change takes 5 minutes less

Training date - - - - - - - -

Trainer - - - - - - - -

Trainee - - - - - - - -

Opl ECRS_S Solving Efeso © 1999 -2-

Apply the E.C.R.S. technique and identify improvement

actions: rapid centring systems

Plant:

One Point Lesson (OPL) WCOM™

Basic Knowledge Problem Improvement N°

Filled by: Date:

Before E C R S After

U-shaped slot

shape

shape

base base

Problem: to change the shape it is necessary to unscrew and Improvement: A U shape slot allows changing the shape

remove the bolt that connects it to the first base by simply loosening the tightening bolt

Results: The set- up time takes one minute less per bolt

Training date - - - - - - - -

Trainer - - - - - - - -

Trainee - - - - - - - -

Opl ECRS_S Solving Efeso © 1999 -3-

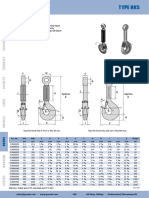

ECRS_S - Opl

Plant:

One Point Lesson (OPL) WCOM™

Basic Knowledge Problem Improvement N°

Filled by: Date:

E C R S

Slacken by means of a 6-mm Allen wrench

the two fixing screws of the first roll on the

left so much so as to lift by 2-3 mm and to

remove the support of the roll from the

slot, pushing the support itself backwards.

Insert the screws of the roll supports into

the slots and pull towards oneself until the

fork support is inserted. Tighten the

screws and repeat the operations

described for all the rolls (except for the

central one which is fixed)

Training date - - - - - - - -

Trainer - - - - - - - -

Trainee - - - - - - - -

Opl ECRS_S Solving Efeso © 1999 -4-

ECRS_S - Opl

Plant:

One Point Lesson (OPL) WCOM™

Basic Knowledge Problem Improvement N°

Filled by: Date:

Before E C R S After

I wish I had another pair of hands Well, this is very handy!

Problem: Awkward equipment changes Improvement: Band fitted to retain machine parts

Results: Reduced set-up time, elimination of tools, accurate setting

Training date - - - - - - - -

Trainer - - - - - - - -

Trainee - - - - - - - -

Opl ECRS_S Solving Efeso © 1999 -5-

ECRS_S - Opl

Plant:

One Point Lesson (OPL) WCOM™

Basic Knowledge Problem Improvement N°

Filled by: Date:

Before E C R S After

chuck chuck

Problem: Head alignment in an uncomfortable position behind the Improvement: Blocking position more comfortable and manual steering

machine (spanner needed) wheels mounted (no spanner needed)

Results: Set-up time reduction

Training date - - - - - - - -

Trainer - - - - - - - -

Trainee - - - - - - - -

Opl ECRS_S Solving Efeso © 1999 -6-

ECRS_S - Opl

Plant:

One Point Lesson (OPL) WCOM™

Basic Knowledge Problem Improvement N°

Filled by: Date:

Before E C R S After

Size check

Size check

Position square

Max gap 1,5 mm

Check that the two ends Check of the gap 1,5 mm Graduated line

are at the same level

Meter Meter

Problem: Need for two checks: Size check of the U-bent resistances and Improvement: Checks facilitated

check of ends’ level

Results: Adjustment and retrieval time reduction

Training date - - - - - - - -

Trainer - - - - - - - -

Trainee - - - - - - - -

Opl ECRS_S Solving Efeso © 1999 -7-

ECRS_S - Opl

Plant:

One Point Lesson (OPL) WCOM™

Basic Knowledge Problem Improvement N°

Filled by: Date:

Before E C R S After

Cup Stake of ABC 3755/7 - 5 type

Hexagonal spanner

Grain

Cone

Extraction

New cone

Problem: To replace the cutting cone it is necessary to unscrew two Improvement: To replace the cutting cone, one just has to lift the

grains. Time waste because the screws are hidden and in an detachment stake and to extract the cone without using any tools

uncomfortable position

Results: Set-up time reduced from 80 sec. to 10 sec. and lower cone building costs (for minor works)

Training date - - - - - - - -

Trainer - - - - - - - -

Trainee - - - - - - - -

Opl ECRS_S Solving Efeso © 1999 -8-

ECRS_S - Opl

Plant:

One Point Lesson (OPL) WCOM™

Basic Knowledge Problem Improvement N°

Filled by: Date:

Before E C R S After

Insert (new)

New main block

Insert

Ray closing mould

Screw

Main block

Problem: To replace the insert of the main block, it is necessary to Improvement: To replace the insert of the main block one just has to

remove the ray closing mould and to unscrew the screw by means of a extract it from its seat without any tool and without taking the ray

spanner closing mould out

Results: Set-up time reduced from 180 sec. to 10 sec

Training date - - - - - - - -

Trainer - - - - - - - -

Trainee - - - - - - - -

Opl ECRS_S Solving Efeso © 1999 -9-

ECRS_S - Opl

Plant:

One Point Lesson (OPL) WCOM™

Basic Knowledge Problem Improvement N°

Filled by: Date:

Before E C R S After

Adjustable retainer

To remove

To insert

Ball grain

Letter-holder

Letter-holder slides

Problem: To replace the letter-holder, it is necessary to move the Improvement: Slides replaced and letter-holder mounted on a new one

retainer, to extract the letter-holder, to insert a new one and to move the with ball grains. To replace the letter-holder, just lift it up and rotate slightly

retainer forth

Results: Set-up time to replace the letter-holder reduced from 20 sec to 5 sec

Training date - - - - - - - -

Trainer - - - - - - - -

Trainee - - - - - - - -

Opl ECRS_S Solving Efeso © 1999 - 10 -

ECRS_S - Opl

Plant:

One Point Lesson (OPL) WCOM™

Basic Knowledge Problem Improvement N°

Filled by: Date:

Before E C R S After

Problem: Device adjusted by trial and error Improvement: Handles and counters mounted

Results: Adjustment time reduction

Training date - - - - - - - -

Trainer - - - - - - - -

Trainee - - - - - - - -

Opl ECRS_S Solving Efeso © 1999 - 11 -

ECRS_S - Opl

Plant:

One Point Lesson (OPL) WCOM™

Basic Knowledge Problem Improvement N°

Filled by: Date:

Before E C R S After

Problem: Too much time to fix the ring Improvement: Fixing hole modified

Results: Reduction of the replacement time

Training date - - - - - - - -

Trainer - - - - - - - -

Trainee - - - - - - - -

Opl ECRS_S Solving Efeso © 1999 - 12 -

ECRS_S - Opl

Plant:

One Point Lesson (OPL) WCOM™

Basic Knowledge Problem Improvement N°

Filled by: Date:

Before E C R S After

Problem: Too much time to change position Improvement: Pneumatic screwdriver adopted

Results: Reduction in the time to replace positions

Training date - - - - - - - -

Trainer - - - - - - - -

Trainee - - - - - - - -

Opl ECRS_S Solving Efeso © 1999 - 13 -

You might also like

- Portal Frame Design ExampleDocument92 pagesPortal Frame Design Examplekstayrosk100% (7)

- Operational Excellence A Complete Guide - 2019 EditionFrom EverandOperational Excellence A Complete Guide - 2019 EditionRating: 1 out of 5 stars1/5 (1)

- 0 Target Kmi, Kpi & Kai Linkage-FinalDocument8 pages0 Target Kmi, Kpi & Kai Linkage-FinalJagdish PalariyaNo ratings yet

- Slide TPM SHEDocument14 pagesSlide TPM SHEhdjdjNo ratings yet

- Vibration Roller Assembly Parts CatalogDocument220 pagesVibration Roller Assembly Parts Catalognkr4726923100% (3)

- Lasco Shower Pan InstallationDocument4 pagesLasco Shower Pan InstallationKen O'ConnellNo ratings yet

- TPMDocument34 pagesTPMJagdeep BajwaNo ratings yet

- WCM - Re-Engineering Rethinking Business ProcessesDocument54 pagesWCM - Re-Engineering Rethinking Business ProcessesPrashant KadamNo ratings yet

- Chapter 6. Education & Training ManualDocument23 pagesChapter 6. Education & Training ManualVivek KumarNo ratings yet

- FMEA Methodology for Quality Improvement in Sheet Metal IndustryDocument5 pagesFMEA Methodology for Quality Improvement in Sheet Metal IndustryDanistergladwinNo ratings yet

- E & Tpillar: Education & Training Pillar ActivitiesDocument21 pagesE & Tpillar: Education & Training Pillar Activitiessamkaria rajeshNo ratings yet

- Study of JH Implementation ReadyDocument27 pagesStudy of JH Implementation ReadyNaveen Jangid100% (1)

- World Class Manufacturing - Workplace Organization (151 Pages)Document151 pagesWorld Class Manufacturing - Workplace Organization (151 Pages)Gwladys BettoNo ratings yet

- JH PPT 18.12.20Document46 pagesJH PPT 18.12.20MAngesh Gade0% (1)

- 5S Visual Management Jun-20Document73 pages5S Visual Management Jun-20Vipul JhaNo ratings yet

- SHE Pillar Activities Chapter-11 Internal Safety ProcessDocument9 pagesSHE Pillar Activities Chapter-11 Internal Safety Processsamkaria rajeshNo ratings yet

- Quality Maintenance Training Programme: Concept & ImplementationDocument46 pagesQuality Maintenance Training Programme: Concept & Implementationdeepak sharmaNo ratings yet

- Autonomous Maintenance: Am-Sw RTT Cil With Routes DmsDocument14 pagesAutonomous Maintenance: Am-Sw RTT Cil With Routes DmsAsanka ChathurangaNo ratings yet

- JH TrainingDocument218 pagesJH TrainingMAngesh GadeNo ratings yet

- WCM BasicsDocument75 pagesWCM BasicsHrishikesh WaghNo ratings yet

- Autonomous Maintenance Step 4 Lubrication ModuleDocument30 pagesAutonomous Maintenance Step 4 Lubrication ModulejesusmemNo ratings yet

- TPM Oficinas-Unilever 1Document20 pagesTPM Oficinas-Unilever 1soydejesusNo ratings yet

- JH Step-1 & 2activitiesDocument34 pagesJH Step-1 & 2activitiesGREENEXE BUSINESS CONSULTANTNo ratings yet

- 16 LossesDocument9 pages16 LossesMuthu Vellayappan100% (1)

- Training ON TPM: Rapl Production SystemDocument25 pagesTraining ON TPM: Rapl Production Systemabhijit bhattacherjeENo ratings yet

- Kaizen KobetDocument19 pagesKaizen KobetShubham SharmaNo ratings yet

- WCM Tofas 2012 EngDocument11 pagesWCM Tofas 2012 Engjames007bondsgNo ratings yet

- SKILL MATRIX StaffDocument3 pagesSKILL MATRIX StaffMAHIPAL baseraNo ratings yet

- TPM Over ViewDocument37 pagesTPM Over ViewHarshad_SNo ratings yet

- Step 0 and 1 Management Part 1Document14 pagesStep 0 and 1 Management Part 1murilocabriniNo ratings yet

- Processing Point AnalysisDocument35 pagesProcessing Point AnalysisSophanNo ratings yet

- Maximizing Knowledge Sharing with One Point Lessons (OPLsDocument4 pagesMaximizing Knowledge Sharing with One Point Lessons (OPLsRakesh TigadiNo ratings yet

- Autonomous Maintenance: CIL DMS Owner Step-Up CardDocument2 pagesAutonomous Maintenance: CIL DMS Owner Step-Up CardAsanka ChathurangaNo ratings yet

- KK PillarDocument30 pagesKK PillarshaktiNo ratings yet

- 5S Best PracticeDocument85 pages5S Best PracticeyogshastriNo ratings yet

- World Class ManufacturingDocument16 pagesWorld Class ManufacturingAmulya KaliaNo ratings yet

- Professional MaintenanceDocument391 pagesProfessional MaintenanceAimar Vanderlei Ferreira Filho100% (1)

- JH - Hta & SocDocument31 pagesJH - Hta & SocAnkurNo ratings yet

- JH - Kaizen Training ModuleDocument19 pagesJH - Kaizen Training Moduleshariq warsiNo ratings yet

- 00the 7 MFG WasteDocument15 pages00the 7 MFG WasteRohit PrakashNo ratings yet

- Focused Improvement PillarDocument19 pagesFocused Improvement PillarDkhissene ImadNo ratings yet

- Autonomous Maintenance Step 3 Audit SheetDocument6 pagesAutonomous Maintenance Step 3 Audit Sheetrecep1No ratings yet

- TPM Step 3 Audit Ensures Alignment to StandardsDocument6 pagesTPM Step 3 Audit Ensures Alignment to StandardsDũng Tây NinhNo ratings yet

- TPM JH Pillar Autonomous MaintenanceDocument39 pagesTPM JH Pillar Autonomous MaintenanceshaktiNo ratings yet

- 01.21 Implementation PhasesDocument2 pages01.21 Implementation PhasesSathish Kumar PNo ratings yet

- TPM and The Extended Supply Chain: Tetra Pak Production D.O.O. Gornji Milanovac, Serbia London, Nov 2016Document36 pagesTPM and The Extended Supply Chain: Tetra Pak Production D.O.O. Gornji Milanovac, Serbia London, Nov 2016Hossam Abdel AzizNo ratings yet

- Office (Eng)Document31 pagesOffice (Eng)kingathur26681No ratings yet

- World Class Manufacturing FinalDocument22 pagesWorld Class Manufacturing Finalshreepal19No ratings yet

- E.C.R.S.: Problem Solving ToolsDocument10 pagesE.C.R.S.: Problem Solving ToolsRahul RawatNo ratings yet

- What is OEEDocument33 pagesWhat is OEERoshan YaduwanshiNo ratings yet

- Chapter 10. Initial Flow Control ManualDocument10 pagesChapter 10. Initial Flow Control ManualVivek KumarNo ratings yet

- 5S TrainingDocument29 pages5S TrainingponNo ratings yet

- Autonomous Maintenance Step 1 7Document18 pagesAutonomous Maintenance Step 1 7Dũng Tây NinhNo ratings yet

- Environment EventDocument90 pagesEnvironment EventRonald Abadi TariganNo ratings yet

- Daily Management Quiz: 2007: SN Question Option A Option B Option C Option D AnswerDocument5 pagesDaily Management Quiz: 2007: SN Question Option A Option B Option C Option D AnswerPrakash Kumar50% (2)

- ECRS - R - Opl: One Point Lesson (OPL)Document2 pagesECRS - R - Opl: One Point Lesson (OPL)Rahul RawatNo ratings yet

- Apply The E.C.R.S. Technique and Identify Improvement Actions: Creation of A Transport KitDocument1 pageApply The E.C.R.S. Technique and Identify Improvement Actions: Creation of A Transport KitRahul RawatNo ratings yet

- Development Modification Phase(s) : Unit/Train: Discipline: HSE System No.: Subsystem No.Document10 pagesDevelopment Modification Phase(s) : Unit/Train: Discipline: HSE System No.: Subsystem No.pankajbhatt376No ratings yet

- Feedback Control System DesignDocument7 pagesFeedback Control System DesignPindi BoyNo ratings yet

- CCS CMCS 611-101 Advanced Computer Architecture Advanced Computer ArchitectureDocument24 pagesCCS CMCS 611-101 Advanced Computer Architecture Advanced Computer Architecturejamal009100% (2)

- Finite Element Analysis of Bonded Repairs and Analysis Methods For The ASIP EngineerDocument38 pagesFinite Element Analysis of Bonded Repairs and Analysis Methods For The ASIP EngineerpuhumightNo ratings yet

- Don Bosco TVET Center Session PlanDocument4 pagesDon Bosco TVET Center Session PlanJuliet N. CoronadoNo ratings yet

- ExamplesDocument5 pagesExamplesRahul RawatNo ratings yet

- ECRS - E - Opl: One Point Lesson (OPL)Document3 pagesECRS - E - Opl: One Point Lesson (OPL)Rahul RawatNo ratings yet

- Ecrs On Maintenance Tasks ExerciseDocument3 pagesEcrs On Maintenance Tasks ExerciseRahul RawatNo ratings yet

- Questionnaire for High Rise Building Fire Safety RequirementsDocument12 pagesQuestionnaire for High Rise Building Fire Safety RequirementsRahul RawatNo ratings yet

- Ecrs - Set Up Tasks OptimisationDocument6 pagesEcrs - Set Up Tasks OptimisationRahul RawatNo ratings yet

- Company Limited: Claim For Reimbursement of Motor Car Running ExpensesDocument1 pageCompany Limited: Claim For Reimbursement of Motor Car Running ExpensesRahul RawatNo ratings yet

- 3844-Internal Fire Hydrants and HoseDocument22 pages3844-Internal Fire Hydrants and HoseSOMU_61100% (1)

- E.C.R.S.: Problem Solving ToolsDocument10 pagesE.C.R.S.: Problem Solving ToolsRahul RawatNo ratings yet

- Is.3034.1993, Fire Code of PracticeDocument24 pagesIs.3034.1993, Fire Code of PracticeRahul RawatNo ratings yet

- Employee HandbookDocument34 pagesEmployee HandbookRahul RawatNo ratings yet

- Hazardous Chemicals RulesDocument58 pagesHazardous Chemicals RulessyamiocNo ratings yet

- What Is Run ChartDocument16 pagesWhat Is Run ChartVijay NaikNo ratings yet

- In Accordance With The Plans Submitted With It.: Form Br-IiiDocument1 pageIn Accordance With The Plans Submitted With It.: Form Br-IiiRahul RawatNo ratings yet

- 7 QC ToolsDocument81 pages7 QC ToolsRahul Rawat100% (7)

- WCMDocument3 pagesWCMRahul RawatNo ratings yet

- Dodec Spinning Wheel Brochure PDFDocument5 pagesDodec Spinning Wheel Brochure PDFamanda grovesNo ratings yet

- (04-01) - StarterDocument3 pages(04-01) - StartereduardoNo ratings yet

- BVD 2044 GBDocument4 pagesBVD 2044 GBMohamed HamadNo ratings yet

- Machine Theory عربيDocument695 pagesMachine Theory عربيahlamNo ratings yet

- Acoplamiento Renold Ajax+VariosDocument96 pagesAcoplamiento Renold Ajax+VariosJuan C. Gonzalez ArayaNo ratings yet

- Deflection Tutorial ProblemsDocument9 pagesDeflection Tutorial Problemsgangs0091No ratings yet

- Weil Mclain Parts Catalog CD Version 2010Document298 pagesWeil Mclain Parts Catalog CD Version 2010123anthonyNo ratings yet

- Built Up SectionDocument48 pagesBuilt Up SectionAboalmaail AlaminNo ratings yet

- Catalogo de Valvulas de Control ArcaDocument28 pagesCatalogo de Valvulas de Control ArcaBere Rhdl0% (1)

- Dom 3151911Document3 pagesDom 3151911Bhagirathsinh ZalaNo ratings yet

- Bridge 2 Raft CalculationDocument3 pagesBridge 2 Raft CalculationAnurag KumarNo ratings yet

- 16 - Hasna Jilan A - Xii TGB 1 - GKB Rab - SKPDocument50 pages16 - Hasna Jilan A - Xii TGB 1 - GKB Rab - SKPHASNA JILANNo ratings yet

- Element 50 Manual 1Document27 pagesElement 50 Manual 1Karvi LapizNo ratings yet

- Lintel and Sunshade DesignDocument17 pagesLintel and Sunshade DesignNikhilNo ratings yet

- Components For Domestic Water Systems: This Diagram Is Just An IndicationDocument22 pagesComponents For Domestic Water Systems: This Diagram Is Just An Indicationravi00098No ratings yet

- DCC20053 - Topic 5 Shear Stress in Beam and Connection 2019Document6 pagesDCC20053 - Topic 5 Shear Stress in Beam and Connection 2019nur hidayah08No ratings yet

- Rov Shank Hooks - GN - Hk5Document2 pagesRov Shank Hooks - GN - Hk5joosuasinagaNo ratings yet

- Terex Rh340 Maintenance TrainingDocument17 pagesTerex Rh340 Maintenance Trainingjicrgz7998100% (2)

- Pre-Amplifier Circuit DiagramDocument2 pagesPre-Amplifier Circuit DiagramrigaboNo ratings yet

- Turb Follow BLR BLR Follow Turb ModeDocument2 pagesTurb Follow BLR BLR Follow Turb ModeĐặng Trung Anh100% (2)

- Welder Qualification PlanDocument3 pagesWelder Qualification PlanphuyangNo ratings yet

- Best Practices in Machinery InstallationDocument2 pagesBest Practices in Machinery InstallationHamzaNoumanNo ratings yet

- Parts List: JTR-MOL254/LBADocument74 pagesParts List: JTR-MOL254/LBAJoseNo ratings yet

- MCON PriceList2014Document22 pagesMCON PriceList2014tengok69No ratings yet

- MOTOR SUN3105E2 MTP 36 KW AT 2300RPM - 67C-P/23: 8574 NW 61 Street MIAMI FL 33166Document38 pagesMOTOR SUN3105E2 MTP 36 KW AT 2300RPM - 67C-P/23: 8574 NW 61 Street MIAMI FL 33166Angel Mendoza RodríguezNo ratings yet

- Metrics For MechanicsDocument63 pagesMetrics For MechanicsAntónio FernandesNo ratings yet

- Uf Module Rack-Rev01Document4 pagesUf Module Rack-Rev01Smit BhivgadeNo ratings yet