Professional Documents

Culture Documents

H Series 4 Installation Checklist: Read This Document Thoroughly and Carefully

Uploaded by

anwar sadatOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

H Series 4 Installation Checklist: Read This Document Thoroughly and Carefully

Uploaded by

anwar sadatCopyright:

Available Formats

TSF1006

H Series 4 Installation Checklist Rev A

Customer Information

Company Name:

Site Address: Series: Capacity: Nm3

/hr

SN: H

Site Contact Name: Title:

Phone:

Cell Phone:

E-mail: Date: MM DD YYYY

READ THIS DOCUMENT THOROUGHLY AND CAREFULLY

Information in this document is provided in connection with Proton Energy Systems Inc. d/b/a Nel Hydrogen

US H Series Hydrogen Generator. This document has been prepared to provide familiarization with Nel

Hydrogen US’s requirements for installation of the H Series Hydrogen Generator and the operation of the H

Series Hydrogen Generator. However, the information in this document is furnished for informational use

only, is subject to change without notice, and should not be construed as a commitment by Nel Hydrogen US.

Nel Hydrogen US assumes no responsibility or liability for any errors or inaccuracies that may appear in this

document.

This document is intended for use only by persons qualified to install and operate the H Series Hydrogen

Generator.

No license, express or implied, by estoppel or otherwise, to any intellectual property rights is granted by this

document. Except as provided in Nel Hydrogen US Terms and Conditions of Sale for such products and

services, Nel Hydrogen US assumes no liability whatsoever, and Nel Hydrogen US disclaims any express or

implied warranty, whether written or oral, relating to sale and/or use of Nel Hydrogen US’s H Series

Hydrogen Generator, including liability or warranties relating to fitness for a particular purpose,

merchantability, or infringement of any patent, copyright or other intellectual property right.

Nel Hydrogen US reserves the right to make changes to this document and the products represented herein

(including, without limitation, specifications and product descriptions) at any time, without notice and

without any obligation or liability whatsoever.

TSF1006 Rev A CONFIDENTIAL – Do not copy PAGE 1 of

7

TSF1006

H Series 4 Installation Checklist Rev A

Overview:

This Installation Checklist document is required to be completed by the Customer and reviewed by Nel

Hydrogen US prior to scheduling a commissioning visit by Nel Hydrogen US or its qualified representatives.

This checklist intends to document the customer’s site installation and site representative review of the

installation. Installation reference information to assist with this checklist can be found in the Installation

and Operations Manual, PD-0100-0040. Sections from the manual are referenced below to assist in the

installation process.

In addition to this Installation Checklist, a SITE SAFETY AND HEALTH HAZARD ASSESSMENT SURVEY (Form:

OFM1005) must be completed and forwarded to Nel Hydrogen US for review prior to scheduling Nel

Hydrogen US representative work activities. OFM1005 and this form shall be forwarded to the email address

noted at the end of the checklist.

Ventilation and Location

Confirmation of Installation Location Ventilation (Manual Section “Facility Ventilation

Requirements”)

Area Ventilation Method of Determination Calculated or Measured Value (with units of

measure)

Installation Location Ventilation Rate

Installation Location (Manual Section “Operating Environment”, “Site Preparation”, “Anchoring

Instructions”)

Description of Installation (Physical Location):

Embed Pictures:

TSF1006 Rev A CONFIDENTIAL – Do not copy PAGE 2 of

7

TSF1006

H Series 4 Installation Checklist Rev A

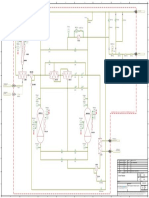

Electrical Interfaces

Electrical Interface (Manual Section “Electrical Interfaces”)

Main Electrical Supply Voltage VAC

Main Electrical Supply Frequency Hz

Main Electrical Source Service Rating supply to the Hydrogen KVA

Generator

YES NO

Main electrical cables routed through side of electrical cabinet per

Installation Manual?

Protective Earth Ground Installed?

Main electrical Supply cables from facility to Hydrogen Generator

reviewed for correct amperage rating per Nameplate?

Electrical Installation per Applicable Codes and Standards

Main electrical interface to hydrogen generator sealed to maintain IP

rating of IP66

Embed Pictures:

Remote Communications and Signals (Manual Section “Customer Control and Indication Connections”

YES NO

Customer Remote E-Stop Connected?

Customer Interlock Connected?

Remote Start Connected?

Remotes Stop Connected?

Remote Shutdown Indicator Connected?

Ethernet / Modbus Connected?

Embed Pictures:

TSF1006 Rev A CONFIDENTIAL – Do not copy PAGE 3 of

7

TSF1006

H Series 4 Installation Checklist Rev A

Mechanical Interfaces

Hydrogen Vent System (Manual Section “H2 Relief Port Interface”)

YES NO

Customer hydrogen vent line routed to safe location away from air

intakes, sources of ignition, personnel, and other potential sources of

hazard in accordance with installation manual.

Customer hydrogen vent system constructed of non-combustible

materials, compatible with hydrogen

Customer condensate drain from customer’s vent system is routed

separately to an air-gapped gravity drain, away from potential sources

of ignition or potential hazard to personnel.

Customer Vent System may be exposed to Freezing Conditions (0°C or

32°F):

If exposed to freezing conditions, the vent line is heat traced to ensure

the line does NOT freeze and obstruct the hydrogen vent.

Customer Vent System has been reviewed by appropriate AHJ and

deemed to NOT impart a back pressure of greater than 0.8 psig at the

hydrogen generator interface at flow rates of 3 times the hydrogen

generator production rate.*

* If the hydrogen generator may be upgraded to a higher production

rate in the future. It is recommended that the future higher

production rate be considered in the vent system design.

Customer Vent system pressure and leak checked to local or national

standard.

Any leaks noted?

Any leaks corrected and verified fixed?

Test Pressure (include Pressure value and units)

Embed Pictures:

TSF1006 Rev A CONFIDENTIAL – Do not copy PAGE 4 of

7

TSF1006

H Series 4 Installation Checklist Rev A

Electrical Cabinet Condensate (Manual Section “Electrical Cabinet Condensate Drain Interface”)

YES NO

Condensate Drain line routed individually to Drip Pan or Air Gapped

(Open) Gravity Drain.

Confirm drain is NOT connected to any source, or potential source, of

hydrogen under normal or failure mode conditions.

Embed Pictures:

Hydrogen Product Line (Manual Section “H2 Product Interface”)

YES NO

Customer product line routed to customer process or capped

Customer product line includes bypass to direct product hydrogen to

customer vent system for maintenance and troubleshooting purposes.

Customer product line pressure and leak checked to local or national

standard.

Any leaks noted?

Any leaks corrected and verified fixed?

Test Pressure (include Pressure value and units)

Embed Pictures:

Cooling Water Inlet (Manual Section “Coolant Water Interfaces”)

YES NO

Customer supplied cooling water inlet supply line/component

materials compatible with Coolant

Proton/NEL Hydrogen supplied Inlet Coolant Isolation Kit Installed

Solenoid valve power cable installed from Coolant Isolation Kit to

Hydrogen Generator

Embed Pictures:

Cooling Water Return (Manual Section “Coolant Water Interfaces”)

TSF1006 Rev A CONFIDENTIAL – Do not copy PAGE 5 of

7

TSF1006

H Series 4 Installation Checklist Rev A

YES NO

Customer supplied cooling water outlet supply line/component

materials compatible with Coolant

Proton/NEL Hydrogen supplied Outlet Coolant Isolation Kit Installed

Embed Pictures:

DI Water Feed (Manual Section “De-Ionized Water Supply Interface”)

YES NO

DI Water supply line/component materials compatible with DI water

DI Water supply pressure at generator interface between 1.5 and 4

Barg (21.8 to 58 psig)

DI water supply traced to source and confirmed as ASTM Type I

(preferred) or Type II source.

Embed Pictures:

DI Water Drain (Manual Section “De-Ionized Water Drain Interface”)

YES NO

DI Water Drain routed to appropriate air gapped gravity drain.

Embed Pictures:

Combustible Gas Detector Calibration Gas

YES NO

2% H2 in Air Calibration Gas Cylinder (P/N: 19-0100-0004) for

TSF1006 Rev A CONFIDENTIAL – Do not copy PAGE 6 of

7

TSF1006

H Series 4 Installation Checklist Rev A

Autocalibration available at site?

Note: The Calibration Gas Cylinder typically ships separately from the

hydrogen generator to the customer’s site.

If the standard calibration gas cylinder is not available, then alternate

source has been secured and available for use? See Maintenance

Manual (P/N: PD-0200-0007) for requirements of the Manual

Calibration.

Explain Alternate Source:

Site Safety Assessment Survey

YES NO

Site Safety and Health Assessment Survey (Form: OFM1005)

completed for submittal with this Installation Checklist.

If the Site Safety Assessment deems the project/job as High Risk then

a written Site (Project/Job) Specific Safety and Health Plan (SSSHP) is

attached for review.

Customer acknowledges they have read and understand the Installation and Operations Manual. Information in

this checklist is accurate and correct

Customer Representative Reviewer: __________________________

Title: __________________________

Submit the completed OFM1005 and this Installation Checklist to

NEL Hydrogen US Technical Service Department at:

techsupport@nelhydrogen.com

Format the email Subject Line per below and include your unit Serial Number:

“OFM1005 and TSF1006: S/N: Hxxxxxxx”

TSF1006 Rev A CONFIDENTIAL – Do not copy PAGE 7 of

7

You might also like

- Axsm 0042Document144 pagesAxsm 0042aliNo ratings yet

- 11.16 Pneumatic/Vacuum (ATA 36) : Basic Maintenance Training Manual Module 11 Aircraft Structures and SystemsDocument14 pages11.16 Pneumatic/Vacuum (ATA 36) : Basic Maintenance Training Manual Module 11 Aircraft Structures and Systemsnajib0% (1)

- O&M Manual SPAC-08N-10NDocument46 pagesO&M Manual SPAC-08N-10Nanwar sadat50% (2)

- 5957 - Sanjay Srivastava - Andritz Hydro PVT LTDDocument13 pages5957 - Sanjay Srivastava - Andritz Hydro PVT LTDroger_peña_7No ratings yet

- Design and Evaluation of Primary Flexible Packaging For Medical ProductsDocument18 pagesDesign and Evaluation of Primary Flexible Packaging For Medical ProductsAlevj DbNo ratings yet

- Swagelok Flexible Metal Hoses MS-01-180Document88 pagesSwagelok Flexible Metal Hoses MS-01-180paula09No ratings yet

- Practical Guides to Testing and Commissioning of Mechanical, Electrical and Plumbing (Mep) InstallationsFrom EverandPractical Guides to Testing and Commissioning of Mechanical, Electrical and Plumbing (Mep) InstallationsRating: 3.5 out of 5 stars3.5/5 (3)

- Hyoffwind Power To Gas End ReportDocument68 pagesHyoffwind Power To Gas End Reportapi-267204600No ratings yet

- P165338A-HPS-1 Rev05Document1 pageP165338A-HPS-1 Rev05Shahzad AhmedNo ratings yet

- 1005 0 Installation ManualDocument65 pages1005 0 Installation ManualKhaledNo ratings yet

- Nel Electrolysers Brochure 2018 PD 0600 0125 Web - 18041145Document9 pagesNel Electrolysers Brochure 2018 PD 0600 0125 Web - 18041145Chaeeon LimNo ratings yet

- Top 2018-03-02 FC Expo Nel FinalDocument37 pagesTop 2018-03-02 FC Expo Nel Finalmsantosu000No ratings yet

- Cummins Hystat 70 SpecsheetDocument2 pagesCummins Hystat 70 SpecsheetamsukdNo ratings yet

- DESMI Self-Priming Centrifugal Pump Operation and Maintenance InstructionDocument20 pagesDESMI Self-Priming Centrifugal Pump Operation and Maintenance InstructiontalabizNo ratings yet

- Annex 1 - Hystat-10 IndoorDocument15 pagesAnnex 1 - Hystat-10 Indoorc108No ratings yet

- Boost High Pressure Air & Nitrogen with bstAIR Compressor LaunchDocument41 pagesBoost High Pressure Air & Nitrogen with bstAIR Compressor LaunchAnonymous mZEUquNo ratings yet

- Hydrogen IcsDocument16 pagesHydrogen IcsVũ PhươngNo ratings yet

- Customer Technical Description Hy - Gen 50 - LDocument18 pagesCustomer Technical Description Hy - Gen 50 - LСтанислав ГрудининNo ratings yet

- H2B2!21!013-MW Scale TechEconProp.0Document57 pagesH2B2!21!013-MW Scale TechEconProp.0ReenNo ratings yet

- Exhaust Air Filter Options for a Gas Purification SystemDocument2 pagesExhaust Air Filter Options for a Gas Purification Systemanwar sadatNo ratings yet

- Exhaust Air Filter Options for a Gas Purification SystemDocument2 pagesExhaust Air Filter Options for a Gas Purification Systemanwar sadatNo ratings yet

- Combine PDFDocument4 pagesCombine PDFMorgan SidesoNo ratings yet

- Comparison of Different Gas Turbine Inlet Air Cooling MethodsDocument6 pagesComparison of Different Gas Turbine Inlet Air Cooling MethodsOmair FarooqNo ratings yet

- Norsok U-Cr-005 Subsea Production Control SystemsDocument25 pagesNorsok U-Cr-005 Subsea Production Control SystemscristianoclemNo ratings yet

- Automated Skid Mounted PlantsDocument22 pagesAutomated Skid Mounted Plantsmaxirey20No ratings yet

- 4000046273-PGCA-EA-C01-002 - C1 - 1 - Liquied FuelDocument6 pages4000046273-PGCA-EA-C01-002 - C1 - 1 - Liquied Fuelrajindo1No ratings yet

- Unesco - Eolss Sample Chapters: Alkaline Water ElectrolysisDocument6 pagesUnesco - Eolss Sample Chapters: Alkaline Water Electrolysisjorge bustosNo ratings yet

- Presentation - HydrogenicsDocument40 pagesPresentation - HydrogenicsAnh NguyenNo ratings yet

- Fuel Cells & Electrolyzers Supply Chain Report - FinalDocument91 pagesFuel Cells & Electrolyzers Supply Chain Report - FinalVishal RastogiNo ratings yet

- AkzoNobel - Hydrogen Peroxide Product Information Manual - December 2015 - tcm56-94028 - 2Document32 pagesAkzoNobel - Hydrogen Peroxide Product Information Manual - December 2015 - tcm56-94028 - 2PungkyRamadhaniPamungkasAminotoNo ratings yet

- Power Plant Design InformationDocument47 pagesPower Plant Design InformationAnonymous gr5Pr9AV100% (1)

- Cummins Hystat 100 SpecsheetDocument2 pagesCummins Hystat 100 SpecsheetamsukdNo ratings yet

- Phase 1 - ITM - GigastackDocument19 pagesPhase 1 - ITM - GigastackamsukdNo ratings yet

- Oil & Gas Valve Types: Gate, Globe, Check, Ball & Butterfly DesignsDocument12 pagesOil & Gas Valve Types: Gate, Globe, Check, Ball & Butterfly DesignsMAHESH CHANDNo ratings yet

- Green Hydrogen: Opportunities in The Energy SystemDocument11 pagesGreen Hydrogen: Opportunities in The Energy SystemAdhi ErlanggaNo ratings yet

- CNG Filling Stations: High Pressure Compressors For Natural Gas Refuelling On Private VehiclesDocument24 pagesCNG Filling Stations: High Pressure Compressors For Natural Gas Refuelling On Private VehiclesAsesoría ContrataciónNo ratings yet

- 005 Hydrogenics Denis Thomas - Electrolyzer Technology of BioCat ProjectDocument26 pages005 Hydrogenics Denis Thomas - Electrolyzer Technology of BioCat ProjectgmolguinpNo ratings yet

- Fiid PumpDocument38 pagesFiid Pumpsridhar100% (1)

- Man Ci 061enDocument4 pagesMan Ci 061enRicardo AzevedoNo ratings yet

- ELS013 - Rev10 - Gen Spec For Fabrication of Composite ThermDocument15 pagesELS013 - Rev10 - Gen Spec For Fabrication of Composite ThermAhmed GomaaNo ratings yet

- Cummins Hylyzer 1000 SpecsheetDocument2 pagesCummins Hylyzer 1000 SpecsheetamsukdNo ratings yet

- M4ET Low Carbon Production Hydrogen RoadmapDocument88 pagesM4ET Low Carbon Production Hydrogen RoadmaptheognisNo ratings yet

- H2 Supply Chain Evidence - Publication VersionDocument126 pagesH2 Supply Chain Evidence - Publication VersionNelly VanessaNo ratings yet

- Blending Hydrogen Into Natural Gas Pipeline Networks: A Review of Key IssuesDocument131 pagesBlending Hydrogen Into Natural Gas Pipeline Networks: A Review of Key IssuesJesseNo ratings yet

- 2 2 2 Hydrogen FuelingDocument16 pages2 2 2 Hydrogen Fuelingsbr4No ratings yet

- Solar Hydrogen ProyectDocument19 pagesSolar Hydrogen ProyectCamilo Ig GoarNo ratings yet

- A1 - Esp002 07 - Especificacao Tecnicas Eletrolisador R0a EnglishDocument12 pagesA1 - Esp002 07 - Especificacao Tecnicas Eletrolisador R0a EnglishbetopagoadaNo ratings yet

- Hydrogenics - Electrolyzer TechnologyDocument39 pagesHydrogenics - Electrolyzer TechnologyAyahKenzieNo ratings yet

- VWT Italia Distillation System Technical SpecificationsDocument9 pagesVWT Italia Distillation System Technical SpecificationsSupoj ChammalaiNo ratings yet

- Wika Hydrogen Handbook - 1.0Document16 pagesWika Hydrogen Handbook - 1.0Leonardo Ladino AgudeloNo ratings yet

- Commissioning ChecklistDocument6 pagesCommissioning Checklistanwar sadatNo ratings yet

- D1 - T3 - Michael Goff - Black & VeatchDocument30 pagesD1 - T3 - Michael Goff - Black & VeatchSumant AggNo ratings yet

- GI Dynamics - Enclosed Flare SystemDocument28 pagesGI Dynamics - Enclosed Flare SystemChris van der ZandeNo ratings yet

- 12.07.20. O&M Manual 41013 - New PLCDocument41 pages12.07.20. O&M Manual 41013 - New PLCFranco Sebastián GenreNo ratings yet

- The energy transition creates opportunities for hydrogenDocument40 pagesThe energy transition creates opportunities for hydrogenSebastián RojasNo ratings yet

- GeneratorDocument9 pagesGeneratorSooraj Surendran SugathaNo ratings yet

- Apeks Supercritical US Pricing 01.01.2019 1Document10 pagesApeks Supercritical US Pricing 01.01.2019 1Pit HipsterNo ratings yet

- DB 01.02.02.17 Booster DLE 30-1Document3 pagesDB 01.02.02.17 Booster DLE 30-1Pramod KumarNo ratings yet

- Compact Substation in 40 CharactersDocument5 pagesCompact Substation in 40 CharactersMarcWorldNo ratings yet

- E 2 HDocument26 pagesE 2 HmanojmenonNo ratings yet

- 01 Genera Lover View of Step Less Capacity Control of Reciprocating CompressorDocument15 pages01 Genera Lover View of Step Less Capacity Control of Reciprocating Compressorsumantabal_uceNo ratings yet

- Prezentation Envitec PDFDocument60 pagesPrezentation Envitec PDFDanilo VermezovcNo ratings yet

- Available on line at Association of the Chemical Engineers AChE: Hydrogen Energy Demonstration Facility on Terceira IslandDocument19 pagesAvailable on line at Association of the Chemical Engineers AChE: Hydrogen Energy Demonstration Facility on Terceira IslanddigecaNo ratings yet

- Expansion Energy LNG BDocument11 pagesExpansion Energy LNG BIvan RinconNo ratings yet

- HydrogenDocument10 pagesHydrogennuzulNo ratings yet

- Operation Manual Oil-Free Oxygen Piston Compressor Water-CooledDocument20 pagesOperation Manual Oil-Free Oxygen Piston Compressor Water-CooledPABLOBOBADILLANo ratings yet

- Hydrogen Cell Summary NRELDocument21 pagesHydrogen Cell Summary NRELJoack RaynorNo ratings yet

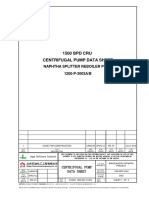

- Technip Document No. 068107C001-702-PDS-0610-003-0Document10 pagesTechnip Document No. 068107C001-702-PDS-0610-003-0Ryan Goh Chuang HongNo ratings yet

- PVEP Electrohydraulic Actuator TN 11022662 Rev-AA Apr-2007Document9 pagesPVEP Electrohydraulic Actuator TN 11022662 Rev-AA Apr-2007Sasko DimitrovNo ratings yet

- Service ManualDocument130 pagesService ManualOliver GaisburgerNo ratings yet

- Alternate Start Up Biography of ARLDocument7 pagesAlternate Start Up Biography of ARLanwar sadatNo ratings yet

- STARTUP IDEAS Rev 03Document5 pagesSTARTUP IDEAS Rev 03anwar sadatNo ratings yet

- D16021.1200.RE.10-003 REV.1 Datasheet (1200-P-3003AB)Document3 pagesD16021.1200.RE.10-003 REV.1 Datasheet (1200-P-3003AB)anwar sadatNo ratings yet

- STARTUP IDEAS Rev 01Document6 pagesSTARTUP IDEAS Rev 01anwar sadatNo ratings yet

- SE Asia TOs Technical Webinar InviteDocument1 pageSE Asia TOs Technical Webinar Inviteanwar sadatNo ratings yet

- Dalian Deepblue Pump Co., LTDDocument2 pagesDalian Deepblue Pump Co., LTDanwar sadatNo ratings yet

- MLADocument2 pagesMLAanwar sadatNo ratings yet

- Offer For Aqua Refinery LTDDocument2 pagesOffer For Aqua Refinery LTDanwar sadatNo ratings yet

- " (, ,, , - )Document63 pages" (, ,, , - )OGR LegalNo ratings yet

- PI For Loading System From Autower PDFDocument5 pagesPI For Loading System From Autower PDFanwar sadatNo ratings yet

- Commissioning fiber optics and accessories for outdoor multimode and single mode fiber networkDocument2 pagesCommissioning fiber optics and accessories for outdoor multimode and single mode fiber networkanwar sadatNo ratings yet

- Forwarded MessageDocument2 pagesForwarded Messageanwar sadatNo ratings yet

- DN80 DN50 20# 3 Asmeb16.5 150LB WN/RF DN100 DN50Document1 pageDN80 DN50 20# 3 Asmeb16.5 150LB WN/RF DN100 DN50anwar sadatNo ratings yet

- LPG Autogas GadgetDocument15 pagesLPG Autogas GadgetShamim HadiNo ratings yet

- Supplier Specification Hot Rolled Steel Strip: Pdmi Page 1 of 2Document2 pagesSupplier Specification Hot Rolled Steel Strip: Pdmi Page 1 of 2anwar sadatNo ratings yet

- F56449 and F56450 Recommended Parts Per Maintenance IntervalDocument31 pagesF56449 and F56450 Recommended Parts Per Maintenance Intervalanwar sadatNo ratings yet

- Supplier Specification Insulation Layer: Pdmi Page 1 of 2Document2 pagesSupplier Specification Insulation Layer: Pdmi Page 1 of 2anwar sadatNo ratings yet

- I. Production III. RPGCL Production Daily Gas & Condensate Production and Distribution ReportDocument1 pageI. Production III. RPGCL Production Daily Gas & Condensate Production and Distribution Reportanwar sadatNo ratings yet

- Parameter's Defination Regarding Life Test Report of Jiaipera CompressorDocument1 pageParameter's Defination Regarding Life Test Report of Jiaipera Compressoranwar sadatNo ratings yet

- Boosting Nitrogen purity and pressure for leak testingDocument4 pagesBoosting Nitrogen purity and pressure for leak testinganwar sadatNo ratings yet

- All Links of (Posts - by Emran)Document1 pageAll Links of (Posts - by Emran)anwar sadatNo ratings yet

- Life Test Report of TT1116YLADocument8 pagesLife Test Report of TT1116YLAanwar sadatNo ratings yet

- Subject: Resignation LetterDocument1 pageSubject: Resignation Letteranwar sadatNo ratings yet

- 100 Question MechanicalDocument33 pages100 Question Mechanicalhz_hridoyNo ratings yet

- GB 4706.1-2005 GB 4706.17-2010 Locked Rotor Test ReportDocument1 pageGB 4706.1-2005 GB 4706.17-2010 Locked Rotor Test Reportanwar sadatNo ratings yet

- FMDocument21 pagesFMawdhesh1213456No ratings yet

- Leak Class TestsDocument12 pagesLeak Class TestsZain AlwaliNo ratings yet

- Bendix Valve Sr5Document3 pagesBendix Valve Sr5miguel cuevasNo ratings yet

- Tips and Tricks From The Experts: Virtual Leaks: Formation, Detection, and AvoidanceDocument4 pagesTips and Tricks From The Experts: Virtual Leaks: Formation, Detection, and Avoidancejack macNo ratings yet

- Geomembrane Installation Specification PDFDocument21 pagesGeomembrane Installation Specification PDFAristoteles Wirawan AdhidarmaNo ratings yet

- Process Pressure Vessels and Piping SystemsDocument5 pagesProcess Pressure Vessels and Piping SystemsEn NdyNo ratings yet

- 0354 98361200191D PDFDocument11 pages0354 98361200191D PDFRavi TulsianNo ratings yet

- Codeline, 150 PSI, Drawing - 80S15Document3 pagesCodeline, 150 PSI, Drawing - 80S15RamanNegiNo ratings yet

- Series 3 Oil-Fired Natural Draft Water Boiler: This Manual Includes: Installation Start-Up Boiler PartsDocument32 pagesSeries 3 Oil-Fired Natural Draft Water Boiler: This Manual Includes: Installation Start-Up Boiler Partsshahisk2000No ratings yet

- Advanced Technology For Acoustic Leak Location and ConfirmationDocument2 pagesAdvanced Technology For Acoustic Leak Location and ConfirmationKishan ChandrasekaraNo ratings yet

- LPG Leak Detector PPT 2Document17 pagesLPG Leak Detector PPT 2Hems Dhurjaty100% (1)

- Flowjet Valves Product BrochureDocument18 pagesFlowjet Valves Product BrochureUday GokhaleNo ratings yet

- Valve Inspection ProtocolsDocument2 pagesValve Inspection ProtocolsaabejaroNo ratings yet

- Apd HC-10 PDFDocument56 pagesApd HC-10 PDFemanuelNo ratings yet

- Ashdown-Ingram - Ashdown-Ingram AC Catalogue 2017Document836 pagesAshdown-Ingram - Ashdown-Ingram AC Catalogue 2017Jimmy BarNo ratings yet

- QAF 2001 Rev. 1 Batch Mixer PM1 ChecklistDocument1 pageQAF 2001 Rev. 1 Batch Mixer PM1 ChecklistMohamed El-SawahNo ratings yet

- 422 Model E Alarm Check ValveDocument6 pages422 Model E Alarm Check ValveraneensysNo ratings yet

- Short Shut Down ReportDocument4 pagesShort Shut Down ReportMuhammad Ahmed AltafNo ratings yet

- Código de Erro Statim G4Document5 pagesCódigo de Erro Statim G4Rafael OliveiraNo ratings yet

- Craftsman Air Compressor Model 919-165510Document52 pagesCraftsman Air Compressor Model 919-165510resisterNo ratings yet

- West Tower Condominium vs. First Phil. Industrial Corporation, GR No. 194239, June 16, 2015Document20 pagesWest Tower Condominium vs. First Phil. Industrial Corporation, GR No. 194239, June 16, 2015Jacquilou Gier MacaseroNo ratings yet

- MACHINE REPAIR LOGDocument34 pagesMACHINE REPAIR LOGwikara godaiNo ratings yet

- PDFDocument37 pagesPDFm.khurana093425No ratings yet