Professional Documents

Culture Documents

Pre-Hydrotest Check List-Format

Uploaded by

Hanuman Rao0%(1)0% found this document useful (1 vote)

1K views1 pageOriginal Title

Pre-Hydrotest Check List-format.xls

Copyright

© © All Rights Reserved

Available Formats

XLS, PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

© All Rights Reserved

Available Formats

Download as XLS, PDF, TXT or read online from Scribd

0%(1)0% found this document useful (1 vote)

1K views1 pagePre-Hydrotest Check List-Format

Uploaded by

Hanuman RaoCopyright:

© All Rights Reserved

Available Formats

Download as XLS, PDF, TXT or read online from Scribd

You are on page 1of 1

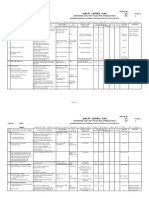

PRE HYDROSTATIC TEST CHECKLIST

Project Description:

Client:

Equipment: Page:

Vessel Tag Number: Date:

Item Description of Check Yes No NA

1 Check that the Fabrication Routing and Inspection Plan (ITP) has been

endorsed by all parties

2 Check the Material & Weld Tracebility Record has been verified and endorsed

3 Check all millcertificates have been endorsed by the relevant parties

4 Check that WPS and PQR have been approved and endorsed

5 Check the welder list has been endorsed

6 Check all NDE have been completed and reports reviewed and endorsed

7 Ensure final dimension been carried out with the reports endorsed

8 Check that Post Weld Heat Treatment has been completed with the

reports and charts endorsed

9 Check that Hardness Test has been carried out with all reports

reviewed and endorsed

10 Ensure the Hydrostatic Test procedure been approved

11 Check all pressure gauges are working with a validity of 6 months

and with the calibration certificates

12 Check the pressure recorder is working with attached certificates

13 Check the hydrostatic pressure has been approved

14 Check the total chlorine content of the test water is below 50ppm

15 Check that all flanges are of the correct rating

16 Check that all nozzles are flanged up

17 Nuts & stud bolts examined visually and deemed to be undamaged and

of the correct size and type

18 Are the joints are pulled up evenly on opposing stud bolts?

19 All nuts pulled up to required tightness?

20 No visible damage to gasket when joint completed

21 No excessive length of stud bolt protruding through each nut

22 Visual inspection on all welds have been carried out and deemed satisfactory

Remarks :

TOE QC DEPARTMENT

Signature

Date

You might also like

- Pressure Vessel Compliance ChecklistDocument3 pagesPressure Vessel Compliance Checklistpineda44444100% (2)

- Appendix 18 Steam Blowing JSADocument3 pagesAppendix 18 Steam Blowing JSAzhang75% (12)

- Hydrotesting ChecklistDocument1 pageHydrotesting ChecklistDwi Iin Novianti67% (3)

- Storage Tank Hydrostatic Test Quality Control and Inspection Report Form PDFDocument1 pageStorage Tank Hydrostatic Test Quality Control and Inspection Report Form PDFJaco CalitzNo ratings yet

- ST Exchanger Inspection ChecklistDocument7 pagesST Exchanger Inspection ChecklistSonaliNo ratings yet

- Check List For Fire HydrantDocument2 pagesCheck List For Fire HydrantKarthick NatrajanNo ratings yet

- ITP Installation of Boiler - R1Document14 pagesITP Installation of Boiler - R1crys100% (4)

- Piping NDT Request Quality Control and Inspection FormDocument1 pagePiping NDT Request Quality Control and Inspection FormEdison WalitNo ratings yet

- Cold Cutting ProcedureDocument9 pagesCold Cutting ProcedureVăn PhúcNo ratings yet

- Underground Piping Pressure Test RecordDocument1 pageUnderground Piping Pressure Test RecordPaulSwinbankNo ratings yet

- Air Compressor Pre-Startup Inspection ChecklistDocument1 pageAir Compressor Pre-Startup Inspection Checklistgede aris prayoga mahardika50% (2)

- Hydrotest Test PacksDocument1 pageHydrotest Test Packsswaraj4u50% (2)

- Pneumatic Test ProcedureDocument12 pagesPneumatic Test ProcedurePower Power100% (4)

- 6) Pneumatic Pressure TestDocument3 pages6) Pneumatic Pressure Testbacabacabaca100% (1)

- Piping Reinstatement: Inspection Test Report Form NoDocument2 pagesPiping Reinstatement: Inspection Test Report Form NoFrancisco75% (4)

- SOP For Pneumatic Testing.Document2 pagesSOP For Pneumatic Testing.Ernst_SNo ratings yet

- Check List After HydrotestDocument1 pageCheck List After Hydrotestரமேஷ் பாலக்காடு91% (11)

- Hydrostatic Test ReportDocument1 pageHydrostatic Test ReportMuhammadShabbirNo ratings yet

- Form Checklist Machine SHD 160 Butt FusionDocument8 pagesForm Checklist Machine SHD 160 Butt FusionYuwantoniAl100% (1)

- Inspection and Test PlanDocument58 pagesInspection and Test PlanTouil Houssem100% (1)

- Tank Commissioning ProcedureDocument7 pagesTank Commissioning ProcedureivanrishiNo ratings yet

- FIT UP ReportDocument2 pagesFIT UP Reportsiva8000No ratings yet

- Table Pengecekan Hydrostatic Pressure Test Product ValvesDocument31 pagesTable Pengecekan Hydrostatic Pressure Test Product ValvesIksan Mustofa50% (2)

- ITP For Storage TankDocument6 pagesITP For Storage TankAhmed Ben HmidaNo ratings yet

- Inspection and Test Plan For Pressure VesselDocument4 pagesInspection and Test Plan For Pressure VesselNurul Amirah Princesza100% (3)

- 008 - Field Hydrotest ProcedureDocument17 pages008 - Field Hydrotest Procedurekaruna346100% (2)

- Welding Machine Safety ChecklistDocument1 pageWelding Machine Safety ChecklistImad Chaudhary100% (7)

- A - Piping Joint HandbookDocument161 pagesA - Piping Joint HandbookCharles Tauk100% (30)

- Storage Tank Hydrostatic Test Quality Control and Inspection Report FormDocument1 pageStorage Tank Hydrostatic Test Quality Control and Inspection Report FormMHT allamNo ratings yet

- Storage Tank Hydrostatic Test Quality Control and Inspection Report Form PDFDocument1 pageStorage Tank Hydrostatic Test Quality Control and Inspection Report Form PDFAdhi PrihastomoNo ratings yet

- Hydro Test ChecklistDocument3 pagesHydro Test Checklistsaquib_jamadarNo ratings yet

- Inspection Report For Installation of Fire & Gas DetectorsDocument1 pageInspection Report For Installation of Fire & Gas Detectorsnayum0% (1)

- Pneumatic TestDocument10 pagesPneumatic Testchitobarba19726762100% (3)

- Check List - Fire Protection Inspection Untuk KomisioningDocument4 pagesCheck List - Fire Protection Inspection Untuk KomisioningRudy Harahap100% (1)

- 0.hydro Test Package Index - 1Document13 pages0.hydro Test Package Index - 1VISHNUPRASAD ARAKKAL MOHANDASNo ratings yet

- Pneumatic Testing Procedure For PipelinesDocument3 pagesPneumatic Testing Procedure For PipelinesKu Masayu Ku HusinNo ratings yet

- To Commissioning Manual: Appendix No. 1Document7 pagesTo Commissioning Manual: Appendix No. 1Bassem BalghouthiNo ratings yet

- Valve ReplacementDocument7 pagesValve ReplacementKamarularifin Kamel100% (2)

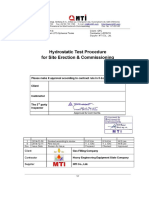

- Hydrostatic Test Procedure Site RevDDocument23 pagesHydrostatic Test Procedure Site RevDBhavani Prasad100% (8)

- Inspection and Test Plan For Pipe Line Works Rev 0Document1 pageInspection and Test Plan For Pipe Line Works Rev 0CrstnScribidNo ratings yet

- Sop For HydrotestDocument3 pagesSop For HydrotestShyam QCNo ratings yet

- 019 - Tank Box Up ChecklistDocument1 page019 - Tank Box Up ChecklistDelil Ozan67% (6)

- Pressure Test & Test Pack ManagementDocument43 pagesPressure Test & Test Pack ManagementStanley Alex100% (4)

- Hydrostatic Test Procedure For Site & Commissioning HT-031-R1Document7 pagesHydrostatic Test Procedure For Site & Commissioning HT-031-R1Hatem Ragab100% (1)

- Itp Piping WorksDocument7 pagesItp Piping WorksRudi EriantoNo ratings yet

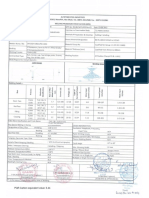

- Report No. TA-V-1456Document2 pagesReport No. TA-V-1456u04ajf3No ratings yet

- INS-004, Hydro-Testing Procedure For Bondstrand GRE and GRV Pipe-R1Document7 pagesINS-004, Hydro-Testing Procedure For Bondstrand GRE and GRV Pipe-R1jayhuacat7743100% (4)

- Form Inspeksi HydrantDocument2 pagesForm Inspeksi HydrantNandikha RizkiNo ratings yet

- Welding Quality Control and Inspection FormDocument1 pageWelding Quality Control and Inspection FormJuli Agus100% (2)

- Cone Roof Tank Erection ProcedureDocument8 pagesCone Roof Tank Erection ProcedureBoby Thomas100% (1)

- Hydrotest Check ListDocument1 pageHydrotest Check ListSaut Maruli Tua SamosirNo ratings yet

- HLG HSE SPI FM 016B r00 Crane Inspection ChecklistDocument1 pageHLG HSE SPI FM 016B r00 Crane Inspection ChecklistLemuel PetronioNo ratings yet

- PSV Test ProcedureDocument36 pagesPSV Test ProcedureMughal Darbar100% (2)

- Pressure Testing of API TanksDocument7 pagesPressure Testing of API TanksRakesh Ranjan50% (2)

- Sop For Fabrication of Fuel TankDocument3 pagesSop For Fabrication of Fuel TankVinod Kumar Verma75% (8)

- Inspection Check List PWHT-Post Weld Heat-Treatment: Inspection Process Yes No N/A CommentsDocument1 pageInspection Check List PWHT-Post Weld Heat-Treatment: Inspection Process Yes No N/A CommentsmukeshayoorNo ratings yet

- SETTLEMENT Test ProcedureDocument9 pagesSETTLEMENT Test Procedurehrdsby100% (2)

- Client: Job No.: Job Title: Client's Job No.:: Company NameDocument13 pagesClient: Job No.: Job Title: Client's Job No.:: Company NamejorgekarlosprNo ratings yet

- Kelly Hose PDFDocument2 pagesKelly Hose PDFKaleem UllahNo ratings yet

- Pressure Test / Leakage Test Quality Control Check Sheet: Project Name & No. Main Contractor MEP ContractorDocument1 pagePressure Test / Leakage Test Quality Control Check Sheet: Project Name & No. Main Contractor MEP ContractorJIJU100% (1)

- Checklist For InspectionDocument12 pagesChecklist For InspectionAnoopNo ratings yet

- Side BarDocument4 pagesSide BarHanuman RaoNo ratings yet

- PQR Carbon Equivalent Value: 0.44Document1 pagePQR Carbon Equivalent Value: 0.44Hanuman RaoNo ratings yet

- Coating Standards PDFDocument5 pagesCoating Standards PDFHanuman RaoNo ratings yet

- Technics Offshore Engineering Pte LTD: ProjectxxxxxxxxxxxxxxxxxxxDocument1 pageTechnics Offshore Engineering Pte LTD: ProjectxxxxxxxxxxxxxxxxxxxHanuman RaoNo ratings yet

- PQR Carbon Equivalent Value: 0.44Document1 pagePQR Carbon Equivalent Value: 0.44Hanuman RaoNo ratings yet

- Hydrotest QI304-sampleDocument3 pagesHydrotest QI304-sampleHanuman Rao100% (1)

- Technics Offshore Engineering Pte LTD: Owner: Contract No.: - Equipment: Project No.: Tag No.: Sheet NoDocument1 pageTechnics Offshore Engineering Pte LTD: Owner: Contract No.: - Equipment: Project No.: Tag No.: Sheet NoHanuman RaoNo ratings yet

- Material & Weld Traceability-Format'Document4 pagesMaterial & Weld Traceability-Format'Hanuman RaoNo ratings yet

- Final Release Certificate-FormatDocument2 pagesFinal Release Certificate-FormatHanuman RaoNo ratings yet

- Material Form FormatDocument1 pageMaterial Form FormatHanuman RaoNo ratings yet

- Policy StatementDocument1 pagePolicy StatementHanuman RaoNo ratings yet

- Technics Offshore Engineering Pte. LTD.: Material & Weld Traceability RecordDocument1 pageTechnics Offshore Engineering Pte. LTD.: Material & Weld Traceability RecordHanuman RaoNo ratings yet

- Thickness (98078)Document1 pageThickness (98078)Hanuman RaoNo ratings yet

- Project No TOE - 08088 TOE - 08089 TOE - 08090: All Vendors DocumentsDocument3 pagesProject No TOE - 08088 TOE - 08089 TOE - 08090: All Vendors DocumentsHanuman RaoNo ratings yet

- Technics Offshore Engineering Pte LTDDocument2 pagesTechnics Offshore Engineering Pte LTDHanuman RaoNo ratings yet

- Material ListDocument1 pageMaterial ListHanuman RaoNo ratings yet

- Internal Document Transmittal: Technics Offshore Engineering Pte LTDDocument2 pagesInternal Document Transmittal: Technics Offshore Engineering Pte LTDHanuman RaoNo ratings yet

- Material Forms-List of ConstruCertDocument4 pagesMaterial Forms-List of ConstruCertHanuman RaoNo ratings yet

- RT RequestDocument1 pageRT RequestHanuman RaoNo ratings yet

- Material Forms-FittingsDocument1 pageMaterial Forms-FittingsHanuman RaoNo ratings yet

- Material Forms-FittingsDocument1 pageMaterial Forms-FittingsHanuman RaoNo ratings yet

- Punch List Report: Client Date Project No. Discipline Location Date of InspectionDocument1 pagePunch List Report: Client Date Project No. Discipline Location Date of InspectionHanuman RaoNo ratings yet

- Material Forms-FittingsDocument1 pageMaterial Forms-FittingsHanuman RaoNo ratings yet

- Cover Page-FormatDocument1 pageCover Page-FormatHanuman RaoNo ratings yet

- Technics Offshore Engineering Pte LTD: This Document Contains 1 COVER & 2 Page(s)Document1 pageTechnics Offshore Engineering Pte LTD: This Document Contains 1 COVER & 2 Page(s)Hanuman RaoNo ratings yet

- Technics Offshore Engineering Pte LTD: Nde RequestDocument1 pageTechnics Offshore Engineering Pte LTD: Nde RequestHanuman RaoNo ratings yet

- Certificate of ComplianceDocument1 pageCertificate of ComplianceHanuman RaoNo ratings yet

- List of Welders and Welding Operators: Project No - Equipment Name: Tag No.Document1 pageList of Welders and Welding Operators: Project No - Equipment Name: Tag No.Hanuman RaoNo ratings yet