Professional Documents

Culture Documents

Compset™ Packers: Section 4: Sealbore Packers and Accessories

Uploaded by

josephbenettonOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Compset™ Packers: Section 4: Sealbore Packers and Accessories

Uploaded by

josephbenettonCopyright:

Available Formats

COMPLETION TOOLS CATALOG

SECTION 4: Sealbore Packers and Accessories COMPLETION SERVICES

CompSet™ Packers

CompSet™ HP-II (≤10,000 psi Differential)

CompSet™ XTR (12,500 psi Differential)

CompSet™ Ultra (15,000 psi Differential)

Superior Completion Services’ CompSetTM externally

retrievable sealbore packers are designed for high-

pressure (HP) and high-temperature completions.

These packers provide positive isolation during

maximum loads, differentials and temperature cycles

for harsh completion. They also provide stimulation

applications, including gravel and frac-packing, high-

rate water packing, stimulations and horizontal

completions. The CompSetTM packers can also be

used as production sealbore packers and have been

tested and manufactured in accordance with API 11D1

specifications.

A P P L I CA T I ONS

• Gravel/frac packing

• Sand control

• Horizontal and vertical wells

• Zonal isolation; production isolation

Features and Benefits

• Single-sealing packing element eliminates extrusion and

extends packer life downhole

• External retrieving sleeve facilitates packer retrieval with

obstruction in sealbore

• Designed for simple external release and retrieval;

optional internal release

• Large bore through packer and seals

• Single high pressure sealing element

• Splined to facilitate milling removal if required

• Gauge ring on lower end of packer helps prevent

premature setting when an obstruction or tight spot is

encountered

• Hydraulic- or wireline-set

• Can be released with restricted ID

• Rotationally locked

COMPLETION TOOLS CATALOG | 2018 57

COMPLETION TOOLS CATALOG

SECTION 4: Sealbore Packers and Accessories COMPLETION SERVICES

CompSet™ Packers

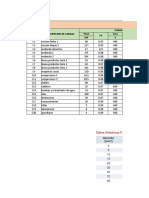

TE CH N I CA L D ATA

CompSet™ Packers

Screen Size Screen Size Isolation String

Casing Size 5” - 11 ¾” 7 ¾” & 9 ⅞” - 10⅛” 7 ¾” & 9 ⅞” - 10⅛”

Packer Bore 2.68” - 6.00” 4.00” & 6.00” 3.88” & 5.50”

Differential Pressure Rating ≤ 10,000 psi 12,500 psi 15,000 psi

Temperature Rating Ambient - ≥250 °F Ambient - 300 °F 40 -300 °F

API 11D1 Validation Grades V6 - V0 V3 - V0 V0

REFERENCES

Completion tools seal systems data sheet

Packer plugs and accessories data sheet

COMPLETION TOOLS CATALOG | 2018 58

COMPLETION TOOLS CATALOG

SECTION 4: Sealbore Packers and Accessories COMPLETION SERVICES

CompSet™ Packers

TE CH N I CA L D ATA

CompSet Packers

Differential

Casing OD Casing Weight Range Maximum OD Minimum ID* Standard Seal ID Pressure Rating

inch mm lb/ft kg/m inch mm inch mm inch mm psi Mpa

5 127.0 11.5-15.0 17.1-22.3 4.25 108.0 2.69 68.2 1.93 48.9 10,000 69.0

18.0-21.0 26.7-31.3 4.00 101.5 2.69 68.2 1.93 48.9 10,000 69.0

5½ 139.7 13.0-15.5 19.3-23.0 4.52 121.8 2.69 68.3 1.93 48.9 10,000 69.0

17.0-23.0 25.3-34.2 4.52 114.7 2.69 68.3 1.93 48.9 10,000 69.0

26.0 38.70 4.52 108.0 2.69 68.3 1.93 48.9 10,000 69.0

6⅝ 168.3 28.0-32.0 41.6-47.6 5.52 140.1 2.69 68.3 1.93 48.9 7,500 51.7

20.0-26.0 29.7-38.7 6.08 154.3 3.25, 4.00 82.6, 101.6 2.38, 2.99 60.3, 75.8 10,000 69.0

26.0-32.0 38.7-47.6 5.89 149.6 3.25, 4.00 82.6, 101.6 2.38, 2.99 60.3, 75.8 10,000 69.0

7 177.8 32.0-38.0 47.6-56.5 5.74 145.7 3.25, 4.00 82.6, 101.6 2.38, 2.99 60.3, 75.8 10,000 69.0

41.0 61.0 5.64 143.3 3.25 82.6 2.38 60.3 10,000 69.0

46.4-51.0 73.70 5.31 140.1 2.69 68.3 1.93 48.9 10,000 69.0

7⅝ 193.7 24.0-29.7 35.7-44.2 6.68 169.7 3.25, 4.00 82.6, 101.6 2.38, 2.99 60.3, 75.8 10,000 69.0

29.7-39.0 44.2-58.0 6.44 163.5 3.25, 4.00 82.6, 101.6 2.38, 2.99 60.3, 75.8 10,000 69.0

9⅝ 244.5 36.0-43.5 53.6-64.7 8.53 216.7 3.25, 4.00 82.6, 101.6 2.38, 2.99 60.3, 75.8 10,000 69.0

36.0-43.5 53.6-64.7 8.53 216.7 4.75, 6.00 120.7-152.4 3.47, 4.99 88.1, 126.6 10,000 69.0

43.5-53.5 64.7-79.6 8.32 211.4 3.25, 4.00 82.6, 101.6 2.38, 2.99 60.3, 75.8 10,000 69.0

43.5-53.5 64.7-79.6 8.32 211.4 4.75, 6.00 120.7-152.4 3.47, 4.99 88.1, 126.6 10,000 69.0

9⅞ 250.8 62.8 93.5 8.42 213.9 6.00 152.4 4.74 120.3 10,001 69.0

10 ¾ 273.1 55.5-65.0 82.6-97.8 9.38 235.7 4.75, 6.00 120.7-152.4 3.47, 5.00 88.1, 127.0 8,000 55.2

11 ¾ 298.5 54.0-65.0 80.4-96.7 10.40 264.2 4.75 120.7 3.47 88.1 8,000 55.2

CompSet Extreme Packers

Differential

Casing OD Casing Weight Range Maximum OD Minimum ID* Standard Seal ID Pressure Rating

inch mm lb/ft kg/m inch mm inch mm inch mm psi Mpa

7¾ 196.9 46.1 68.6 6.68 169.7 4.00 101.6 2.99 76.0 12.500 86.2

9⅞ 250.8 62.8 93.5 8.42 213.9 6.00 152.4 4.74 120.3 12,500 86.2

10 ⅛ 257.1 79.3 117.9 8.42 213.9 6.00 152.4 4.74 120.3 12,500 86.2

* Alternate bore configurations available upon request.

REFERENCES

Completion tools seal systems data sheet

Packer plugs and accessories data sheet

COMPLETION TOOLS CATALOG | 2018 59

COMPLETION TOOLS CATALOG

SECTION 4: Sealbore Packers and Accessories COMPLETION SERVICES

Seal Systems

Superior Completion Services provides a variety of Seal Systems and

alloy materials to accommodate most well conditions. It is important

to know the well conditions and the work needed before choosing the

proper seal system. Consideration should be given to temperatures,

hostile elements, seal movements and maximum pressure

differentials. These factors will determine the seal type, metal material

and accessories to be utilized.

For all sealbore tubing accessories, standardization of threads, seal

diameters and seal lengths have been carefully considered in the

design to maximize interchangeability with competitive sealbore

equipment. All steel components for the sealbore tubing accessories

are manufactured to meet NACE MR0175 standards for H2S service.

The accessories are also available in several types of material with the

following examples: Molded Seal System

• High-strength alloy steel for high-pressure applications

• 9CR-1MO alloy steel for H2S and CO2 applications

• High-nickel alloy steel for severe corrosion applications

Two basic seal types are currently available:

• Elastomer bonded to metal commonly known as molded seals

available in:

• Nitrile, Viton®, Fluorel®, EPDM, ECO

• HSN materials Chevron-style, lip-type seals commonly known as

V-rings available in:

• Nitrile, Viton, Fluorel, Teflon®, AFLAS®, Ryton® and Kalrez®

materials

Standard Chevron

Molded Seal System Seal System

This system is recommended for applications where it is likely that

the seals will be disengaged from the packer sealbore with differential

pressure pre-sent. Two seal rings are bonded to a metal sleeve with

an internal O-ring to provide a positive seal. This system is available in

various elastomers and is application dependent.

Standard Chevron Seal System

This system’s seal stack consists of chevron seal rings with steel

spacers. This seal configuration is best suited for applications in which

the seals will not disengage from the packer sealbore.

HSN seal stack: recommended for maximum temperatures of 350°F

(177°C) in a standard service environment

COMPLETION TOOLS CATALOG | 2018 61

COMPLETION TOOLS CATALOG

SECTION 4: Sealbore Packers and Accessories COMPLETION SERVICES

Sealbore Packer Accessories

Sealbore Extension

This extension is generally used in installations where floating

seals are required due to excessive tubing contraction. Sealbore

extensions have the same sealing bore ID as the corresponding

packer to allow a continuous sealbore for the lower-most seals of

a long seal assembly. Sealbore extensions are available in a variety

of lengths.

Millout Sub

The millout sub is used in installations where a larger ID is

required to accommodate the latching mechanism of a washover

tool. This allows the permanent packer to be retrieved with the

tool after milling over the outside of the packer. Millout subs are

commonly installed between the packer and sealbore extension in

installations using floating seal units.

Sealbore

Extension

Millout Sub

COMPLETION TOOLS CATALOG | 2018 65

COMPLETION TOOLS CATALOG

SECTION 4: Sealbore Packers and Accessories COMPLETION SERVICES

Tubing Seal Accessories

Locator Seal Nipple

Superior Completion Services’ locator seal nipple is run between

the seal assembly and production tubing. The locator is designed

to locate on the top of the sealbore to provide an indication of

the seal assembly’s location. The locator is designed to prevent

downward tubing movement but allows the seals to move freely

with tubing contraction.

Pop-Lock Locator

The pop-lock locator is run between the seal assembly and

production tubing. The locator’s latch assembly is designed to

engage a corresponding thread in the downhole completion Locator

Seal Nipple

assembly. At a predetermined overpull, the latch will release Assembly

from the thread, providing a surface indication of positive latch

engagement and release. The locator provides a positive depth

confirmation by tagging a large surface at the top of the packer’s

sealbore. Pop-lock locators are offered in a variety of threads,

including premium threads. Pop-Lock

Locator

Anchor Latch

Superior Completion Services’ anchor latch is run between the seal

assembly and the production string. A positive latch snaps into the

corresponding thread on the completion assembly and anchors

the tubing in place. The anchor latch may be released by applying

a slight upstrain with RH rotation.

Tubing Seal Nipple

The tubing seal nipple allows the seal assembly to connect directly

to the tubing without a locating shoulder or pop-lock locator

assembly. The seals and tubing are then able to pass through the

corresponding sealbore without locating.

Anchor Latch Tubing Seal

Nipple

COMPLETION TOOLS CATALOG | 2018 67

You might also like

- Stainless Steel Pipe Dimensions and Weight ChartDocument5 pagesStainless Steel Pipe Dimensions and Weight ChartArun Chopra33% (3)

- Drilling Fluids Processing HandbookFrom EverandDrilling Fluids Processing HandbookRating: 4.5 out of 5 stars4.5/5 (4)

- Working Guide to Drilling Equipment and OperationsFrom EverandWorking Guide to Drilling Equipment and OperationsRating: 5 out of 5 stars5/5 (9)

- Electro Mechanical Setting ToolDocument2 pagesElectro Mechanical Setting TooljosephbenettonNo ratings yet

- Switchword PairsDocument6 pagesSwitchword PairsLaleKulahli100% (7)

- Superior Completion Services Sealbore PackersDocument27 pagesSuperior Completion Services Sealbore Packersalok_789No ratings yet

- Tubos PVCDocument4 pagesTubos PVCcesar paitanNo ratings yet

- SSPCDocument2 pagesSSPCmir31721No ratings yet

- 1 WIRE HYDRAULIC HOSE SPECSDocument5 pages1 WIRE HYDRAULIC HOSE SPECSSHANENo ratings yet

- 34 Model AD-1 Tension PackerDocument2 pages34 Model AD-1 Tension PackerDenier RubianoNo ratings yet

- Steel Pipe-Unit WeightDocument3 pagesSteel Pipe-Unit Weightsujan daraiNo ratings yet

- Nexum Technical DataDocument8 pagesNexum Technical DatadesignsNo ratings yet

- Recommended Input Sizes For RollingDocument7 pagesRecommended Input Sizes For RollingTushar PachlangiaNo ratings yet

- Weights NewDocument16 pagesWeights NewQuintusNo ratings yet

- Ecrou 2H Brk-Heavy-Hex-Nuts-Dimensions-Weight-Imperial-Metric-SizesDocument2 pagesEcrou 2H Brk-Heavy-Hex-Nuts-Dimensions-Weight-Imperial-Metric-SizesNarimane BentyNo ratings yet

- HDPE Pipe Properties and ApplicationsDocument5 pagesHDPE Pipe Properties and ApplicationsCarlos KraljevicNo ratings yet

- Petrochem Catalogue 87Document1 pagePetrochem Catalogue 87Oke DiliardiNo ratings yet

- Campbell Chain PDFDocument46 pagesCampbell Chain PDFrisiana_limuriaNo ratings yet

- Hdpe Spec Sheet Pe4710Document5 pagesHdpe Spec Sheet Pe4710thanguctNo ratings yet

- Hdpe Pipe ChartDocument1 pageHdpe Pipe ChartBENJAMIN UNALANNo ratings yet

- HDPE Pipe Dimensions TableDocument4 pagesHDPE Pipe Dimensions TableNagarjun ReddyNo ratings yet

- Link Pitch, Height, Bushing, and Idler Wear Life ChartsDocument11 pagesLink Pitch, Height, Bushing, and Idler Wear Life ChartsFrank Felipe Cruz ChavezNo ratings yet

- Metering Pumps: Models A and BDocument5 pagesMetering Pumps: Models A and Bbmanojkumar16No ratings yet

- Hatim PDFDocument2 pagesHatim PDFআফজাল -উল ইসলাম নূর100% (1)

- Style 257Document5 pagesStyle 257Ummes AhmedNo ratings yet

- C Purlin Technical Data SheetDocument6 pagesC Purlin Technical Data SheetAkhil VNNo ratings yet

- Electrical Load Parameters and Cable SizingDocument7 pagesElectrical Load Parameters and Cable SizingGUTARRA QUISPE OSCAR ALEXANDERNo ratings yet

- Tata Steel Section Ciold and Hot Section PDFDocument96 pagesTata Steel Section Ciold and Hot Section PDFSyedNo ratings yet

- Tecumseh RD 0003 e - Rev 1 Service Guidelines HCFC r22 To HFC Blends - Oct2017Document8 pagesTecumseh RD 0003 e - Rev 1 Service Guidelines HCFC r22 To HFC Blends - Oct2017Bazin TsegayeNo ratings yet

- Pipe DimensionDocument10 pagesPipe DimensionruzlaNo ratings yet

- Anchor Flange Dimensions and SpecificationsDocument8 pagesAnchor Flange Dimensions and SpecificationsHanda Bin AdiNo ratings yet

- Fr Codo de 90 Ac Ced80 Astm a234 Gr. WpbDocument1 pageFr Codo de 90 Ac Ced80 Astm a234 Gr. WpbSERVICIOS INTEGRALES OSDANo ratings yet

- Weight and dimensions of water-filled steel and PVC pipesDocument11 pagesWeight and dimensions of water-filled steel and PVC pipesmoh. rusli bahtiarNo ratings yet

- Wheatland ASTM A 53 Schedule 40 Pipe SpecsDocument1 pageWheatland ASTM A 53 Schedule 40 Pipe SpecsKelvin RojasNo ratings yet

- Mueller Equivalent Lengths PDFDocument1 pageMueller Equivalent Lengths PDFkuchaitanyaNo ratings yet

- SD Reinforcing Mesh Q131Document12 pagesSD Reinforcing Mesh Q131Mohand EliassNo ratings yet

- SD Reinforcing Mesh Q131Document12 pagesSD Reinforcing Mesh Q131Mohand EliassNo ratings yet

- Halliburton Screens: Filtration TechnologyDocument10 pagesHalliburton Screens: Filtration TechnologyVGNo ratings yet

- Specific Steel WireDocument1 pageSpecific Steel WireThanh Anh MaiNo ratings yet

- Steel Wire Rope Breaking Loads and WeightsDocument1 pageSteel Wire Rope Breaking Loads and WeightsThanh Anh MaiNo ratings yet

- Slings Weight-Breaking-LoadDocument1 pageSlings Weight-Breaking-LoadNed VasicNo ratings yet

- (New) E-Flex Viet Nam Catalogue 2021Document10 pages(New) E-Flex Viet Nam Catalogue 2021Trung Trinh BaoNo ratings yet

- Superior Landing Nipples: SECTION 7: Subsurface SafetyDocument2 pagesSuperior Landing Nipples: SECTION 7: Subsurface SafetyHadi KoraniNo ratings yet

- HDPE Spec Sheet 3608 PDFDocument5 pagesHDPE Spec Sheet 3608 PDFfrnandoxNo ratings yet

- Wastewater Technical ManualDocument32 pagesWastewater Technical ManualagonzalezcordovaNo ratings yet

- AHC Packer H012992 PDFDocument2 pagesAHC Packer H012992 PDFAhmed Mamdouh100% (1)

- Incoloy 800 Thread Flange 300LB 300# ASME B16.5Document2 pagesIncoloy 800 Thread Flange 300LB 300# ASME B16.5Yilia WangNo ratings yet

- MS Seamless Pipe ASTM A106Document3 pagesMS Seamless Pipe ASTM A106imtz20130% (1)

- Wall thickness table for steel pipe standardsDocument1 pageWall thickness table for steel pipe standardsMukesh Kumar Jha100% (1)

- Stainless Steel Pipe Weight Per Meter and Pipe Thickness Chart in MMDocument4 pagesStainless Steel Pipe Weight Per Meter and Pipe Thickness Chart in MMAnilkumar CENo ratings yet

- @tspkco: Construction: 6x19 / 6x36 Group IWRC Construction: 6x19 / 6x36 Group Fibre Core (Document1 page@tspkco: Construction: 6x19 / 6x36 Group IWRC Construction: 6x19 / 6x36 Group Fibre Core (amirhosseinNo ratings yet

- SprinklerBrochures Schedule10 40Document4 pagesSprinklerBrochures Schedule10 40Keshia Murillo PinnockNo ratings yet

- Standard Pipe Schedule 40 ASTM A 53 Grades A and BDocument2 pagesStandard Pipe Schedule 40 ASTM A 53 Grades A and Btarek eidNo ratings yet

- Standard Pipe Schedule 40 ASTM A 53 Grades A and BDocument2 pagesStandard Pipe Schedule 40 ASTM A 53 Grades A and BAngel PintoNo ratings yet

- Manufacturer/Exporter of Stainless Steel Pipe Fittings and DimensionsDocument2 pagesManufacturer/Exporter of Stainless Steel Pipe Fittings and DimensionsMohammad SaleemNo ratings yet

- Barrett Steel General Steels CatalogueDocument56 pagesBarrett Steel General Steels Cataloguedaranivel.kcNo ratings yet

- Catalogo Vibrador NeumaticoDocument2 pagesCatalogo Vibrador NeumaticoJuan David MontoyaNo ratings yet

- Brosura VarifixDocument52 pagesBrosura VarifixDan LimburgNo ratings yet

- Pipes - European Standards: EEMUA 144 10 Bar 20 Bar 14 Bar 16 BarDocument4 pagesPipes - European Standards: EEMUA 144 10 Bar 20 Bar 14 Bar 16 BarjoehodohNo ratings yet

- Fresh Air Sand Trap Louver With Vertical Fixed BladesDocument2 pagesFresh Air Sand Trap Louver With Vertical Fixed BladesAmr Adeeb Abd-ElaahNo ratings yet

- Pump Head Calculations Using Darcy-Weisbach FormulaDocument6 pagesPump Head Calculations Using Darcy-Weisbach FormulaHind ZarifNo ratings yet

- 38-Drill Pipe-5875-01Document2 pages38-Drill Pipe-5875-01zainalharrisNo ratings yet

- Simulacion Torque y ArrastreDocument1 pageSimulacion Torque y ArrastrejosephbenettonNo ratings yet

- VolumenesDocument1 pageVolumenesjosephbenettonNo ratings yet

- Simulacion HidraulicaDocument1 pageSimulacion HidraulicajosephbenettonNo ratings yet

- Simulacion Surgencia 2Document2 pagesSimulacion Surgencia 2josephbenettonNo ratings yet

- Tube Move Shoe Setting HangerDocument11 pagesTube Move Shoe Setting HangerjosephbenettonNo ratings yet

- PesosDocument4 pagesPesosjosephbenettonNo ratings yet

- 2RH™ Liner Setting ToolDocument14 pages2RH™ Liner Setting TooljosephbenettonNo ratings yet

- Apiay 1 Wbco 7 W Taper Mill PDFDocument31 pagesApiay 1 Wbco 7 W Taper Mill PDFjosephbenettonNo ratings yet

- 4 - Motor Overview and Book Explan - WFD - Rev8Document21 pages4 - Motor Overview and Book Explan - WFD - Rev8josephbenettonNo ratings yet

- Torque & Drag: Entrenamiento Básico de T&DDocument41 pagesTorque & Drag: Entrenamiento Básico de T&DjosephbenettonNo ratings yet

- Simulacion SurgenciaDocument1 pageSimulacion SurgenciajosephbenettonNo ratings yet

- C2™ Liner Setting Sleeve With Tieback ExtensionDocument5 pagesC2™ Liner Setting Sleeve With Tieback Extensionjosephbenetton100% (1)

- Superior Quality Sand Screens: PortfolioDocument16 pagesSuperior Quality Sand Screens: PortfoliojosephbenettonNo ratings yet

- SUPERIOR SCS - Catalog Complete - 2 PDFDocument213 pagesSUPERIOR SCS - Catalog Complete - 2 PDFjosephbenettonNo ratings yet

- Citadel Casing Solutions Technical Overview 2020 PDFDocument39 pagesCitadel Casing Solutions Technical Overview 2020 PDFjosephbenettonNo ratings yet

- Citadel Brochure PDFDocument20 pagesCitadel Brochure PDFjosephbenettonNo ratings yet

- SUPERIOR SCS - Catalog Complete - 2 PDFDocument213 pagesSUPERIOR SCS - Catalog Complete - 2 PDFjosephbenettonNo ratings yet

- Citadel Casing Solutions Technical Overview 2020 PDFDocument39 pagesCitadel Casing Solutions Technical Overview 2020 PDFjosephbenettonNo ratings yet

- Completion Tools Catalog PDFDocument174 pagesCompletion Tools Catalog PDFjosephbenettonNo ratings yet

- SUPERIOR SCS - Catalog Complete - 2 PDFDocument213 pagesSUPERIOR SCS - Catalog Complete - 2 PDFjosephbenettonNo ratings yet

- Completion Tools Catalog PDFDocument174 pagesCompletion Tools Catalog PDFjosephbenettonNo ratings yet

- Xpak Drilldown System CatalogoDocument4 pagesXpak Drilldown System CatalogojosephbenettonNo ratings yet

- Catalogo Liner Hanger TIWDocument84 pagesCatalogo Liner Hanger TIWjosephbenettonNo ratings yet

- Completion Tools Catalog PDFDocument174 pagesCompletion Tools Catalog PDFjosephbenettonNo ratings yet

- TM Journal Class 5 Pharma Trademarks 2018Document1,192 pagesTM Journal Class 5 Pharma Trademarks 2018Tahir LabbeNo ratings yet

- AMS 2750 E Heat Treatment Standards ComplianceDocument3 pagesAMS 2750 E Heat Treatment Standards ComplianceQualidadeTFNo ratings yet

- Boutique HotelsDocument61 pagesBoutique Hotelsnour alkhateeb100% (1)

- The Biology of Vascular Epiphytes Zotz 2016 PDFDocument292 pagesThe Biology of Vascular Epiphytes Zotz 2016 PDFEvaldo Pape100% (1)

- 3 Huang2015Document10 pages3 Huang2015kikoNo ratings yet

- Lecture Notes in Computer Science-7Document5 pagesLecture Notes in Computer Science-7Arun SasidharanNo ratings yet

- Negros IslandDocument18 pagesNegros IslandGrace AmaganNo ratings yet

- Foundations Paper MIF PDFDocument70 pagesFoundations Paper MIF PDFBárbara NunesNo ratings yet

- European Commission: The Traineeships OfficeDocument3 pagesEuropean Commission: The Traineeships Officenasrine hachimNo ratings yet

- Global Detection - Electronic and Electromechanical Sensors Catalogue 2006.10 PDFDocument800 pagesGlobal Detection - Electronic and Electromechanical Sensors Catalogue 2006.10 PDFSarah RichardNo ratings yet

- German UnificationDocument40 pagesGerman UnificationJosephlangeloNo ratings yet

- A Survey of English and American Literature Module 1 3Document80 pagesA Survey of English and American Literature Module 1 3Jathalia VillaNo ratings yet

- Parenteral Fluid Therapy: Types of Intravenous SolutionDocument18 pagesParenteral Fluid Therapy: Types of Intravenous SolutionKathleen Joy Costales Magtanong100% (1)

- Manual THT70 PDFDocument54 pagesManual THT70 PDFwerterNo ratings yet

- AJPMenu Bar MCQDocument8 pagesAJPMenu Bar MCQAkNo ratings yet

- A New Approach To The Deposition of Elemental Boron and Boron-Based Coatings by Pulsed Magnetron Sputtering of Loosely Packed Boron Powder TargetsDocument6 pagesA New Approach To The Deposition of Elemental Boron and Boron-Based Coatings by Pulsed Magnetron Sputtering of Loosely Packed Boron Powder TargetsyouamareNo ratings yet

- Visual Communication, Summary WritingDocument8 pagesVisual Communication, Summary WritingAsumpta MainaNo ratings yet

- MAKING THINGS SIMPLER Review of Related LiteratureDocument72 pagesMAKING THINGS SIMPLER Review of Related Literaturejuju_batugal100% (1)

- L&T Type 2 Co-Ordination Selection ChartsDocument48 pagesL&T Type 2 Co-Ordination Selection Chartsrdeepak99100% (7)

- Case StudiesDocument19 pagesCase StudiesSorin MarkovNo ratings yet

- Elah'Im CultureDocument60 pagesElah'Im CultureRichard David DellermanNo ratings yet

- Literature Review On OscilloscopeDocument5 pagesLiterature Review On Oscilloscopedhjiiorif100% (1)

- Manual vs Air Rotor Stripping SEM EvaluationDocument8 pagesManual vs Air Rotor Stripping SEM Evaluationlocos3dNo ratings yet

- The Vatican As A World Power (1939)Document481 pagesThe Vatican As A World Power (1939)sexylove1477No ratings yet

- Biology 1090 Exam 1 Study GuideDocument5 pagesBiology 1090 Exam 1 Study GuideAmandaNo ratings yet

- 2Tafseer2019Sep4 17 24oc1 8 29nov5 262020jan7 21F11 18 25Document96 pages2Tafseer2019Sep4 17 24oc1 8 29nov5 262020jan7 21F11 18 25Aroob YaseenNo ratings yet

- DBMS Notes For BCADocument9 pagesDBMS Notes For BCAarndm8967% (6)

- Festivals WorksheetDocument8 pagesFestivals WorksheetlurdesNo ratings yet

- AGUILA Automatic Coffee Machine User Manual - Instructions for Use EN DE FR ITDocument19 pagesAGUILA Automatic Coffee Machine User Manual - Instructions for Use EN DE FR ITPena Park HotelNo ratings yet