Professional Documents

Culture Documents

Job Hazard Analysis Worksheet: M-BCW-000DS0-GH00-JHA-000017 Rev.00

Uploaded by

Al Mughsar CompanyOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Job Hazard Analysis Worksheet: M-BCW-000DS0-GH00-JHA-000017 Rev.00

Uploaded by

Al Mughsar CompanyCopyright:

Available Formats

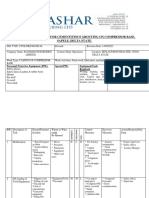

JOB HAZARD ANALYSIS WORKSHEET

Project/ RIYADH METRO PROJECT Date: 04th October 2017

Specific 1B1 STATION – DEEP UNDERGROUND STATIONS BACS Emergency

Location contact no:

SPIC – Anas

Shelbayeh

0580919913

ERT No (If

available):

Job Concrete Placement Site Medical Facility As Per Individual Sites

Description: Construction of Concrete Slab, walls & column. Location:

JHA Preparation Team: Responsible Implementation Team: Evacuation/Muster point: As Per Individual Sites

1 – Hazem Yousef – Arail / Construction Manager 1 – DUS Construction

2 – Anas Maher – Arail / Project Engineer 2- Tools and or Equipment required:

3 – Naser Aryani – Arail / HSE Manager 3- Crane, Boom Truck, Concrete Pump, mixer

4 – Mansour Subaihi – Arail / HSE Supervisor 4- truck.

5 – Ahmad Fadlulla – BACS / Project Engineer 5- Hand Tools, Mandatory PPE.

6 – Wayne Simpson – BACS / Construction Manager 6-

JHA No: M-BCW-000DS0-GH00-JHA-000017 Rev.00

RISK RESIDU ACTION

Job Steps HAZARDS IDENTIFIED RATI CONTROL METHOD AL BY/RECOR

NG RISK D

STEP 1. - Risks/Hazards not identified at work location 12 - Permits must be adhered to at all times 4 Supervisor

- Deliver daily STARRT card before undertaking works. - Undertake effective daily STARRT

briefing. H briefing before conducting works. Obtain L

- Poor communication / no crew engagement. signatures and forward copies to the ES&H

department.

Refn: Safety Task Analysis and Risk - Miscommunication due to language barrier - Open discussions are to be promoted

Reduction Talk (STARRT) through a more informal forum when the

(M-BCW-000000-GH00-PRO-000005)

- Failure to convey the JHAs content, JHA is delivered. JHA is to call on workers

procedures and hazards efficiently. to discuss their personal experiences of

safety issues for similar activities.

- Workers used for the task are not qualified or - JHA will be communicated by an

M-BCW-000DS0-GH00-JHA-000017 Rev.00 Page 1 of

11

Construction of Strip Footing for Temporary Traffic Deck

insufficiently trained. authorized translator through the workers’

native language.

- No PPE in place. - Appropriate PPE for the job to be used

- All workers are confirmed competent for

the task they are to carry out.

- Ensure all operators have necessary

licenses for both driving of the trucks as

well as operating the crane/boom truck, as

per local legislation requirements.

- Striking overhead cables / objects. - Ensure operators check surrounding area

for overhead cables and obstacles in

advance of using the trucks boom.

STEP 2. Supervisor /

- Delivery of equipment and - Vehicle striking a person. 12 - Physical barriers are to be used to 4 Operator /

materials to site/ Receiving segregate vehicles and pedestrians. Banksman

trucks. - Vehicle striking a piece of plant / equipment. H - All work areas are to be well lit. L

- All vehicles are to be equipped reverse

parking beepers.

- All drivers are to be competent and trained

to the required project standard.

- Clearly defined vehicle routes and

laydown areas.

-All movements within a work area are

controlled by a trained banks man located in

a protected position. Trained Banks man is

to wear identifiable PPE and ensure area is

clear of workers prior to use.

- Following the site specific MEPI control

plan.

STEP 3. Supervisor /

-Establishing Site -Placing barricades unevenly on the ground 8 -Ensure competent personnel are employed Banksman

might mislead the public and result in an for site establishment 4

accident -Placing barricades to secure area to be

poured concrete.

-Working close to live traffic 12 -Ensure that the traffic management plan is

in place before starting work. 4

-If no traffic management plan is in place,

place concrete barriers around work area.

M-BCW-000DS0-GH00-JHA-000017 Rev.00 Page 2 of

11

Construction of Strip Footing for Temporary Traffic Deck

-These concrete barriers shall be placed

when traffic is low.

-Flagmen to be used if necessary.

-At no time will employees be exposed to

uncontrolled vehicles.

-Access and Egress 8 -Work area identified and signposted.

-Access and egress points identified.

-Personnel on ground to have high visibility 4

clothing and hard hats, safety glasses. Steel

toe boots

-Only experienced operator to operate

-Contractor induction to familiarize

personnel with site

STEP 4. - Physical barriers are to be used to 4 Supervisor /

- Conveying Materials to site - Vehicle striking a person. 12 segregate vehicles and pedestrians. Operator /

(Rebar, forms etc.) - No personnel shall be allowed within the Banksman

work area extended boom radius including

the flagman/banks-man and supervisor.

- A barricade around work area shall be

- Vehicle striking a piece of plant / equipment. 12 erected with appropriate sign post and only

4

the banks-man will be allowed inside the

barricade.

- Banks-man/Flagman shall keep un-

authorized Personnel away from area.

- All work areas are to be well lit.

- All vehicles are to be equipped reverse

parking beepers.

- Operator/driver must be authorized and

competent to operate the equipment, must

have valid Saudi license and certification

from approved third party.

- Clearly defined vehicle routes and

laydown areas.

-All movements within a work area are

controlled by a banks man located in a

protected position. Trained Banks man is to

wear identifiable PPE and ensure area is

M-BCW-000DS0-GH00-JHA-000017 Rev.00 Page 3 of

11

Construction of Strip Footing for Temporary Traffic Deck

clear of workers prior to use.

- Following the site specific MEPI control

plan.

-A valid inspection/certification shall be

8 present on the equipment.

-Equipment malfunction -Daily Equipment Inspection check shall be

conducted by the operator prior to start 4

work.

-Equipment operator and supervisor shall

ensure that the daily safety check (checklist)

is carried out prior to starting the work.

-If any major faults are identified, cease

12

operations and call supervisor, Under no

circumstances operate equipment with

-Working During Inclement Weather defects. 3

-Work shall cease if the weather creates

8 additional hazard in the operation (e.g.

Rain, Thunder storms, High Humidity, etc.)

STEP 5. Supervisor /

-Lifting / uploading of Materials -Equipment malfunction 16 -all equipment must be approved by the Operator /

PMV dept. 4 Banksman

-Riggers in line of fire (pinch point) -all workers are competent for the task

they are to carry out (riggers).

- Manual Handling - Personnel injury from moving materials 16 - Avoid lifting above shoulder height.

-Don’t jerk a load and avoid dragging loads.

-Carry the load close to the body

-Assess items for packing, stability, weight

and awkwardness before lifting them.

-The route to be travelled is to be assessed

for hazards.

M-BCW-000DS0-GH00-JHA-000017 Rev.00 Page 4 of

11

Construction of Strip Footing for Temporary Traffic Deck

STEP 6. –- Positioning of - STARRT Meeting shall be conducted Foreman

concrete truck to fill concrete - Moving mixer truck hitting personnel, plant, 12 and JHA shall be discussed with the 4 /Supervisor

pump and facilities. Crew involved in the task. /Sift Engineer

NO JHA/NO STARRT-NO WORK.

- Flagman will assist vehicle movement

from the main site entrance towards the

work area. NO Flagman – No equipment

movement inside the site.

- Equipment driver must have valid Saudi

license.

- Flagman will assist the vehicle movement

- Mixer truck must be equipped with

reverse alarm and a working beacon

light.

- Equipment moving inside must have

head lights and hazard lights on.

All personnel working inside the site shall

wear high-visibility vest.

STEP 7. –- Pouring Foreman

Concrete Works - Blockage of Pipes or Hoses – Eye/Face 12 - Equipment shall be inspected daily prior 5 /Supervisor

/Sift Engineer

struck by concrete material caused by to use.

bursting. - Personnel shall wear appropriate eye and

face protection; Safety gloves.

- Release the pressure in the pipe or hose

- Clean out pipes fully after each use

- Preventative maintenance on all plant

- Toolbox talk provided to operatives on

safe cleaning out of the pipes procedure

- Clear line of communication between

pump man and sprayer/nozzle man to be

maintained.

- Personnel shall use appropriate hearing

protection

-Noise - Area will be isolated by a barrier with

12 sign posted. 2 Foreman

-Injury caused to other workers/personnel who - Only authorized personnel to enter the /Supervisor

working area controlled by a marshal and /Sift Engineer

M-BCW-000DS0-GH00-JHA-000017 Rev.00 Page 5 of

11

Construction of Strip Footing for Temporary Traffic Deck

are not involved in the concrete works lead miner

- All personnel entering the work area to

wear the correct PPE for the tasks being

undertaken at the time

- Manual handling training to be provided

15 to all operatives Foreman

-Manual Handling – Over-exertion / Personnel - Plan works to minimize manual handling. 6 /Supervisor

in danger of Back Injuries - Use of lightweight materials preferable or /Sift Engineer

design materials to be below 25Kg

- Store materials as near to the workface as

possible

-Use of mechanized lifting wherever

possible

- Eye and face protection to be worn by

9 operatives.

-Injury caused by Nozzle End – - Exclusion zone in place

Separated/Blown off from Hose - Periodic equipment maintenance Foreman

4

/Supervisor

- Periodic plant checks to ensure concrete /Sift Engineer

build up is minimized

- Quality control checks of size of

aggregates at Batching Plant

- Competent and trained plant operator

6 - Banksman to direct plant

-Workers or other Personnel struck by the - High visible PPE for all operatives

concrete pump/boom/hose skip causing injury - Exclusion Zone shall be in place Foreman

2 /Supervisor

- Regular safety reviews and briefings /Sift Engineer

- Tag line to be placed to control the hose

- Ensure all operatives know dangers of

12 working with cement/concrete

-Cement Burns from direct contact with - Impervious gloves and suitable boot

concrete footwear to be worn

- Safety glasses / face protection to be worn Foreman

- Freshly sprayed areas to be segregated in 4 /Supervisor

case of slumping /collapse of concrete /Sift Engineer

M-BCW-000DS0-GH00-JHA-000017 Rev.00 Page 6 of

11

Construction of Strip Footing for Temporary Traffic Deck

-

- Inspect power tools prior to use

- All Power supply shell be through ECLB.

8

- Electrocution (using power tool)

2 Foreman

/Supervisor

/Sift Engineer

STEP-8 - Slip, trip, fall from loose concrete, cables, 12 - Tools shall be kept away from walkways. 4 Foreman

- Housekeeping hoses and tools. - Hoses shall be maintained in good /Supervisor

/Sift Engineer

arrangement to prevent personnel tripping

on it.

- Rebound shall be removed and disposed

before shift ends to prevent accumulation

of material.

HAZARDS WHICH ARE NOT TASK SPECIFIC

- Conditional Risks - Sand - Damage to surrounding property from flying 12 - Provide sufficient sheltered areas with 3 Supervisor /

Storm. materials. enclosed sides for all employees. All Team

H - Actively monitor the local weather L Members

- Dust and particles entering employees eyes conditions

- Cease work during the storm.

- Prepare for high winds by securing loose

materials.

- All workers are to take shelter during

extreme weather.

- All workers are to wear safety glasses

(Mandatory PPE).

- Conditional Risks - Extreme - Heat stress. 16 - Working hours will be as per Saudi laws 4 Supervisor /

Heat. and weather conditions. Periodic brakes for All Team

- Heat exhaustion. H rest will be given. L Members

Refn: Heat and Cold Stress Prevention - Provide sufficient sheltered areas for all

(M-BCW-000000-GH00-PRO-000059) - Sun Burn. employees.

- Provide sufficient cooled drinking water

for all employees.

M-BCW-000DS0-GH00-JHA-000017 Rev.00 Page 7 of

11

Construction of Strip Footing for Temporary Traffic Deck

- Ensure all works take regular breaks when

working in the sun.

- Provide barrier / sun cream for application

in all welfare locations.

- Emergency Response (Site - Worker Injury. 8 - Adequate number of First Aiders on site 3 All Team

Wide). for the quantity of workers present. Members

- Fire on site. M - Emergency procedure & locations of first L

Refn: Emergency Preparedness aid kits clearly communicated.

(M-BCW-000000-GH00-PRO-000017) -Clearly communicated & defined muster

points.

- Address and directions to nearest Hospital

displayed at all access & egress points.

- Project emergency number distributed to

all employees and displayed at each work

location.

- Adequate number of First Aiders on site

for the tasks being carried out.

- Personal Hygiene. - Skin Disease. 8 - Regular housekeeping and bathing. 3 All Team

- Eat quality foods and hydrate regularly. Members

Refn: Welfare Arrangements - Illness. M Seek medical advice if in doubt. L

(M-BCW-000000-GH00-PRO-000075) - Individual is to immediately report to their

- Body Odour. supervisor in a case of illness.

- Ensure of adequate welfare facilities to a

suitable standard are in place prior to work

commencing.

- Considering Location’s - Difficult Terrain, Vegetation, Snake Bites, 5 -Wear appropriate boots and clothing. 3 Supervisor /

Environment Risks. Scorpion, Camel Spider etc. - Store all personal belongings indoors and All Team

M inspect areas regularly. L Members

Refn: HS&E Responsibilities - Inform staff of the Clinics located on site

(M-BCW-000000-GV00-MPL-00001) to provide emergency assistance.

M-BCW-000DS0-GH00-JHA-000017 Rev.00 Page 8 of

11

Construction of Strip Footing for Temporary Traffic Deck

SEVERITY LEVEL POTENTIAL CONSEQUENCES / IMPACTS

COMPANY LIABILITY/

SAFETY AND HUMAN HEALTH ENVIRONMENTAL

REPUTATION PROPERTY LOSS

First aid or slight injury/illness no Company/client concern, no

1 - Slight Insignificant impact, fully contained (Env Level 3) Slight loss (<$10K)

treatment media attention

OSHA recordable, medical Negligible short-term impact, confined on site, no regulatory

Community concern with

2 - Minor treatment, restricted work, exceedance Minor loss ($10-<$100K)

local media attention

temporary effect (Env Level 3)

Lost time injury/illness or Moderate to significant impact confined on site, regulatory State or provincial concern Moderate loss ($100-

3 - Moderate

permanent disability exceedance, or any off site impact(Env Level 2) with regional media attention <$1M)

Single fatality or permanent Significant impact on or off site, or potential enforcement

4 - Major National media attention Major loss ($1M-<$10M)

disability of 3 or more persons action (Env Level 1)

Catastrophic impact, long-term liability, or irreversible

5 - Catastrophic Multiple fatalities International media attention Catastrophic loss (>$10M)

damage (Env Level 1)

PROBABILITY TEST

PROBABILITY LEVEL

PROBABILIITY DEFINITION

1 Practically Never Occurs Consequence unheard of or not known to have occurred on Bechtel, Almabani or CCC projects or in the EPC industry

2 Not likely to Occur Consequence rarely occurs on Bechtel, Almabani or CCC projects or in the EPC industry

3 Could Occur Consequence may have occurred on Bechtel, Almabani or CCC projects and could occur again

4 Known to Occur Consequence has occurred more than once on Bechtel, Almabani or CCC projects and will likely occur again

5 Occurs Frequently Consequence has occurred multiple times on Bechtel, Almabani or CCC projects and will very likely occur again

PROBABILITY LEVEL

SEVERITY Increasing Probability

LEVEL

1 – Practically Never Occurs 2 – Not Likely to occur 3 – Could Occur 4 – Known to Occur 5 – Occurs Frequently

Increasing Severity

1 - Slight 1 - LOW 2 - LOW 3 - LOW 4 - LOW 5 - MEDIUM

2 - Minor 2 - LOW 4 - LOW 6 - MEDIUM 8 - MEDIUM 10 - HIGH

3 - Moderate 3 - LOW 6 - MEDIUM 9 - MEDIUM 12 - HIGH 15 - HIGH

4 - Major 4 - LOW 8 - MEDIUM 12 - HIGH 16 - HIGH 20 - HIGH

5 - 5 - MEDIUM 10 - HIGH 15 - HIGH 20 - HIGH 25 - HIGH

Catastrophic

PLANNED HIGH RISK CONSTRUCTION ACTIVITY

M-BCW-000DS0-GH00-JHA-000017 Rev.00 Page 9 of

11

Construction of Strip Footing for Temporary Traffic Deck

Excavation Explosives use Confined Space Entry Hazardous Substance use Work in/over water

Traffic Management Segment Installation Public Safety Mobile plant movement Lifting Activity

Gas/chemical fuel line

Road/rail work Energised Electrical work Temperature extreme Heavy haulage

work

Man and Equipment

Demolition work Work at heights Flammable/contaminated atmosphere

Interface

P.P.E REQUIREMENTS PLANT, EQUIPMENT & TOOLS FOR JOB TAGGING & SIGNS PERMITS/INSTRUCTION

“Check ” “Check ” “Check ” “Check ”

Full Body Safety Persons Working

Air Purifying Respirator Boom truck / Trailer Ladder SDS’s

Harness Above

Confined Space Hard Barrier/ Instruction

Static Line Crane & Lifting eq. Misc. Hand Tools

Harness Orange Fence Manual

Working on Live

Tinted Safety Glasses Gloves – PVC Shovel Extension Leads Flagging / Signalling

Electricity

Floor/Roof

Clear Safety Glasses Gloves – Hyflex (Nitrile) Welding Machine Backhoe Personal Locks

Opening

Personal Danger

Goggles Dust mask Vibro Compactor Power Source Hot Work

Tags

Powder actuated

Face Shield Safety Gloves Drilling Machine Out of Service Tags Lockout/ Tag out

Tools

Sun Screen Life jacket Grinder/Saw EWP Information Tags Excavation

Hearing Protection Tripod Scaffold Power Hand Tools Do not Use tag Confined Space

Do not Enter High Pressure /

SCBA Retractable Life line Fire Extinguisher Scissor Lift

signage Abrasive Blasting

Suspended

Compressor Unauthorised Keep

Airline Restraint Line Jack Hammer Personnel

machine away

Platform

Tunnel Boring Hazardous

machine Substances

M-BCW-000DS0-GH00-JHA-000017 Rev.00 Page 10 of

11

Construction of Strip Footing for Temporary Traffic Deck

SKILLS/COMPETENCIES/AUTHORISATIONS

“Check ”

EWP boom <11m Operator Crane Signaller / Banksman Rigger I Demolisher

EWP boom > 11m Tunnel Boring machine Excavator Rigger II Asbestos removalist

Scissor Lift Articulate Boom Platform Front End Loader Rigger III Light Vehicle

Concrete Placing Boom Working inside manhole Backhoe Dogger Heavy Rigid

Personnel Hoist Forklift Type and Capacity: Grader Scaffolder I Articulated

Working with Hazardous

Material Hoist Loader Scaffolder II Modular Transporter

Substances

Speed Boat for

Skid Steer Working on Electricity Scraper Scaffolder III

Transporting Personnel

EMERGENCY PRE PLAN

“Check ”

Emergency Response team Mobile Medical Facilities Emergency Medical Kit Fire Fighter Spill Response Team

Emergency Nearest Hospital Contact Outside Emergency Contact

First Aider Risk Assessment

Vehicle/Ambulance No. No.

Utility Contact No

NOTE: For further guidance please refer to the following project procedure - M-BAC-000000-GH00-PRO-000081 Job Hazard Analysis

M-BCW-000DS0-GH00-JHA-000017 Rev.00 Page 11 of

11

Construction of Strip Footing for Temporary Traffic Deck

You might also like

- F5B-BMJV-0001-AHA-HSE 00 AHA For Precast Storm Drain and Subdrain Uty.Document13 pagesF5B-BMJV-0001-AHA-HSE 00 AHA For Precast Storm Drain and Subdrain Uty.Taiwo Oshin100% (1)

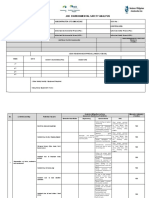

- JHA FOR CEMENTITIOUS GROUTING ON COMPRESSOR BASEDocument8 pagesJHA FOR CEMENTITIOUS GROUTING ON COMPRESSOR BASEaloysius akpanNo ratings yet

- Activity Hazard AnalysisDocument7 pagesActivity Hazard AnalysisAnthony MacatangayNo ratings yet

- AHA Roofing SystemDocument8 pagesAHA Roofing SystemLawrence adeleke Omisakin100% (1)

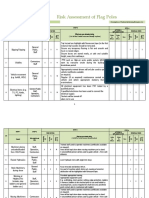

- Risk Assessment of Flag PolesDocument5 pagesRisk Assessment of Flag Polesطارق رضوانNo ratings yet

- Removal of Debris-Filling - Levelling & CompactingDocument8 pagesRemoval of Debris-Filling - Levelling & CompactingAl Mughsar CompanyNo ratings yet

- 001 SWMS - Piling WorkDocument20 pages001 SWMS - Piling Worksasi kumar0% (1)

- Job Activity Hazard Effect Control Measures: Project in ChargeDocument3 pagesJob Activity Hazard Effect Control Measures: Project in Chargeperquino oasanNo ratings yet

- Rapid P20ai Jsa Box CulvertDocument8 pagesRapid P20ai Jsa Box Culvertfadli.lpgNo ratings yet

- TieDocument5 pagesTieshinto LawrenceNo ratings yet

- Appendix-B - Construction Safey Manual at ProjectsDocument112 pagesAppendix-B - Construction Safey Manual at ProjectsvinodNo ratings yet

- Safe Work Method Statement: Excavation, Trenching and Underground ServicesDocument5 pagesSafe Work Method Statement: Excavation, Trenching and Underground ServicesMorhne RufinNo ratings yet

- JHA (Excavation of IPS Rev. B)Document4 pagesJHA (Excavation of IPS Rev. B)Armando AballeNo ratings yet

- SEOT JSA For Fence Installation 16-08-2021Document4 pagesSEOT JSA For Fence Installation 16-08-2021Archana SoorajNo ratings yet

- Tower Crane Dismantling JSA HSE ProfessionalsDocument2 pagesTower Crane Dismantling JSA HSE ProfessionalsnabeelNo ratings yet

- All JSAsDocument88 pagesAll JSAsQamar KhanNo ratings yet

- Job Hazard Analysis (Jha) WorksheetDocument4 pagesJob Hazard Analysis (Jha) WorksheetSamer AlsumaryNo ratings yet

- Activity Hazard Analysis FinalDocument23 pagesActivity Hazard Analysis FinalPedro PereiraNo ratings yet

- JSA for safe fence installationDocument5 pagesJSA for safe fence installationMoaatazz Nouisri50% (2)

- ARK JSA Manual ExcavationDocument8 pagesARK JSA Manual ExcavationMohammed Ali QaziNo ratings yet

- AHA-003, ExcavationDocument5 pagesAHA-003, ExcavationBuddhika100% (2)

- JSA For Pipe Installation TS 3Document8 pagesJSA For Pipe Installation TS 3Shilpiengg SafetyNo ratings yet

- Concrete Pouring JSaDocument12 pagesConcrete Pouring JSaTheo Vidallon BautistaNo ratings yet

- Risk Assesment Form For ScaffoldingDocument1 pageRisk Assesment Form For Scaffoldingchandanprakash30No ratings yet

- Fall Protection Plan CHECKLIST - GRUNLEY PDFDocument2 pagesFall Protection Plan CHECKLIST - GRUNLEY PDFAlexander LopezNo ratings yet

- Jsa Fueling Equipment On DeckDocument2 pagesJsa Fueling Equipment On DeckIlya BordonosovNo ratings yet

- JSA Formwork (Shuttering), Concrete Pouring, Curing, Surface PreparationDocument10 pagesJSA Formwork (Shuttering), Concrete Pouring, Curing, Surface PreparationMohammad Al Masa'dehNo ratings yet

- JSA For The Steel Fixing and Manual Conxrete Pouring at New Flare Line Phase 2 (Brown Area)Document7 pagesJSA For The Steel Fixing and Manual Conxrete Pouring at New Flare Line Phase 2 (Brown Area)Marvin BerrensteinNo ratings yet

- Block Work and PlasteringDocument7 pagesBlock Work and Plasteringmohammed sohailNo ratings yet

- SG-12 Safety Guideline For Demolition of Building and Structure-Final NewDocument39 pagesSG-12 Safety Guideline For Demolition of Building and Structure-Final NewrajiNo ratings yet

- Excavations JSA Final 2015Document5 pagesExcavations JSA Final 2015jithin shankarNo ratings yet

- Composite Works at Manglore For Hpclproject: Project No. W-488 Rev. 01 Page1 0f 2Document2 pagesComposite Works at Manglore For Hpclproject: Project No. W-488 Rev. 01 Page1 0f 2Bhargav BbvsNo ratings yet

- AHA-007, Concrete PouringDocument4 pagesAHA-007, Concrete PouringBuddhikaNo ratings yet

- Final Risk AssessmentDocument8 pagesFinal Risk Assessmentapi-514194726No ratings yet

- JHA For Positive IsolationDocument1 pageJHA For Positive IsolationShahid RazaNo ratings yet

- Concrete Work - Truck & PumpingDocument1 pageConcrete Work - Truck & PumpingGanga DaranNo ratings yet

- cONSTRUCTION WORK JSADocument21 pagescONSTRUCTION WORK JSAMohammed AlshehhiNo ratings yet

- Project HS Risk AssessmentDocument8 pagesProject HS Risk AssessmentParasNo ratings yet

- JSA For Manual Excavation Inside The Operation Area (Access Road)Document6 pagesJSA For Manual Excavation Inside The Operation Area (Access Road)Mohammed MinhajNo ratings yet

- Risk Assessment - FinalDocument7 pagesRisk Assessment - FinalHaymanAHMEDNo ratings yet

- Excavation SafetyDocument11 pagesExcavation SafetyDenease CrummieNo ratings yet

- Demolition JhaDocument2 pagesDemolition JhaElvyn Fabellore HerreraNo ratings yet

- JESA - HVAC Control WorksDocument7 pagesJESA - HVAC Control WorksResearcherNo ratings yet

- Safe Work Method Statement: One World Place Manila, 32nd ST, Taguig, Metro ManilaDocument6 pagesSafe Work Method Statement: One World Place Manila, 32nd ST, Taguig, Metro Manilanani ferrerNo ratings yet

- Work Method Statement: Confined SpaceDocument3 pagesWork Method Statement: Confined SpaceKarthik babu0% (1)

- Job Safety AnalysisDocument2 pagesJob Safety AnalysiscitraNo ratings yet

- Construction Demolition HazardsDocument2 pagesConstruction Demolition Hazardschirese2000No ratings yet

- Jsa Civil Work (00000002)Document6 pagesJsa Civil Work (00000002)Ali AlahmaNo ratings yet

- SWP Excavation Near Overhead Electrical Live LinesDocument2 pagesSWP Excavation Near Overhead Electrical Live LinesSn AhsanNo ratings yet

- AHA-009, Construction & Removing FormsDocument4 pagesAHA-009, Construction & Removing FormsBuddhikaNo ratings yet

- Doka FormworkDocument124 pagesDoka FormworkTranタオNo ratings yet

- JSA For Pressure Test 2ND REVISIONDocument10 pagesJSA For Pressure Test 2ND REVISIONMuthu AlaguRaj100% (1)

- Risk Assessment: Method Statement Painting ActivitiesDocument11 pagesRisk Assessment: Method Statement Painting ActivitiesWalid Amdouni100% (1)

- Scaffold CampaignDocument9 pagesScaffold CampaignAdel SukerNo ratings yet

- JSA Gathering Tent: Basic Job Step Potential Hazards Controls Action PartyDocument4 pagesJSA Gathering Tent: Basic Job Step Potential Hazards Controls Action PartyMuhammad TariqNo ratings yet

- Risk Assess T-23 - Hilti Cartridge Tool OperationDocument2 pagesRisk Assess T-23 - Hilti Cartridge Tool OperationMAB Ali100% (1)

- Installing External Signage SafelyDocument4 pagesInstalling External Signage SafelyAya MagdyNo ratings yet

- Hot Work Activities (Cutting)Document9 pagesHot Work Activities (Cutting)Al Mughsar CompanyNo ratings yet

- Job Hazard Analysis Worksheet: SupervisorDocument8 pagesJob Hazard Analysis Worksheet: SupervisorAl Mughsar CompanyNo ratings yet

- Job Hazard Analysis Worksheet: M-BCW-2B4DS0-GH00-JHA-00003 Rev.00Document13 pagesJob Hazard Analysis Worksheet: M-BCW-2B4DS0-GH00-JHA-00003 Rev.00Al Mughsar CompanyNo ratings yet

- Job Hazard Analysis Worksheet: SupervisorDocument8 pagesJob Hazard Analysis Worksheet: SupervisorAl Mughsar CompanyNo ratings yet

- Job Hazard Analysis Worksheet: M-BCW-2B4DS0-GH00-JHA-00003 Rev.00Document13 pagesJob Hazard Analysis Worksheet: M-BCW-2B4DS0-GH00-JHA-00003 Rev.00Al Mughsar CompanyNo ratings yet

- Job Hazard Analysis Worksheet: M-BCW-000DS0-GH00-JHA-000019Document13 pagesJob Hazard Analysis Worksheet: M-BCW-000DS0-GH00-JHA-000019Al Mughsar CompanyNo ratings yet

- Hot Work Activities (Cutting)Document9 pagesHot Work Activities (Cutting)Al Mughsar CompanyNo ratings yet

- Taking A History of DEPRESSIONDocument3 pagesTaking A History of DEPRESSIONPrarthana Thiagarajan100% (13)

- Plagiarism - Paraphrase and Summary HandoutDocument10 pagesPlagiarism - Paraphrase and Summary HandoutTika VirginiyaNo ratings yet

- SikaGrout Aid SDS 1683389Document10 pagesSikaGrout Aid SDS 1683389om prakashNo ratings yet

- Dr. Bondoc Found Liable for Grave Misconduct in Delivery CaseDocument3 pagesDr. Bondoc Found Liable for Grave Misconduct in Delivery CaseSalie VillafloresNo ratings yet

- Master Nauli for a Strong Core and DigestionDocument7 pagesMaster Nauli for a Strong Core and DigestionOVVCMOULINo ratings yet

- 36Document8 pages36Andra IrinaNo ratings yet

- Danone Integrated Annual Report 2021Document40 pagesDanone Integrated Annual Report 2021mohit gedamNo ratings yet

- (112 Benefits of Kalonji) Black SeedsDocument8 pages(112 Benefits of Kalonji) Black Seedsrizu23455No ratings yet

- Scott Cunningham - Cunningham's Encyclopedia of Wicca in The KitchenDocument6 pagesScott Cunningham - Cunningham's Encyclopedia of Wicca in The KitchenPandora Storm0% (1)

- Gynaecological Clinical Guidelines - NHSDocument39 pagesGynaecological Clinical Guidelines - NHSvchendilNo ratings yet

- Maternal Adaptations To Pregnancy - Hematologic Changes - UpToDate PDFDocument27 pagesMaternal Adaptations To Pregnancy - Hematologic Changes - UpToDate PDFDiego Andres VasquezNo ratings yet

- Mental Health and WellbeingDocument5 pagesMental Health and WellbeingNicole Ofili100% (1)

- UPPSCDocument4 pagesUPPSCSwati Pathak GiriNo ratings yet

- Blood Typing Lab Activity FinalDocument3 pagesBlood Typing Lab Activity FinalMrRightNo ratings yet

- Theories of ConsentDocument4 pagesTheories of ConsentUyên BíchNo ratings yet

- LOLER Inspection Checklist SheetDocument4 pagesLOLER Inspection Checklist SheetaliNo ratings yet

- EndometriosisDocument2 pagesEndometriosisIrham KasyfulNo ratings yet

- User Manual For The SpirometerDocument4 pagesUser Manual For The SpirometerAlex WilliamsNo ratings yet

- Sympatholytic DrugsDocument8 pagesSympatholytic DrugsJianne CaloNo ratings yet

- Tugas Aplikasi K3 Di Rumah SakitDocument6 pagesTugas Aplikasi K3 Di Rumah SakitSyifa marha GhaisaniNo ratings yet

- IEEE 1540 - Software Engineering Risk Management: Measurement-Based Life CycleDocument28 pagesIEEE 1540 - Software Engineering Risk Management: Measurement-Based Life Cycleminhlongyb89No ratings yet

- HLTH 308 Group Assignment 1Document9 pagesHLTH 308 Group Assignment 1api-681327493No ratings yet

- Journal 3 Personal Nutrition AssessmentDocument2 pagesJournal 3 Personal Nutrition Assessmentapi-456566589No ratings yet

- Cost Control in Health Care......................................Document11 pagesCost Control in Health Care......................................Rifat ParveenNo ratings yet

- Improve Your Deadlift 12-Week TRAINERDocument23 pagesImprove Your Deadlift 12-Week TRAINERNagan Ecomagu100% (1)

- 1.05 Liver and Portal HypertensionDocument12 pages1.05 Liver and Portal HypertensionZazaNo ratings yet

- Msds PG LyondellDocument9 pagesMsds PG LyondellGia Minh Tieu TuNo ratings yet

- Case Report PresbycusisDocument9 pagesCase Report PresbycusisSMA N 1 TOROHNo ratings yet

- Thinking Skills ExplainedDocument7 pagesThinking Skills Explainedmr_jamzNo ratings yet

- IELTS Mock Test - Latest Paper. Sri Lanka October,2020Document28 pagesIELTS Mock Test - Latest Paper. Sri Lanka October,2020Huma JabeenNo ratings yet