Professional Documents

Culture Documents

Quality Engineering PDF

Quality Engineering PDF

Uploaded by

Gopesh Virmani0 ratings0% found this document useful (0 votes)

7 views2 pagesOriginal Title

QUALITY-ENGINEERING.pdf

Copyright

© © All Rights Reserved

Available Formats

PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

0 ratings0% found this document useful (0 votes)

7 views2 pagesQuality Engineering PDF

Quality Engineering PDF

Uploaded by

Gopesh VirmaniCopyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

You are on page 1of 2

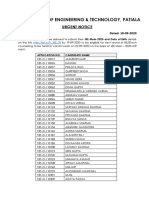

FACULTY OF ENGINEERING TECHNOLOGY & RESEARCH

MECHANICAL ENGINEERING DEPARTMENT

SUBJECT NAME : QUALITY ENGINEERING

SUBJECT CODE : 2181920

YEAR & SEMESTER : B.E. 4TH YEAR 8TH SEMESTER

Course Outcome (CO)

After learning the subject student will be able to,

1. Recognize the basic concepts of Quality Engineering and service sector.

2. Have the knowledge of fundamentals of Management Tools, Techniques & Standards.

3. Understand the basic principles of Total Quality Management.

4. Have basic understanding of Designing for Quality.

5. Apply methods of Design of Experiments.

6. Be aware of Contemporary Trends in Quality Engineering & Management.

Course Content

Sr. CO Total %

Content

No. Fulfilled Hrs. Weig.

Introduction: Different Definitions and Dimensions of Quality, Historical

Perspective (From Evolution of Quality Control, Assurance and 05

1. 1 10

Management to Quality as Business Winning Strategy), Contribution of

Renowned Quality Gurus (Their Philosophies and Impact on Quality).

Quality Engineering and Management Tools, Techniques &

Standards: 7 QC tools, 7 New Quality Management Tools, 5S Technique,

Kaizen, Poka-Yoke, Quality Circle, Cost of Quality Technique,

Introduction to Quality Management Standards – ISO : 9000, ISO:14000,

2. 2 10 20

QS:9000 (Concept, Scope, Implementation Requirements & Barriers, and

Benefits), Introduction to National and International Quality Awards

(Malcolm Baldrige National Quality Award – MBNQA, The Deming

Prize Rajiv Gandhi National Quality Award)

Total Quality Management: Basic Philosophy, Approach,

3. 3 03 10

Implementation Requirements & Barriers.

Designing for Quality: Introduction to Concurrent Engineering, Quality

4. Function Deployment (QFD) and Failure Mode and Effect Analysis 4 08 20

(FMEA) – Concept, Methodology and Application (with case studies).

Introduction to Design of Experiments: Introduction, Methods, Taguchi

5. 5 03 10

approach, Achieving robust design, Steps in experimental design.

Contemporary Trends in Quality Engineering & Management: Just in

time (JIT) Concept, Lean Manufacturing, Agile Manufacturing, World

Class Manufacturing, Total Productive Maintenance (TPM), Bench 10 20

6. 6 10 20

Marking, Business Process Re-engineering (BPR), Six Sigma - Basic

Concept, Principle, Methodology, Implementation, Scope, Advantages and

Limitation of all as applicable.

Quality in Service Sectors: Characteristics of Service Sectors, Quality

7. Dimensions in Service Sectors, Measuring Quality in Different Service 1 05 10

Sectors.

Reference Books:

1. Total Quality Management – Dr. S. Kumar, Laxmi Publication Pvt. Ltd.

2. Quality Control & Application by B. L. Hanson & P. M. Ghare, Prentice Hall of India.

3. Statistical Quality Control by M. Mahajan, Dhanpat Rai & Co. (P) Ltd

4. Total Quality Management by Dale H. Besterfield, Carol Besterfield-Michna, Glen H. Besterfield

and Mary Besterfield-Sacre, Pearson Educaiton

5. Quality Management by Kanishka Bedi

6. Quality Assurance and Total Quality Management (ISO 9000, QS 9000 ISO 14000) by K C Jain and

A K Chitale, Khanna Publishers 6. Total Quality Management by K C Arora, S K Kataria & Sons.

List of Open Source Software’s and learning website:

1. http://nptel.ac.in/

2. www.learnerstv.com

3. http://fetr.ac.in/departments/Mechanical-engineering/

4. http://www.ocw.mit.edu

Active Learning Assignment:

Preparation of slide show which includes videos, animations, pictures, graphics for better understanding

theory, practical work and presentation in front of other students and faculties.

You might also like

- TS1311 Instruction Sheet PDFDocument24 pagesTS1311 Instruction Sheet PDFnaveen100% (4)

- TQM SyllabusDocument4 pagesTQM SyllabusMazumder SumanNo ratings yet

- TQM Question BankDocument20 pagesTQM Question Bankbhuvansparks100% (1)

- CERTIFIED Quality EngineerDocument16 pagesCERTIFIED Quality Engineeracadjournals. comNo ratings yet

- Gujarat Technological University: Page 1 of 3Document3 pagesGujarat Technological University: Page 1 of 3Fa CaNo ratings yet

- Total Quality ManagementDocument3 pagesTotal Quality Managementraghav dhamaniNo ratings yet

- Course Duration: The Course Duration Is of 40 Sessions of 60 Minutes Each. 3. Course ContentsDocument3 pagesCourse Duration: The Course Duration Is of 40 Sessions of 60 Minutes Each. 3. Course Contentschirag khokhriNo ratings yet

- IE488 Total Quality ManagementDocument2 pagesIE488 Total Quality ManagementPraveen H Praveen H100% (1)

- Chapter 1Document36 pagesChapter 1Ratul DriveNo ratings yet

- A Project Report OnDocument67 pagesA Project Report Onpramodbms1369No ratings yet

- 6 Semester OEME 14601 Total Quality Management Internal Marks: 40 L T P External Marks: 60 3 0 0 Total Marks: 100 Course OutcomesDocument3 pages6 Semester OEME 14601 Total Quality Management Internal Marks: 40 L T P External Marks: 60 3 0 0 Total Marks: 100 Course OutcomesShubham MahajanNo ratings yet

- QeDocument2 pagesQenhpancholi01No ratings yet

- TQM - Introduction - 1Document4 pagesTQM - Introduction - 1Pratik AdhikaryNo ratings yet

- Total Quality Managementnt NoteDocument116 pagesTotal Quality Managementnt NoteAnthony Witava100% (1)

- PGDM OM 4.3 Quality Management and Six SigmaDocument1 pagePGDM OM 4.3 Quality Management and Six SigmaAlok SinghNo ratings yet

- GE8077 Total Quality Management 1Document124 pagesGE8077 Total Quality Management 1dhanush kannaNo ratings yet

- GE8077 Total Quality Management-By WWW - LearnEngineering.inDocument124 pagesGE8077 Total Quality Management-By WWW - LearnEngineering.inGopinathNo ratings yet

- Total Quality Management TQMDocument1 pageTotal Quality Management TQMDhaneshKumarNo ratings yet

- 058 - GE8077 Total Quality Management - Anna University 2017 Regulation SylDocument2 pages058 - GE8077 Total Quality Management - Anna University 2017 Regulation Sylvijay cvijayNo ratings yet

- TQMDocument1 pageTQMamar nathNo ratings yet

- Mba IV Total Quality Management (12mba42) NotesDocument113 pagesMba IV Total Quality Management (12mba42) NotesPradeep GsNo ratings yet

- Syllabus - TQMDocument2 pagesSyllabus - TQMjvanandhNo ratings yet

- Introduction To QualityDocument58 pagesIntroduction To QualityAswaja313No ratings yet

- Advance Quality Management & Lean Six Sigma: Course Title: Course Code: XXXXXXX Credit Hours: 3 + 0 Course InstructorDocument4 pagesAdvance Quality Management & Lean Six Sigma: Course Title: Course Code: XXXXXXX Credit Hours: 3 + 0 Course InstructorUmar AslamNo ratings yet

- DR - Alaa Mashiel: Report About Quality AssuranceDocument13 pagesDR - Alaa Mashiel: Report About Quality Assuranceحسين ميثم سعيد مهديNo ratings yet

- Effect of Iso 9000 Certification On TQM Implementation: December 2014Document27 pagesEffect of Iso 9000 Certification On TQM Implementation: December 2014ranjithNo ratings yet

- GE2022 Total Quality Management PDFDocument132 pagesGE2022 Total Quality Management PDFYash JainNo ratings yet

- 17ME664 TQM Module 1Document11 pages17ME664 TQM Module 11BE20ME448 Yashwanth H SNo ratings yet

- BPH4113Document99 pagesBPH4113gerald mwauraNo ratings yet

- Quality Engineering Quality Engineering ( (ME17307 ME17307) ) : Dr. S. B. MishraDocument8 pagesQuality Engineering Quality Engineering ( (ME17307 ME17307) ) : Dr. S. B. MishraAutomax MNNITNo ratings yet

- Module Information Module Title Quality Management and Six Sigma Module Code EMM502Document5 pagesModule Information Module Title Quality Management and Six Sigma Module Code EMM502sigmasundarNo ratings yet

- GE2022Document7 pagesGE2022Senthil RajkumarNo ratings yet

- BPL 2317 Total Quality ManagementDocument3 pagesBPL 2317 Total Quality Managementpeterdouglas489No ratings yet

- Presidency UniversityDocument4 pagesPresidency UniversityDark Gamer BDNo ratings yet

- Cqe Cert InsertDocument17 pagesCqe Cert InsertParush guptaNo ratings yet

- Ehs404: Total Quality ManagementDocument1 pageEhs404: Total Quality ManagementraghuNo ratings yet

- A Review and Analysis Concerning The Effects of Quality On Innovation PerformanceDocument12 pagesA Review and Analysis Concerning The Effects of Quality On Innovation PerformanceHuseyn AgayevNo ratings yet

- GE8077Document2 pagesGE8077shobhana cNo ratings yet

- Ge8077-Total Quality Management Syllabus 2017 Regulation: ObjectiveDocument2 pagesGe8077-Total Quality Management Syllabus 2017 Regulation: ObjectiveDinesh Kumar RNo ratings yet

- Unit 1 Quality Assurance SystemDocument1 pageUnit 1 Quality Assurance SystemRupesh BavadekarNo ratings yet

- QPI Chapter 2 SlidesDocument28 pagesQPI Chapter 2 SlidesLemon MoyoNo ratings yet

- Nptel: Quality Management - Web CourseDocument1 pageNptel: Quality Management - Web CourseDrMohamed MansourNo ratings yet

- IC364 Total Quality ManagementDocument2 pagesIC364 Total Quality ManagementAKSHAY KRISHNA K RNo ratings yet

- Product Quality Is Often Judged On Service Quality Is Often Judged On EightDocument36 pagesProduct Quality Is Often Judged On Service Quality Is Often Judged On EightRaj DharodNo ratings yet

- CIVIL-GE8077 Total Quality ManagementDocument124 pagesCIVIL-GE8077 Total Quality ManagementisvaryacivilengineeringNo ratings yet

- Cert Insert PDFDocument16 pagesCert Insert PDFKeerthi Kumar M. J.No ratings yet

- Ba5107 TQMDocument2 pagesBa5107 TQMRagunath PalanichamyNo ratings yet

- Cqe Cert InsertDocument16 pagesCqe Cert InsertNairda LopNo ratings yet

- Management & Control of QualityDocument2 pagesManagement & Control of QualityDeepak Singh NegiNo ratings yet

- BA9203 TQM Lesson PlanDocument12 pagesBA9203 TQM Lesson PlanvasanthasenanNo ratings yet

- Chapter TwoDocument28 pagesChapter TwoAlfiya DemozeNo ratings yet

- 2006 Common Body of Knowledge For The Certified Software Quality Analyst (CSQA)Document9 pages2006 Common Body of Knowledge For The Certified Software Quality Analyst (CSQA)Raviteja_Vegur_1170No ratings yet

- Tqm-Cse-2020-21 SyllabusDocument2 pagesTqm-Cse-2020-21 SyllabusapakkiNo ratings yet

- Unit 1Document41 pagesUnit 1Shruti ShrivastavaNo ratings yet

- Quality Management System in Contractor Organisations: An Empirical Study On Costs and Benefits of Iso 9001:2008 ImplementationDocument10 pagesQuality Management System in Contractor Organisations: An Empirical Study On Costs and Benefits of Iso 9001:2008 ImplementationHtet lin AgNo ratings yet

- Winsem2017-18 Mgt1010 TH Sjt703 Vl2017185005519 Reference Material I Crse Matrl-1 TQM MGT 1010 Win Sem 2017-18Document32 pagesWinsem2017-18 Mgt1010 TH Sjt703 Vl2017185005519 Reference Material I Crse Matrl-1 TQM MGT 1010 Win Sem 2017-18IshuJainNo ratings yet

- DCM 202 SyllabusDocument4 pagesDCM 202 SyllabusStanley CheruiyotNo ratings yet

- Quality in The Current Business Scenario - ContDocument17 pagesQuality in The Current Business Scenario - ContjayanNo ratings yet

- E-Notes PDF All-Units 21052019032434AMDocument84 pagesE-Notes PDF All-Units 21052019032434AMNananu hahaNo ratings yet

- Air Layer PaperDocument11 pagesAir Layer PaperRajesh ShuklaNo ratings yet

- Dr. Rajesh Shukla: TIET, PatialaDocument27 pagesDr. Rajesh Shukla: TIET, PatialaRajesh ShuklaNo ratings yet

- Operations ManagementDocument65 pagesOperations ManagementRajesh ShuklaNo ratings yet

- MCN 111: Introduction To P&I Exposure To Industrial EngineeringDocument48 pagesMCN 111: Introduction To P&I Exposure To Industrial EngineeringRajesh ShuklaNo ratings yet

- Session - 10: Online Sessions: TopicDocument8 pagesSession - 10: Online Sessions: TopicRajesh ShuklaNo ratings yet

- Mass and Energy Analysis of Control Volumes: Dr. Rajesh ShuklaDocument24 pagesMass and Energy Analysis of Control Volumes: Dr. Rajesh ShuklaRajesh ShuklaNo ratings yet

- Assignment 01 ProductivityDocument3 pagesAssignment 01 ProductivityRajesh ShuklaNo ratings yet

- Entropy Balance: Prof. Dr. Uğur AtikolDocument14 pagesEntropy Balance: Prof. Dr. Uğur AtikolRajesh ShuklaNo ratings yet

- ASMESIMPLE DrivenCavity PDFDocument9 pagesASMESIMPLE DrivenCavity PDFRajesh ShuklaNo ratings yet

- Assign ProDocument3 pagesAssign ProRajesh ShuklaNo ratings yet

- JEE Main - 2020 Missing DetailsDocument83 pagesJEE Main - 2020 Missing DetailsRajesh ShuklaNo ratings yet

- Pelton Turbine: Department of Mechanical Engg Indian Institute of Technology (ISM), DhanbadDocument8 pagesPelton Turbine: Department of Mechanical Engg Indian Institute of Technology (ISM), DhanbadRajesh ShuklaNo ratings yet

- Interfacial Phenomena in Impact of Droplet Array On Solid WallDocument15 pagesInterfacial Phenomena in Impact of Droplet Array On Solid WallRajesh ShuklaNo ratings yet

- Computer Simulation of Metals Ionization Process DDocument7 pagesComputer Simulation of Metals Ionization Process DRajesh ShuklaNo ratings yet

- SC Book 2011-021 PDFDocument8 pagesSC Book 2011-021 PDFRajesh ShuklaNo ratings yet

- Model Test Paper - 1 CMA Inter Group-II Paper - 9 Operations Management & Strategic Management Section - A (Operations Management) 1Document17 pagesModel Test Paper - 1 CMA Inter Group-II Paper - 9 Operations Management & Strategic Management Section - A (Operations Management) 1Rajesh ShuklaNo ratings yet

- Vdocuments - MX - Military Radar 20 Pages Documentation PDFDocument25 pagesVdocuments - MX - Military Radar 20 Pages Documentation PDFMohammed WasimNo ratings yet

- Correction: Brand: Model: Model Year: Vin: Engine: Transmission: Brand: Model: Engine: TransmissionDocument2 pagesCorrection: Brand: Model: Model Year: Vin: Engine: Transmission: Brand: Model: Engine: Transmissionأمجد راضي هادي /A1No ratings yet

- 2-16-2012 WISP Document From Vartel, LLCDocument7 pages2-16-2012 WISP Document From Vartel, LLCFederal Communications Commission (FCC)No ratings yet

- CSCDocument1 pageCSCMaulik MulaniNo ratings yet

- Portaria 377 2021 Televisores Compulsoriedade - Pt.enDocument43 pagesPortaria 377 2021 Televisores Compulsoriedade - Pt.enSylvioAlvesNo ratings yet

- Ministry of Education, Sports & Youth Affairs: Draft DocumentDocument46 pagesMinistry of Education, Sports & Youth Affairs: Draft DocumentEdward MulondoNo ratings yet

- Wib Brochure enDocument2 pagesWib Brochure enedsan alinsuagNo ratings yet

- Tesi Ufficiale Roberto Mario de StefanoDocument146 pagesTesi Ufficiale Roberto Mario de StefanoRoberto Mario De StefanoNo ratings yet

- JanyaDocument2 pagesJanyaTarun LuckyNo ratings yet

- AutoCAD 2D I Course SyllabusDocument2 pagesAutoCAD 2D I Course SyllabusTamy2012100% (3)

- PalletDocument6 pagesPalletSUBHOJIT BANERJEENo ratings yet

- Daa UnitiDocument41 pagesDaa UnitiRAJESHNo ratings yet

- Design & Analysis of Beam & SlabDocument30 pagesDesign & Analysis of Beam & Slabraahul_nNo ratings yet

- TLE Reviewer FundamentalDocument1 pageTLE Reviewer FundamentalCeelyn QuiambaoNo ratings yet

- IDES MK Returnable PackagingDocument9 pagesIDES MK Returnable Packagingaprian100% (1)

- Tle Computer Systems Servicing - 9: Let Us DiscoverDocument4 pagesTle Computer Systems Servicing - 9: Let Us DiscoverWilma Montis-AbendanNo ratings yet

- Radar System Using Arduino: Project ReportDocument31 pagesRadar System Using Arduino: Project ReportpoojaNo ratings yet

- R Rec SM.2097 0 201608 I!!pdf eDocument9 pagesR Rec SM.2097 0 201608 I!!pdf eAhmed HussainNo ratings yet

- WEEK 2 DSGN8290 The User and InteractionDocument10 pagesWEEK 2 DSGN8290 The User and InteractionMihir SataNo ratings yet

- CC Unit-1Document17 pagesCC Unit-1sreeharidas2124No ratings yet

- SoftwareTutorial ZXT58Document17 pagesSoftwareTutorial ZXT58Luis Oscar Quispe ValeroNo ratings yet

- DeskDocument1 pageDeskAyad GamalNo ratings yet

- David James Ignacio - Label The MicroscopeDocument3 pagesDavid James Ignacio - Label The MicroscopeDavid James IgnacioNo ratings yet

- Lab ManDocument33 pagesLab Manapi-3693527No ratings yet

- Directional Coupler - Theory-ApplicationDocument14 pagesDirectional Coupler - Theory-ApplicationSusilo Edy PNo ratings yet

- HW-C430 Xu FM 00 Eng 230206Document39 pagesHW-C430 Xu FM 00 Eng 230206ddr95827No ratings yet

- Planning and Control of Maintenance Systems - Modelling and Analysis-Springer International Publishing (2015)Document361 pagesPlanning and Control of Maintenance Systems - Modelling and Analysis-Springer International Publishing (2015)dahi100% (1)

- Conceptual Theoretical Framework of The StudyDocument27 pagesConceptual Theoretical Framework of The StudyEli de OcampoNo ratings yet

- Resume Ibm San Storage EngineerDocument43 pagesResume Ibm San Storage Engineerakbisoi1No ratings yet