Professional Documents

Culture Documents

Roughness PDF

Roughness PDF

Uploaded by

Suman Salanke0 ratings0% found this document useful (0 votes)

0 views1 pageOriginal Title

roughness.pdf

Copyright

© © All Rights Reserved

Available Formats

PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

0 ratings0% found this document useful (0 votes)

0 views1 pageRoughness PDF

Roughness PDF

Uploaded by

Suman SalankeCopyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

You are on page 1of 1

Roughness

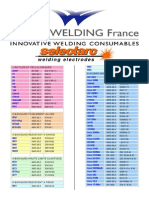

Roughness conversion table

Centre Line

Ra AA Rz Ry

Average Rt

μm μinch μm JIS μm ISO

CLA μinch μm UEFCO MCC

ISO 468 USA mean of 10 max 1302

GB Germany

e 4287 ASA B.46.1 points height

BS 1134

0.006 0.25 N01

0.012 0.5 0.05 0.05 N0

0.025 1 0.25 0.1 0.1 N1

0.05 2 0.5 0.2 0.2 N2

0.1 4 4 0.8 0.4 0.4 N3 f5

0.2 8 8 1.6 0.8 0.8 fP N4

0.4 16 16 2.5 1.6 1.6 fP N5 f4

0.8 32 32 4 3.2 3.2 fG N6 f3

1.6 63 63 8 6.3 6.3 fF N7 f2

3.2 125 125 16 12.5 12.5 fO N8 f1

6.3 250 250 25 25 25 fO N9 f

12.5 500 500 50 50 50 fR N10

25 1000 1000 100 100 100 fT N11

50 2000 200 200 N12

100 4000 400 400 N13

200 8000 N14

Symbols and level of finishing

Ra μm AA- CLA μinch Conventional symbols Surface description

0.025 1 Superfinishing

0.05 2 Burnishing diamond paste

0.1 4 Lapped, high level of finish, perfectly smooth

0.2 8 Lapped for seal joints

0.4 16 Ground, electric spark machining

0.8 32 Extra fine for machine tools, finish to the papers

1.6 63 Very smooth for machine tools

3.2 125 Smooth for machine tools

6.3 250 Medium for machine tools

12.5 500 Coarse for machine tools

25 1000 ~ Raw material

50 2000 ~ Raw material

- Roughness is the series of micro-geometrical errors present

on a surface prepared with any machining process.

- Roughness is measured on the surface in a transversal

direction to the main grooves.

- The mean arithmetical value “Ra” in μm is assumed for the

roughness measurement.

- Rt = maximum value of roughness or height from the lowest

point to highest point

- Rz = average roughness in 10 points

You might also like

- Foundation Design Philosophy For Vertical VesselDocument6 pagesFoundation Design Philosophy For Vertical VesselKyaw Kyaw AungNo ratings yet

- One Steel ReoDataDocument40 pagesOne Steel ReoDatapete0980100% (1)

- Saso Astm A615mDocument12 pagesSaso Astm A615mMohammed Imadullah Khan100% (1)

- EN6114Document14 pagesEN6114akayirNo ratings yet

- Astm A615m PDFDocument12 pagesAstm A615m PDFAnonymous q8HhQ4w50% (2)

- Crane Engineering Data2Document40 pagesCrane Engineering Data2jerry666aNo ratings yet

- Uncoated, Weldless, 2-And 3-Wire Steel Strand For Prestressed ConcreteDocument4 pagesUncoated, Weldless, 2-And 3-Wire Steel Strand For Prestressed ConcreteGustavo SuarezNo ratings yet

- Line Choke - EMC FiltersDocument15 pagesLine Choke - EMC FiltersHector MoragaNo ratings yet

- Common Steel StandardsDocument3 pagesCommon Steel Standardsva3ttnNo ratings yet

- Stud Bolt SpecificationDocument8 pagesStud Bolt SpecificationsantoshblonkarNo ratings yet

- RCC Slab Design Template As Per BSDocument1 pageRCC Slab Design Template As Per BSsudhir12345No ratings yet

- Steel EquivalentDocument4 pagesSteel EquivalentsudeponnaniNo ratings yet

- Leaded Tin Bronze C54400Document3 pagesLeaded Tin Bronze C54400nfcastingsNo ratings yet

- RF-370C DC MOTOR Series: Motor Torque/Speed/CurrentDocument1 pageRF-370C DC MOTOR Series: Motor Torque/Speed/CurrentGivago MolenaNo ratings yet

- Data PTDocument14 pagesData PTCofhely EthionNo ratings yet

- Classification Pns Grade Astm Yield Strength (Mpa) Tensile Strength (Mpa) Color CodingDocument3 pagesClassification Pns Grade Astm Yield Strength (Mpa) Tensile Strength (Mpa) Color CodingJoseff Anthony FernandezNo ratings yet

- Alumoweld Wire and Strand Phys Elec CharDocument1 pageAlumoweld Wire and Strand Phys Elec CharGabriel Alexis Malagon CarvajalNo ratings yet

- Spacing Limitations For ReinforcementsDocument3 pagesSpacing Limitations For ReinforcementsEric VillenasNo ratings yet

- Ubkhep Ob Design CheckDocument72 pagesUbkhep Ob Design CheckPrayas SubediNo ratings yet

- Transmit Tube Comparison ChartDocument3 pagesTransmit Tube Comparison Chartbellscb100% (2)

- Shalamcheh Old Alternator OnDocument16 pagesShalamcheh Old Alternator OnNihar RoyNo ratings yet

- Prestressed Concrete Analysis and Design Fundamentals 2nd Ed CAP 2 PDFDocument54 pagesPrestressed Concrete Analysis and Design Fundamentals 2nd Ed CAP 2 PDFCarlos Alberto Pacheco SierraNo ratings yet

- Ref: Optimized Cutting of Steel Angles Using EXCELDocument1 pageRef: Optimized Cutting of Steel Angles Using EXCELLuz DuarteNo ratings yet

- Aci DescriptionDocument18 pagesAci DescriptionSandy KavitakeNo ratings yet

- Saso Astm A706mDocument12 pagesSaso Astm A706mEduard AbastillasNo ratings yet

- Informative Annex 2 - Surface FinishDocument10 pagesInformative Annex 2 - Surface FinishzaheerNo ratings yet

- Is StandardDocument10 pagesIs Standardsarkararup100% (1)

- Data Sheet Standard ChannelsDocument2 pagesData Sheet Standard Channelsmanan_mansoorNo ratings yet

- SR 4Document12 pagesSR 4Parker333No ratings yet

- Weight Conductor CableDocument94 pagesWeight Conductor CablemehulrabariNo ratings yet

- Material Specifications and Mechanical PropertiesDocument1 pageMaterial Specifications and Mechanical PropertiesSagarKBLNo ratings yet

- 6A DiodeDocument2 pages6A DiodeMutharasu SelvaNo ratings yet

- 4.1 Analisa Perencanaan Struktur 4.1.1 Tabel Material Baja Yang DigunakanDocument11 pages4.1 Analisa Perencanaan Struktur 4.1.1 Tabel Material Baja Yang DigunakanannidianNo ratings yet

- AISI 8620 SteelDocument2 pagesAISI 8620 SteelVinit AhluwaliaNo ratings yet

- Aluminum 6061Document3 pagesAluminum 6061Achmad Rizal MustaqimNo ratings yet

- 044 RSHDocument6 pages044 RSHsandi_oilNo ratings yet

- 2.0" DM Dotmatrix 5X7: Kwality Photonics Private LimitedDocument1 page2.0" DM Dotmatrix 5X7: Kwality Photonics Private LimitedKike GutierrezNo ratings yet

- Low Alloy Steels Part2Document1 pageLow Alloy Steels Part2fedaquiNo ratings yet

- Mechanical Properties of Metric FastenersDocument2 pagesMechanical Properties of Metric Fastenersghostghost123No ratings yet

- IS-3757 HT BoltDocument6 pagesIS-3757 HT BoltRam Balak RoyNo ratings yet

- Tensile and Chemical Requirements (Excerpts From API Specifications, 1983 Edition)Document4 pagesTensile and Chemical Requirements (Excerpts From API Specifications, 1983 Edition)Yap Wen KhongNo ratings yet

- Table: Joint Displacements Joint Outputcase Casetype Steptype U1 U2 U3 R1Document4 pagesTable: Joint Displacements Joint Outputcase Casetype Steptype U1 U2 U3 R1AndiNo ratings yet

- Quality Standards Manual Tightening Loads and Torques For Standard Metric Bolts and Foundation BoltsDocument6 pagesQuality Standards Manual Tightening Loads and Torques For Standard Metric Bolts and Foundation Boltsgabriel_517180914No ratings yet

- Electrodes SelectarcDocument138 pagesElectrodes Selectarcfediss2014100% (2)

- Aluminum 6063Document2 pagesAluminum 6063Laurence SarmientoNo ratings yet

- Specifications of Rebar Grade: As Per ASTM StandardDocument2 pagesSpecifications of Rebar Grade: As Per ASTM StandardMyat SuNo ratings yet

- TC CatalogDocument79 pagesTC Catalogpayolin77100% (1)

- Steel Wire, Music Spring Quality: Standard Specification ForDocument4 pagesSteel Wire, Music Spring Quality: Standard Specification ForJosé Ramón Gutierrez100% (1)

- Dispro BehaDocument83 pagesDispro BehaCandra Anggit DewantaraNo ratings yet

- Stainless Steel PropertiesDocument3 pagesStainless Steel Propertieskiwanis_lamNo ratings yet

- API RP 07G Errata 1 Drill String Design N Oper Limits May2000Document12 pagesAPI RP 07G Errata 1 Drill String Design N Oper Limits May2000Budi KurniawanNo ratings yet

- Prioritas IiDocument1 pagePrioritas IiAdi SumarnoNo ratings yet

- LV Technical BrochureDocument44 pagesLV Technical BrochurenssainiNo ratings yet

- Surface Finish ChartDocument2 pagesSurface Finish Chartdeshpravin100% (1)

- British Commercial Computer Digest: Pergamon Computer Data SeriesFrom EverandBritish Commercial Computer Digest: Pergamon Computer Data SeriesNo ratings yet

- Reverberation Chambers: Theory and Applications to EMC and Antenna MeasurementsFrom EverandReverberation Chambers: Theory and Applications to EMC and Antenna MeasurementsNo ratings yet

- Friction Stir Welding of High Strength 7XXX Aluminum AlloysFrom EverandFriction Stir Welding of High Strength 7XXX Aluminum AlloysNo ratings yet

- Modern Glass CharacterizationFrom EverandModern Glass CharacterizationMario AffatigatoNo ratings yet

- Physics and Technology of Crystalline Oxide Semiconductor CAAC-IGZO: Application to LSIFrom EverandPhysics and Technology of Crystalline Oxide Semiconductor CAAC-IGZO: Application to LSINo ratings yet

- Ball Lock Pins: Self-Locking, With Combination Handle, Precipitation-Hardened EH 22380Document10 pagesBall Lock Pins: Self-Locking, With Combination Handle, Precipitation-Hardened EH 22380dreamingscientist3393No ratings yet

- Din 7349Document1 pageDin 7349dreamingscientist3393No ratings yet

- Ans RotDocument58 pagesAns Rotdreamingscientist3393No ratings yet

- Deep Groove Ball Bearings, Single Row, InSOCOAT - 6330 C3VL2071Document1 pageDeep Groove Ball Bearings, Single Row, InSOCOAT - 6330 C3VL2071dreamingscientist3393No ratings yet

- GB T 1804 200Document7 pagesGB T 1804 200dreamingscientist3393No ratings yet

- CV EnglishDocument3 pagesCV Englishdreamingscientist3393No ratings yet

- Tekton Test FormDocument40 pagesTekton Test FormNorman CanlasNo ratings yet

- Republic Act 9003Document17 pagesRepublic Act 9003Elijah FelipeNo ratings yet

- Unicom ValveDocument27 pagesUnicom ValveSandi AslanNo ratings yet

- MCQ On SWMDocument23 pagesMCQ On SWMSaquibh ShaikhNo ratings yet

- Lubrication SpecificationDocument5 pagesLubrication SpecificationManish ManiNo ratings yet

- MINOLTA EP3015 TroubleshoootingDocument132 pagesMINOLTA EP3015 TroubleshoootingciphardNo ratings yet

- Construction of Workstations at The Main Market-Capital Projects 2018Document48 pagesConstruction of Workstations at The Main Market-Capital Projects 2018Eng Hinji RudgeNo ratings yet

- FTM FinatTestMethods - Adhesivo de Papel Tapiz en MaderasDocument3 pagesFTM FinatTestMethods - Adhesivo de Papel Tapiz en MaderasnadiarhNo ratings yet

- Meter Moving CoilDocument4 pagesMeter Moving Coilabecdf100% (1)

- Electric Motors and GeneratorsDocument19 pagesElectric Motors and GeneratorsfahrimmiNo ratings yet

- Capacitor Bank Spec.Document2 pagesCapacitor Bank Spec.Ratana KemNo ratings yet

- ALFA ENGINEERING ISOLATION JOINTS Brochure PDFDocument11 pagesALFA ENGINEERING ISOLATION JOINTS Brochure PDFSamrandNo ratings yet

- Code of Practice For Precast Concrete Construction 2003 PDFDocument77 pagesCode of Practice For Precast Concrete Construction 2003 PDFNarasimha DvlNo ratings yet

- Techno-Economic Assessment About Sodium ChlorateDocument3 pagesTechno-Economic Assessment About Sodium ChlorateIntratec SolutionsNo ratings yet

- Foundry ShopDocument2 pagesFoundry ShopAhmed rehmanNo ratings yet

- Mill Housings Mangal SinghDocument5 pagesMill Housings Mangal SinghGun SmithNo ratings yet

- Drug NanocrystalDocument30 pagesDrug NanocrystalFahmi Aditya YulvandiNo ratings yet

- Plastiment®-BV 40Document3 pagesPlastiment®-BV 40KevinNo ratings yet

- Smartpack Monitoring and Control Unit PDFDocument20 pagesSmartpack Monitoring and Control Unit PDFSohaib Omer SalihNo ratings yet

- Selection of Column Internals Coker Unit Prohorenko Johnson Sulzer DCU Rio de Janiero 2009Document36 pagesSelection of Column Internals Coker Unit Prohorenko Johnson Sulzer DCU Rio de Janiero 2009zaibNo ratings yet

- US2033148 Barium GreaseDocument5 pagesUS2033148 Barium GreaseVirender KumarNo ratings yet

- Documen - Tips Bill of Quantities Architect StairsDocument85 pagesDocumen - Tips Bill of Quantities Architect StairsUsman AbdulkarimNo ratings yet

- Book of AbstractDocument261 pagesBook of AbstractSUNDRAMNAGANo ratings yet

- Datasheet MH600Document2 pagesDatasheet MH600Diego Barboza PenteadoNo ratings yet

- Color Codes For Pipe LinesDocument24 pagesColor Codes For Pipe Linesamantania12386% (14)

- InventoryDocument29 pagesInventoryBujang SuksesNo ratings yet

- Fiber Optic SensorsDocument12 pagesFiber Optic SensorsDhanasekarNo ratings yet

- Gad ProposalDocument29 pagesGad ProposalOOGA TITUS PATRICKNo ratings yet

- PP 2016Document54 pagesPP 2016Adam FullerNo ratings yet