Professional Documents

Culture Documents

Coupling Selection Method PDF

Coupling Selection Method PDF

Uploaded by

Arun Kumar0 ratings0% found this document useful (0 votes)

35 views2 pagesOriginal Title

Coupling Selection Method.pdf

Copyright

© © All Rights Reserved

Available Formats

PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

0 ratings0% found this document useful (0 votes)

35 views2 pagesCoupling Selection Method PDF

Coupling Selection Method PDF

Uploaded by

Arun KumarCopyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

You are on page 1of 2

Coupling selection method

Selection by

kW/100 method

Step 1: Obtain required factor from Service Factor Tables

Step 2: Determine the application kW per 100 RPM:

Motor kW x 100 x Service Factor

kW per 100 RPM =

Coupling RPM

Step 3: From Rating Tables, find a rating equal to or greater than the kW/100 RPM

Note coupling size from left hand column.

Step 4: Check maximum RPM capability.

Step 5: Check maximum bore capacity. If maximum bore is exceeded, move to larger size with

adequate bore, but be sure maximum RPM of coupling is not exceeded.

Selection by

torque method

Step 1: Obtain required factor from Service Factor Tables

Step 2: Determine the application Torque (N-m):

Motor kW x 9550 x Service Factor

Torque (N-M) =

Coupling RPM

Step 3: From Rating Tables, find a rating equal to or greater than the Calculated torque.

Note coupling size from left hand column.

Step 4: Check maximum RPM capability.

Step 5: Check maximum bore capacity. If maximum bore is exceeded, move to larger size with

adequate bore, but be sure maximum RPM of coupling is not exceeded.

Couplings and mechanical soft starts | PT Components | ABB 15

Coupling service factors

Application (Read Footnotes) Para-Flex D-Flex Grid-Lign Gear Disc

Agitators

Paddle or Propeller (Vert. or Horiz.) 1.00 1.25 1.00 1.00 1.00

Screw 1.00 1.25 1.00 1.00 1.00

Blowers

Centrifugal 1.00 1.25 1.00 1.00 1.00

Lobe 1.50 1.50 1.25 1.25 1.25

Vane 1.00 1.25 1.25 1.25 1.25

Brewing & Distilling

Bottling Machinery, Brew Kettle 1.00 1.25 1.00 1.00 1.00

Cooker (Continuous Duty) 1.00 1.25 1.00 1.00 1.00

Mash Tub 1.00 1.25 1.00 1.00 1.00

Scale Hopper-Frequent Starting Peaks 1.50 1.75 1.75 1.75

Can Filling Machine 1.00 1.25 1.00 1.00 1.00

Car Dumper 1.50 2.00 2.50 2.50 2.50

Car Puller 1.50 1.50 1.50 1.50 1.50

Clarifier 1.00 1.25 1.00 1.00 1.00

Classifier 1.00 1.25 1.00 1.00 1.00

Clay-Working Machines

Brick Press, Briquette Mach., Clay 1.50 1.50 1.50 1.75 1.50

Working Mach., Pug Mill

Compressor**

Centrifugal. Lobe, Screw 1.00 1.25 1.00 1.00 1.00

Lobe, Rotary 2.00 2.00 1.25 1.25 1.25

Reciprocating 1 cylinder -single acting 3.50 3.00 3.00 3.00

1 cylinder -double acting 3.00 3.00 3.00 3.00

2 cylinder-single acting 3.00 3.00 3.00 3.00

2 cylinder -double acting 2.50 3.00 3.00 3.00

3 cl. or more -single acting 2.50 3.00 3.00 3.00

3 cl. or more -double acting 2.00 2.00 2.00 2.00

Conveyors

Apron, Assembly, Belt, Chain, Flight, Oven 1.00 1.25 1.00 1.00 1.00

Reciprocating 2.50 © 3.00 3.00 3.00

Screw 1.00 1.25 1.00 1.00 1.00

Cranes and Hoists

Main Hoist-Medium Duty 1.50 1.50 1.75 1.75 1.75

Main Hoist-Heavy Duty 2.00 2.00 2.00 2.00 2.00

Skip Hoist, Travel Motion, Trolley 1.50 1.00 1.75 1.75 1.75

Motion, Slope 1.50 1.00 1.75 1.75 1.75

Crushers

Cane 2.00 2.00 2.00 2.00 2.00

Gyratory 2.50 2.50 2.50 2.50

Dredges

Cable Reel, Screen Drive, Stacker 1.50 1.50 1.75 1.75 1.75

Conveyor 1.50 1.50 1.75 1.25 1.75

Cutter Head Drive, Jig Drive 2.50 2.00 2.00 2.00 2.00

Pump, Utility Winch 1.50 1.50 1.75 1.50 1.75

Dynamometer 1.00 1.25 1.00 1.00 1.00

Elevators

Bucket, Freight 2.00 2.00 1.25 1.25 1.25

Exciter 1.00 1.25 1.00 1.00 1.00

Fans

Centrifugal 1.00 1.25 1.00 1.00 1.00

Cooling Tower 2.00 2.00 2.00 2.00 2.00

Heavy Duty (Forced Draft) 1.50 2.00 1.50 1.50 1.50

Induced Draft 1.50 2.00 1.50 1.50 1.50

Light 1.00 1.25 1.00 1.00 1.00

Propeller Indoor 1.50 2.00 1.50 1.50 1.50

16 ABB | PT Components | Couplings and mechanical soft starts

You might also like

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5819)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1093)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (845)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (590)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (897)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (540)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (348)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (822)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (122)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (401)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- Gas ExpanderDocument12 pagesGas ExpanderArun KumarNo ratings yet

- CCPP Flow Diagram PDFDocument1 pageCCPP Flow Diagram PDFArun KumarNo ratings yet

- PMBOK SummarizedDocument47 pagesPMBOK SummarizedArun KumarNo ratings yet

- Iron and Manganese RemovalDocument2 pagesIron and Manganese RemovalArun KumarNo ratings yet

- API Oil Water Separator DiscussionDocument4 pagesAPI Oil Water Separator DiscussionArun Kumar100% (1)

- Preconisation Kerui2Document12 pagesPreconisation Kerui2zinouNo ratings yet

- 45 MM 45 MM: For Contact Details - Visit WWW - Warman.co - Za For Contact Details - Visit WWW - Warman.co - ZaDocument1 page45 MM 45 MM: For Contact Details - Visit WWW - Warman.co - Za For Contact Details - Visit WWW - Warman.co - ZaMamiherintsoa Issaia RanaivoarimananaNo ratings yet

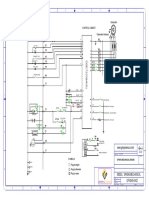

- GP Mechanical Wiring DiagramDocument2 pagesGP Mechanical Wiring DiagramRamon Thales Domeniconi100% (1)

- New Seal Kit Availability - 9-19-14 - IRM New Seal Kit Availability - 9-19-14Document23 pagesNew Seal Kit Availability - 9-19-14 - IRM New Seal Kit Availability - 9-19-14GUILLERMO SEGURANo ratings yet

- L04-L05 Parts 13-25-550 v05 42021Document84 pagesL04-L05 Parts 13-25-550 v05 42021Brandi HillNo ratings yet

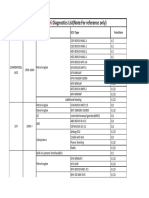

- Peugeot Diagnostics List (Note:For Reference Only) : Year Functions ECU Type Vehicle SystemDocument138 pagesPeugeot Diagnostics List (Note:For Reference Only) : Year Functions ECU Type Vehicle SystemWinston WolfNo ratings yet

- Mobile Refueling Equipment Evaluation FormDocument12 pagesMobile Refueling Equipment Evaluation Formsamson anyumbaNo ratings yet

- XT660R XT660X: Owner'S ManualDocument92 pagesXT660R XT660X: Owner'S ManualXGACDNo ratings yet

- Diesel Power 50Hz Open Type Generator SetDocument8 pagesDiesel Power 50Hz Open Type Generator Setchock channel 19No ratings yet

- SUZUKI-DT40S Motor Fuera de BordaDocument199 pagesSUZUKI-DT40S Motor Fuera de BordaDiego martinez castellanosNo ratings yet

- SQ8 - TFSI 373 KW TiptronicDocument10 pagesSQ8 - TFSI 373 KW Tiptronicvzky2016No ratings yet

- Ake Rigging - WAG9Document24 pagesAke Rigging - WAG9Ashutosh RajNo ratings yet

- MINOR PROJECT Final Draft !Document59 pagesMINOR PROJECT Final Draft !Kevin Sunil PappanNo ratings yet

- A330 ATA 70 - GE-CF680 E1 Components Location Guide - RedactedDocument82 pagesA330 ATA 70 - GE-CF680 E1 Components Location Guide - RedactedPenciu Marian Ionut100% (4)

- Otr Product CatalogDocument116 pagesOtr Product CatalogIwan KurniawanNo ratings yet

- EC145 Tech SpecificsDocument49 pagesEC145 Tech SpecificsVishnu SankarNo ratings yet

- Xerox Phaser 3020 Service Manual: 702P02829 June 2014Document14 pagesXerox Phaser 3020 Service Manual: 702P02829 June 2014aliNo ratings yet

- Instruction Manual For AC Generators EnglishDocument60 pagesInstruction Manual For AC Generators EnglishAlexNo ratings yet

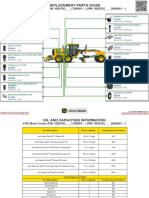

- Plano de Manutenção - MN-23 e 24 (JOHN DEERE 670-G)Document4 pagesPlano de Manutenção - MN-23 e 24 (JOHN DEERE 670-G)islanmateusfrNo ratings yet

- HD1500-8 Shop Manual (81001) SEN06630-02Document2,730 pagesHD1500-8 Shop Manual (81001) SEN06630-02Hamdanil ComNo ratings yet

- SHOAIB SHAIKH FRM 6th Apr OnwardsDocument507 pagesSHOAIB SHAIKH FRM 6th Apr OnwardsAnand Venugopal MenonNo ratings yet

- VARIO W Parts List and Exploded ViewDocument6 pagesVARIO W Parts List and Exploded Viewzein2000No ratings yet

- A Novel Implementation of Phase Control Technique For Speed Control of Induction Motor Using ARDUINODocument5 pagesA Novel Implementation of Phase Control Technique For Speed Control of Induction Motor Using ARDUINONg MeriedNo ratings yet

- R Series 3-3.5T Catalogue 2014-12-24 VersionDocument499 pagesR Series 3-3.5T Catalogue 2014-12-24 Versionkarsnab100% (2)

- Engine Terminology & CharacteristicsDocument45 pagesEngine Terminology & CharacteristicsAuto_DeloNo ratings yet

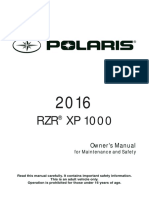

- RZR XP 1000: Owner's ManualDocument151 pagesRZR XP 1000: Owner's ManualRachid KrikriNo ratings yet

- Premium Blue GEO LA 40 ES-PI SheetDocument2 pagesPremium Blue GEO LA 40 ES-PI SheetTexol BangladeshNo ratings yet

- 50kva MinesViewBaguioxlsDocument3 pages50kva MinesViewBaguioxlsRM DulawanNo ratings yet

- Manual de Operacion Dumper TerexDocument146 pagesManual de Operacion Dumper TerexChristian Pavez Viscay100% (1)

- Danymics - Homeworks - Chapter 3 Kinetics of Particles - Energy and Momentum MethodsDocument3 pagesDanymics - Homeworks - Chapter 3 Kinetics of Particles - Energy and Momentum MethodsRed DemonsNo ratings yet