Professional Documents

Culture Documents

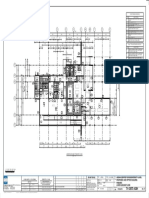

281119-221119 - MDS CST 18 Rev T05

Uploaded by

rajeshOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

281119-221119 - MDS CST 18 Rev T05

Uploaded by

rajeshCopyright:

Available Formats

Corporate Office:

3,ASHWINI, 160-14 A Main Road,

HAL 2nd Stage, Bangalore 560008, INDIA

Tel:91-80 - 2526 2339, 2527 3448;

Fax :91 - 80 - 2527 3627:

E-mail: contact@tmsindia.net.

Web site: www.tmsindia.com

Doc. No MDS/CST-18

This property belongs to TMS India Pvt. Ltd. These shall not be copied or reproduced without prior permission. Copyright reserved. Controlled copy in RED is authenticated & should be used as reference. All others are not authenticated.

MATERIAL DATA SHEET (MDS)

Rev No. T05

Date 28/11/19- 22/11/2019

Page No 1 of 1

Aluminium

Gravity Die ANSI A356-T64 Standard Equivalent

RM Group

Casting

Standard Grade

(partially Aged)

Material Alloy -T6 Heat

for Ref.

ASTM B26/B26M-09

Standards -

Treat

STANDARD ASTM B26/B26M-09 AIMED CHEMISTRY Remarks

Chemical Properties Element % Min % Max %

Si 6.5-7.5 6.5-7.5

Fe 0.20Max 0.15-0.20 if Mg percentage exceed 0.35%, yield strength value exceeds

Cu 0.20Max 0.20

the spec.

Mn 0.10Max 0.10

Mg 0.23-0.45 0.28-0.35

Ni % tends to reduce the elongation. So target as much lower as

Ni 28/11/19-- revised from 0.03Max 0.01

0.002 -0.005 to 0.002- possible --and not to exceed 0.01%.

Zn 0.006

0.10Max 0.10

Sr 0.010 - 0.030 0.015-0.025

B 0.002 -0.006 0.002-0.005 Use onle Al master alloys of Ti+ B & Sr for additions.

Ti levels should be as >0.10% <0.20%

Ti 0.10 to 0.20 0.17

<0.15 with individual <0.10 with Ni < 0.01% &

Others incl. Ni

element <0.03% other elements <0.03%

Mechanical Properties Min. Max. Heat treatment: "T64" -- partially Aged

Solutionised Hardness Bhn 50 62 50 58 Solution Annealed

As Aged Bhn 78 92.6 80 89 Pre-heat to 535℃ ± 5℃ for 5 hours and Soak/Hold at 535℃ ± 5℃ for

UTS, Mpa >250 >250

8Hrs , Water Quenched

YS, Mpa >172 >172

Targeted 50 to 62 Bhn. If higher,re-Solutionize

Elongation, % 7% >5

RA, 120 RA <120RA Revised Aging temperature to 160 C from 165 C

Age Hardened

Preheat slowly to 160℃ - over >4.5 hrs -- Soaked / hold at 160℃

approx For 2hr to 2hr10' mins to draw at 80 to 90 BHn-- target at 85

Bhn, Air Cooled

Targeted 85 Bhn. if lower than 80 or higher than 92.6 Bhn re-

Solutionise and re-age harden to required range.

ACCEPTANCE TESTS ON RECEIVING SAMPLES CERTIFICATION REQUIREMENTS ON RM

Chemical Analysis a

a

Mechanical test reports Hardness test On trowel mount in supply at designated

location-- in each Tray of Each heat treat ( post aging

batch).

To ensure required specification heat treatment standards

as per actually mentioned in TC.

Heat Treatment Heat treatment graph generated by automatic recorder to

be attached for every heat-- identifying cast heat no & qty

also

- 100% on all samples and 5% sample in Pilots

Digital X-ray Test - If required we take check shot on production lots

to maintain record for Production

100% ID-TR packing list with heat Nos+ box wts & graphs Required

100% Visual Inspection Report Must be done at the foundry. No report required

100% in samples.

Dimesnional Inspection Report Critical dimensions by Sampling Plan per ISO 2859 Level G-

II in production lot

Parts Used On : Trowel Mounts--WC131-R , WC106-R , WC108-R , WC111-R , WC121-R , WC126-R

REV T01 NEW MDS FOR TROWEL MOUNTING Dtd:31-12-2018

You might also like

- 18 - GRE ScoreDocument2 pages18 - GRE ScoreNaghizadehrokniNo ratings yet

- B209M ASTM Aluminum StandardsDocument26 pagesB209M ASTM Aluminum StandardsDanny SeeNo ratings yet

- Your Scores For The General Test Taken On October 11, 2017Document3 pagesYour Scores For The General Test Taken On October 11, 2017AsifNo ratings yet

- Test Taker Score Report: December 21, 2019 Test Date Scores ScoresDocument2 pagesTest Taker Score Report: December 21, 2019 Test Date Scores ScoresMuhammad Rizwan KhalidNo ratings yet

- MSDS - Sweet Almond OilDocument3 pagesMSDS - Sweet Almond Oilasetaldehit yıldırımNo ratings yet

- 2 PlansDocument1 page2 PlansMark Nathan Sta. MonicaNo ratings yet

- PlumbingDocument6 pagesPlumbingalan udenNo ratings yet

- Saipim Indonesia electrical schematicDocument1 pageSaipim Indonesia electrical schematicWasis Muharam BhayangkaraNo ratings yet

- ETS GRE Score ReportDocument3 pagesETS GRE Score ReportAtheer HakeemNo ratings yet

- 2mc625e4 PDFDocument3 pages2mc625e4 PDFRameshwor PoudelNo ratings yet

- Santosh's Resume 2Document2 pagesSantosh's Resume 2santosh tamtaNo ratings yet

- 1l LorenzoDocument3 pages1l LorenzoAnonymous KMVhQx5i3nNo ratings yet

- IFC - Issued Field RevisionDocument1 pageIFC - Issued Field RevisionazarNo ratings yet

- ADY-FORM Sample Submission FormDocument1 pageADY-FORM Sample Submission FormalexNo ratings yet

- ARC BARA R (30 April)Document1 pageARC BARA R (30 April)Randika SpNo ratings yet

- Phase-I: Job No. 26148Document1 pagePhase-I: Job No. 26148Rodrigo Andres CeledonNo ratings yet

- Your Scores For The General Test Taken On August 14, 2013: Vishakha A Rawal Most Recent Test Date: August 14, 2013Document3 pagesYour Scores For The General Test Taken On August 14, 2013: Vishakha A Rawal Most Recent Test Date: August 14, 2013swabrijNo ratings yet

- Decking SupportDocument1 pageDecking SupportPhú NguyễnNo ratings yet

- Company ProfileDocument4 pagesCompany ProfileMareks LezevskisNo ratings yet

- Test Gamker 2Document1 pageTest Gamker 2Oky AlfianNo ratings yet

- LF Plant STG S.p.A. Main Control PanelDocument98 pagesLF Plant STG S.p.A. Main Control Panelharetha all nassanNo ratings yet

- Dhemaji District Income CertificateDocument1 pageDhemaji District Income CertificateBoishal Bikash BaruahNo ratings yet

- D038 Evs Co000 1091 - 00Document1 pageD038 Evs Co000 1091 - 00Mussarat BabasahebNo ratings yet

- Dhemaji: Dhemaji District (Assam E-District Project)Document1 pageDhemaji: Dhemaji District (Assam E-District Project)Boishal Bikash BaruahNo ratings yet

- Dhemaji: Dhemaji District (Assam E-District Project)Document1 pageDhemaji: Dhemaji District (Assam E-District Project)Boishal Bikash BaruahNo ratings yet

- 172 I1909e 000 46 DW 0104Document1 page172 I1909e 000 46 DW 0104Jose Carlos Moraga LópezNo ratings yet

- 15 RCPDocument1 page15 RCPMark Nathan Sta. MonicaNo ratings yet

- RADIALL - RP66393 Plug With Backshell CapDocument1 pageRADIALL - RP66393 Plug With Backshell CapIlaiarajaNo ratings yet

- 3 P 132 9301 1a3a N 01 - Rev01Document1 page3 P 132 9301 1a3a N 01 - Rev0146 JOSHI SWAPNIL OMNo ratings yet

- 02.1 Retaining Wall (12-15)Document2 pages02.1 Retaining Wall (12-15)WILIAMNo ratings yet

- Your Scores For The General Test Taken On December 30, 2017Document3 pagesYour Scores For The General Test Taken On December 30, 2017kshipra123No ratings yet

- 4 - SAB - Traffic Signage PlanDocument18 pages4 - SAB - Traffic Signage PlanAkshay MannNo ratings yet

- ششششششDocument1 pageششششششMohamed Sayed FouadNo ratings yet

- Plano de SeccionsDocument1 pagePlano de SeccionsAugusto Mamani HinojosaNo ratings yet

- Appendix A-1-Gtg Busduct LayoutDocument1 pageAppendix A-1-Gtg Busduct LayoutShuhan Mohammad Ariful HoqueNo ratings yet

- Kitchen Plumbing LayoutDocument1 pageKitchen Plumbing Layoutrahul kumarNo ratings yet

- Layout IDM - PemantauanDocument1 pageLayout IDM - Pemantauandepy dwitasitepuNo ratings yet

- Jainson Clip On Terminals & Connector Price List Wef 01-03-2022Document8 pagesJainson Clip On Terminals & Connector Price List Wef 01-03-2022M/S.TEJEET ELECTRICAL & ENGG. CORP.No ratings yet

- MOTONIVELADORA HYD PLANO HYDDocument4 pagesMOTONIVELADORA HYD PLANO HYDAlejandro ReyesNo ratings yet

- A102 (Initial Set) - 2023-02-03 - 11-18-11amDocument1 pageA102 (Initial Set) - 2023-02-03 - 11-18-11amDavid KisaluNo ratings yet

- Your Scores For The General Test Taken On July 16, 2020Document3 pagesYour Scores For The General Test Taken On July 16, 2020tanmay rahmanNo ratings yet

- 172 I1909e 000 46 DW 0106Document1 page172 I1909e 000 46 DW 0106Jose Carlos Moraga LópezNo ratings yet

- Zak Residence (Shell Estimate) - Linear Thickened Edges, Beams, Joists, Etc. 5.5.2023 @9.04PMDocument5 pagesZak Residence (Shell Estimate) - Linear Thickened Edges, Beams, Joists, Etc. 5.5.2023 @9.04PMJames RecañaNo ratings yet

- ARCHITECTURALDocument13 pagesARCHITECTURALKhalil AlluhaybiNo ratings yet

- PS-1 PS-2 PS-3: Side View Elevation Side Viev Elevation Side Viev ElevationDocument1 pagePS-1 PS-2 PS-3: Side View Elevation Side Viev Elevation Side Viev ElevationYusuf HungundNo ratings yet

- SD MTB Subfolder 2010 GB RZ WWWDocument2 pagesSD MTB Subfolder 2010 GB RZ WWWAustrian National Tourism BoardNo ratings yet

- Redmi-8 ADocument36 pagesRedmi-8 A103293105No ratings yet

- Your Residential Electricity Bill: Total To PayDocument2 pagesYour Residential Electricity Bill: Total To PayJaram JohnsonNo ratings yet

- 3 Plans ElevDocument1 page3 Plans ElevMark Nathan Sta. MonicaNo ratings yet

- Srishti Launch CP Outreach and Activity TrackingDocument7 pagesSrishti Launch CP Outreach and Activity Trackingdarshan shettyNo ratings yet

- LS-2371 L2 Sunken Lounge 'A' Details PDFDocument1 pageLS-2371 L2 Sunken Lounge 'A' Details PDFvin ssNo ratings yet

- Propiedad de Don Pollo Loreto S.A.C. P.E. #11055640Document1 pagePropiedad de Don Pollo Loreto S.A.C. P.E. #11055640Cecilia Mego GomezNo ratings yet

- Tax Invoice for Designing & Adaptation ChargesDocument1 pageTax Invoice for Designing & Adaptation ChargesPrem Kumar YadavalliNo ratings yet

- AAT GulfJobPaper 12 SeptDocument2 pagesAAT GulfJobPaper 12 SeptMd AsifNo ratings yet

- Ele SLD 202 CDocument1 pageEle SLD 202 CIzarulhaq AwangNo ratings yet

- Dhemaji District (Assam E-District Project) : CSC Name: Dhemaji, MADURI PATHARDocument1 pageDhemaji District (Assam E-District Project) : CSC Name: Dhemaji, MADURI PATHARkaminaladka72No ratings yet

- Equipment Loading Estimation (Max. Operating) Equipment Loading Estimation (Max. Operating)Document1 pageEquipment Loading Estimation (Max. Operating) Equipment Loading Estimation (Max. Operating)Lim Yi SernNo ratings yet

- 010 VCARD, QR Code, 85x54mm, US-Address FormatDocument1 page010 VCARD, QR Code, 85x54mm, US-Address Formatعلاء البناءNo ratings yet

- Planonodocvdcañaveral4 (1) 1705762681086Document1 pagePlanonodocvdcañaveral4 (1) 1705762681086Otoniel Rodriguez G.No ratings yet

- Your Scores For The General Test Taken On June 22, 2017: Pranav Reddy Anumula Most Recent Test Date: June 22, 2017Document3 pagesYour Scores For The General Test Taken On June 22, 2017: Pranav Reddy Anumula Most Recent Test Date: June 22, 2017pandu.prathish26No ratings yet

- CoimbatoreDocument1 pageCoimbatorerajeshNo ratings yet

- CoimbatoreDocument1 pageCoimbatorerajeshNo ratings yet

- CoimbatoreDocument1 pageCoimbatorerajeshNo ratings yet

- Test Certificate Dart CoimbatoreDocument1 pageTest Certificate Dart CoimbatorerajeshNo ratings yet

- CoimbatoreDocument1 pageCoimbatorerajeshNo ratings yet

- QFS04 WC111 92BHN 4Document1 pageQFS04 WC111 92BHN 4rajeshNo ratings yet

- QFS04 WC111 92BHN 4Document1 pageQFS04 WC111 92BHN 4rajeshNo ratings yet

- CoimbatoreDocument1 pageCoimbatorerajeshNo ratings yet

- QFS 12092022Document1 pageQFS 12092022rajeshNo ratings yet

- CoimbatoreDocument1 pageCoimbatorerajeshNo ratings yet

- QFS 15092022Document1 pageQFS 15092022rajeshNo ratings yet

- Static and Fatigue Strength of A Die Cast Aluminium Alloy Under Different Feeding ConditionsDocument5 pagesStatic and Fatigue Strength of A Die Cast Aluminium Alloy Under Different Feeding ConditionsrajeshNo ratings yet

- Generate E-Way Bill for Transportation of GoodsDocument1 pageGenerate E-Way Bill for Transportation of GoodsrajeshNo ratings yet

- Generate SEO-Optimized Title for E-Way Bill DocumentDocument1 pageGenerate SEO-Optimized Title for E-Way Bill DocumentrajeshNo ratings yet

- QFS 18092022Document1 pageQFS 18092022rajeshNo ratings yet

- Generate E-Way Bill for Transportation of GoodsDocument1 pageGenerate E-Way Bill for Transportation of GoodsrajeshNo ratings yet

- Vital 03022023Document1 pageVital 03022023rajeshNo ratings yet

- Radiographic Examination: Standard Practice ForDocument17 pagesRadiographic Examination: Standard Practice ForrajeshNo ratings yet

- Static and Fatigue Strength of A Die Cast Aluminium Alloy Under Different Feeding ConditionsDocument5 pagesStatic and Fatigue Strength of A Die Cast Aluminium Alloy Under Different Feeding ConditionsrajeshNo ratings yet

- TMS03022023Document1 pageTMS03022023rajeshNo ratings yet

- ASTM E 1815 - 2008 Classification of Film Systems For Industrial Radiography1Document8 pagesASTM E 1815 - 2008 Classification of Film Systems For Industrial Radiography1grimaguilNo ratings yet

- B Esimating 10-22Document13 pagesB Esimating 10-22Mursaleen BawarNo ratings yet

- Sikadur-42 HF PDS PDFDocument4 pagesSikadur-42 HF PDS PDFMiljan MilanovicNo ratings yet

- Asean Centre For Biodiversity (Acb) Proposed Acb Office Building Lower Ground Floor Finishes 0Document1 pageAsean Centre For Biodiversity (Acb) Proposed Acb Office Building Lower Ground Floor Finishes 0Vince Bagsit PolicarpioNo ratings yet

- Esab Ferroweld 1: Covered (Stick) Electrodes (Smaw) Low Hydrogen ElectrodesDocument1 pageEsab Ferroweld 1: Covered (Stick) Electrodes (Smaw) Low Hydrogen Electrodesraghubhaimantra4136No ratings yet

- Refractory Ceramic Fiber BlanketDocument2 pagesRefractory Ceramic Fiber BlankethailmarylugoNo ratings yet

- GMM Mag.Document1 pageGMM Mag.Ehsan KhanNo ratings yet

- Plumbing plans for college buildingDocument3 pagesPlumbing plans for college buildingFeMarie BesanNo ratings yet

- Categorias Pipin ClassGRI 3007567 18007 ID MET If 001 - A01 0Document26 pagesCategorias Pipin ClassGRI 3007567 18007 ID MET If 001 - A01 0Geovanny MarquezNo ratings yet

- ASME B31.3 InterpretationsDocument338 pagesASME B31.3 InterpretationsRamdasNo ratings yet

- Floor DiaphragmDocument24 pagesFloor DiaphragmChristian LeobreraNo ratings yet

- Tyco Fig.110-190 Ball Valves DatasheetDocument24 pagesTyco Fig.110-190 Ball Valves DatasheetMahdi Daly100% (1)

- Literature Review:: Polymer BlendsDocument2 pagesLiterature Review:: Polymer BlendsWhy SadNo ratings yet

- Din-2353 Гайки и ЛещиDocument17 pagesDin-2353 Гайки и Лещиyulian.stanevNo ratings yet

- ETA - 110030 - Rotho Blaas HBS ScrewsDocument25 pagesETA - 110030 - Rotho Blaas HBS ScrewsGuillaumeHNONo ratings yet

- PART 65 ASME IX - Part 3 How To Carry Out A Welder QualificationDocument9 pagesPART 65 ASME IX - Part 3 How To Carry Out A Welder Qualificationravindra_jivaniNo ratings yet

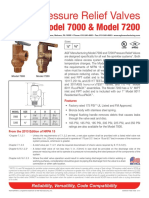

- Valvula Alivio PDFDocument2 pagesValvula Alivio PDFyesid rodriguezNo ratings yet

- Effect of Multi-Pass SMAW Welding On The Surface HDocument7 pagesEffect of Multi-Pass SMAW Welding On The Surface HYousab CreatorNo ratings yet

- Ceiling TechnologyDocument6 pagesCeiling Technologypdf2004No ratings yet

- Types of Building FramesDocument23 pagesTypes of Building FramesimaniNo ratings yet

- 12 Basic Plumbing Supplies For Home Tool Kits - DIY GuyDocument8 pages12 Basic Plumbing Supplies For Home Tool Kits - DIY GuyuraiNo ratings yet

- List of INDIAN METALS SectorDocument6 pagesList of INDIAN METALS SectorSwapnil BagulNo ratings yet

- Indiga Indiga: Tech TechDocument32 pagesIndiga Indiga: Tech Techsunny100% (1)

- Brass PPTDocument41 pagesBrass PPTAbhiram shuklaNo ratings yet

- NASM Conservation Exhibit Design Guidelines PDFDocument14 pagesNASM Conservation Exhibit Design Guidelines PDFPrakash KumarNo ratings yet

- Dezurik Eccentric Plug Valves Pec Pef 12 3 Pec Eccentric Plug Valves Technical 12-00-1bDocument12 pagesDezurik Eccentric Plug Valves Pec Pef 12 3 Pec Eccentric Plug Valves Technical 12-00-1bOleg ShkolnikNo ratings yet

- Bamboo - 7Document6 pagesBamboo - 7Sumanth NNo ratings yet

- Argelite - Horizontal SystemsDocument9 pagesArgelite - Horizontal Systemsmada009No ratings yet

- Wall Footing CalculationsDocument12 pagesWall Footing Calculationsbsreenu393No ratings yet

- Injection System Brochure PDFDocument9 pagesInjection System Brochure PDFPavala AyyanarNo ratings yet

- CX Tds 2322s EngDocument5 pagesCX Tds 2322s EngKeiwer SuárezNo ratings yet