Professional Documents

Culture Documents

Solidification and Liquation Cracking PDF

Solidification and Liquation Cracking PDF

Uploaded by

ravi00098Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Solidification and Liquation Cracking PDF

Solidification and Liquation Cracking PDF

Uploaded by

ravi00098Copyright:

Available Formats

Overview Welding

Solidification and Liquation Cracking

Issues in Welding

Sindo Kou

Solidification cracking can occur in Figure 2a and b shows examples of between grains.8 When localized tensile

the fusion zone during the solidification solidification cracking and liquation stresses/strains in the material exceed

of the weld metal. Liquation cracking, on cracking in circular-patch welds of its resistance to cracking, solidification

the other hand, can occur in the partially aluminum alloys. As shown, solidifica- cracking occurs.

melted zone during the solidification tion cracking occurs more or less

ASSESSING SOLIDIFICATION-

of the liquated material. These two along the centerline of the weld, while

CRACKING SUSCEPTIBILITY

types of cracking are reviewed in this liquation cracking takes place along

article, including the factors that affect the outer edge of the weld. These two Several tests have been used to

cracking and the remedies. types of cracking will be discussed in evaluate susceptibility to solidification

this article. cracking,9,10 including the Houldcroft

INTRODUCTION

SOLIDIFICATION CRACKING

Solidification cracking can occur in

the fusion zone and liquation cracking Solidification cracking, as shown in

can occur in the partially melted zone Figure 3a, is intergranular. The fracture

during welding. During the welding of surface often reveals the dendritic

an alloy, the weld pool is surrounded morphology of the solidifying weld

by semisolid materials (Figure 1).1 For metal.1 These two characteristics suggest

convenience, circular-patch welding is that solidification cracking occurs during

used as an example here. The workpiece the terminal stage of solidification,

shown in Figure 1 consists of an inner where dendrites have grown nearly fully

piece in the form of a circular patch into grains that are separated from one

and an outer piece, which is held tightly another by a small amount of liquid in

to the fixture with bolts (not shown) the form of grain-boundary films. At

that go through the holes. The pool this time, the weld metal can be rather

boundary is the liquidus temperature of weak and thus susceptible to cracking in

the weld metal during welding. Behind the presence of tensile stresses/strains.

the weld pool is the solidifying material Tensile stresses/strains can be induced

called the mushy zone, which is a in the weld metal if it cannot contract

semisolid consisting of dendrites (S) and freely during cooling, for instance, in

the interdendritic liquid (L). Behind the a highly restrained workpiece such

mushy zone is the completely solidified as in circular-patch welding (Figure 1).

material called the fusion zone or the The weld metal tends to contract during

weld metal. cooling because of solidification shrink-

In front of and on the sides of the age and thermal contraction.

weld pool is a semisolid consisting of Various theories of solidification

partially melted base-metal grains (S) cracking have been proposed.2–7 Accord-

and the intergranular liquid (L). Here, ing to Borland,8 there are essentially three

the temperature is above the eutectic solidification cracking theories—the

temperature of the base metal (or the shrinkage-brittleness theory, the strain

solidus temperature if the workpiece theory, and the generalized theory that

is solutionized to dissolve eutectic includes the relevant ideas from the

completely before welding). Behind first two theories. According to the Figure 1. Semisolid materials, namely,

the partially melted grains on the generalized theory, cracking can take partially melted base-metal grains and

the mushy zone, around the weld pool

pool sides is the completely solidified place in a material in which continu- of an alloy during welding (for instance,

material called the partially melted ous liquid films separate grains or in circular-patch welding).

zone (PMZ). which some solid-solid bridges exist

2003 June • JOM 37

solidification The crack length serves as the index of Dupont et al.23 observed in some

cracking cracking sensitivity. niobium-bearing superalloys that the

amount of the terminal liquid undergo-

FACTORS AFFECTING

ing the L→γ + Laves reaction is small

SOLIDIFICATION CRACKING

and remains isolated, thus not really

Several factors can affect the solidi- contributing to solidification cracking.

fication cracking susceptibility of weld This type of morphology, unlike the

metals, including1 the solidification continuous terminal liquid undergoing

temperature range, the amount and the same reaction in the more crack-

distribution of liquid at the terminal susceptible alloys, should be more

stage of solidification, the primary resistant to crack propagation throughout

a solidification phase, the surface tension the mushy zone.

of the grain-boundary liquid, the grain For austenitic stainless steels, the

structure, the ductility of the solidifying susceptibility to solidification cracking

weld metal, and the tendency of weld- is much lower when the primary

metal contraction and the degree of solidification phase is δ-ferrite rather

restraint. All these factors are directly than austenite. 34–36 As the ratio of

or indirectly affected by the weld-metal the chromium equivalent to nickel

composition. The first two factors are equivalent increases, the primary

affected by microsegregation during solidification phase changes from

solidification. Microsegregation in turn austenite to δ-ferrite and cracking is

can be affected by the cooling rate reduced. As shown by Takalo et al.,35

during solidification. In some cases, the this change occurs at about Creq/Nieq =

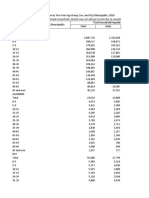

b

5 mm primary solidification phase can also be 1.5, where Creq = Cr + 1.37Mo + 1.5Si

Figure 2. Macrographs showing cracking affected by the cooling rate (for instance, + 2Nb + 3Ti and Nieq = Ni + 0.3Mn

in aluminum circular-patch welds: (a) austenitic stainless steels). + 22C + 14.2N + Cu. However, this

solidification cracking; (b) liquation Generally speaking, the wider the value can increase with increasing

cracking.71

solidification temperature range, the cooling rate during welding because of

larger the area that is weak and suscep- undercooling, for instance, to Creq/Nieq =

tible to weld-solidification cracking. 1.6–1.7 in pulsed-laser welding.36

test,11–14 Varestraint test,15–18 circular- DuPont et al.23 showed that in niobium- The effect of the surface tension of

patch test,19–21 and Sigamajig test.22 The bearing superalloys, the maximum the grain-boundary liquid is such that

Varestraint test and the circular-patch crack length in Varestraint testing the smaller the dihedral angle, the more

test are used often and described briefly increases with increasing solidification the grain-boundary liquid tends to form

here. In the Varestraint test, developed temperature range. S and P can widen continuous films on grains.37 Nakata and

by Savage and Lundin,15 an augmented the solidification temperature range of Matsuda16 showed that solidification

tensile strain is applied to the test steels, stainless steels, and nickel-base cracking in several aluminum alloys

specimen by bending it to a controlled superalloys significantly, thus increasing increases with deceasing dihedral angle

radius at an appropriate moment during their cracking susceptibility.24–27 of the grain-boundary liquid.

welding. Both the amount of the applied In pure aluminum there is no solute- For aluminum alloys, welds with finer

strain and the crack length (either the rich liquid of a low freezing point at equiaxed grains were found less sus-

total length of all cracks or the maximum grain boundaries to cause solidification ceptible to solidification cracking.16,38–40

crack length) serve as the index of cracking. In highly alloyed aluminum, Fine equiaxed grains can deform to

cracking sensitivity. The specimen can on the other hand, there is abundant accommodate contraction strains more

also be bent transverse to the welding solute-rich liquid of a low freezing easily; that is, they are more ductile.

direction. This transverse Varestraint point between grains to backfill and Liquid feeding and the healing of

test16 may promote cracking inside “heal” any incipient cracks that form.3 incipient cracks can also be more

the weld metal more than outside the Somewhere in between these two cases effective in fine-grained material. In

weld metal. there exists a composition where just addition, the grain-boundary area is

In the circular-patch test19–21 (shown enough solute-rich liquid can form much greater in fine-grained material

in Figure 1), where the outer piece is thin continuous grain-boundary films to and, therefore, segregates of low melting

restrained by bolts, the weld tends to cause the maximum sensitivity to crack- points are less concentrated at the grain

contract upon cooling, inducing tension ing. Figure 4a through d shows the effect boundary.

at its outer edge and compression at of composition on the solidification- Nakata and Matsuda16 proposed that

its inner edge. The tensile stresses and cracking sensitivity of several binary the ductility of the solidifying weld

strains at the outer edge are in the aluminum alloys.28–32 Figure 4e shows metal has a strong effect on solidification

direction transverse to the weld. This the crack sensitivity in pulsed-laser cracking. They used the transverse

is why liquation cracking occurs along welding of Al-Cu alloys.33 Each curve Varestraint test to determine ductility of

the outer edge of the weld (Figure 2b). shows a maximum crack sensitivity. the solidifying weld metal as a function

38 JOM • June 2003

with titanium and aluminum nitride,51,52

REMEDIES FOR

and in aluminum alloys with titanium

SOLIDIFICATION CRACKING

and zirconium.53–56 Dudas and Collins32

Solidification cracking can be reduced produced grain refining and eliminated

by adjusting the weld-metal composi- solidification cracking in an Al-Zn-Mg

tion, the grain structure, and the welding filler weld by adding small amounts of

condition.1 zirconium to the filler metal.

a

When welding aluminum alloys, Solidification cracking has been

it is desirable to have a weld-metal reduced by the following means: Gar-

composition that is away from the peak land57 grain refined welds of aluminum-

of the crack sensitivity curve (shown magnesium alloys by mechanically

in Figure 4). To reach the desired weld- vibrating the arc during welding; Kou

metal composition, a filler metal of a and Le58 grain refined welds of 5052

proper composition can be used and the aluminum by magnetic-arc oscillation

welding parameters can be selected to (20 Hz); David and Liu59 refined iridium

achieve the desired dilution ratio (the welds by magnetic-arc oscillation;

b fraction of the base metal in the weld and Tseng and Savage60 refined the

0.5 µm

metal). The maps of crack sensitivity solidification structure within the grains

Figure 3. Micrographs showing cracking vs. composition for ternary aluminum of HY-80 steel, though not the grains

in aluminum welds: (a) solidification

cracking; (b) liquation cracking. alloys are also useful.31,41 themselves.

When welding austenitic stainless Kou and Le58,61,62 used low-frequency

steels, as mentioned previously, it (1 Hz) magnetic-arc oscillation during

is desirable to have a weld-metal gas-tungsten-arc welding of aluminum

composition such that the weld-ferrite alloys and forced the weld-metal

of temperature. The resultant ductility vs. content is at a level of 5–10% in columnar grains to change their growth

temperature curve is called the ductility order to avoid solidification cracking. direction periodically. Solidification

curve, with the liquidus temperature TL Quantitative relationships between the cracking was reduced effectively because

as the upper bound and the temperature weld-ferrite content and the weld-metal a crack had to change its direction

at the tip of the longest crack as the composition in austenitic stainless steels periodically in order to propagate down

lower bound. The slope of a line passing have been determined by Schaeffler,42

through TL and tangent to the ductility DeLong,43 Kotecki,44,45 Balmforth et

curve is called the critical strain rate al.,46 and Vitek et al.47,48 With the help of

for temperature drop (CST), that is, the such quantitative information, proper Relative Crack Sensitivity

critical rate at which the strain varies filler metals and dilution ratios can be

with temperature drop. According to selected to insure enough weld-ferrite

Nakata and Matsuda,16 CST correlates content.

well with the cracking susceptibility of When welding carbon and low-alloy

the weld metal. steels, it is desirable to have a weld-

Both the tendency of weld-metal metal composition such that the weld-

contraction and the degree of restraint metal Mn/S ratio is sufficiently high to

are factors that can affect solidification avoid solidification cracking. Increasing

cracking.1 As already mentioned, the the Mn/S ratio promotes the formation

weld metal tends to contract due to of MnS rather than FeS. This is because

Composition of Weld, % Alloying Element

solidification shrinkage and thermal the high melting point and the globular

contraction. Austenitic stainless steels morphology of MnS tend to make

Total Crack Length (mm)

have relatively high thermal expansion sulfur less detrimental. At relatively low

coefficients (as compared to mild steels) carbon levels the solidification-cracking

and, therefore, are often prone to tendency can be reduced by increasing

solidification cracking. The solidifica- the Mn/S ratio.49 However, at higher

tion shrinkage of aluminum is as high carbon levels (i.e., 0.2–0.3% C),

as 6.6%.5 The thermal expansion coef- increasing the Mn/S ratio is no longer

Copper Content (wt%)

ficient of aluminum is roughly twice effective. 50 In such cases lowering

Figure 4. Effect of composition on crack

that of iron-based alloys. As a result, the weld-metal carbon content, if sensitivity of some aluminum alloys. (a–d)

many aluminum alloys are susceptible permissible, is more effective. from Reference 32; (e) from Reference

to solidification cracking. As mentioned The grains of the weld metal can be 33. (Reprinted from Kou.1)

previously, tensile stress/strains are refined by inoculation and arc oscilla-

induced in the weld metal when the tion to reduce solidification cracking.

weld metal cannot contract freely during Grain refining by inoculation has been

welding. achieved in steels and stainless steels

2003 June • JOM 39

likely to increase primarily with the

solid fraction, they proposed that if

the weld-metal fS exceeds the PMZ fS

during PMZ terminal solidification, the

solidifying and contracting weld metal

can become stronger than the PMZ it

pulls, and liquation cracking is likely

to occur if tensile stresses/strains and

liquation are both significant in the

PMZ.

For example, Huang and Kou72 made

full-penetration, circular-patch welds

in 6061 aluminum with filler metals

5356 (Al-5Mg) and 4043 (Al-5Si). At

the dilution ratio of about 65%, severe

liquation cracking occurred in the weld

made with 5356 but no cracking was

observed in the weld made with 4043.

Figure 6 shows the T-fS curves for

both the weld metal and the PMZ at

the fusion boundary, calculated using

Pandat73 based on the multicomponent

Scheil equation. The curves show that,

at about 65% dilution, 5356 made the

Figure 5. Mechanism of liquation cracking in the partially melted weld metal fS greater than the PMZ

zone of a full-penetration aluminum weld.71 fS during PMZ terminal solidification

while 4043 made the weld metal fS

less than the PMZ fS throughout PMZ

solidification.

The susceptibility of the PMZ to

the weld along grain boundaries. surface is sometimes evident,64 but not hot cracking can be evaluated using

In addition, favorable welding condi- always.65,66 several different methods, such as

tions can be used to reduce solidification Liquation cracking occurs in the the Varestraint test,74–76 circular-patch

cracking. For instance, reducing restraint PMZ of a weld, which is immediately test,65,71,72 and hot-ductility test.66

helps reduce solidification cracking. outside the fusion zone, because of

FACTORS AFFECTING

Making the weld surface slightly convex heating above the eutectic temperature

LIQUATION CRACKING

can help prevent surface shrinkage (or the solidus temperature if the

cracks that tend to occur in welds with workpiece is completely solutionized The liquation cracking susceptibility

a concave surface.63 This is because before welding) in the PMZ.1 Liquation of the PMZ can be affected by the extent

the surface is less in tension when it can occur along the grain boundary of liquation, the grain structure, the hot

is slightly convex. Reducing the weld as well as in the grain interior. Grain- ductility, and weld-metal contraction

depth-to-width ratio can help prevent boundary liquation makes the PMZ and the degree of restraint.1

centerline cracking that tends to occur susceptible to liquation cracking. The greater the extent of liquation,

in welds with a steep angle of abutment Liquation cracking1,70 has also been the more likely that liquation cracking

between columnar grains growing from called edge-of-weld cracking,32 base- can occur. The extent of liquation in the

opposite sides of the weld pool.63 This metal cracking,67 hot cracking,68 and PMZ depends on the tendency of the

type of cracking is often observed heat-affected zone cracking.69 The name material to liquate and the level of heat

in deep and narrow welds produced liquation cracking is used here. input. The tendency of an aluminum

by electron beam or submerged arc Huang and Kou71 showed in Figure 5 alloy to liquate increases with increasing

welding. the development of liquation cracking in freezing temperature range and fraction

the PMZ of a full-penetration aluminum of liquid during freezing. For instance,

LIQUATION CRACKING

weld. Since the PMZ is weakened by alloy 7075 liquates much more severely

Liquation cracking, as shown in grain-boundary liquation, it can crack than alloy 6061 because the former

Figure 3b, is intergranular just like if the solidifying and contracting weld has a wider freezing temperature range

solidification cracking. However, unlike metal is stronger than it. and a greater fraction of liquid during

solidification cracking, the fracture Huang and Kou72 used curves of freezing.77 The tendency to liquate can

surface does not reveal any dendritic temperature (T) vs. solid fraction (fS) also increase with increasing grain-

morphology. The presence of a liquid to help understand liquation cracking. boundary segregation in the workpiece

phase at the intergranular fracture Since the strength of a semisolid is material. As-cast materials, for instance,

40 JOM • June 2003

tend to have more grain-boundary Katoh et al.,74 Kerr et al.,75 and Miyazaki of liquation-inducing segregates. As-cast

segregation. et al.76 studied liquation cracking in materials are particularly susceptible

The higher the heat input, the greater 6000-series alloys including 6061. to liquation cracking because of the

the liquation and the more likely liqua- Longitudinal liquation cracking occurred presence of low-melting segregates

tion cracking can occur. The heat input when alloy 6061 was welded with a along grain boundaries. Upon heating

depends on the welding process and 5356 filler but not with a 4043 filler. during welding, severe grain-boundary

parameters and the workpiece thickness. As shown previously, Huang and Kou72 liquation can occur in the PMZ, making it

Miyazaki et al.76 observed in 6061 showed that T-fS curves can be used to highly susceptible to liquation cracking.

aluminum welds made with filler 5356 help select the weld-metal composition Examples include as-cast 304 stainless

that liquation cracking increased with to avoid liquation cracking. steel82 and as-cast corrosion-resistant

increasing heat input per unit length The sensitivity of the PMZ to liquation austenitic stainless steel.83 By heat

of weld. cracking can be reduced by decreasing treating to homogenize the castings

A base metal with coarser grains is the degree of restraint and, hence, the before welding, liquation cracking can

more susceptible to liquation cracking. level of tensile stresses. The size of the be reduced.

The coarser the grain, the less ductile PMZ and, hence, the extent of PMZ

CONCLUSION

the PMZ becomes. Furthermore, the liquation can be reduced by reducing

coarser the grains, the smaller the the heat input. In order to minimize Experimental data of crack sensitivity

grain-boundary area and hence, the liquation cracking, the heat input can be vs. composition are useful for selecting

more concentrated the impurities or kept low by using multi-pass welding or the proper weld-metal composition to

low-melting segregates are at the grain low-heat-input welding processes (such avoid solidification cracking. To avoid

boundary. Increasing liquation cracking as electron beam and gas-tungsten-arc liquation cracking at the same time,

with increasing grain size has been welding) when possible. however, the weld-metal composition

observed in aluminum alloys76,78 and Liquation cracking can be reduced should be such that the weld metal

Inconel 718.79,80 by selecting the proper base metal solidifies after the partially melted zone

Hot ductility can also play a role in for welding if it is feasible. The base- does. Curves of temperature vs. solid

liquation cracking. Several different metal composition, grain structure, fraction of the weld metal and the base

criteria have been used for interpreting and microsegregation can affect the metal (same as the partially melted zone)

hot-ductility curves. 81 It has been susceptibility of the PMZ to liquation can help select the proper weld-metal

suggested that an alloy that recovers its cracking significantly. Using base metals composition.

ductility easily during cooling tends to that have low sulfur and phosphorus can

ACKNOWLEDGEMENTS

be more crack resistant.66 help reduce the freezing temperature

Both the tendency of weld-metal range and, hence, liquation cracking. This work was supported by the

contraction and the degree of restraint Using fine-grained materials helps National Science Foundation under

can affect the susceptibility to liquation reduce liquation cracking because of Grant No. DMR-0098776. The authors

cracking.1 The more the weld metal better ductility and lower concentrations are grateful to Bruce Albrecht and

contracts, the more likely the PMZ will

crack. The more severely the workpiece

is restrained, the more likely liquation

cracking will occur.

REMEDIES FOR LIQUATION

CRACKING

Liquation cracking can be reduced by

)

controlling the weld-metal composition,

(

the welding condition, and the base

metal.

The weld-metal composition can be

adjusted by selecting a proper filler

metal and dilution ratio. Metzger67

observed liquation cracking in 6061

aluminum welds made with Al-Mg Figure 6. Temperature vs.

fillers at high dilution ratios but not in solid fraction for 6061 base

welds made with Al-Si fillers at any metal (PMZ) and weld metal

of 6061 welds made with filler

dilution ratios. Gittos et al.65 observed metals 5356 and 4043 at

liquation cracking in alloy 6082 welded about 65% dilution. Curves

with NG61 (equivalent to 5356) filler at ( )

calculated using Pandat 73 of

CompuTherm LLC.72

high dilution ratios (about 80%) but not

in welds made with NG21 (equivalent

to 4043) filler at any dilution ratios.

2003 June • JOM 41

Todd Holverson of Miller Electric 26. W.F. Savage, E.F. Nippes, and G.M. Goodwin, Weld. 62. S. Kou and Y. Le, Metall. Trans., 16A (1985),

J., 56 (1977), p. 245s. p. 1345.

Manufacturing Company, Appleton, 63. O.W. Blodgett, Weld. Innovation Q., 2 (3) (1985),

27. D.H. Kah and D.W. Dickinson, Weld. J., 60 (1981),

Wisconsin for donating the welding p. 135s. p. 4.

equipment (including Invision 456P 28. A.R.E. Singer and P.H. Jennings, J. Inst. Metals, 64. R.G. Thompson, ASM Handbook, volume 6

73 (1947), p. 197. (Materials Park, OH: ASM International, 1993), p.

power source and XR-M wire feeder and 566.

29. W.I. Pumphrey and J.V. Lyons, J. Inst. Metals,

gun) and for their technical assistance. 74 (1948), p. 439. 65. N.F. Gittos and M.H. Scott, Weld. J., 60 (1981),

The authors thank Y.A. Chang, a profes- 30. J.D. Dowd, Weld. J., 31 (1952), p. 448s. p. 95s.

31. P.H. Jennings, A.R.E. Singer, and W.L. Pumphrey, 66. M.J. Cieslak, ASM Handbook, Welding, Brazing

sor at the University of Wisconsin- and Soldering, vol. 6 (Materials Park, OH: ASM

J. Inst. Metals, 74 (1948), p. 227.

Madison, for letting them use the 32. J.H. Dudas and F.R. Collins, Weld. J., 45 (1966), International, 1993), p. 88.

database required for calculating the p. 241s. 67. G.E. Metzger, Weld. J., 46 (10) (1967), pp.

33. E.J. Michaud, H.W. Kerr, and D.C. Weckman, 457s–469s.

T-fS curves. 68. J.E. Steenbergen and H.R. Thornton, Weld. J., 49

Trends in Welding Research, ed. H.B. Smartt, J.A.

Johnson, and S.A. David (Materials Park, OH: ASM (2) (1970), pp. 61s–68s.

References International, 1995), p. 154. 69. N.F. Gittos and M.H. Scott, Weld. J., 60 (6) (1981),

34. A. Gueussier and R. Castro, Rev. Metall., 57 pp. 95s–103s.

1. S. Kou, Welding Metallurgy, 2nd edition (New York: (1960), p. 117. 70. T. Ma and G. Den Ouden, Int. J. for the Joining of

John Wiley, 2003), pp. 263–339. 35. T. Takalo, N. Suutala, and T. Moisio, Metall. Trans., Materials (Denmark), 11 (3) (1999), pp. 61–67.

2. G.J. Davies and J.G. Garland, Int. Metal Rev., 10A (1979), p. 1173. 71. C. Huang and S. Kou, “Liquation Cracking in

20 (1975), p. 83. 36. T.J. Lienert, Trends in Welding Research, ed. J.M. Full-Penetration Aluminum Welds: Binary Al-Cu Welds,”

3. D.C.G. Lees, J. Inst. Metals, 72 (1946), p. 343. Vitek et al. (Materials Park, OH: ASM International, submitted to Welding Journal.

4. A.R.E. Singer and P.H. Jennings, J. Inst. Metals, 1998), p. 726. 72. C. Huang and S. Kou, “Liquation Cracking in

73 (1947), p. 273. 37. C.R. Smith, Trans. AIME, 175 (1948), p. 15. Full-Penetration Aluminum Welds: Al-Mg vs. Al-Si

5. M.C. Flemings, Solidification Processing (New York: 38. F. Matsuda et al., Trans JWRI, 12 (1983), p. 93. Fillers for Welding Al-Mg-Si Alloys,” submitted to

McGraw-Hill, 1974). 39. F. Matsuda et al., Trans JWRI, 13 (1984), p. 57. Welding Journal.

6. H.F. Bishop et al., Trans. AFS, 68 (1960), p. 518. 40. M.J. Dvornak, R.H. Frost, and D.L. Olson, Weld. 73. Pandat, computer software developed by Compu-

7. J.C. Borland, Br. Weld. J., 7 (1960), p. 508. J., 68 (1989), p. 327s. Therm LLC, Madison, WI.

8. J.C. Borland, Welding and Metal Fabrication, 47 41. W.L. Pumphrey and D.C. Moore, J. Inst. Metals, 74. M. Katoh and H.W. Kerr, Weld. J., 66 (1987),

(January/February 1979), pp. 19–29. 73 (1948), p. 425. p. 360s.

9. R.D. Stout, Weldability of Steels, 3rd edition, ed. 42. A.L. Schaeffler, Metal. Prog., 56 (1949), p. 680. 75. H.W. Kerr and M. Katoh, Weld. J., 66 (1987),

R.D. Stout and W.D. Doty (New York: Welding Research 43. W.T. Delong, Weld. J., 53 (1974), p. 273s. p. 251s.

Council, 1978), p. 252. 44. D.J. Kotecki, Weld. J., 78 (1999), p. 180s. 76. M. Miyazaki et al., Weld. J., 69 (1990), p. 362s.

10. R.W. Messler, Jr., Principles of Welding, Processes, 45. D.J. Kotecki, Weld. J., 79 (2000), p. 346s. 77. C. Huang, G. Cao, and S. Kou, “Liquation Cracking

Physics, Chemistry and Metallurgy (New York: Wiley, 46. M.C. Balmforth and J.C. Lippold, Weld. J., 79 in Partial-Penetration Aluminum Welds: Assessing

1999), pp. 557–589. (2000), p. 339s. Tendencies to Liquate, Crack and Backfill,” submitted to

11. P.T. Houldcroft, Br. Weld. J., 2 (1955), p. 471. 47. J.M. Vitek, Y.S. Iskander, and E.M. Oblow, Weld. J., Science and Technology of Welding and Joining.

12. J.A. Liptax and F.R. Baysinger, Weld. J., 47 79 (2000), pp. 33s and 41s. 78. C. Huang, S. Kou, and J.R. Purins, Proceedings

(1968), p. 173s. 48. J.M. Vitek, S.A. David, and C.R. Hinman, Weld. of Merton C. Flemings symposium on Solidification

13. J.G. Garland and G.J. Davies, Metals Const. Br. J., 82 (2003), p. 43s. and Materials Processing, ed. R. Abbaschian, H.

Weld. J., 16 (December 1969), p. 565. 49. R.B. Smith, Welding, Brazing, and Soldering, Brod, and A. Mortensen (Warrendale, PA: TMS,

14. J.H. Rogerson, B. Cotterell, and J.C. Borland, Weld. Volume 6 (Materials Park, OH: ASM International, 2001), p. 229.

J., 42 (1963), p. 264s. 1993), p. 642. 79. R.G. Thompson et al. Weld. J., 64 (1985), p. 91s.

15. W.F. Savage and C.D. Lundin, Weld. J., 44 (1965), 50. J.C. Borland, Br. Weld. J., 8 (1961), p. 526. 80. H. Guo, M.C. Chaturvedi, and N.L. Richards,

p. 433s. 51. G.N. Heintze and R. McPherson, Weld. J., 65 Science and Technology of Welding and Joining, 4

16. K. Nakata and F. Matsuda, Trans. JWRI, 24 (1986), p. 71s. (1999), p. 257.

(1995), p. 83. 52. W.A. Petersen, Weld. J., 53 (1973), p. 74s. 81. W. Yeniscavich, Methods of High-Alloy Weldability

17. K.F. Krysiak et al., Welding, Brazing, and Soldering, 53. B.P. Pearce and H.W. Kerr, Metall. Trans., 12B Evaluation, (New York: Welding Research Council,

Volume 6 (Materials Park, OH: ASM International, (1981), p. 479. 1970), p. 1.

1993), p. 443. 54. F. Matsuda et al., Trans. JWRI, 12 (1983), p. 93. 82. W.R. Apblett and W.S. Pellini, Weld. J., 33 (1954),

18. J.N. DuPont, J. R. Michael, and B.D. Newbury, Weld. 55. H. Yunjia et al., Weld. J., 68 (1983), p. 280s. p. 83s.

J., 78 (1999), p. 408s. 56. S. Sundaresan et al., Science and Technology of 83. M.J. Cieslak, ASM Handbook, Welding, Brazing

19. M.J. Cieslak, Weld. J., 66 (1987), p. 57s. Welding and Joining, 5 (2000), p. 257. and Soldering, vol. 6 (Materials Park, OH: ASM

20. S.A. David and J.J. Woodhouse, Weld. J., 66 57. J.G. Garland, Metal Const. Br. Weld. J., 21 (1974), International, 1993), p. 495.

(1987), p. 129s. p. 121.

21. T.W. Nelson et al., Weld. J., 76 (1997), p. 110s. 58. S. Kou and Y. Le, Weld. J., 64 (1985), p. 51. Sindo Kou is professor and chair of the Department

22. G.M. Goodwin, Weld. J., 66 (1987), p. 33s. 59. S.A. David and C.T. Liu, Grain Refinement in of Materials Science and Engineering at the

23. J.N. DuPont, C.V. Robino, and A.R. Marder, Sci. Castings and Welds, ed. G.J. Abbaschian and S.A. University of Wisconsin.

Technol. Weld. Join., 4 (1999), p. 1. David (Warrendale, PA: The Metallurgical Society of

24. G.R. Pease, Weld. J., 36 (1957), p. 330s. AIME, 1983), p. 249. For more information, contact Sindo Kou, University

25. D.A. Canonico et al., Welding Research Council 60. C. Tseng and W.F. Savage, Weld. J., 50 (1971), of Wisconsin, Department of Materials Science and

Symposium on Effects of Minor Elements on the p. 777. Engineering, 1509 University Avenue, Madison,

Weldability of High-Nickel Alloys (New York: Welding 61. S. Kou and Y. Le, Metall. Trans., 16A (1985), Wisconsin 53706; (608) 262-0576; fax (608) 262-8648;

Research Council, 1969), p. 68. p. 1887. e-mail kou@engr.wisc.edu.

42 JOM • June 2003

You might also like

- Optimization of MIG Welding ParametersDocument6 pagesOptimization of MIG Welding ParametersMario Antonio Araya MorosoNo ratings yet

- An Astrological Mandala Cycles of Transformation Dane Rudhyar PDFDocument394 pagesAn Astrological Mandala Cycles of Transformation Dane Rudhyar PDFpomadita395% (39)

- Book - Vol.1&2 - BasicsAndQuality - 22junDocument82 pagesBook - Vol.1&2 - BasicsAndQuality - 22junlth770310No ratings yet

- The Importance of Visual Welding InspectionDocument4 pagesThe Importance of Visual Welding Inspectionhekayat71No ratings yet

- Cladding PDFDocument6 pagesCladding PDFlibid_rajNo ratings yet

- Taking Your Weld's TemperatureDocument6 pagesTaking Your Weld's Temperatureweldingheattreatment100% (1)

- Weldinglectures4 6 141006115241 Conversion Gate02 PDFDocument102 pagesWeldinglectures4 6 141006115241 Conversion Gate02 PDFramuNo ratings yet

- Welding Procedure Specification: Company Dodsal Pte Ltd. Approved by KBRT Signature Name DateDocument1 pageWelding Procedure Specification: Company Dodsal Pte Ltd. Approved by KBRT Signature Name DateS GoudaNo ratings yet

- Logic - Categorical Syllogism Quiz 2Document12 pagesLogic - Categorical Syllogism Quiz 2Marcos Monderin0% (2)

- Shielded Metal Arc Welding Electrodes: Chapter ObjectivesDocument8 pagesShielded Metal Arc Welding Electrodes: Chapter ObjectivesWilly UioNo ratings yet

- Solidification and Liquation CrackingDocument6 pagesSolidification and Liquation CrackingNnamdi Celestine Nnamdi100% (2)

- L&T Construction: Sno Desription Frequency of Updation Date of UpdationDocument2 pagesL&T Construction: Sno Desription Frequency of Updation Date of UpdationANILNo ratings yet

- Observation On Quality Aspects 083Document3 pagesObservation On Quality Aspects 083Moorthy NaveenNo ratings yet

- L&T Construction: Sno Desription Frequency of Updation Date of UpdationDocument4 pagesL&T Construction: Sno Desription Frequency of Updation Date of UpdationANILNo ratings yet

- Fir - 01 - Ioc Petronas - Cable Laying - 12.03 PDFDocument3 pagesFir - 01 - Ioc Petronas - Cable Laying - 12.03 PDFgaladrialNo ratings yet

- CV-AIT KOUFI Metallurgist Engineer - QAQC Welding NDT Coating Head DPT - EnGDocument3 pagesCV-AIT KOUFI Metallurgist Engineer - QAQC Welding NDT Coating Head DPT - EnGait.koufiNo ratings yet

- TVL-Shielded Metal Arc Welding 12 Third: PanimulaDocument3 pagesTVL-Shielded Metal Arc Welding 12 Third: PanimulaFlorinda Gagasa100% (1)

- Duqm Refinery Project EPC Package 2 - Utilities and OffsitesDocument2 pagesDuqm Refinery Project EPC Package 2 - Utilities and OffsitesDadaso Baburao JamdarNo ratings yet

- L&T Construction: R ReportDocument2 pagesL&T Construction: R ReportANILNo ratings yet

- Welding Process Related DefectsDocument1 pageWelding Process Related DefectskapsarcNo ratings yet

- Welding InspectionDocument15 pagesWelding InspectionSreedhar Patnaik.MNo ratings yet

- 120 PDFDocument28 pages120 PDFqczoomenNo ratings yet

- Ir 5073 Ppa 005Document6 pagesIr 5073 Ppa 005ValiNo ratings yet

- WOWLibrary Preheating of Materials ConsumablesDocument4 pagesWOWLibrary Preheating of Materials ConsumableshreerNo ratings yet

- TWI-2009-Improved Welding, Inspection and Integrity of Clad Pipeline Girth Welds First Progress Report PDFDocument60 pagesTWI-2009-Improved Welding, Inspection and Integrity of Clad Pipeline Girth Welds First Progress Report PDFRicardoSchayerSabinoNo ratings yet

- 2037-PL-PL-0058-FR-T-025 Dated 18.12.19 PDFDocument14 pages2037-PL-PL-0058-FR-T-025 Dated 18.12.19 PDFDadaso Baburao JamdarNo ratings yet

- Company Name Key Information Questions Answers File Reference Test Conducted On Reviews & ApprovalsDocument11 pagesCompany Name Key Information Questions Answers File Reference Test Conducted On Reviews & ApprovalsMAT-LIONNo ratings yet

- Native Inspection - Report - CleanedDocument6 pagesNative Inspection - Report - CleanedPrathamesh OmtechNo ratings yet

- MMAWDocument21 pagesMMAWAkash PandeyNo ratings yet

- Tubular Butt Joint Configurations For Welder Qualification (With and Without Backing)Document21 pagesTubular Butt Joint Configurations For Welder Qualification (With and Without Backing)attaulla100% (1)

- Material Inspection Report 6219-1Document2 pagesMaterial Inspection Report 6219-1คุณพ่อน้อง บิ๊กบอสNo ratings yet

- Acerca de ISO 9712Document5 pagesAcerca de ISO 9712qw wqNo ratings yet

- How To Choose Electrodes For Joining High-Strength SteelsDocument3 pagesHow To Choose Electrodes For Joining High-Strength SteelsmakcodetechNo ratings yet

- E-Mail Transmission: TO: Transmittal Ref. No.Document7 pagesE-Mail Transmission: TO: Transmittal Ref. No.Rahul MoottolikandyNo ratings yet

- Alstom IRDocument4 pagesAlstom IRkasi reddyNo ratings yet

- Study of Mechanical Properties Microstru PDFDocument6 pagesStudy of Mechanical Properties Microstru PDFAyyappanSubramanianNo ratings yet

- STIR (Surface Treatment Inspection) Qaqc-003Document1 pageSTIR (Surface Treatment Inspection) Qaqc-003AliDadKhanNo ratings yet

- A Review of The Application of Weld Symbols On Drawings - Part 1 - Job Knowledge 64Document4 pagesA Review of The Application of Weld Symbols On Drawings - Part 1 - Job Knowledge 64Billy TanNo ratings yet

- Ir 0703Document3 pagesIr 0703sheikmoinNo ratings yet

- 3 Welding Imperfections and Materials InspectionDocument31 pages3 Welding Imperfections and Materials InspectionSamerNo ratings yet

- Corrosion Behavior of Welded Stainless Steel PDFDocument20 pagesCorrosion Behavior of Welded Stainless Steel PDFLanang Dian NugrohoNo ratings yet

- Section 9 - Welding ControlDocument6 pagesSection 9 - Welding ControlYasser Hammad MohamedNo ratings yet

- Casting Defects and How To Prevent Them in Your ProductsDocument7 pagesCasting Defects and How To Prevent Them in Your ProductsArun t nNo ratings yet

- Casting DefectsDocument4 pagesCasting DefectsHamza KayaniNo ratings yet

- Admitere Conditional ClausesDocument6 pagesAdmitere Conditional ClausesGeorgiana Argentina DinuNo ratings yet

- TGN-M-02 Voltage Reducing DevicesDocument11 pagesTGN-M-02 Voltage Reducing Devicessalekojic5332No ratings yet

- SMAW, FCAW, and SAW High-Strength Ferritic Deposits - The Challenge Is Tensile Properties PDFDocument11 pagesSMAW, FCAW, and SAW High-Strength Ferritic Deposits - The Challenge Is Tensile Properties PDFbiancogallazziNo ratings yet

- Inspection and Engineering Unit 5.1Document13 pagesInspection and Engineering Unit 5.1sflynn79No ratings yet

- When Using SAW To Weld Creep-Resistence SteelsDocument2 pagesWhen Using SAW To Weld Creep-Resistence SteelsJames PhillipsNo ratings yet

- ARTICLE - Destructive Testing Basics (2012)Document4 pagesARTICLE - Destructive Testing Basics (2012)Sangameswaran RamarajNo ratings yet

- Third Party Inspection Report: Industry & Facilities Division Page 1 of 9Document9 pagesThird Party Inspection Report: Industry & Facilities Division Page 1 of 9mustafa nasihNo ratings yet

- What Is Peening?: Frequently Asked QuestionsDocument2 pagesWhat Is Peening?: Frequently Asked QuestionstuanNo ratings yet

- Tungsten Inert Gas (TIG or GTA) Welding: Job Knowledge 6Document2 pagesTungsten Inert Gas (TIG or GTA) Welding: Job Knowledge 6tuanNo ratings yet

- Electro Slag Strip Cladding ProcessDocument5 pagesElectro Slag Strip Cladding ProcessIJMERNo ratings yet

- Welding Defects and Its RemediesDocument3 pagesWelding Defects and Its Remediesebrahem_sahil5188No ratings yet

- Assignment 1 WeldingDocument4 pagesAssignment 1 WeldingHazim HamdanNo ratings yet

- Bluewater MIR Roc Master CPP IR 003 (Jun.20 PDFDocument8 pagesBluewater MIR Roc Master CPP IR 003 (Jun.20 PDFANIL PLAMOOTTIL100% (1)

- Saudi Aramco Consulting Services Department Me&Ccd/Meu Procedure Review SheetDocument3 pagesSaudi Aramco Consulting Services Department Me&Ccd/Meu Procedure Review SheetabdullaNo ratings yet

- Welding Consumables-Mild Steel BocDocument43 pagesWelding Consumables-Mild Steel Bocargentino_ar01No ratings yet

- Duplex Stainless Steel - Part 2 - TWIDocument6 pagesDuplex Stainless Steel - Part 2 - TWItuanNo ratings yet

- An Investigation On Ductility-Dip Cracking in The Base MetalDocument12 pagesAn Investigation On Ductility-Dip Cracking in The Base MetalRafaella SilvaNo ratings yet

- Emivest Layer PS Vax Programme (Medion Vaccines) - 01.2021Document1 pageEmivest Layer PS Vax Programme (Medion Vaccines) - 01.2021ong ching wattNo ratings yet

- Finite Element Primer For Engineers: Part 3: Mike Barton & S. D. RajanDocument30 pagesFinite Element Primer For Engineers: Part 3: Mike Barton & S. D. RajanJohann BarcelosNo ratings yet

- Quantities, Measurements, and VectorsDocument34 pagesQuantities, Measurements, and VectorsDiane RosarioNo ratings yet

- Cheer and Banner Making GuidelinesDocument2 pagesCheer and Banner Making GuidelinesSunnyNo ratings yet

- Ewma NotesDocument8 pagesEwma NotesMeer Mazhar AliNo ratings yet

- 8.04 Climate - Closeup - WorksheetcompleteDocument2 pages8.04 Climate - Closeup - WorksheetcompletealexaNo ratings yet

- DLL DiassDocument7 pagesDLL DiassGlide ParkNo ratings yet

- Stat Prog7Document7 pagesStat Prog7Vikrant ChaudharyNo ratings yet

- Std. X - Maths Paper IV - EXTENDED - 1 - Mock-2Document16 pagesStd. X - Maths Paper IV - EXTENDED - 1 - Mock-2YashodhaNo ratings yet

- STATS MC Practice Questions 50Document6 pagesSTATS MC Practice Questions 50Sta Ker0% (1)

- Mgt301 Midterm Mcqs Mega FileDocument423 pagesMgt301 Midterm Mcqs Mega FilerijagrammarschoolNo ratings yet

- LP G8 - Relation and FunctionDocument1 pageLP G8 - Relation and FunctionAlberto LazaroNo ratings yet

- Meiosis: Cell DivisionDocument21 pagesMeiosis: Cell DivisionAthena AretaNo ratings yet

- Bidle Dan Thomas Teori PeranDocument17 pagesBidle Dan Thomas Teori PeranA608 Faizin iwan ariyantoNo ratings yet

- McGraw Hill - SAT Practice Test 3Document48 pagesMcGraw Hill - SAT Practice Test 3Linh TrầnNo ratings yet

- s0434 LagunaDocument522 pagess0434 LagunaPauline Don HernandezNo ratings yet

- Evaluation of Total Corneal Power MeasurementsDocument7 pagesEvaluation of Total Corneal Power MeasurementsMariana Luzardo bravoNo ratings yet

- 500-Word Essay: Epidemiological StudiesDocument4 pages500-Word Essay: Epidemiological StudiesmuhdfarhanNo ratings yet

- Clack EI Programming ManualDocument16 pagesClack EI Programming ManualAndres GarciaNo ratings yet

- ISO Standards 06 June 2017Document19 pagesISO Standards 06 June 2017ayyaz123No ratings yet

- Common Interview QuestionDocument4 pagesCommon Interview QuestionimmamNo ratings yet

- Part1-VIB-Subset3-Analysis of MDOF-Discrete Systems-#3EoM-Flexibility Matrix of Flexural Systems v3Document22 pagesPart1-VIB-Subset3-Analysis of MDOF-Discrete Systems-#3EoM-Flexibility Matrix of Flexural Systems v3Faze QadriNo ratings yet

- Insulation - Coordination of - Arcing Horns - On - HVDC - Electrode - Lines - Protection - Perforance - Evaluation - Influence - Factors - and - Improvement - Method PDFDocument19 pagesInsulation - Coordination of - Arcing Horns - On - HVDC - Electrode - Lines - Protection - Perforance - Evaluation - Influence - Factors - and - Improvement - Method PDFLuis Angel PerezNo ratings yet

- Basic Electronics PPT Lesson 4 SeriesDocument35 pagesBasic Electronics PPT Lesson 4 SeriesStacie DDDNo ratings yet

- 1.3 Prinsipyo NG Ekokritisismo at Ekokritisismo Bilang Interdisiplinaryong LapitDocument11 pages1.3 Prinsipyo NG Ekokritisismo at Ekokritisismo Bilang Interdisiplinaryong LapitMerwin Andrew UyNo ratings yet

- Pemanfaatan Media Sosial (Instagram) Sebagai Media Penyajian Kreasi Seni Dalam PembelajaranDocument13 pagesPemanfaatan Media Sosial (Instagram) Sebagai Media Penyajian Kreasi Seni Dalam PembelajaranAbraham Mora TumanggorNo ratings yet

- Civil and Environmental Engineering DepartmentDocument12 pagesCivil and Environmental Engineering DepartmentMuhd SyahidNo ratings yet

- 04 SchemeSyllabus BTech EE 7th 8thDocument91 pages04 SchemeSyllabus BTech EE 7th 8thsantanu janaNo ratings yet