Professional Documents

Culture Documents

R Series Valves PDF

R Series Valves PDF

Uploaded by

Ronald LlerenaOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

R Series Valves PDF

R Series Valves PDF

Uploaded by

Ronald LlerenaCopyright:

Available Formats

Gas-Lift Valves

R Series Injection Pressure-Operated,

Wireline-Retrievable Valves

Weatherford’s McMurry-Macco® R series injection pressure-operated

(IPO) gas-lift valves are the most frequently used valves in gas-lift systems

today because of their durability, performance and wireline retrievability.

These versatile valves are used for continuous or intermittent gas-lift

operations and for applications involving tubing flow or casing flow when

installed in an EC configuration side-pocket mandrel.

R series IPO gas-lift valves have a nitrogen-charged dome-and-bellows

configuration. Because nitrogen is affected by temperature, the preset

nitrogen dome pressure is calculated based on the operating temperature

at the production depth. The nitrogen charge located inside the bellows

acts on the three-ply MONEL® bellows to hold the valve in a closed

position. This closing force is opposed by two opening forces: the injection

gas pressure acting on the external side of the bellows, and the production

pressure acting over the area of the valve port. When these combined

opening forces exceed the nitrogen charge, the valve opens, and injection

gas flows into the production string.

All R series IPO gas-lift valves contain an integral check valve to prevent

the occurrence of reverse flow from the tubing to the casing. The check

valve uses dual seals. Initially, an elastomer seal is established. As the

differential pressure increases, a metal-to-metal seal is established.

Dual-check versions are available in the 1 1/2-in. OD valves for increased

protection against backflow.

The R series injection valves are available in stainless steel or MONEL

materials that meet NACE MR0175 requirements. Special erosion-

resistant coatings and a wide variety of standard, chemical-resistant and

high-temperature elastomers are also available.

Applications

• Continuous or intermittent gas-lift operation

• Tubing or casing flow applications (based on the side-pocket porting

configuration)

• Kickoff gas wells that are loaded up with production fluid

• Flowback enhancement of stimulation and waterflood applications

R-1 R-2B

Valve Valve

10 © 2007 Weatherford. All rights reserved.

Gas-Lift Valves

R Series Injection Pressure-Operated,

Wireline-Retrievable Valves

Features, Advantages and Benefits

• Wireline-retrievable design eliminates the need to pull the tubing to repair or replace the valve.

• The unique positive bellows protection (PBP) feature of every R series 1 1/2-in. OD valve traps silicon fluid

within the bellows as the valve reaches its full open position. The trapped silicon fluid forms a hydraulic barrier

that protects the bellows from high hydrostatic pressures in the well.

• Maximum bellows travel stop prevents the bellows from stacking.

• Patented Teflon® support-ringed bellows are available (models R-1T and R-2T) for added support for bellows

convolution.

• Silicon-dampening fluid in the bellows also minimizes chattering, preventing valve seat damage and vibration

that can lead to failure of other valve components.

• Internal bellows guidance system prevents corkscrewing of the bellows, thereby increasing cycle life.

• Integral reverse-flow check valve, with elastomer primary seal and metal-to-metal secondary seal, prevents

tubing-to-casing communication, thus avoiding costly workover operations.

• Optional dual-check-valve design (model R-2DC) provides increased protection against backflow.

• The R-1BL model includes an integral bottom latch which acts as a backup for the primary latch.

• The R-1D model features a double O-ring seal on the tail plug that provides enhanced sealing integrity of the

nitrogen dome pressure charge, thereby increasing the service life of the valve. In addition, the design of these

models allows for an increased dome volume, which reduces the bellows load rate.

• Compatibility with all common top latches allows the valves to be deployed in a wide variety of applications.

• Replaceable floating MONEL or tungsten carbide seat allows the valve to be easily serviced.

• Standard packing element system enhances performance and extends the service life of the valve. Numerous

packing materials and elastomers are available to meet specific application requirements.

• Valves are available with special coatings to prevent scale buildup and enhance erosion resistance.

MONEL and Teflon are registered trademarks of their respective owners.

© 2007 Weatherford. All rights reserved. 11

Gas-Lift Valves

R Series Injection Pressure-Operated,

Wireline-Retrievable Valves

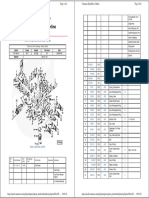

Specifications

Ab

Effective

Bellows Ap1

Valve PPEF2

Valve OD Area Port Size Area of Port

Series Ap/Ab Ap/Ab

(in.) (mm) (in.2) (mm2) Model (in.) (mm) (in.2) (mm2) Ratio 1–(Ap/Ab) 1–(Ap/Ab)

1/8 3.18 0.013 8.40 0.042 0.958 0.044

5/32 3.97 0.021 13.55 0.067 0.933 0.072

R-1

3/16 4.76 0.029 18.71 0.095 0.905 0.105

1.0 25.4 0.31 200.0 R-1D

1/4 6.35 0.052 33.55 0.166 0.834 0.199

5/16 7.94 0.08 51.61 0.257 0.743 0.346

R-1HV 3/8 9.53 0.114 73.55 0.368 0.632 0.582

3/16 4.76 0.029 18.71 0.038 0.962 0.040

1/4 6.35 0.052 33.55 0.067 0.933 0.072

R-2

1.5 38.1 0.77 496.8 5/16 7.94 0.08 51.61 0.104 0.896 0.115

R-2B

3/8 9.53 0.114 73.55 0.148 0.800 0.174

7/16 11.11 0.154 99.35 0.200 0.739 0.250

1

Port diameter based on port size plus 0.006 in. (0.152 mm) for lapped seat

2

Production pressure effect factor, formerly referred to as tubing effect factor

12 © 2007 Weatherford. All rights reserved.

You might also like

- Prevention of Valve Fugitive Emissions in the Oil and Gas IndustryFrom EverandPrevention of Valve Fugitive Emissions in the Oil and Gas IndustryNo ratings yet

- Engine Izusu 4h Shop Manual PDFDocument88 pagesEngine Izusu 4h Shop Manual PDFJayath Bogahawatte100% (5)

- Gas Lift PresentationDocument242 pagesGas Lift PresentationRonald PrietoNo ratings yet

- Operational and Maintenance Manual PDFDocument19 pagesOperational and Maintenance Manual PDFNano Villanueva100% (3)

- Komatsu D37EX-22 Dozer Bulldozer Service Repair Manual SN 60001 and Up PDFDocument27 pagesKomatsu D37EX-22 Dozer Bulldozer Service Repair Manual SN 60001 and Up PDFfhsjekkdmme100% (1)

- Mj-1645-Us Expanding Gate Valve MJDocument16 pagesMj-1645-Us Expanding Gate Valve MJgm_revankar3942No ratings yet

- Injection Pressure Operated BarrierDocument1 pageInjection Pressure Operated Barrierafzal7No ratings yet

- Gas Lift Válvula PilotoDocument2 pagesGas Lift Válvula PilotoFabio ParceroNo ratings yet

- Mento - Katalog API 6A Valves & Manifolds - 21.06.21 - Rev18Document46 pagesMento - Katalog API 6A Valves & Manifolds - 21.06.21 - Rev18DIEGO CONCEIÇÃO DE OLIVEIRANo ratings yet

- Butterfly Valve BrochureDocument6 pagesButterfly Valve BrochureRohiNo ratings yet

- RNP Actuator Metso NewDocument11 pagesRNP Actuator Metso NewOGPE-AMC1No ratings yet

- How It Works Gate ValvesDocument1 pageHow It Works Gate ValvesWael FaragNo ratings yet

- Industrial Grade Sealed Unit: PVC & CPVC Compact Ball ValvesDocument2 pagesIndustrial Grade Sealed Unit: PVC & CPVC Compact Ball ValvesPoro ChanNo ratings yet

- GIE Diaphragm ValveDocument8 pagesGIE Diaphragm ValveZeeshan AnwarNo ratings yet

- Valv - Nugget 500Document22 pagesValv - Nugget 500FRANK PRUDENCIO OBREGONNo ratings yet

- Power & Severe ServiceDocument220 pagesPower & Severe ServiceJeremiah CayondongNo ratings yet

- SE1.80.80.40.A.4.51D: Posición Contar Descripción Precio UnitarioDocument5 pagesSE1.80.80.40.A.4.51D: Posición Contar Descripción Precio Unitariomatias contrerasNo ratings yet

- Valvula Piloto 1.5 inDocument10 pagesValvula Piloto 1.5 inDurvis Joel Romero LopezNo ratings yet

- Fisher Control Valve Sourcebook - Power and Severe ServiceDocument220 pagesFisher Control Valve Sourcebook - Power and Severe Servicemtrj59No ratings yet

- Revata-R1 IPO GLVDocument1 pageRevata-R1 IPO GLVPetraindo Jaya AbadiNo ratings yet

- Valvulas para Gas Industrial v5097Document12 pagesValvulas para Gas Industrial v5097Jesid ApraezNo ratings yet

- AMG阀门电子样本 2Document20 pagesAMG阀门电子样本 2zhyhh100% (1)

- Valv-Powr® Series VPVL Model D Double-Acting and Spring-Return Rack-And-Pinion Compact Pneumatic ActuatorsDocument10 pagesValv-Powr® Series VPVL Model D Double-Acting and Spring-Return Rack-And-Pinion Compact Pneumatic ActuatorsibharNo ratings yet

- Spherical ValveDocument4 pagesSpherical ValveHrshiya SharmaNo ratings yet

- Company Profile (ACE VALVE)Document20 pagesCompany Profile (ACE VALVE)DDFSFNo ratings yet

- CFS FM638 639 DM638 639 IomDocument4 pagesCFS FM638 639 DM638 639 IomMahmoud KhirfanNo ratings yet

- Series 10 - Fixed Cone Valve 2013Document10 pagesSeries 10 - Fixed Cone Valve 2013nunezalbertoNo ratings yet

- E30C - Globe Valves NewDocument20 pagesE30C - Globe Valves NewTaha FaNo ratings yet

- Air Release Valve: Jeevan Bhar Ka Saath..Document2 pagesAir Release Valve: Jeevan Bhar Ka Saath..arjun 11No ratings yet

- ACA0255 Specialty For UreaDocument28 pagesACA0255 Specialty For UreawidiantoekoNo ratings yet

- General Brochure PDFDocument8 pagesGeneral Brochure PDFramudo ZNo ratings yet

- Butterfly Valve CATALOGDocument36 pagesButterfly Valve CATALOGGloriaNo ratings yet

- Pentair Aquamatick530Document4 pagesPentair Aquamatick530herysyam1980No ratings yet

- Sizing & Selection: The Control ValveDocument7 pagesSizing & Selection: The Control ValveJamesTorresPalmaNo ratings yet

- Valtek Full Book PDFDocument529 pagesValtek Full Book PDFSamuel OnyewuenyiNo ratings yet

- Resilient Seat Gate Valve SolutionsDocument24 pagesResilient Seat Gate Valve SolutionsMohamed shehataNo ratings yet

- OTECODocument8 pagesOTECOBoedi SyafiqNo ratings yet

- Aot Om2700aDocument9 pagesAot Om2700aModestyNo ratings yet

- Screw Pumps Series SPF: Application Shaft SealingDocument16 pagesScrew Pumps Series SPF: Application Shaft Sealingmsh16000No ratings yet

- Proper Valve SelectionDocument3 pagesProper Valve SelectionAatish ChandrawarNo ratings yet

- Parker Válvula de Segurança Modelos Type HDocument2 pagesParker Válvula de Segurança Modelos Type HFrancisco Javier Leal BrachoNo ratings yet

- Epv Bro Pres 02Document20 pagesEpv Bro Pres 02Miguel CastilloNo ratings yet

- Jamesbury Ball Valves PDFDocument20 pagesJamesbury Ball Valves PDFGabriel Andrés Barcha Angulo100% (1)

- PacificValvesCastSteelBoltedBonnetCatalogCV 421 PDFDocument28 pagesPacificValvesCastSteelBoltedBonnetCatalogCV 421 PDFGoutham KSNo ratings yet

- 5 de 5) VÁLVULA DE RETENCIÓN Marca TYCO (Inglés)Document6 pages5 de 5) VÁLVULA DE RETENCIÓN Marca TYCO (Inglés)Maximiliano StaitiNo ratings yet

- Forbes Marshall Turbine Bypass Valves PDFDocument28 pagesForbes Marshall Turbine Bypass Valves PDFAnonymous lmCR3SkPrKNo ratings yet

- Lbs End Suction Pump PDFDocument4 pagesLbs End Suction Pump PDFAndrew StanleyNo ratings yet

- Lit C316 Usa - 2013 PDFDocument20 pagesLit C316 Usa - 2013 PDFLuis Eduardo Albarracin RugelesNo ratings yet

- Product Overview: Valves Actuators Automation TechnologyDocument36 pagesProduct Overview: Valves Actuators Automation TechnologyBrion Bara IndonesiaNo ratings yet

- Single-Seat-Valves SVP-Select Sudmo BrochureDocument16 pagesSingle-Seat-Valves SVP-Select Sudmo BrochurehrodriguezNo ratings yet

- Data Sheets Bulletin Safeflo Safety Thermal Relief Valves Birkett en en 3674320Document10 pagesData Sheets Bulletin Safeflo Safety Thermal Relief Valves Birkett en en 3674320pedro torresNo ratings yet

- KOSO Kent Introl Top and Bottom Guided ValvesDocument18 pagesKOSO Kent Introl Top and Bottom Guided ValvesDEFRIZALNo ratings yet

- Valve Solutions For Pipelines PDFDocument8 pagesValve Solutions For Pipelines PDFCristhian Niño MartinezNo ratings yet

- Design and Analysis of High Pressure Globe Valve Body With Two ElementsDocument6 pagesDesign and Analysis of High Pressure Globe Valve Body With Two ElementsCarlos HinostrozaNo ratings yet

- TT OpEXL Eccentric Plug Rotary Valve BrochureDocument16 pagesTT OpEXL Eccentric Plug Rotary Valve BrochureSergio Gana GonzalezNo ratings yet

- Tech Sheet Series CDocument2 pagesTech Sheet Series CLalu Adam Akmal IsnenNo ratings yet

- Steam Tracing StudyDocument4 pagesSteam Tracing StudypalluraviNo ratings yet

- BRAHMA Gas Sol Valve EG12....Document5 pagesBRAHMA Gas Sol Valve EG12....Efril DIlen FranciscoNo ratings yet

- Alco Valves DBB Brochure Compiled v6 01.02.21Document102 pagesAlco Valves DBB Brochure Compiled v6 01.02.21Alfonsus W.M.No ratings yet

- Perar Trunnion Ball ValvesDocument54 pagesPerar Trunnion Ball ValvesUday GokhaleNo ratings yet

- Heat Transfer: Non-Stationary Heat Transfer Through Walls, Measurement of Thermal Conductivity, Heat Transfer with Two Phase RefrigerantsFrom EverandHeat Transfer: Non-Stationary Heat Transfer Through Walls, Measurement of Thermal Conductivity, Heat Transfer with Two Phase RefrigerantsRating: 5 out of 5 stars5/5 (1)

- Pump RateDocument5 pagesPump RateRonald LlerenaNo ratings yet

- SPE 89373 Enhanced Oil Recovery With Horizontal Waterflooding, Osage County, OklahomaDocument7 pagesSPE 89373 Enhanced Oil Recovery With Horizontal Waterflooding, Osage County, OklahomaRonald LlerenaNo ratings yet

- SPE 78705 Development of Composite Progressing Cavity PumpsDocument4 pagesSPE 78705 Development of Composite Progressing Cavity PumpsRonald LlerenaNo ratings yet

- SPE 77730 Experimental Study of Two-Phase Pumping in A Progressive Cavity Pump Metal To MetalDocument10 pagesSPE 77730 Experimental Study of Two-Phase Pumping in A Progressive Cavity Pump Metal To MetalRonald LlerenaNo ratings yet

- Corod SWR High Strength 29feb12Document3 pagesCorod SWR High Strength 29feb12Ronald LlerenaNo ratings yet

- RD Dummy Valves PDFDocument1 pageRD Dummy Valves PDFRonald LlerenaNo ratings yet

- Sucker Rods Brochure 851 06Document12 pagesSucker Rods Brochure 851 06Ronald LlerenaNo ratings yet

- RD Dummy Valves PDFDocument1 pageRD Dummy Valves PDFRonald LlerenaNo ratings yet

- External Corod Product Specification Sheet R4Document1 pageExternal Corod Product Specification Sheet R4Ronald LlerenaNo ratings yet

- Series 659 OverviewDocument1 pageSeries 659 OverviewRonald LlerenaNo ratings yet

- Espglobal Overview: DescriptionDocument1 pageEspglobal Overview: DescriptionRonald LlerenaNo ratings yet

- ESPglobal Startup Operation ManualDocument3 pagesESPglobal Startup Operation ManualRonald LlerenaNo ratings yet

- SFTT Best PracticesDocument9 pagesSFTT Best PracticesRonald Llerena100% (1)

- Down-Hole Sensor Package: Data SheetDocument2 pagesDown-Hole Sensor Package: Data SheetRonald LlerenaNo ratings yet

- J Qual Prog Onthetrail RCA Part2Document4 pagesJ Qual Prog Onthetrail RCA Part2Ronald LlerenaNo ratings yet

- Eastman Chemical's Success Story: Root Cause AnalysisDocument5 pagesEastman Chemical's Success Story: Root Cause AnalysisRonald LlerenaNo ratings yet

- ESPglobal To VCI-142 DrawingDocument1 pageESPglobal To VCI-142 DrawingRonald LlerenaNo ratings yet

- Down-Hole Sensor Package: Data SheetDocument2 pagesDown-Hole Sensor Package: Data SheetRonald LlerenaNo ratings yet

- J Qual Prog Onthetrail RCA Part4Document7 pagesJ Qual Prog Onthetrail RCA Part4Ronald LlerenaNo ratings yet

- Screw-In Direct Operated Pressure Relief Valve (DBDE04) For Use in ManifoldsDocument8 pagesScrew-In Direct Operated Pressure Relief Valve (DBDE04) For Use in ManifoldsTejas MahadikNo ratings yet

- Self-Operated Pressure Regulators ANSI Version: T 2521 EN Type 2405 Pressure Reducing ValveDocument6 pagesSelf-Operated Pressure Regulators ANSI Version: T 2521 EN Type 2405 Pressure Reducing ValveMuhammad Anas KNo ratings yet

- Butterfly Valve PrincipleDocument2 pagesButterfly Valve PrincipleDevendra Bangar100% (1)

- 2240 EvpDocument3 pages2240 Evptrestiros100100% (1)

- Lebw4957 05Document50 pagesLebw4957 05PhamLeDanNo ratings yet

- Unidad Rotacion Serie l30Document22 pagesUnidad Rotacion Serie l30Raphael Ruiz RamosNo ratings yet

- FC Installation SheetDocument4 pagesFC Installation SheetSamuel Lopez BenitesNo ratings yet

- Alaa-Pipeline Mechanical DesignDocument106 pagesAlaa-Pipeline Mechanical DesignDavid Muñoz Castro100% (1)

- Hydraulic HammerDocument7 pagesHydraulic HammerUbaldo Enrique Caraballo EstradaNo ratings yet

- Valve Body: ZF 4 HP 16 Automatic Transaxle 5A1 - 235Document5 pagesValve Body: ZF 4 HP 16 Automatic Transaxle 5A1 - 235Rafael Celso Lombano EscalonaNo ratings yet

- Drainage (Floor Cleanout Bills)Document28 pagesDrainage (Floor Cleanout Bills)febousNo ratings yet

- Turbo Expander CompressorDocument8 pagesTurbo Expander CompressorSaidFerdjallahNo ratings yet

- Manual de Partes 4069 LEDocument222 pagesManual de Partes 4069 LEcarlos salez100% (1)

- Hydraulic ExcavatorDocument10 pagesHydraulic ExcavatorLutfi RohmatNo ratings yet

- Equipments Presentation1Document49 pagesEquipments Presentation1Sheru PashahNo ratings yet

- NAVIGARE PARS Electrical SpecificationDocument813 pagesNAVIGARE PARS Electrical SpecificationElectrical Learn BDNo ratings yet

- Semi-Lugged Lever Operated Butterfly Valves PN16: Features & BenefitsDocument1 pageSemi-Lugged Lever Operated Butterfly Valves PN16: Features & BenefitsRonaldNo ratings yet

- DBB-06 Spare Parts List 933ER1Document86 pagesDBB-06 Spare Parts List 933ER1Younis AlsmadiNo ratings yet

- Fp11066-13 - Fuel PumpDocument3 pagesFp11066-13 - Fuel PumpBoBoMilovanovicNo ratings yet

- Divyesh DDocument3 pagesDivyesh DVIMALNo ratings yet

- MB 100Document12 pagesMB 100dearonNo ratings yet

- FHC 35 KDocument244 pagesFHC 35 KLawas UnikNo ratings yet

- Erection Manual-Pc PipingDocument219 pagesErection Manual-Pc Pipingalinor_tn100% (2)

- Apd HC-10 PDFDocument56 pagesApd HC-10 PDFemanuelNo ratings yet

- Zanussi Vd54 55 Timer AkoDocument23 pagesZanussi Vd54 55 Timer AkoOvidiuPNo ratings yet

- 1 - Differences Between API 600 & API 6DDocument9 pages1 - Differences Between API 600 & API 6Dعزت عبد المنعمNo ratings yet