Professional Documents

Culture Documents

GROUND STABILISATION - The Why's and How's of High Pressure Grouting (Editor's Choice) Part 1

Uploaded by

Af RymOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

GROUND STABILISATION - The Why's and How's of High Pressure Grouting (Editor's Choice) Part 1

Uploaded by

Af RymCopyright:

Available Formats

See discussions, stats, and author profiles for this publication at: https://www.researchgate.

net/publication/321918651

GROUND STABILISATION - the why's and how's of high pressure grouting

(Editor's choice) Part 1.

Article in Tunnels and Tunnelling International · January 2004

CITATIONS READS

0 76

1 author:

Nick Ryland Barton

Nick Barton & Associates

308 PUBLICATIONS 12,296 CITATIONS

SEE PROFILE

Some of the authors of this publication are also working on these related projects:

Fracture mechanics and rock mechanics applied to tunnels, cliffs, mountain walls and mountains View project

seismic attributes of rock masses related to rock quality aspects View project

All content following this page was uploaded by Nick Ryland Barton on 19 December 2017.

The user has requested enhancement of the downloaded file.

GROUND STABILISATION

The why’s and how’s

of high pressure

grouting - Part 1

A

Nick Barton, of recent consultant’s article (Pells, T&TI tunnels is that inflows have to be controlled, perhaps

March, p34[10]) and an experienced down to 1 to 2lt/min/100m. Permeabilities lower

Nick Barton & contractor’s reactions (Garshol, T&TI than 10-8m/s or lower than 0.1 Lugeon are implied –

Associates, May, p36[8]) has again put focus on the and these are also achieved when owners and

results obtained by pre-grouting ahead consultants become aware of what is achievable

explains the

of tunnels. Garshol emphasised the need to use high today, with stable ultrafine and microcements and

theory behind pressures to get an acceptable result. The proviso is the vitally necessary additives like microsilica and

high pressure pre- of course that the work is done ahead of the face (as plasticizers.

in most of Garshol’s excellent grouting case records) It has been found from recent Norwegian

injection of stable and not from behind the face where lower pressures tunnelling projects that high pressure pre-injection

particulate grouts have to be used (as in most of Pell’s case records). may be fundamental to a good result, i.e. much

With a long-standing rule for injection pressure reduced inflow and improved stability. The pressures

ahead of tunnel gradients of 0.23 bars/m depth for dam foundation used are far higher than have traditionally been used

faces in jointed, grouting in the US, but usually higher elsewhere, it is at dam sites, where in Europe, Brazil and the US,

clear that there will be reactions when 50 to 100 bars maximum grouting pressures (for deep dam

water-bearing

is recommended by an experienced contractor for a foundations) have been limited to about 0.1, 0.05

rock. Although stretch of tunnel whose 20m depth suggests only 5 and 0.023MPa/m depth respectively (Quadros and

opinions differ bars. Abrahão, 2002[12]).

The reasons for performing high pressure (50 to According to a recent report by Klüver (2000[9]), a

about the need for 100 bars) injection when pre-grouting ahead of shallow tunnel in phyllite with 5m of cover, with

high pressure, its

effectiveness has

been proved in

numerous

projects.

Conversely, the

use of insufficient

pressure has often

led to wet and less

stable tunnels

Drilling holes for successful high-pressure pre-

injection at the Jong-Asker rail tunnel west of Oslo

Left: What can happen without these measures!

28 Tunnels & Tunnelling International SEPTEMBER 2004

GROUND STABILISATION

severe environmental requirements for low inflow,

was injected at invert level to a final pressure of Joint entry J2

6.5MPa and to 5MPa even at the shallow depth of area=LxE

L1 L2 L3

the arch, only 5m below the surface (however, dmaks

J3

establishment of an outer screen was advised by d95

Klüver in such extreme situations). 3

The reality is that while grout is still flowing, there 2

1 When grout is flowing

is such a steep pressure gradient away from the E

injection holes (from logarithmic to linear depending P0>P1>P2>P3>

on joint intersection angle) that ‘damage’ to the rock

P0 Pressure decay trends

mass is limited to local, near-borehole, joint aperture J1 Fig 1 - Sources of pressure

P1 P2

increase. P3 drop and joint entry

Measurements in Norway have also shown that problems (Barton,

there can be a pressure drop of 1MPa up to the 2003[ref?])

"Log" "Linear"

injection point for these low w/c ratio, frictional-and-

cohesive fluids (Åndal et al, 2001[14]). So with at least

40% to 80% pressure drop in the first 1m radius A simplified model for visualising grout

from an injection hole, even for Newtonian fluids like penetration

water, it is clear that at the very minimum, an excess Because the author and readers of this magazine

pressure of 25 bars may be needed to inject are engineers, a practical, calculable model is

significant volumes of grout into connected joint required for first pass estimates of grouting needs.

planes and flow channels. For this reason a simple, classical model from Snow

On at least one joint set there may be local shear (1968[13]) has been applied, with two important

and dilation. Each of these effects is probably in the additions, namely the differentiation of hydraulic (e)

region of small fractions of a mm, judging by the and physical (E) average apertures, and the

average grout take of numerous rock masses. About recognition that deformation (local joint opening) can

1 to 5lt/m3 of rock mass is typical, if we assume that occur. Figure 2 shows the cubic network concept

a 6m thick cylinder of rock around the tunnel has and the E > e concept.

been thoroughly injected (Barton, 2003[ref?]). Assuming the cubic law is sufficiently valid for

engineering purposes that we can ignore non-linear

Some pre-grouting results or turbulent flow, we can write permeability K =

From recent compilations of practical experiences, e2/12 for one parallel plate, while

we can derive from Åndal et al, 2001[14] the following K1 = e

2 e (1)

quantities of grout used in successful, high pressure 12 S

pre-injection. for one set of parallel plates of mean spacing (S).

Snow (1968[13]) further assumed that the ‘rock mass

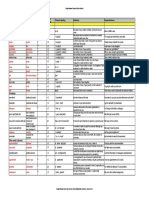

Table 1: Pre-grouting data derived from Åndal et al. permeability’ would be constituted, on average, by

2001 flow along two of the three sets of parallel plates.

Rock type kg/m2 ≈kg/m3 * ≈Litres/m3 * Thus: 2e

tunnel surface

Kmass = 2 e = e3 (2)

Gneiss 11.0 to 16.5 1.8-2.8 1.0-1.6 12 S 6S

Granite 12.0 to 52 2.0-8.7 1.1-5.0 Making further simplifications that 1 Lugeon ≈ 10-7

Phyllite 26 4.3 2.5

Rhomb porphyry 28 to (99) 4.7-(16.5) 2.7-(9.4) Left and below left: Fig 2 -

H2O Water conductor

Syenite (dike) 30 to (186) 5.0-(31) 2.9-(17.7) Cubic network model of

Non-water

Fracture zone 19 to 50 3.-8.3 1.8-4.7 conductor Snow (1968[14]), and

An average 'cylinder' thickness of 6m of grouted rock mass has been

*assumed definitions of e and E,

. A grout density of 1.75gm/cc is also assumed

from Barton et al (1985[1])

e

Values in parentheses signify presumed ‘escape’

of grout in these two cases, and break-down of the s

‘6m grouted cylinder’ assumption. A certain Idealized

percentage of leaking bolt holes of 4m to 5m length cubic network

is the logic behind an average choice of a 6m Lugeon test in with same average

jointed rock permeability

cylinder. We can see from Table 1 that 1-5lt of grout

1 lugeon ≈ 10-7m/s

per m3 of rock mass is a typical range, for projects

(or ≈ 10-14m2) Flow

where post-grouting water leakages were mostly in of H2O

the desired range of 1 to 4lt/min/100m of tunnel. equal

Tunnel cross-sections were mostly 65m2 to 95m2.

Note that an average pre-grouting screen of 25m smooth wall

Physical aperture Eaverage e equivalent aperture

length, with 30 holes of 50mm diameter will require

at least 1,500lt of grout just to fill the holes.

When distributed through an assumed 6m thick e is imaginary and ungroatable

E is real and can be grouted

cylindrical volume of 25m length, this nevertheless

Both E and e respond Part 2 of ‘The why’s

represents only about 0.1lt/m3, so hardly affecting Stress transfer to injection pressure and how’s of high

the above ‘rule-of-thumb’ result of between 1 and

E e pressure grouting’ will

5lt/m3. Tunnels with poor grouting results may

appear in next month’s

typically lie a long way below 1lt/m3 in injected

T&TI and will feature

volume, resulting in poor connection between the No points the complete reference

grout ‘lenses’ and possible (continued) wet of contacts

table.

conditions as a result.

SEPTEMBER 2004 Tunnels & Tunnelling International 29

GROUND STABILISATION

m/s ≈ 10-14m2, therefore 1 Lugeon ≈ 10-8mm2, we directions (the cubic model) are suggested by

can finally write the simplified relation: 1.0lt/m3 of grout. It is therefore clear that joint

deformation is taking place (most likely on most of

e≈ (3)

the water conducting sets). Shear and dilation is

where (e) and (S) are in mm, and L is the average also a likely, local mechanism, for at least one of the

number of Lugeon (each of the above apply to a inclined joint directions depicted in Figure 1.

given structural domain, to the whole borehole, or to The value of JRC0 can be estimated from (a/L) x

a specific rock type). 400 (at 100mm length scale), using profiling. A broad

From equation 3, five examples of (e) and (S) are selection of joint roughness measurements in

derived. These are shown in Figure 3, assuming a 1000m of core by Barton (2002[4]), revealed an

typical range of (average) S = 0.5m-3.0m. Although approximate relationship between JRC0 and Jr

hydraulic aperture (e) is not strictly a ‘groutable (‘joint roughness number’) from the Q-system. This

can be used prior to more accurate profiling

Right: Fig 3 - Derivation of S(m) methods.

3.5

mean hydraulic apertures 0.01L

3.0 0.1L 1L 10L 100L JRC0 ≈ 7Jr – 3 (6)

(e) and mean spacings (S)

from Snow (1968[14]) 2.5 Which hydraulic aperture (e) will be approximately

equations 2.0 equivalent to, for instance E ≈ 50 ?m. The answer is

1.5 ‘many possible apertures’, because of joint wall

1.0

roughness JRC0. Barton and Quadros (1997[2])

Data from Snow's showed that JRC0, which is proportional to

0.5 3D network

approximation amplitude of roughness (a) divided by length of

0.0 profile (Ln), is equivalent to the classic ‘relative

0 50 100 150 200 250 300

Hydraulic aperture - e (µm) roughness’ used in hydraulics. From equation 4 we

Below: Table 2 - see some of the possible solutions for hydraulic

Equivalence of (e) and (E) aperture’, it is easy to imagine the likely difficulties of apertures (e) equivalent to E = 50 ?m.

with respect to varied joint grouting rock masses of less than 1.0 Lugeon, Joint entry by the grout particles is depicted

wall roughness JRC0 (from unless we can argue for E > e, or can increase E by schematically in Figure 5. Firstly, a micro cement

smooth slightly undulating using higher pre-grouting pressures than in the with d95 = 30 microns may well penetrate a joint with

to very rough and Lugeon test. We will return to both these important e = 25 microns – it is a question of roughness,

undulating) aspects in a moment.

JRC0 E(_m) e(_m) Roughness, apertures and particle sizes e ? ??

5 50 44.7 The potential difference between (E) and (e) has

10 50 7.9 been shown to be dependent on the joint

15 50 2.9

roughness, as shown in Figure 4 and a simple

rearrangement of the empirical equation:

e

E ≈ e JRC02.5 (4)

The groutable porosity for three assumed sets of

joints in Figure 2 can, in principle, be written: E

Far right: Fig 5 - The

n ≈ 3E (5)

inequality of (e) and (E) and S because E may be >>25 microns. Secondly, there is

the E > 4 d95 entry limit, due when assuming an average cubic network, and that a certain logic (boundary layer theory) and

to particles ‘delayed’ on the (E) gives the average joint space available for flow experimental evidence (Bahsin et al, 2002[7]), for

rough walls of the joint. A and for grouting. Clearly this is a tenuous blocked entry (i.e. filtering) if E < 3 x dmax (if there are

higher w/c ratio allows this assumption, as the real aperture available for water sufficient numbers of dmax particles). A modified

rule to be broken, but gives flow has a distribution of apertures, and as contact rule-of-thumb for joint entry limits that is easier to

an incompletely blocked points are approached, larger grout particles will be use, as d95 is easier to measure, is that:

end product, unless w/c is blocked. This is another reason for increasing E ≤ 4 d 95 (7)

reduced at the end of injection pressures.

grouting, and applied under We can note that average grouted apertures (E) of When for instance, d95 = 12 ?m, and dmax = 16µm

high pressure 333µm at 1m intervals in three perpendicular (as for a typical ultra-fine cement), these relations

both suggest great difficulty when E ≈ 50 ?m.

However a very high water/cement+filler ratio can

1mm 0.1mm 0.01mm 0.001mm

‘over-rule’ here, just as a busy city street could

e easily allow all vehicles to pass fast, if they came

7

‘one-at-a-time’. This would be no way to ‘block the

6 street’ however – the objective here.

E

The above suggests joint roughness assessment

5 is fundamental to the interpretation of Lugeon tests,

Ratio of (E/e)

JRC02.5

Right: Fig 4 - The inequality e= (µm)

as it may help not only to decide upon which types

(E/e)2

of (E) and (e) for mated 4 of grout (ultrafine, microfine, industrial cement etc.),

joints under normal closure

3

but also whether high pressures will be needed.

(or opening) is a function of 20 5 .5 For example, from Figures 3 and 4 : if L = 1.0, S =

= 15 10

= = = =2

2 JRC RC 0

0 C0

joint roughness coefficient

R C0 JR C 0 1.5m and e = 45µm (average values for a given

J J JR

JRC0. (Barton et al, 1985[1]). domain) and further, if JRC0 is only 3 or 4 (or Jr ≈ 1),

The hydraulic aperture (e) is 1 we would be unlikely to get a successful grouting

not however smaller than result even with ultrafine (d95 = 12µm), unless we

the physical aperture (E ≈ 1000 500 300 200 100 30 20 10 5 3 2 1 deformed the joints using high injection pressures,

2m) Theoretical smooth wall aperture [e] µm we fail, due to equation 7 size limitations. T&T

30 Tunnels & Tunnelling International SEPTEMBER 2004

View publication stats

You might also like

- BartonN.2011.Anengineeringassessmentofpre Injectionintunnelling - keynote3rdIndianRockMech - Conf.Document14 pagesBartonN.2011.Anengineeringassessmentofpre Injectionintunnelling - keynote3rdIndianRockMech - Conf.Manish Kumar SinghNo ratings yet

- Barton-High Pressure Pre-Grouting. TTI Sept 2004 p28-30 PART IDocument3 pagesBarton-High Pressure Pre-Grouting. TTI Sept 2004 p28-30 PART Icastille1956No ratings yet

- Comparative Analysis of Unburied and Buried Pipeline Structure in Seismic Zone Using Caesar IiDocument6 pagesComparative Analysis of Unburied and Buried Pipeline Structure in Seismic Zone Using Caesar IiDinesh Kumar CNo ratings yet

- H Mahgrefteh A Dynamic Boundary Ductile-Fracture Propagation Model For Co2 PipelinesDocument12 pagesH Mahgrefteh A Dynamic Boundary Ductile-Fracture Propagation Model For Co2 Pipelinesargentino_ar01No ratings yet

- Jet Grout Strut For Deep Station BoxesDocument10 pagesJet Grout Strut For Deep Station BoxesMarco Dos Santos NevesNo ratings yet

- 2012 PEERS TandraTranBussmannJonesDocument19 pages2012 PEERS TandraTranBussmannJonesMOISE DIONNo ratings yet

- Scour Mechanism Detection and Mitigation For Subsea Pipeline IntegrityDocument14 pagesScour Mechanism Detection and Mitigation For Subsea Pipeline Integritymarcelohtz3136No ratings yet

- Notes 6Document4 pagesNotes 6Ruben ChirinosNo ratings yet

- MEXICO '13 NB4 Pre-Grouting and Rock Improvement 104 ScreensDocument104 pagesMEXICO '13 NB4 Pre-Grouting and Rock Improvement 104 Screensalejandra castañedaNo ratings yet

- WGC 2010 Paper On Erosion-CorrosionDocument4 pagesWGC 2010 Paper On Erosion-Corrosionangcoy.ecNo ratings yet

- Evaluation and Remediation of Shield Tunnels Affected by Soil LiquefactionDocument8 pagesEvaluation and Remediation of Shield Tunnels Affected by Soil LiquefactionxcvNo ratings yet

- HDPE Pipes MichelangeloDocument58 pagesHDPE Pipes MichelangeloAleksa CavicNo ratings yet

- Methods of Vacuum Consolidation and Their Deformation AnalysesDocument14 pagesMethods of Vacuum Consolidation and Their Deformation AnalysesLinh GeotechniqueNo ratings yet

- Modelling The Water Injection Induced Fault Slip in An Argillaceous RockDocument4 pagesModelling The Water Injection Induced Fault Slip in An Argillaceous RockMarcelo AguilarNo ratings yet

- Performance of The Tunnel Lining Subjected To Decompression Effects On Very Soft Clay DepositsDocument2 pagesPerformance of The Tunnel Lining Subjected To Decompression Effects On Very Soft Clay DepositsFederico MontesverdesNo ratings yet

- Scrubbing LineDocument7 pagesScrubbing LineRafi AkbarNo ratings yet

- Well CompletionDocument82 pagesWell CompletionFlorian Ananias ByarugabaNo ratings yet

- A Universal Model of Stress Sensitive Coefficient in Low Permeability ReservoirDocument7 pagesA Universal Model of Stress Sensitive Coefficient in Low Permeability ReservoirAl JawadNo ratings yet

- Geomembrane Materials Rehabilitate Open Water CanalsDocument7 pagesGeomembrane Materials Rehabilitate Open Water CanalsGeotecniaNo ratings yet

- Stability of Placed Block Revetments in The Wave Run-Up ZoneDocument12 pagesStability of Placed Block Revetments in The Wave Run-Up ZoneAnonymous MAQrYFQDzVNo ratings yet

- Otc 10979 MS PDFDocument8 pagesOtc 10979 MS PDFChinmaya Ranjan JenaNo ratings yet

- Risks of TBM and hybrid tunneling methods for deep tunnelsDocument12 pagesRisks of TBM and hybrid tunneling methods for deep tunnelsinf jectNo ratings yet

- GUIDELINES For SEISMIC DESIGN of BURIED PIPELINESDocument23 pagesGUIDELINES For SEISMIC DESIGN of BURIED PIPELINESVinoth SathyaNo ratings yet

- Hazards30 - 148 Davide MoresDocument21 pagesHazards30 - 148 Davide Moreskiarashkaveh46No ratings yet

- Z Wan en Burg Jardine 2015Document19 pagesZ Wan en Burg Jardine 2015Maruda8382No ratings yet

- Stability of A Mine Tailings Dam Considering Dynamic LiquefactionDocument7 pagesStability of A Mine Tailings Dam Considering Dynamic LiquefactionyelsinsoteloNo ratings yet

- Deepwater Pipeline Design Against Collapse Under External PressureDocument25 pagesDeepwater Pipeline Design Against Collapse Under External PressurekrainajackaNo ratings yet

- 4.TBM Under Liquefiable SoilDocument6 pages4.TBM Under Liquefiable Soilparimala_ragunathanNo ratings yet

- Settlement Characteristics Deep Engineering Fills 40-4-7Document16 pagesSettlement Characteristics Deep Engineering Fills 40-4-7Sen HuNo ratings yet

- Unique Geotechnical Problems at Hydro Projects Deere0001Document7 pagesUnique Geotechnical Problems at Hydro Projects Deere0001Selçuk GülarıNo ratings yet

- Environmental Influence On The Near Thre PDFDocument8 pagesEnvironmental Influence On The Near Thre PDFArab WeldersNo ratings yet

- De SiltingDocument6 pagesDe Siltingtarang001No ratings yet

- Nick Barton PregroutingDocument71 pagesNick Barton Pregroutingdeepakverma33546No ratings yet

- Volume Loss in Shallow TunnellingDocument14 pagesVolume Loss in Shallow TunnellingAida RafrinNo ratings yet

- IWCS 2021 Guidelines Blowing TestsDocument6 pagesIWCS 2021 Guidelines Blowing TestsnzyanmaNo ratings yet

- Arifienetal 2015Document8 pagesArifienetal 2015justmaulNo ratings yet

- Schaumann Raba Et Al. - 2013 - Impact of Contact Interface Conditions - EWEA - GeschDocument10 pagesSchaumann Raba Et Al. - 2013 - Impact of Contact Interface Conditions - EWEA - GeschaekockautNo ratings yet

- The theory behind high pressure grouting - Effects of joint deformation and sealingDocument3 pagesThe theory behind high pressure grouting - Effects of joint deformation and sealingRajnish Bahuguna0% (1)

- 1 s2.0 S0734743X08000778 MainDocument11 pages1 s2.0 S0734743X08000778 Mainfa.jamshidiNo ratings yet

- Civil Engineering Standard DatasDocument14 pagesCivil Engineering Standard DatasP S HARSHITANo ratings yet

- 1 s2.0 S0029801822020157 MainDocument16 pages1 s2.0 S0029801822020157 Mainshijin.li888No ratings yet

- R5 MRJDocument7 pagesR5 MRJRISHABH JAMBHULKARNo ratings yet

- Fluid Dynamics of Casting FillingDocument4 pagesFluid Dynamics of Casting FillingOskr Wero NoriegaNo ratings yet

- 05-Wall Thickness DesignDocument18 pages05-Wall Thickness DesignOlufemi AdeniyeNo ratings yet

- Blow-Out Failures Part 1:: Frictional SoilsDocument6 pagesBlow-Out Failures Part 1:: Frictional SoilsDEBASIS BARMANNo ratings yet

- Flow Electrification Behavior: Wall Shearing Stress Affects Current DensityDocument6 pagesFlow Electrification Behavior: Wall Shearing Stress Affects Current DensitywinkiNo ratings yet

- Pages From (Adam Bezuijen, Haike Van Lottum) Tunnelling-3Document12 pagesPages From (Adam Bezuijen, Haike Van Lottum) Tunnelling-3Luca BrandiNo ratings yet

- Understanding The Need For Pre Injection From - 2019 - Journal of Rock MechanicsDocument22 pagesUnderstanding The Need For Pre Injection From - 2019 - Journal of Rock MechanicsDiego CastilloNo ratings yet

- InstructionDocument10 pagesInstructiongreenday3No ratings yet

- Stress Strain Strength Flow Parameters From Enhanc by Mayne 2001Document24 pagesStress Strain Strength Flow Parameters From Enhanc by Mayne 2001Juan Manuel Betancur MarinNo ratings yet

- Stress-Strain Parameters from Enhanced In-Situ TestsDocument24 pagesStress-Strain Parameters from Enhanced In-Situ TestslinoficNo ratings yet

- Icsge 2015 Primary and Secondary Consolidation Characteristic During The Embankmentconstruction Over Soft Ground Assisted by Vacuum Consolidation With Air-Water Separation System PDFDocument9 pagesIcsge 2015 Primary and Secondary Consolidation Characteristic During The Embankmentconstruction Over Soft Ground Assisted by Vacuum Consolidation With Air-Water Separation System PDFNipon TeerachaikulpanichNo ratings yet

- Ibp2132 12Document14 pagesIbp2132 12Marcelo Varejão CasarinNo ratings yet

- Barutzki PDFDocument9 pagesBarutzki PDFesutjiadiNo ratings yet

- D-9-Stresses and Buckling2016-Final PDFDocument44 pagesD-9-Stresses and Buckling2016-Final PDFRichard YentumiNo ratings yet

- Face Pressure Calculations TBM Anag & Kovari 1996Document10 pagesFace Pressure Calculations TBM Anag & Kovari 1996nikita saleNo ratings yet

- Mayne2001Keynote BaliIN SITUDocument25 pagesMayne2001Keynote BaliIN SITUBreno RochaNo ratings yet

- Elasto-Hydrodynamic Lubrication: International Series on Materials Science and TechnologyFrom EverandElasto-Hydrodynamic Lubrication: International Series on Materials Science and TechnologyNo ratings yet

- Ppr12 262alr PDFDocument17 pagesPpr12 262alr PDFAf RymNo ratings yet

- Unsatchlef 2024 ProlongationDocument2 pagesUnsatchlef 2024 ProlongationAf RymNo ratings yet

- 2023 AlKhafajietalDocument17 pages2023 AlKhafajietalAf RymNo ratings yet

- Ppr12 262alr PDFDocument17 pagesPpr12 262alr PDFAf RymNo ratings yet

- President and Fellows of Harvard CollegeDocument2 pagesPresident and Fellows of Harvard CollegeAf RymNo ratings yet

- Remedial Measures - LuDocument9 pagesRemedial Measures - LuAf RymNo ratings yet

- Engineering geological properties assessment of northwest Damghan rocksDocument2 pagesEngineering geological properties assessment of northwest Damghan rocksAf RymNo ratings yet

- Simplified new approaches for seismic performance evaluation of earthfill damsDocument24 pagesSimplified new approaches for seismic performance evaluation of earthfill damsAf RymNo ratings yet

- 1 s2.0 014890629193108I MainDocument1 page1 s2.0 014890629193108I MainAf RymNo ratings yet

- Evaluation of Open Pit Mine Slope Stability AnalysisDocument12 pagesEvaluation of Open Pit Mine Slope Stability AnalysisAf RymNo ratings yet

- Lugeon Test Interpretation, RevisitedDocument10 pagesLugeon Test Interpretation, Revisitedmanu100% (2)

- GROUND STABILISATION - The Why's and How's of High Pressure Grouting (Editor's Choice) Part 1Document4 pagesGROUND STABILISATION - The Why's and How's of High Pressure Grouting (Editor's Choice) Part 1Af RymNo ratings yet

- Modelling Approach For Gravity Dam Break Analysis: Mourad Boussekine, Lakhdar DJEMILIDocument6 pagesModelling Approach For Gravity Dam Break Analysis: Mourad Boussekine, Lakhdar DJEMILIAf RymNo ratings yet

- Prediction of in Situ Permeability For Limestone Rock Using Rock Quality Designation IndexDocument4 pagesPrediction of in Situ Permeability For Limestone Rock Using Rock Quality Designation IndexAf RymNo ratings yet

- Application of The Theory of Limit Analysis For The Study of The Behavior of The Ground Anchor in Homogeneous SoilDocument14 pagesApplication of The Theory of Limit Analysis For The Study of The Behavior of The Ground Anchor in Homogeneous SoilAf RymNo ratings yet

- 1-S2.0-S0013795201000850-Main Lu PDFDocument11 pages1-S2.0-S0013795201000850-Main Lu PDFAf RymNo ratings yet

- ANTISEEPAGE AND CONSOLIDATION GROUTING OF THE CHIRKEY HYDROELECTRIC DAM FOUNDATIONDocument5 pagesANTISEEPAGE AND CONSOLIDATION GROUTING OF THE CHIRKEY HYDROELECTRIC DAM FOUNDATIONAf RymNo ratings yet

- 2) Word - List - Straightforward - Pre-Intermediate - Translations - French PDFDocument51 pages2) Word - List - Straightforward - Pre-Intermediate - Translations - French PDFAf RymNo ratings yet

- Logix 5000 CIP Sync ConfigurationDocument180 pagesLogix 5000 CIP Sync Configurationاحتشام چوہدریNo ratings yet

- Shaw's play about a sculptor and his creationDocument8 pagesShaw's play about a sculptor and his creationEmanuel BurculetNo ratings yet

- Chapter OneDocument36 pagesChapter Onepretoria agreement21No ratings yet

- cobas8000-DataManager - Host Interface Manual10205 PDFDocument286 pagescobas8000-DataManager - Host Interface Manual10205 PDF박수희No ratings yet

- Fire and Ice by Robert FrostDocument2 pagesFire and Ice by Robert Frostapi-561976496No ratings yet

- Biology of Tooth MovementDocument22 pagesBiology of Tooth MovementsakshiNo ratings yet

- Parts List of Engine Assy Ofdz-00536Document1 pageParts List of Engine Assy Ofdz-00536CwsNo ratings yet

- Eng. XI, U18 Meaning Into WordsDocument4 pagesEng. XI, U18 Meaning Into Wordssanad BhattaraiNo ratings yet

- Ch1 SlidesDocument47 pagesCh1 SlidesPierreNo ratings yet

- Spraying TechniquesDocument12 pagesSpraying TechniquesX800XLNo ratings yet

- Dh76 Auto HemaDocument271 pagesDh76 Auto HemaJoshua NarvaezNo ratings yet

- Future Developments in Management AccountingDocument4 pagesFuture Developments in Management AccountingAmar narayanNo ratings yet

- 20170322190836toms CaseDocument9 pages20170322190836toms CaseJay SadNo ratings yet

- Lubricated Coupling TrainingDocument47 pagesLubricated Coupling TrainingTheerayootNo ratings yet

- Build Pulse Oximeter InstructionsDocument3 pagesBuild Pulse Oximeter InstructionsPrabhuDevNo ratings yet

- Vocabulary - Vocabulario de Salud y de Sintomas en InglesDocument4 pagesVocabulary - Vocabulario de Salud y de Sintomas en InglesCarlos MiguelNo ratings yet

- Nato Military Policy On Public AffairsDocument21 pagesNato Military Policy On Public AffairsiX i0No ratings yet

- Chap3-2e SO2 Absorption ExampleDocument8 pagesChap3-2e SO2 Absorption Exampledarkelf_riderNo ratings yet

- Kitchen Tools & EquipmentDocument40 pagesKitchen Tools & EquipmentLymenson BoongalingNo ratings yet

- Icarus & DaedalusDocument2 pagesIcarus & DaedalusIsrael AsinasNo ratings yet

- ENGG378 - 948 HydroPower-Lecture - 1 - 2019 PDFDocument34 pagesENGG378 - 948 HydroPower-Lecture - 1 - 2019 PDFJ CNo ratings yet

- Cissp NotesDocument83 pagesCissp NotesRobert Mota HawksNo ratings yet

- Domain Logic and SQLDocument23 pagesDomain Logic and SQLatifchaudhryNo ratings yet

- CancioneroDocument7 pagesCancioneroJocelyn Almaguer LariosNo ratings yet

- PP 1Document33 pagesPP 1Vishnu IngleNo ratings yet

- Data CollectionDocument4 pagesData CollectionjochukoNo ratings yet

- Making Charts With Excel 2003: Income & ProfitDocument9 pagesMaking Charts With Excel 2003: Income & ProfitArunNo ratings yet

- MEL - Math 10C Item Writing - MC & NR ReviewDocument71 pagesMEL - Math 10C Item Writing - MC & NR ReviewMya TseNo ratings yet

- BearingsDocument26 pagesBearingstmscorreiaNo ratings yet

- Bamuoingaythienquan NguyenduynhienDocument9 pagesBamuoingaythienquan NguyenduynhienFLed NguyenNo ratings yet