Professional Documents

Culture Documents

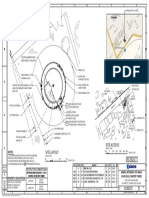

Detail G: Notes

Uploaded by

Felipe CastroOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Detail G: Notes

Uploaded by

Felipe CastroCopyright:

Available Formats

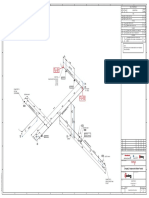

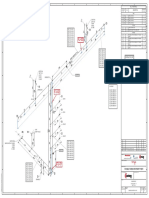

8 7 6 5 4 3 2 1

REV BY

SSK

GSJ

BILL OF MATERIALS

JL

NOTES W SEE ITEM QTY. PART NUMBER DESCRIPTION

19'-0" ( 5.79 m ) MAX. NOTE 12

7/25/2011

8/28/2014

7/2/2015

REVISIONS

1'-9" ( 0.53 m ) MIN.

DATE

1. SEE INSTRUCTION SHEET ( ITEM 30 ) FOR INSTALLATION DETAILS. 1 0 SEE TABLE I ALDUTI-RUPTER SWITCH

SEE DETAIL K SEE NOTE 3

2. MAXIMUM HEIGHT ( 'X' ) CAN BE INCREASED USING SUFFIXES S5A, S5B OR S5C

U SEE NOTE 12 2 1 SDA-10185 HANDLE ASSEMBLY 1-1/2" NPS

6'-5" ( 1.96 m ) MAX.

ST510959-B

UP TO 66'-7" ( 20.29 m ). WHEN 'X' IS LESS THAN 24'-11" ( 7.59 m ) CENTER PIPE 3 1 SA-36716 FOOT BEARING ASSEMBLY

ST506371

ST510061

10-9/16" ( 0.27 m ) MAX.

ECO NO.

SECTION CAN BE REMOVED. MINIMUM RECOMMENDED 'X' DIMENSION IS 12' ( 3.65 m ). SEE DETAIL A IN OPPOSITE DIRECTION

8 4 1 1011-010-9 1-1/2" IPS GALVANIZED PIPE 10'-4"

SEE NOTE 3 LONG

3. MAX./MIN. DIMENSIONS 'X', 'U AND 'W CAN ONLY BE ACHIEVED INDEPENDENTLY SEE NOTE 8 SEE NOTE 8 SEE NOTE 8

17 13 12 5 2 VU-865-1 GUIDE BEARING ASSEMBLY

007

008

009

OF ONE ANOTHER DEPENDING ON ORIENTATION OF UPPER VERTICAL PIPE SECTION. 18

NO.

R 28

710 20 21 20 19 SEE NOTE 12 125° 6 1 SAT-31516 RIGID COUPLING ASSEMBLY

4. DISTRIBUTE GUIDE BEARINGS BETWEEN THE BASE OF THE SWITCH AND SEE DETAIL J TRAVEL

D CENTERLINE OF OPERATING HANDLE PIVOT TO MINIMIZE OFFSET OF UPPER SEE DETAIL H 7 1 1011-010-9 1-1/2" IPS GALVANIZED PIPE 10'-4"

LONG

VERTICAL PIPE SECTION. 8 3/4 ±7/8 DETAIL G

A A 3-3/8

8 1 VU-857-1 THRUST BEARING ASSEMBLY

5. FOOT AND GUIDE BEARINGS MAY BE ROTATED UP TO 180 DEG. (AROUND SEE DETAIL G 2-1/4 86

VERTICAL PIPES) FROM POSITION SHOWN. 22 57 9 1 SDA-10095 UNIVERSAL COUPLING

10 1 1011-010-9 1-1/2" IPS GALVANIZED PIPE 10'-4"

6. THRUST BEARING ( ITEM 8 ) MUST REST ON UPPERMOST GUIDE BEARING. D D C 4 F LONG

10'-0" ( 3.05 m ) MAX. 10'-0" ( 3.05 m ) MAX. 5'-8" ( 1.72 m ) MAX. 8 102 1 11 1 SDA-10144 UNIVERSAL COUPLING

4'-0" ( 1.22 m ) MIN. 4'-0" ( 1.22 m ) MIN. 1'-9" ( 0.53 m ) MIN. 203 G SEE DETAIL E OR F

7. THE UNIVERSAL COUPLINGS ( ITEMS 9 & 11 ) WILL ACCOMMODATE VERTICAL

12 1 SA-34392 OUTBOARD BEARING ASSEMBLY

SLOPE IN UPPERMOST PIPE SECTION FROM 0 DEG. TO 20 DEG. MAX.

O 11/16

17 TYP.

13 1 S-69239 OUTBOARD BEARING PLATE

8 8. THREE 10'-4" ( 3.15 m ) LENGTHS OF 1-1/2" IPS PIPE, ONE 5'-2" ( 1.57 m ) LENGTH OF 17 1 VUT-626 CLEVIS PIPE COUPLING ASSEMBLY

1" IPS PIPE, AND TWO 10'-4" ( 3.15 m ) LENGTHS OF 1" IPS PIPE ARE PROVIDED. IWHEN

FIELD CUT, LENGTHS ARE AS FOLLOWS: DETAIL H 18 28-13/16 18 1 1011-003-33 1" IPS GALVANIZED PIPE 5'-2"

OUTBOARD BEARING 457 732

MOUNTING 19 1 SA-41178 COUPLING ASSEMBLY

ITEM 4 = 'Z' PLUS 9-3/4" ( 248 mm )

ITEM 7 = 'V' MINUS 3/4" ( 19 mm ) 20 2 1011-003-3 1" IPS GALVANIZED PIPE 10'-4" LONG

ITEM 10 = 'Y' MINUS 17-7/8" ( 454 mm ) 21 1 SA-41178 COUPLING ASSEMBLY

ITEM 18 = 'C' MINUS 6-1/4" ( 159 mm )

ITEM 22 = 'D' MINUS 7/8" ( 22 mm ) 22 1 SA-40877 OFFSET COUPLING

4-3/4 MINIMUM CLEARANCE

120 23 1 SA-38829 BLADE STOP BRACKET ASSEMBLY

9. GROUND STRAP AND GROUND CONNECTORS ARE INCLUDED WITH OPERATING HANDLE. REQUIRED FOR

CLEARANCE 11 24 1 1023-330 1/2-13 X 1 1/4 HEX HEAD GALVANIZE

10. ROTATE OPERATING HANDLE TO THE RIGHT (COUNTER-CLOCKWISE) TO OPEN 1/2 MINIMUM EXTENSION 25 1 1040-056 1/2 LOCKWASHER GALV.

SWITCH; ROTATE TO THE LEFT (CLOCKWISE) TO CLOSE SWITCH. WITH HANDLE 13

IN CLOSED POSITION, ENSURE ALL SWITCH POLES ARE FULLY CLOSED. 26 1 1023-812 1/2-13 HEX NUT GALVANIZED

FOR ALL PIPE TO

C COUPLING CONNECTIONS 10 SEE NOTES 30 1 761-570 INSTRUCTION SHEET

11. PROVISION FOR PADLOCKING IN OPEN AND CLOSED POSITIONS. 7&8 Y

11'-11" ( 3.63 m ) MAX 31 1 RD-10008 STANDARD MINOR MODIFICATION

SEE NOTE 6 8

12. WITH THE SWITCH POLES FINALLY ADJUSTED AND FULLY CLOSED, THE

OUTBOARD BEARING LEVER IS TO BE IN TOGGLE (APPROXIMATELY 1-1/2 DEG.

TO 2 DEG.). LEVER IS ADJUSTABLE FROM 5-1/2" TO 8-1/4" (PRESET AT 6-3/4"). 9

ASSEMBLED ON

9 HANDLE BY S&C { 32

33 4

1 GTB-2907

TR-20250

ALDUTI-RUPTER SWITCH NAMEPLATE

3/16 HEAD METAL TACK S/S

STOP BOLT IS ADJUSTABLE (PRESET AT 1"). 3-1/2 WHEN E.D. NUMBER HAS SUFFIXES REFER TO RD-10008 FOR

2 89 STANDARD BILL OF MATERIAL MODIFICATIONS

13. CUSTOMER TO MOUNT STOP ASSEMBLY ( ITEM 23 ) TO BASE OF SWITCH 51

8

POLE CLOSEST TO VERTICAL OPERATING MECHANISM AND ADJUST FOR

90 DEG. OPENING.

SECTION A-A SEE DETAIL B & C OR D

8 14. MAXIMUM LOAD ON SWITCH TERMINAL PADS IS 90 LBS (400 N) FOR IN-LINE FORCES

DETAIL B

AT UPPERMOST PIPE SECTION

TO THE BLADE AND 30 LBS (130 N) FOR PERPENDICULAR FORCES TO THE BLADE.

REFER TO ANSI STANDARD C37.32-2002 (TABLE 4). 5 SEE NOTES

4&5

2 X O 11/16

17 FOR 5/8"

5/8

16 2 X O 9/16

14

8-7/8 THRU BOLTS 7 SEE NOTE 8

1-1/2 225 23 24 25 26 (BY OTHERS) V

38 7 O 9/16

14 TYP. 1 10'-5" ( 3.18 m ) MAX

SEE NOTE 13 25 6

178 152

TABLE II - OPTION SUFFIXES AVAILABLE FOR THIS E.D.

3/4 6 S1 INSULATED VERTICAL PIPE SECTION

1 TYP. 1-3/4

19

90°

DETAIL C X

35'-4" ( 10.77 m ) MAX. S2 CYPOXY INSULATOR SECTION

25 44 DRILL PATTERN FOR FOOT &

B

DETAIL E TRAVEL

GUIDE BEARINGS (FOR POLE

SEE NOTES 2 & 7

SEE DETAIL C OR D S3 INSULATED VERT. & INTERPHASE PIPE SECTIONS

600 AMP SWITCH TERMINAL PAD MOUNTING WITH GAINING CHANNEL) CYPOXY INSULATOR SECTION & INSULATED

S4

HOLE PATTERN ( SEE NOTE 14 ) DETAIL J 2 INTERPHASE PIPE SECTIONS

INTERPHASE OPEN STOP 51 S5 2" IPS OPERATING PIPE SECTIONS

S5A 1 EXTRA PIPE SECTION (2" IPS PIPE)

42 4 X O 9/16

14 ADJUSTABLE 5 SEE NOTES

1067 4" ( 102 mm ) TO S5B 2 EXTRA PIPE SECTIONS (2" IPS PIPE)

3-1/2 2 X O 11/16

17 6-1/2" ( 165 mm )

4&5 S5C 3 EXTRA PIPE SECTIONS (2" IPS PIPE)

3-13/16 2-3/8 89

97 60 1-1/4 S6 KEY INTERLOCK ON HANDLE (WITH LOCK)

3 1-3/4 32 Z S6L KEY INTERLOCK PROVISIONS (LESS LOCK)

76 44 9'-6" ( 2.90 m ) MAX.

4 SEE NOTE 8 S7 AUXILIARY CONTACT SWITCH

2 TYP. 14-1/2 S8 AS-1A OPERATOR PROVISIONS-POLE MOUNTING

51 1-1/2 2-1/2 33 32 2

10-3/4 368 38 64 SEE NOTE 9 S9 AS-1A OPERATOR PROVISIONS-FLAT MOUNTING

273 2-1/2 SEE NOTES

5/8 1-3/4 64 8 S16 M-SERIES OPERATOR PROVISIONS

16 44 4-1/4 2-1/4 10 & 11

108 57 REFER TO RD-10008 FOR OPTION DETAILS & EXCEPTIONS

DETAIL D SEE DETAIL C OR D

2-1/2

64

O 9/16 ( 14 ) X 1-9/16 ( 40 )

TYP. DETAIL F DETAIL K DRILL PATTERN FOR FOOT &

TERMINAL PAD GUIDE BEARINGS (FOR FLAT SURFACE CENTERLINE OF 8 TABLE III - SWITCH OPTIONS AVAILABLE

1200 AMP SWITCH TERMINAL PAD

HANDLE PIVOT R 24

610

DETAIL A HOLE PATTERN ( SEE NOTE 14 ) MOUNTING WITHOUT GAINING CHANNEL)

(ONE SET OF HOLES TO BE USED)

B ICE SHIELDS

SWITCH MOUNTING 3 SEE NOTE 5 E CYPOXY INSULATORS

3'-6" ( 1.07 m ) L CONVERTIBLE DISCONNECTS (LESS INTERRUPTERS)

RECOMMENDED

Z3 HIGHER LEAKAGE DISTANCE INSULATORS

A

Z5 TIN PLATED TERMINAL PADS

P1 ONE POLE SWITCH

TABLE I - SWITCHES APPLICABLE TO THIS E.D.

DIMENSIONAL UNITS : IMPERIAL (IN) P2 TWO POLE SWITCH

CATALOG * RATINGS DIMENSIONS SWITCH *** METRIC (MM) REFER TO S&C SALES BULLETIN 761-31 FOR SWITCH DETAILS

NUMBER KV AMPERES F G WEIGHT MATERIAL FINISH DRAWING SIZE DRAWN BY

DRAWING NO.

UNLESS OTHERWISE SPECIFIED: (ITEM 1) NOM. MAX. BIL CONT./INTER. ** MOMENT. in. mm in. mm lbs kg D JLEONG

ED-103ER2

SCALE ORIGINATION DATE

DECIMAL DIMS TO BE: ±

138314 600 36-7/8 937 5-1/2 140 158 72

ANGLES TO BE: ± 34.5 38 200 40,000 NONE 7/25/2011

WHEN CHECKED, BREAK ALL CORNERS

7 158314 1200 41-1/4 1048 1-1/2 29 161 73 PROPRIETARY STATEMENT PROJECTION UNITS DESCRIPTION

WHEN CHECKED, REMOVE ALL BURRS

* BASIC CATALOG NUMBERS ARE SHOWN (REVISION SUFFIX'S OMITTED) - SEE TABLE III FOR AVAILABLE SUFFIXES THIS DOCUMENT AND ALL PREVIOUS ISSUES ARE THE SECRET AND CONFIDENTIAL PROPERTY OF

S&C ELECTRIC COMPANY ("S&C"), 6601 NORTH RIDGE BOULEVARD, CHICAGO, ILLINOIS, AND NEITHER INCHES STANDARD MOUNTING ARRANGEMENT-34.5 KV SIDE

RECEIPT NOR POSSESSION THEREOF INFERS OR TRANSFERS ANY RIGHT IN OR LICENSE TO USE

NEXT ASSEMBLY

** INTERRUPTER RATING DOES NOT APPLY TO S&C CONVERTIBLE DISCONNECTS THIS DOCUMENT, THE SUBJECT MATTER THEREOF, OR ANY DESIGN OR TECHNICAL INFORMATION

SHOWN THEREON; OR ANY RIGHT TO REPRODUCE THIS DOCUMENT OR ANY PART THEREOF, BREAK 3-POLE ALDUTI-RUPTER SWITCH-UPRIGHT

NEITHER THIS DOCUMENT NOR ANY INFORMATION CONTAINED THEREIN MAY BE COPIED, REPRODUCED,

DRAWING NO. SE

*** WEIGHTS SHOWN ARE PER POLE FOR STANDARD SWITCHES - WEIGHTS MAY VARY DUE TO SWITCH OPTIONS OR OTHERWISE USED OR DISCLOSED TO ANY OTHER PARTY WITHOUT FIRST OBTAINING THE

EXPRESS WRITTEN PERMISSION OF S&C. THIS DOCUMENT IS PROVIDED UNDER THE EXPRESS PRODUCT DESCRIPTION MOUNTING-CCW OPENING-ROTATING MECH.-SINGLE

CONDITION THAT IT WILL BE HELD IN CONFIDENCE BY THE RECIPIENT, THAT IT IS SUBJECT TO

ALDUTI-RUPTER OFFSET ED-103ER2

SE

RETURN UPON DEMAND, AND THAT IT WILL NOT BE USED IN ANY WAY DETRIMENTAL TO S&C.

You might also like

- Voltages in Must Be Measured Using Pcom As A Ground Reference. Voltages in Must Be Measured Using PGND As A Ground ReferenceDocument2 pagesVoltages in Must Be Measured Using Pcom As A Ground Reference. Voltages in Must Be Measured Using PGND As A Ground ReferenceSv KoNo ratings yet

- Companion 5 - DSP SCH PDFDocument4 pagesCompanion 5 - DSP SCH PDFManimaran MaranNo ratings yet

- 401G - Skid Gas Wiring DiagramDocument30 pages401G - Skid Gas Wiring DiagramfaisalnadimNo ratings yet

- RRPR-OPR-PRB-BR1-SB52 - Rev 1Document1 pageRRPR-OPR-PRB-BR1-SB52 - Rev 1sanjeev sharmaNo ratings yet

- Bill of Materials ListDocument1 pageBill of Materials Listsanjeev sharmaNo ratings yet

- RRPR-OPR-PRB-BR1-SB85 - Rev 1Document1 pageRRPR-OPR-PRB-BR1-SB85 - Rev 1sanjeev sharmaNo ratings yet

- Bose Sounddock System SCHDocument1 pageBose Sounddock System SCHhsjsdhNo ratings yet

- Bose Sounddock System SCHDocument1 pageBose Sounddock System SCHjose luis Rojas MuñozNo ratings yet

- Bose Sounddock System SCH PDFDocument1 pageBose Sounddock System SCH PDFdanielradu27100% (1)

- J3BGDF02BR030 07 02Document1 pageJ3BGDF02BR030 07 02Nauman TahirNo ratings yet

- SA04C2-03-WP-D-42008-01-5: 3. FJ - Field Joint 4. SJ - Shop JointDocument4 pagesSA04C2-03-WP-D-42008-01-5: 3. FJ - Field Joint 4. SJ - Shop JointABAID ULLAHNo ratings yet

- Bill of materials for structural steel assemblyDocument1 pageBill of materials for structural steel assemblysanjeev sharmaNo ratings yet

- Shop material listDocument1 pageShop material listTamil Arasu SNo ratings yet

- J3BGDF02BR030 09 02Document1 pageJ3BGDF02BR030 09 02Nauman TahirNo ratings yet

- Fire Parmit Drawing (Final Floors Plans)Document15 pagesFire Parmit Drawing (Final Floors Plans)Moe Oo HtunNo ratings yet

- 1 BDinsideoutoutsidein March2019Document1 page1 BDinsideoutoutsidein March2019Anna GorakNo ratings yet

- BOM for GRP pipe systemDocument2 pagesBOM for GRP pipe systemABAID ULLAHNo ratings yet

- Bill of materials list for structural assemblyDocument1 pageBill of materials list for structural assemblysanjeev sharmaNo ratings yet

- Key Plan Notes: Saudi Consulting Services CoDocument1 pageKey Plan Notes: Saudi Consulting Services CoJini DasNo ratings yet

- 270 S.J. S.J.: ID QTY DN Description Sch/Cla SSDocument2 pages270 S.J. S.J.: ID QTY DN Description Sch/Cla SSABAID ULLAHNo ratings yet

- J3BGDF11BR001 01 04Document1 pageJ3BGDF11BR001 01 04Nauman TahirNo ratings yet

- J3BGDF02BR025 01 01Document1 pageJ3BGDF02BR025 01 01saleem naheedNo ratings yet

- Shougang Hierro Peru S.A.A.: Plano No. Plano NoDocument1 pageShougang Hierro Peru S.A.A.: Plano No. Plano NoFrank Jerry Aylas TejedaNo ratings yet

- RRPR-OPR-PRB-BR1-SB53 - Rev 1Document1 pageRRPR-OPR-PRB-BR1-SB53 - Rev 1sanjeev sharmaNo ratings yet

- EVH 2x12Document5 pagesEVH 2x12ffuhnnadNo ratings yet

- SA04C2-03-WP-D-42013-01-5: 3. FJ - Field Joint 4. SJ - Shop JointDocument4 pagesSA04C2-03-WP-D-42013-01-5: 3. FJ - Field Joint 4. SJ - Shop JointABAID ULLAHNo ratings yet

- Estructural 1Document1 pageEstructural 1Sarahii RamosNo ratings yet

- Section A-A Section B-B Section C-C: Table Ii - Option Suffixes Available For This E.DDocument1 pageSection A-A Section B-B Section C-C: Table Ii - Option Suffixes Available For This E.DEduardo ZamoranoNo ratings yet

- 05270SS1Document1 page05270SS1Shakil SynnovaNo ratings yet

- 30LBF11BR411 - 2Document1 page30LBF11BR411 - 2Mohd Effiezool YaserNo ratings yet

- RRPR-OPR-PRB-BR1-SB71 - Rev 1Document1 pageRRPR-OPR-PRB-BR1-SB71 - Rev 1sanjeev sharmaNo ratings yet

- Jl. Sultan Iskandar Muda: Site PlanDocument1 pageJl. Sultan Iskandar Muda: Site PlanNadine Christabelle GadjuliNo ratings yet

- LD PC CH.199+590Document4 pagesLD PC CH.199+590Aerotide InfrastructuresNo ratings yet

- 06 CRDocument1 page06 CRwiraarkana23No ratings yet

- To Up Mindanao Sports Complex To Regional Rehabilitation For YouthDocument13 pagesTo Up Mindanao Sports Complex To Regional Rehabilitation For YouthSLNo ratings yet

- IIEE-01: Propietario: Compañia Electroandina SacDocument1 pageIIEE-01: Propietario: Compañia Electroandina SacCESAR AUGUSTO TIRADO MONSALVENo ratings yet

- Materials List: Quebrada Blanca Phase 2 Tailings Management FacilityDocument1 pageMaterials List: Quebrada Blanca Phase 2 Tailings Management FacilityNicole ChávezNo ratings yet

- Second Floor Plan (Main Building) : Stair Lobby Connecting Walk/PathwayDocument1 pageSecond Floor Plan (Main Building) : Stair Lobby Connecting Walk/PathwayCarl Justin AzucenaNo ratings yet

- 3 P 132 9501 1a3a N 02 - Rev01Document1 page3 P 132 9501 1a3a N 02 - Rev0146 JOSHI SWAPNIL OMNo ratings yet

- Fender Rumble 350 2010 Schematic Rev BDocument2 pagesFender Rumble 350 2010 Schematic Rev Bqwe123free1231962100% (1)

- J3BGDF02BR025 01 06Document1 pageJ3BGDF02BR025 01 06Naheed AkhtarNo ratings yet

- KTYM YARD HQ23-Sheet-2Document1 pageKTYM YARD HQ23-Sheet-2Anujith K BabuNo ratings yet

- Structure Drawings PDFDocument21 pagesStructure Drawings PDFxyzhynNo ratings yet

- Siddharth AdminDocument1 pageSiddharth AdminFan FollowingNo ratings yet

- Fire Line Second Floor Final BindalDocument1 pageFire Line Second Floor Final BindalKaran SethiNo ratings yet

- J3BGDF02BR010 01 05Document1 pageJ3BGDF02BR010 01 05Naheed AkhtarNo ratings yet

- J3BGDF02BR009 01 05Document1 pageJ3BGDF02BR009 01 05Naheed AkhtarNo ratings yet

- J3BGDF02BR011 01 01Document1 pageJ3BGDF02BR011 01 01saleem naheedNo ratings yet

- J3BGDF02BR009 01 01Document1 pageJ3BGDF02BR009 01 01saleem naheedNo ratings yet

- Copia Controlada: ESP: 03101.T136Document1 pageCopia Controlada: ESP: 03101.T136Samuel MuñozNo ratings yet

- 12lba52br002 Rev0Document1 page12lba52br002 Rev0ruralashishNo ratings yet

- Flowchart of meat processing facility layoutDocument12 pagesFlowchart of meat processing facility layoutTolol BegoNo ratings yet

- Mapa Turistico ESDocument2 pagesMapa Turistico ESRicardoLópezChacónNo ratings yet

- Shougang Hierro Peru S.A.A.: Plano No. Plano NoDocument1 pageShougang Hierro Peru S.A.A.: Plano No. Plano NoFrank Jerry Aylas TejedaNo ratings yet

- SMS Nobreak Sen T03395-02 Manager 1400 USBDocument1 pageSMS Nobreak Sen T03395-02 Manager 1400 USBSamuel LopesNo ratings yet

- Schematic Pros3Document1 pageSchematic Pros3Ricardo Villagomez DominguezNo ratings yet

- Hydraulic SchematicsDocument7 pagesHydraulic SchematicspaulosouzabhNo ratings yet

- Proposed road and storm water channel scheduleDocument1 pageProposed road and storm water channel schedulephanikrishnabNo ratings yet

- Tupi BV: Cosco (Dalian)Document4 pagesTupi BV: Cosco (Dalian)Robles DreschNo ratings yet

- AC Machines Single Phase - PPT (Guntur TTL)Document28 pagesAC Machines Single Phase - PPT (Guntur TTL)Indra ArdiansyahNo ratings yet

- Srs PDFDocument54 pagesSrs PDFenmanuel de js gomezNo ratings yet

- Reinforcing Detailing of R.C.C Members - K.kaviTHADocument47 pagesReinforcing Detailing of R.C.C Members - K.kaviTHAGurupriyaNo ratings yet

- Royal Endfield UCE Fuel Injection ManualDocument13 pagesRoyal Endfield UCE Fuel Injection ManualLuis GamboaNo ratings yet

- 48 ModularDocument1 page48 ModularPawluchNo ratings yet

- TempDocument1 pageTempgrwgNo ratings yet

- NTPC Unchahar Schedule Bhel Format-1Document3 pagesNTPC Unchahar Schedule Bhel Format-1Anjaneyulu Bodhanapu100% (1)

- Power Inverter: Model BI800T and BI800FDocument18 pagesPower Inverter: Model BI800T and BI800FG NAIRNo ratings yet

- Horn SystemDocument15 pagesHorn Systemandres rangelNo ratings yet

- ENGINE DIAGNOSIS TROUBLE CODESDocument6 pagesENGINE DIAGNOSIS TROUBLE CODESGiancarlo CostantiniNo ratings yet

- Mandatory Rule of Thumb for Reinforced Concrete Framed Buildings without Masonry InfillDocument35 pagesMandatory Rule of Thumb for Reinforced Concrete Framed Buildings without Masonry InfillSanZib PandeyNo ratings yet

- Bill of Material For PCUDocument2 pagesBill of Material For PCUIqraSaeedNo ratings yet

- Overhead Electric Distribution ManualDocument636 pagesOverhead Electric Distribution ManualAlvaro DiazNo ratings yet

- Chapter9 Braking DCDocument43 pagesChapter9 Braking DCPacoNo ratings yet

- Standard Operating Procedure for LT PanelDocument5 pagesStandard Operating Procedure for LT PanelKarthik Mandya100% (3)

- Celestron PowerTank ManualDocument3 pagesCelestron PowerTank ManualvinaykumarjainNo ratings yet

- Construction of Irrigation Well EstimateDocument7 pagesConstruction of Irrigation Well Estimatesantosh.manojNo ratings yet

- D2 HARD DISK PCB REPAIR TRAINING MODULEDocument4 pagesD2 HARD DISK PCB REPAIR TRAINING MODULEFalco de ZwartNo ratings yet

- Motor Protection: 5.08kV, 7.2kV AND 15.5kV Bolt-In FusesDocument4 pagesMotor Protection: 5.08kV, 7.2kV AND 15.5kV Bolt-In FusesRafael LopezNo ratings yet

- Method Statement CladdingDocument2 pagesMethod Statement Claddingasrihamid77% (26)

- Kenr6233 00Document2 pagesKenr6233 00Boris BabicNo ratings yet

- SM 58Document93 pagesSM 58Tzvetan DimitrovNo ratings yet

- Sug 17003Document30 pagesSug 17003namNo ratings yet

- Is SPH8701Document3 pagesIs SPH8701dayshift5No ratings yet

- 600lbs EM Lock: La - Emlock La - Emlock.LedDocument2 pages600lbs EM Lock: La - Emlock La - Emlock.LedSaufiy SarminNo ratings yet

- 8 Urban Cruiser: Engine Immobiliser System (W/o Entry & Start System)Document1 page8 Urban Cruiser: Engine Immobiliser System (W/o Entry & Start System)HEMIL ROBERTO RODRIGUEZ HERRERANo ratings yet

- Setting-Up ArduCopter Electronics V 002Document19 pagesSetting-Up ArduCopter Electronics V 002Marco ReisNo ratings yet

- "Orange Line": AC Contactors, AC OperatedDocument2 pages"Orange Line": AC Contactors, AC OperatedfelipeffcNo ratings yet

- Datasheet 50-8231-0 en 220V 50HzDocument4 pagesDatasheet 50-8231-0 en 220V 50HzJosé Manuel Retamal FuentealbaNo ratings yet

- 2a CTRL DecDocument75 pages2a CTRL Decramanathan balamoorthyNo ratings yet