Professional Documents

Culture Documents

Gulf No Rust C2 Protects Metal Surfaces from Corrosion

Uploaded by

atripathi2009Original Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Gulf No Rust C2 Protects Metal Surfaces from Corrosion

Uploaded by

atripathi2009Copyright:

Available Formats

Gulf No Rust C2

Water displacing rust preventive forming oily greasy protective film

Product Description

Gulf No Rust C2 is water displacing type rust preventive and leaves an oily greasy protective film. It is

specifically designed to provide medium-term protection of spare parts, components and machined surfaces

made of ferrous and non-ferrous metals including aluminium, copper and their alloys with improved

coverage. It is blended from selected rust prevention components and solvent to provide excellent

dewatering properties, effective protective film and fast drying capability.

Features & Benefits

• Facilitates rapid removal of water or coolant from metal surfaces

• Effective fingerprint corrosion suppressant thus making the film resistant to handling

• Forms effective protective film against aggressive atmospheres

• Excellent spreading allowing them to be applied either by dipping or by spraying.

• Rapid drying assists in increasing process speed.

Applications

• Gulf No Rust C2 is recommended for medium-term protection of precision metal components made

of ferrous and non-ferrous metals including aluminium, copper and their alloys after machining,

extrusion, galvanizing or degreasing/ washing processes.

• Gulf No Rust C2 is best applied by dipping but if such facilities are not available it can also be

sprayed. However, all precautions applicable to solvent-based products should be observed.

• Brushing of the fluid can also be used but extra care must be taken to ensure that brush fibres or

extraneous dirt/ particulates are not inadvertently introduced as they have negative impact on anti-

corrosion performance.

• If needed, the protective film can be removed by wiping off with rags/waste soaked in

kerosene/mineral turpentine or by alkaline degreasants or solvent degreasing methods.

NOTE : Gulf No Rust C2 is compatible with normal steel components and pipework prevalent in the construction of

application systems. Care should be exercised with selection and use of seals and paints in contact with this product.

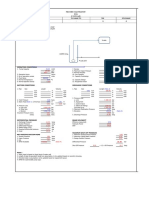

Specifications, Approvals & Typical Properties

Meets the following Specifications

ISO 6743-8 (1987): ISO-L-REE category

Typical Properties

Test Parameters ASTM Method Typical Values

Appearance Visual Thin Amber Fluid

Viscosity @ 20 ºC, cSt D 445 2.8

Flash Point, PMCC , ºC D 93 42

Pour Point, ºC D 97 -54

Density @ 15ºC, Kg/l D 1298 0.802

Coverage (m2/l) 60

Film thickness, microns 4

Salt Spray test, hours to fail B 117 100+

Humidity cabinet, days to fail D 1748 120+

Indoor Protection, months 9

Outdoor Protection, months 3

March 2010

You might also like

- Assets & Liabilities Form Above 25 LakhsDocument2 pagesAssets & Liabilities Form Above 25 Lakhsrathinamh956% (9)

- Gulf Synthetic Gear Oil - PAGDocument1 pageGulf Synthetic Gear Oil - PAGatripathi2009No ratings yet

- Pump Sizing SpreadsheetDocument2 pagesPump Sizing Spreadsheetandrew rachmanNo ratings yet

- New Product Development ProcessDocument29 pagesNew Product Development ProcessGAURAV SHARMA100% (1)

- GRP and Buildings: A Design Guide for Architects and EngineersFrom EverandGRP and Buildings: A Design Guide for Architects and EngineersNo ratings yet

- DC 781 Acetoxy SealantDocument3 pagesDC 781 Acetoxy SealantL.S.No ratings yet

- EY - NASSCOM - M&A Trends and Outlook - Technology Services VF - 0Document35 pagesEY - NASSCOM - M&A Trends and Outlook - Technology Services VF - 0Tejas JosephNo ratings yet

- Mhcci ListDocument1,074 pagesMhcci ListShaiwal Parashar57% (7)

- Aclu List Research Export 20160810050210Document2 pagesAclu List Research Export 20160810050210api-285701682100% (1)

- CCST+Cybersecurity+Objecitve+Domain Cisco Final wCiscoLogoDocument3 pagesCCST+Cybersecurity+Objecitve+Domain Cisco Final wCiscoLogoQazi ZayadNo ratings yet

- Ficha Técnica Roto Synthetic Fluid XTEND DUTYDocument2 pagesFicha Técnica Roto Synthetic Fluid XTEND DUTYWanderson FIALHONo ratings yet

- Data Sheet Roto Synthetic Fluid Xtend Duty enDocument2 pagesData Sheet Roto Synthetic Fluid Xtend Duty enFArras FakhiraNo ratings yet

- Jotun Tankguard HBDocument5 pagesJotun Tankguard HBrheriNo ratings yet

- Latest HR Details 2014Document1 pageLatest HR Details 2014Raghu Varan67% (9)

- Gulf No Rust WXD 32 Protects Machines from Rust with Waxy FilmDocument1 pageGulf No Rust WXD 32 Protects Machines from Rust with Waxy Filmatripathi2009No ratings yet

- DTM Bonding Primer: Protective & Marine CoatingsDocument4 pagesDTM Bonding Primer: Protective & Marine CoatingsAna CabreraNo ratings yet

- Folheto Tecnico - Molykote 7400 Anti-Friction Coating 71-0073E-01Document2 pagesFolheto Tecnico - Molykote 7400 Anti-Friction Coating 71-0073E-01marcosNo ratings yet

- Safecoat DW 33Document2 pagesSafecoat DW 33carmaNo ratings yet

- BitugardDocument2 pagesBitugardAhmad SamyNo ratings yet

- Nox-Rust 307 HF TDSDocument1 pageNox-Rust 307 HF TDSpankaj chaudharyNo ratings yet

- Molykote D 321R - BrochureDocument2 pagesMolykote D 321R - Brochuretaufik perdanaNo ratings yet

- Product Data Sheet: 6 IN 1 Multipurpose LubricantDocument2 pagesProduct Data Sheet: 6 IN 1 Multipurpose LubricantDaniel ColinsNo ratings yet

- Jotamastic 80 MIO Epoxy Mastic Technical Data SheetDocument5 pagesJotamastic 80 MIO Epoxy Mastic Technical Data SheetBiju_PottayilNo ratings yet

- Bel-Ray 6 in 1 Multipurpose LubricantDocument2 pagesBel-Ray 6 in 1 Multipurpose LubricantdhowardjNo ratings yet

- Ambigard - 2K Waterproof Coating For ConcreteDocument4 pagesAmbigard - 2K Waterproof Coating For ConcreterudrabirNo ratings yet

- Concrete PrimerDocument2 pagesConcrete Primerumn_mlkNo ratings yet

- Gulf FidelityDocument1 pageGulf FidelityBassam AljiffryNo ratings yet

- Roto Synthetic Fluid Xtend Duty en Atlas CopcoDocument2 pagesRoto Synthetic Fluid Xtend Duty en Atlas CopcoTamara GarciaNo ratings yet

- Advanced Rust Preventive FluidDocument2 pagesAdvanced Rust Preventive FluidmiteshNo ratings yet

- TDS 35042 Marathon IQ2 Euk GBDocument5 pagesTDS 35042 Marathon IQ2 Euk GBserge.angarita.sNo ratings yet

- Technical Data Sheet for Tankguard Storage CoatingDocument5 pagesTechnical Data Sheet for Tankguard Storage Coatingabdulgafoor54No ratings yet

- Q8 Handel 46Document1 pageQ8 Handel 46chandan sahooNo ratings yet

- PDS Poweroil RP CRDocument2 pagesPDS Poweroil RP CRNitant MahindruNo ratings yet

- PDS Poweroil RP HPDocument2 pagesPDS Poweroil RP HPNitant MahindruNo ratings yet

- SP Eng NLGI 1,2,3 2012 OctDocument3 pagesSP Eng NLGI 1,2,3 2012 OctundraazolbayarNo ratings yet

- Titanpro PD701 Product Data PDFDocument1 pageTitanpro PD701 Product Data PDFJoni Sie MssNo ratings yet

- Tankguard StorageDocument5 pagesTankguard StorageBiju_PottayilNo ratings yet

- PDS STRATA EPOXY MT 45520 en-GB PDFDocument2 pagesPDS STRATA EPOXY MT 45520 en-GB PDFMohamed NouzerNo ratings yet

- Paint - Technical Specification 2022-01...Document1 pagePaint - Technical Specification 2022-01...Weng Hoe ChooNo ratings yet

- Bpxe 8v8uszDocument2 pagesBpxe 8v8uszAzad MisirliNo ratings yet

- Jotamastic 80: Technical Data SheetDocument5 pagesJotamastic 80: Technical Data SheetArif dwi prasetyoNo ratings yet

- PC 7337-EnDocument3 pagesPC 7337-EnJuan LondonoNo ratings yet

- Dogger Bank ADocument11 pagesDogger Bank AGRZEGORZ GNo ratings yet

- 高溫油脂MOLYKOTE D-321 R Anti-Friction 71-0219G-01Document2 pages高溫油脂MOLYKOTE D-321 R Anti-Friction 71-0219G-01If ChenNo ratings yet

- WWW - Techsil.co - Uk: Stainless Steel Putty Product BulletinDocument2 pagesWWW - Techsil.co - Uk: Stainless Steel Putty Product BulletinVinodKandukuriNo ratings yet

- Protective DTM Acrylic Primer/Finish Product DescriptionDocument4 pagesProtective DTM Acrylic Primer/Finish Product DescriptionVernon Jiménez FonsecaNo ratings yet

- Sikadur®-188 Normal: For Internal Use OnlyDocument3 pagesSikadur®-188 Normal: For Internal Use OnlySUCHARITNo ratings yet

- Protective Industrial Enamel CoatingDocument4 pagesProtective Industrial Enamel CoatingAna CabreraNo ratings yet

- Repsol Hydroflux Ep PDFDocument1 pageRepsol Hydroflux Ep PDFrandiNo ratings yet

- AnabondDocument3 pagesAnabondmangesh.pandharpureNo ratings yet

- Product Data: Titanpro Sm198Document1 pageProduct Data: Titanpro Sm198李万福No ratings yet

- Tankguard HB Classic Jotun PaintDocument5 pagesTankguard HB Classic Jotun PaintGurdeep Sungh AroraNo ratings yet

- Globalene ST031: Technical Data Sheet / 技術資料表Document1 pageGlobalene ST031: Technical Data Sheet / 技術資料表Ale AriasNo ratings yet

- Masterflow 916 An TdsDocument4 pagesMasterflow 916 An TdsThet LinnNo ratings yet

- Pertamina-Dex English VersionDocument1 pagePertamina-Dex English VersionrekaelektraNo ratings yet

- Industrial Oil Rust PreventiveDocument2 pagesIndustrial Oil Rust PreventiveNitant MahindruNo ratings yet

- ShaliPoxy CTE 103Document4 pagesShaliPoxy CTE 103Prashant BaruaNo ratings yet

- Mariseal 400 Aqua Version18Document2 pagesMariseal 400 Aqua Version18Chetal BholeNo ratings yet

- Korapur PU 928 Marine InglesDocument2 pagesKorapur PU 928 Marine InglesselvaNo ratings yet

- Hempadur Avantguard 770 Product Data SheetDocument4 pagesHempadur Avantguard 770 Product Data SheetNithin MathaiNo ratings yet

- Industrial Aluminum Paint: Protective & Marine CoatingsDocument4 pagesIndustrial Aluminum Paint: Protective & Marine CoatingsAna CabreraNo ratings yet

- TDS Pidifin 2K Eng Rev.09 23 07 19Document3 pagesTDS Pidifin 2K Eng Rev.09 23 07 19Sumit SinhaNo ratings yet

- Jota Floor Top Coat TDSDocument5 pagesJota Floor Top Coat TDSthar gyiNo ratings yet

- Barrier 80Document5 pagesBarrier 80Biju_PottayilNo ratings yet

- Molykote 3402Document2 pagesMolykote 3402Dicky PratamaNo ratings yet

- Tankguard HB ClassicDocument5 pagesTankguard HB ClassicMuhammad Iqbal Al HaidarNo ratings yet

- Technical Data Sheet for Epoxy Mastic CoatingDocument5 pagesTechnical Data Sheet for Epoxy Mastic CoatingRamlialianNo ratings yet

- Tankguard AR: Technical Data SheetDocument5 pagesTankguard AR: Technical Data SheetAzar SKNo ratings yet

- AlugardDocument2 pagesAlugardmk779900mkNo ratings yet

- Project Service - PO GuidelinesDocument4 pagesProject Service - PO Guidelinesatripathi2009No ratings yet

- PO Guidelines Check ListDocument3 pagesPO Guidelines Check Listatripathi2009No ratings yet

- Assets and Liability Bank LetterDocument2 pagesAssets and Liability Bank Letteratripathi2009No ratings yet

- Purchase Order ChecklistDocument1 pagePurchase Order Checklistatripathi2009No ratings yet

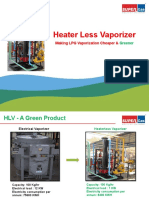

- SHV India Pioneering Efficient LPG Energy SolutionsDocument41 pagesSHV India Pioneering Efficient LPG Energy Solutionsatripathi2009No ratings yet

- Conversion PPT (FINAL)Document34 pagesConversion PPT (FINAL)atripathi2009No ratings yet

- Maxima LPG Installation PresentationDocument20 pagesMaxima LPG Installation Presentationatripathi2009No ratings yet

- FAQ On PO AccptanceDocument1 pageFAQ On PO Accptanceatripathi2009No ratings yet

- Pioneering Efficient Energy SolutionDocument36 pagesPioneering Efficient Energy Solutionatripathi2009No ratings yet

- Pioneering Efficient Energy Solutions Through LPGDocument36 pagesPioneering Efficient Energy Solutions Through LPGatripathi2009No ratings yet

- Gulf EP Lubricant SY - PAODocument1 pageGulf EP Lubricant SY - PAOatripathi2009No ratings yet

- LPG Vaporizer Reduces Costs & EmissionsDocument9 pagesLPG Vaporizer Reduces Costs & Emissionsatripathi2009No ratings yet

- Cathodic Protection - PresentationDocument24 pagesCathodic Protection - Presentationatripathi2009No ratings yet

- Gulf Gear EP protects gears and componentsDocument1 pageGulf Gear EP protects gears and componentsatripathi2009No ratings yet

- Gulf EP Lubricant HDDocument1 pageGulf EP Lubricant HDatripathi2009No ratings yet

- Gulf Harmony AW: High Performance Anti-Wear Hydraulic OilDocument2 pagesGulf Harmony AW: High Performance Anti-Wear Hydraulic Oilatripathi2009No ratings yet

- Gulf Industrial Lubricant Portfolio GuideDocument21 pagesGulf Industrial Lubricant Portfolio Guideatripathi2009No ratings yet

- Safety Data Sheet: Section 1: Identification of The Substance/Mixture and of The Company/UndertakingDocument11 pagesSafety Data Sheet: Section 1: Identification of The Substance/Mixture and of The Company/Undertakingatripathi2009No ratings yet

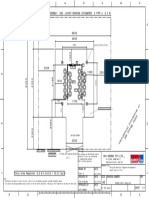

- VL2 - 2 X9 SL Type ADocument1 pageVL2 - 2 X9 SL Type Aatripathi2009No ratings yet

- Gulf Lubricants Brief ProfileDocument10 pagesGulf Lubricants Brief Profileatripathi2009100% (1)

- Gulf Oil Lubricants IntroductionDocument12 pagesGulf Oil Lubricants Introductionatripathi2009No ratings yet

- VL1 - 2 X9 SU Type ADocument1 pageVL1 - 2 X9 SU Type Aatripathi2009No ratings yet

- Gulf Corporate BrochureDocument6 pagesGulf Corporate Brochureatripathi2009No ratings yet

- Therminol TFDocument8 pagesTherminol TFShiv RajNo ratings yet

- Organophosphorus Pesticide Residues in Vegetables and Soil Samples From Alau Dam and Gongulong Agricultural Areas, Borno State, NigeriaDocument7 pagesOrganophosphorus Pesticide Residues in Vegetables and Soil Samples From Alau Dam and Gongulong Agricultural Areas, Borno State, NigeriaWiro JuangNo ratings yet

- UmehDocument2 pagesUmehAdeleke AyobamiNo ratings yet

- Younis 2020Document5 pagesYounis 2020nalakathshamil8No ratings yet

- Newnew 151 ModelDocument1 pageNewnew 151 ModelCrestine Lily DongosaNo ratings yet

- B.Tech Digital Principles and System Design Exam Question BankDocument24 pagesB.Tech Digital Principles and System Design Exam Question Bankdigital1206No ratings yet

- Basf TapesDocument3 pagesBasf TapesZoran TevdovskiNo ratings yet

- Elementos ElectrónicosDocument9 pagesElementos ElectrónicosKratt DeividNo ratings yet

- National Electrification Administration Vs GonzagaDocument1 pageNational Electrification Administration Vs GonzagaDonna Amethyst BernardoNo ratings yet

- Central Council For Research in Ayurvedic Sciences: CCRAS Post Doctoral Fellowship Scheme (CCRAS PDF Scheme)Document2 pagesCentral Council For Research in Ayurvedic Sciences: CCRAS Post Doctoral Fellowship Scheme (CCRAS PDF Scheme)TUSHAR DASHNo ratings yet

- The Role of Molecular Testing in The Differential Diagnosis of Salivary Gland CarcinomasDocument17 pagesThe Role of Molecular Testing in The Differential Diagnosis of Salivary Gland CarcinomasMariela Judith UCNo ratings yet

- HistoryDocument13 pagesHistoryMuhamed Zimić ZimaNo ratings yet

- Elite Physics G10 T2 SLA1Document7 pagesElite Physics G10 T2 SLA1thecubeg0No ratings yet

- Ulliensb PDF 1516040087Document30 pagesUlliensb PDF 1516040087Jose Daniel ArangoNo ratings yet

- C++ Module 2Document58 pagesC++ Module 2Kaye CariñoNo ratings yet

- SE John Deere 6020 Series Filter Overview and Capacities 6120 6120L 6220 6220L 6320 6320L 6420 6420L 6520L NOV20Document2 pagesSE John Deere 6020 Series Filter Overview and Capacities 6120 6120L 6220 6220L 6320 6320L 6420 6420L 6520L NOV20marianNo ratings yet

- Community Development and Umbrella BodiesDocument20 pagesCommunity Development and Umbrella Bodiesmoi5566No ratings yet

- SRX835 Spec Sheet - 11 - 11 - 19Document4 pagesSRX835 Spec Sheet - 11 - 11 - 19Eric PageNo ratings yet

- Lentz Criminal ComplaintDocument16 pagesLentz Criminal ComplaintKristen Faith SchneiderNo ratings yet

- LSRetailDataDirector UserGuideDocument89 pagesLSRetailDataDirector UserGuideRock Lee60% (5)

- SDA HLD Template v1.3Document49 pagesSDA HLD Template v1.3Samuel TesfayeNo ratings yet

- Patient-Centred CareDocument15 pagesPatient-Centred CareMwanja MosesNo ratings yet

- Pendiq User Manual enDocument64 pagesPendiq User Manual enMartin JoseNo ratings yet

- PPE Use Tool Box TalkDocument3 pagesPPE Use Tool Box Talkanon_348105361No ratings yet

- Kalokal Barangay Highway HillsDocument35 pagesKalokal Barangay Highway HillsDixie MirandaNo ratings yet

- Treehouse Avatar Technologies v. TurbineDocument5 pagesTreehouse Avatar Technologies v. TurbinePriorSmart0% (1)