Professional Documents

Culture Documents

Control Valve Pn16: Series Vla300 and Vlb300

Uploaded by

SultanOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Control Valve Pn16: Series Vla300 and Vlb300

Uploaded by

SultanCopyright:

Available Formats

LINEAR MOTORIZED VALVES

CONTROL VALVE PN16

SERIES VLA300 AND VLB300

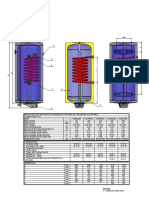

ESBE flanged control valves series for PN16, DN15-150. VLA325 VLB325

Flange PN16 Flange PN16

2-way valves: VLA325 and VLB325.

3-way valves: VLA335 and VLB335

MEDIA VLA335 VLB335

These valves can handle the following types of media: Flange PN16 Flange PN16

– Hot and cold water.

– Water with antifreeze additives such as glycol. CONTROL VALVE DESIGNED FOR

If the valve is used for media at temperatures below 0°C Heating Ventilation

(32°F), it should be equipped with a stem heater in order to Comfort Cooling District Heating

prevent ice formation on the valve stem. The stem heater Solar heating District Cooling

ALF802 is fixed on the actuator fixing point.

These control valves are used to control fluids belonging SUITABLE ACTUATORS

to the group showed in teh table in accordance to annex

ALB140 ALF36x DN15-150

IV of 2014/68/EU (PED) directive, in air-conditioning, ALF13x DN15-50 ALF46x DN65-150

thermoventilation and heating plants and in industrial ALF26x DN15-150

processes; therefore they cannot be used as safety valves.

VALVE MOUNTING ACCESSORIES DN 15 – 50

Before mounting the valve, make sure pipes are clean, free Art. No.

from welding slags. The pipes must be perfectly aligned 26000700_____________________Adaptor kit, Siemens SQX

with the valve body and not subject to any vibrations.

For installations on plants with high temperature fluids

(overheated water) always use expansion joints to avoid

dilatation of pipes to stress the valve body.

Install the valves with the actuator in vertical position

for fluid temperature up to 120°C, with higher temperatures

they must be mounted horizontally.

TECHNICAL DATA, DN15-50 TECHNICAL DATA, DN65-150

Type:______________________________2- and 3-way plug valve Type:______________________________2- and 3-way plug valve

Pressure class:___________________________________ PN 16 Pressure class:___________________________________ PN 16

Flow characteristic A–AB:____________________________EQM Flow characteristic A–AB:____________________________EQM

Flow characteristic B–AB:__________________ Complementary Flow characteristic B–AB:___________________________Linear

Stroke:_________________________________________ 20 mm Stroke: __________________________________ DN 65, 25 mm

Rangeability Kv/Kvmin:___________________________ see graph ______________________________DN 80-150, 45 mm

Leakrate A–AB:_____________________________ Tight sealing Rangeability Kv/Kvmin:________________________________ >50

Leakrate B–AB:_____________________________ Tight sealing Leakrate A–AB:____________________________ 0.03% of Kvs

∆Pmax:________________________________________ see graph Leakrate B–AB:_______________________________ 2% of Kvs

Media temperature: ________________________ max. +130°C ∆Pmax: ____________________________ Mixing, 200 kPa (2 bar)

___________________________ min. -20°C _________________________ Diverting: 70 kPa (0.7 bar)

Connection: __________________________Flange, ISO 7005–2 Media temperature: ________________________ max. +150°C

___________________________ min. -10°C

Material Connection: __________________________Flange, ISO 7005–2

Body:___________________________ Nodular iron EN-JS 1030

Stem:____________________________ Stainless steel SS 2346 Material

Plug:____________________________________ Brass CW602N Body:__________________________ Grey cast iron EN-JL 1040

Seat:___________________________ Nodular iron EN-JS 1030 Stem:__________________________ Stainless steel DIN 1.4305

Blind plug:_______________________________ Brass CW602N Plug:____________________________________ Brass CW617N

Seat seal:_______________________________________ EPDM Seat:__________________________ Grey cast iron EN-JL 1040

Packing box seal:_____________________________ PTFE/EPDM Seat seal:______________________________________ Metallic

Packing box seal:__________________________________ EPDM

DN15–50 PED 2014/68/EU, article 4.3 DN65–150 PED 2014/68/EU, Annex IV

ESBE SERIES VLA300, VLB300 • EN • L

© Copyright. Rights reserved to make alterations. 1

LINEAR MOTORIZED VALVES

CONTROL VALVE PN16

SERIES VLA300 AND VLB300

E

M8 M8

C

C

D

H

F

G

G

B

B

A A

VLA325 VLB325 VLA335/VLB335

2-WAY CONTROL VALVE SERIES VLA325/VLB325

Weight

Art. No. Reference DN Kvs* A B C D E F G H [kg]

21200100 1.6

21200200 15 2.5 130 42 123 4x14 20 38 95 65 2.1

21200300 4

21200400 20 6.3 150 44 126 4x14 20 41 105 75 2.6

VLA325

21200500 25 10 160 44 131 4x14 20 46 115 85 3.2

21200600 32 16 180 58 144 4x19 20 60 140 100 4.6

21200700 40 25 200 60 146 4x19 20 61 150 110 5.8

21200800 50 38 230 74 161 4x19 20 76 165 125 8.0

21220100 65 63 290 175 155 4x18 25 95 185 145 23.0

21220200 80 100 310 187 165 8x18 45 105 200 160 30.0

21220300 VLB325 100 130 350 207 176 8x18 45 116.5 220 180 45.6

21220400 125 200 400 234 199 8x18 45 139 250 210 55.0

21220500 150 300 480 277 217 8x22 45 157 285 240 71.0

3-WAY CONTROL VALVE SERIES VLA335/VLB335

Weight

Art. No. Reference DN Kvs* A B C D E F G H [kg]

21200900 1.6

21201000 15 2.5 130 65 123 4x14 20 38 95 65 2.5

21201100 4

21201200 20 6.3 150 75 126 4x14 20 41 105 75 3.2

VLA335

21201300 25 10 160 80 131 4x14 20 46 115 85 3.8

21201400 32 16 180 90 144 4x19 20 60 140 100 6.6

21201500 40 25 200 100 146 4x19 20 61 150 110 7.5

21201600 50 38 230 115 161 4x19 20 76 165 125 10.0

21221100 65 63 290 145 155 4x18 25 95 185 145 19.0

21221200 80 100 310 155 165 8x18 45 105 200 160 24.0

21221300 VLB335 100 130 350 175 176 8x18 45 116.5 220 180 32.0

21221400 125 200 400 200 199 8x18 45 139 250 210 46.0

21221500 150 300 480 240 217 8x22 45 157 285 240 61.0

* Kvs-value in m3/h at a pressure drop of 1 bar.

2 ESBE SERIES VLA300, VLB300 • EN • L

© Copyright. Rights reserved to make alterations.

LINEAR MOTORIZED VALVES

CONTROL VALVE PN16

SERIES VLA300 AND VLB300

VALVE CHARACTERISTICS, DN15-50

2-way valves, DN15-50 3-way valves, DN15-50

100 100

Flow capacity, Kv/Kvs [%]

Flow capacity, Kv/Kvs [%]

80 80

60 Port A 60 Port A

As installed, Port B

ß=0,5

A+B

40 40

As installed,

20 20

ß=0,5

0 0

0 20 40 60 80 100 0 20 40 60 80 100

Stroke [%] Stroke [%]

DIFFERENTIAL PRESSURE DROP CHARACTERISTICS,

DN15-50 (mixing)

1600

Static pressure before valve [kPa]

140°C

1400

1200 120°C

100°C

1000 80°C

20°C

800

600

400

200

0

0 100 200 300 400 500 600

Pressure drop over valve [kPa]

Pressure drop limit where caviation might occur. Is dependent of valve inlet pressure and

temperature of water.

VALVE CHARACTERISTICS, DN65-150

2-way valves, DN65-150 3-way valves, DN65-150

100 100

Flow capacity, Kv/Kvs [%]

Flow capacity, Kv/Kvs [%]

80 80

60 60

Port A

Port A

Port B

As installed,

ß=0,5 As installed,

40 40

ß=0,5

20 20

0 0

0 20 40 60 80 100 0 20 40 60 80 100

Stroke [%] Stroke [%]

ESBE SERIES VLA300, VLB300 • EN • L

© Copyright. Rights reserved to make alterations. 3

LINEAR MOTORIZED VALVES

CONTROL VALVE PN16

SERIES VLA300 AND VLB300

FLOW CHART

Flow

m3/h l/s Kvs [m3/h at P = 100 kPa] Kvs (m3/h)

300 DN 150 200 DN 125

200

130 DN 100

50

100 DN 80

100

63 DN 65

200

▲

50

▲ 38 DN 50

25 DN 40

100

▲

20 ▲ 16 DN 32

50

▲ 10 DN 25

10

▲ 6.3 DN 20

20

5 ▲ 4.0 DN 15

▲ 2.5 DN 15

10

2 ▲ 1.6 DN 15

5 ▲ 1.0 DN 15

1

▲ 0.63 DN 15

2

0.5 ▲ 0.4 DN 15

1

▲ 0.25 DN 15

0.2 ▲

0.5 ▲

0.1

▲

0.2

0.05 ▲

0.1

0.02

0.05

0.01

1 2 5 10 20 50 100 200 500 1000 2000

Pressure drop [kPa]

▯ = max differential pressure drop allowed in mixing function

▲ = max differential pressure drop allowed in diverting function

To be considered: As both the viscosity and the thermal conduction are affected when glycol is added to the system water, this fact has to be considered when dimensioning the valve.

A good rule is to choose one size higher Kv-value when 30 – 50% glycol is added. A lower concentration of glycol may be disregarded.

N.B.! Maximum 50% glycol for freezing protection and oxygen absorbing compounds are allowed as additives.

4 ESBE SERIES VLA300, VLB300 • EN • L

© Copyright. Rights reserved to make alterations.

LINEAR MOTORIZED VALVES

CONTROL VALVE PN16

SERIES VLA300 AND VLB300

INSTALLATION

The valve should be mounted with flow direction in accordance To ensure that suspended solids will not become jammed

with the valve marking. between the valve plug and seat, a filter should be installed

If possible, the valve should be installed in the return pipe, upstream of the valve, and the pipe system should be flushed

in order to avoid exposing the actuator to high temperatures. before the valve is installed.

The valve must not be installed with the actuator mounted

T fluid –20°C... +120°C

below the valve.

Mounting positions:

T fluid T fluid

A = Allowed mounting position with fluid temperature 0°C... +150°C 0°C... +150°C

between –20ºC to +120ºC.

B = Allowed mounting position with fluid temperature

between 0ºC to +150ºC.

C = Not allowed mounting position.

VALVE AUTHORITY [β]

∆pv – pressure losses over the valve [bar]

∆psys – pressure losses over the system with variable flow [bar]

∆pinst – pressure losses over the installation [bar]

Recommendation : Valve authority [β] shall be between 0.3 to 0.7

a) 2-way valve b) 3-way valve

∆pv ∆pv

β= β=

∆pv + ∆pinst ∆pv + ∆psys

INSTALLATION EXAMPLES

2-WAY CONTROL VALVES

A B

Installation without local circulating pump Installation with local circulating pump

3-WAY CONTROL VALVES

C D E

AB A

AB A

B B

A B

AB

Circuit without local circulation pump Circuit with local circulation pump Circuit with local circulating pump

ESBE SERIES VLA300, VLB300 • EN • L

© Copyright. Rights reserved to make alterations. 5

You might also like

- Semiconductor Data Book: Characteristics of approx. 10,000 Transistors, FETs, UJTs, Diodes, Rectifiers, Optical Semiconductors, Triacs and SCRsFrom EverandSemiconductor Data Book: Characteristics of approx. 10,000 Transistors, FETs, UJTs, Diodes, Rectifiers, Optical Semiconductors, Triacs and SCRsNo ratings yet

- 2.5.30 Wey Knife Gate Valve MGC PN 10: DN 50-600 Standard ConstructionDocument1 page2.5.30 Wey Knife Gate Valve MGC PN 10: DN 50-600 Standard ConstructionSugianto BarusNo ratings yet

- BV422 Pressure Reducing-Sustaining ValveDocument4 pagesBV422 Pressure Reducing-Sustaining ValveFAIYAZ AHMEDNo ratings yet

- Series M250: Tit Prodotto It Cilindro Doppio Effetto Standard Con AttacchiDocument2 pagesSeries M250: Tit Prodotto It Cilindro Doppio Effetto Standard Con AttacchiCami CarrascoNo ratings yet

- Spirax Sarco - Non Return Valve Type DCV3Document4 pagesSpirax Sarco - Non Return Valve Type DCV3jimmiilongNo ratings yet

- Interacumulador Ac 80-200 T Vertikalni Za Stena enDocument1 pageInteracumulador Ac 80-200 T Vertikalni Za Stena ennachoxxiNo ratings yet

- Butterfly ValveDocument4 pagesButterfly ValveCatalina NutaNo ratings yet

- Indoor Voltage TransformersDocument4 pagesIndoor Voltage TransformersBruno Nemer TattonNo ratings yet

- 3) Actuator Valve - Johnson Control VG8000NDocument4 pages3) Actuator Valve - Johnson Control VG8000Nfaris.tlksNo ratings yet

- Relief Valves: V SeriesDocument8 pagesRelief Valves: V SeriesRafael OrtizperezNo ratings yet

- F.F. Pressure Reducing Valve With Inox SeatDocument4 pagesF.F. Pressure Reducing Valve With Inox SeatAlen KuzmanovicNo ratings yet

- 42560421fisatehnica 24921 41 1695258836Document4 pages42560421fisatehnica 24921 41 1695258836Sebastian HAVASINo ratings yet

- Valvulas SporlanDocument24 pagesValvulas SporlanCesar VillarNo ratings yet

- Gfps-Dk-Technical Data Metal Butterfly Valve Type 039Document7 pagesGfps-Dk-Technical Data Metal Butterfly Valve Type 039Omar GuillenNo ratings yet

- Ketju Datasheet 8165 FV Series A4 ENG 100821 LRDocument3 pagesKetju Datasheet 8165 FV Series A4 ENG 100821 LReidlberto casedoNo ratings yet

- VRG130 GB E3 LRDocument3 pagesVRG130 GB E3 LRHalmanNo ratings yet

- Sae CatDocument1 pageSae Catamits37No ratings yet

- Speedaire 10 and 15 HP 2 Stage Air Compressors Owners ManualDocument84 pagesSpeedaire 10 and 15 HP 2 Stage Air Compressors Owners ManualKeron Trotz100% (1)

- Staf-Sg Ansi en MainDocument12 pagesStaf-Sg Ansi en MainSantosh KumarNo ratings yet

- A2L-A4L Data Sheet en 01Document10 pagesA2L-A4L Data Sheet en 01zibbex555No ratings yet

- DS2 12 ValveDocument9 pagesDS2 12 ValvejpmanikandanNo ratings yet

- ES24A Installation Operation Maintenance Manual (2022)Document8 pagesES24A Installation Operation Maintenance Manual (2022)A LopNo ratings yet

- WWW - Superiorelectric.in: Making MachinesDocument52 pagesWWW - Superiorelectric.in: Making MachinesPinali Mahendradas MistryNo ratings yet

- 65328g10 PDFDocument7 pages65328g10 PDFbnNo ratings yet

- Directional Control Valve: Service and Parts ManualDocument22 pagesDirectional Control Valve: Service and Parts ManualRichard SchmidtNo ratings yet

- S Touch MANUAL - ENDocument18 pagesS Touch MANUAL - ENLaurentiu LapusescuNo ratings yet

- Mechanical Pinch Valves of OV SeriesDocument5 pagesMechanical Pinch Valves of OV SeriesDaniel SanNo ratings yet

- 95FL - Válvula Control Proporcional (Bridada)Document13 pages95FL - Válvula Control Proporcional (Bridada)Rafael SalazarNo ratings yet

- Warning: L1200 Superseded by LS200. For L1100 & DVU, See New InfoDocument6 pagesWarning: L1200 Superseded by LS200. For L1100 & DVU, See New InfoRiky AyalaNo ratings yet

- Electromagnetic Flowmeter Upser Manual External PoweredDocument33 pagesElectromagnetic Flowmeter Upser Manual External Poweredevct1989No ratings yet

- FlowCon SH 50 150 Data Sheet EngDocument8 pagesFlowCon SH 50 150 Data Sheet EngJerry FebriansyahNo ratings yet

- Avk Handwheel 08Document2 pagesAvk Handwheel 08Popescu OctavianNo ratings yet

- HM 2Document2 pagesHM 2Miguel HazaNo ratings yet

- Belimo Control ValveDocument106 pagesBelimo Control ValveAnderson SiqueiraNo ratings yet

- SystemSpecification PVC-U Metric 2015 en PDFDocument24 pagesSystemSpecification PVC-U Metric 2015 en PDFpablo mendoza ibarraNo ratings yet

- STAD Balancing ValvesDocument10 pagesSTAD Balancing ValvesNestramiNo ratings yet

- 对夹蝶阀Document1 page对夹蝶阀SUNNo ratings yet

- Valbol Worcester Actuador ElectricoDocument5 pagesValbol Worcester Actuador ElectricoasdrumelNo ratings yet

- Manual Changeover Switches & Automatic Transfer SwitchesDocument16 pagesManual Changeover Switches & Automatic Transfer SwitchesMitchell DanielsNo ratings yet

- Marathon LDocument16 pagesMarathon LmohamedNo ratings yet

- Mustang Series M100 (Globe), M1100 (Angle) Specification SheetDocument3 pagesMustang Series M100 (Globe), M1100 (Angle) Specification SheetWattsNo ratings yet

- A63 A64 Multi Position CylinderDocument2 pagesA63 A64 Multi Position CylinderBiswanath LenkaNo ratings yet

- Ptfe-Lined Butterfly Valve T 214-A Ptfe-Lined Butterfly Valve T 214-ADocument4 pagesPtfe-Lined Butterfly Valve T 214-A Ptfe-Lined Butterfly Valve T 214-AFernando Ortiz De La CruzNo ratings yet

- SDM140EDocument36 pagesSDM140Eseaqu3stNo ratings yet

- Bv421 Pressure Reducing ValveDocument4 pagesBv421 Pressure Reducing ValveFAIYAZ AHMEDNo ratings yet

- Slot Diffuser: Type VSD50Document14 pagesSlot Diffuser: Type VSD50Kim Nicolas SaikiNo ratings yet

- DB - 710 - 717 - 723 - GB - GEMU 723Document16 pagesDB - 710 - 717 - 723 - GB - GEMU 723KrisNo ratings yet

- ACF-2064 PsDocument1 pageACF-2064 PsDavid RivardNo ratings yet

- Brass Gate Valve PN16: Technical CatalogueDocument10 pagesBrass Gate Valve PN16: Technical Cataloguekikokiko KarimNo ratings yet

- Boiler Automatic Bottom Blowdown SystemsDocument4 pagesBoiler Automatic Bottom Blowdown SystemsSebastian LeivaNo ratings yet

- Forging ToleranceDocument44 pagesForging Tolerancehisaj4uNo ratings yet

- Gfps Datasheet 561 562 Cone Check Valve enDocument8 pagesGfps Datasheet 561 562 Cone Check Valve encarnaticshankNo ratings yet

- Boiler Automatic Bottom Blowdown SystemsDocument4 pagesBoiler Automatic Bottom Blowdown SystemsCristopher LobosNo ratings yet

- Visual Index: Catalog 4400 USDocument17 pagesVisual Index: Catalog 4400 USPartsGopher.comNo ratings yet

- Use With 781, 782TC, 782ST Hoses. Visual Index: Catalog 4400 USDocument10 pagesUse With 781, 782TC, 782ST Hoses. Visual Index: Catalog 4400 USPartsGopher.comNo ratings yet

- ELD Catálogo Hook PDFDocument34 pagesELD Catálogo Hook PDFCristian Alonso Gonzalez MolinaNo ratings yet

- SDM 080 eDocument28 pagesSDM 080 eseaqu3stNo ratings yet

- AVF Jhonson Controls PDFDocument6 pagesAVF Jhonson Controls PDFRendy MulyadiNo ratings yet

- Ev DG05Document14 pagesEv DG05mtbecerrapNo ratings yet

- 01 06 0013 PDFDocument48 pages01 06 0013 PDFoleg-spb100% (1)

- 1100E Iom PDFDocument15 pages1100E Iom PDFIngFernando21100% (9)

- Imt - 15-113 Instruction ManualDocument26 pagesImt - 15-113 Instruction ManualJuan Carlos ChaparroNo ratings yet

- Terex Crane Owner'S Manual TXCR326/H/A: A/C & Oil Heat SystemDocument52 pagesTerex Crane Owner'S Manual TXCR326/H/A: A/C & Oil Heat Systemابراهيم حافظ100% (1)

- Specification For Inspection, Flushing and Testing of Piping System (HydroTesting)Document9 pagesSpecification For Inspection, Flushing and Testing of Piping System (HydroTesting)SrinivasNo ratings yet

- LPG CO2 BrochureDocument6 pagesLPG CO2 BrochureAhmed GalalNo ratings yet

- BTPMANODocument6 pagesBTPMANOJavier Rodriguez PaezNo ratings yet

- Ape City Plus Bs4 Nov 2020Document125 pagesApe City Plus Bs4 Nov 2020DEEPAKNo ratings yet

- Olympus GIF 180 Gastrointestinal Videoscope - Instructions PDFDocument110 pagesOlympus GIF 180 Gastrointestinal Videoscope - Instructions PDFFatima HammoudNo ratings yet

- Challenger enDocument2 pagesChallenger enluis miguel escobar rondinelNo ratings yet

- Ga 1064Document31 pagesGa 1064Cuong DinhNo ratings yet

- RP 30 2 Selection and Use of Measurement InstrumentDocument212 pagesRP 30 2 Selection and Use of Measurement Instrumentmohammed el erianNo ratings yet

- Instrumentation and Control Systems Reddy Full ChapterDocument67 pagesInstrumentation and Control Systems Reddy Full Chapterbarbara.young530100% (5)

- Method Statement For Testing & Commissioning of Vacuum SystemDocument5 pagesMethod Statement For Testing & Commissioning of Vacuum SystemDong VanraNo ratings yet

- Dve150 Dhe200Document20 pagesDve150 Dhe200MannyBaldonadoDeJesusNo ratings yet

- 99406-13200 - Service Manual S16R-Z3MPTAW - Sep.'2009 PDFDocument268 pages99406-13200 - Service Manual S16R-Z3MPTAW - Sep.'2009 PDFmlaouhi majed100% (1)

- Subject: Page 1 of 57Document57 pagesSubject: Page 1 of 57PHÁT NGUYỄN THẾNo ratings yet

- Flow-Tek Part Number Selection GuideDocument18 pagesFlow-Tek Part Number Selection GuideAmanda50% (2)

- Fluid Flow DividersDocument11 pagesFluid Flow Dividersprajakt_pieNo ratings yet

- Instructions and Parts List For Model 50H Hand-Operated Hydraulic PressDocument6 pagesInstructions and Parts List For Model 50H Hand-Operated Hydraulic PressWaqar DarNo ratings yet

- Condensing Units: Installer's GuideDocument8 pagesCondensing Units: Installer's GuideHoàngViệtAnhNo ratings yet

- JackhammerDocument8 pagesJackhammerMika PrameswariNo ratings yet

- CMCDocument7 pagesCMCwasim_scribed100% (3)

- Sistema Hidraulico 320BDocument2 pagesSistema Hidraulico 320BJuan Fer100% (16)

- Sportage 2.7L 2005Document2,538 pagesSportage 2.7L 2005lukasz.mietlowskiNo ratings yet

- Sperre Instrument Air CompressorDocument51 pagesSperre Instrument Air CompressorTalha Mairaj0% (1)

- 2010 - 06 - 30 Service Manual Silver2 En-05Document72 pages2010 - 06 - 30 Service Manual Silver2 En-05Victor Hugo Quiñonez QuintanaNo ratings yet

- Electric Fuel PumpsDocument52 pagesElectric Fuel Pumpsgk218No ratings yet

- Proportional and ServovalvesDocument14 pagesProportional and ServovalvesMarius IsdrailaNo ratings yet

- Valve Test Record Form: Range Date Calibrated Calibration Certificate NumberDocument1 pageValve Test Record Form: Range Date Calibrated Calibration Certificate NumberAzuwan MohamadNo ratings yet

- Module 11A OxygenDocument69 pagesModule 11A OxygenTaha CellatNo ratings yet