Professional Documents

Culture Documents

Network Planning - PGDM 2019-21

Uploaded by

aditya nemaOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Network Planning - PGDM 2019-21

Uploaded by

aditya nemaCopyright:

Available Formats

Supply Chain Network

Planning

PGDM (2019-21): Term IV

Supply Chain and Logistics Management (OPM 19402)

Sessions # 10 ~ 11

8/12/2020 Prof Kalyana C Chejarla

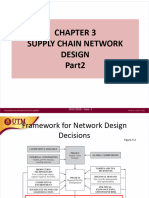

Framework for Network Design Decisions

Competitive STRATEGY GLOBAL COMPETITION

PHASE I

Supply Chain

INTERNAL CONSTRAINTS Strategy

Capital, growth strategy, TARIFFS AND TAX

existing network INCENTIVES

PRODUCTION TECHNOLOGIES REGIONAL DEMAND

Cost, Scale/Scope impact, support PHASE II Size, growth, homogeneity,

required, flexibility Regional Facility local specifications

Configuration

COMPETITIVE

ENVIRONMENT POLITICAL, EXCHANGE

RATE AND DEMAND RISK

PHASE III

Desirable Sites AVAILABLE

INFRASTRUCTURE

PRODUCTION METHODS

Skill needs, response time

FACTOR COSTS PHASE IV LOGISTICS COSTS

Labor, materials, site specific Location Choices Transport, inventory, coordination

8/12/2020 Prof Kalyana C Chejarla Chopra & Meindl

Network Design Decisions

4. Decide 1. Facility

whether to keep Location

a location open (Regional) &

or shut Capacity

(TelecomOptic) (SunOil)

3. Allocate

demand to 2. Site Selection

existing (Steel

locations Appliances)

(TelecomOptic)

8/12/2020 Prof Kalyana C Chejarla Chopra & Meindl

PRELIMINARIES

8/12/2020 Prof Kalyana C Chejarla

Network Planning Solution Techniques

• Mathematical optimization techniques:

1. Exact algorithms: find optimal solutions

2. Heuristics: find “good” solutions, not

necessarily optimal

• Simulation models: provide a mechanism to

evaluate specified design alternatives created by

the designer.

8/12/2020 Prof Kalyana C Chejarla Simchi-Levi et al

Simple Example (Market & Supply Allocation)

• Single product

• Two plants p1 and p2

– Plant p2 has an annual capacity of 60,000 units.

– Plant p1 can product any quantity

• The two plants have the same production costs.

• There are two warehouses w1 and w2 with identical

warehouse handling costs.

• There are three markets areas c1,c2 and c3 with demands of

50,000; 100,000 and 50,000, respectively.

• Unit Distribution costs are as below:

Facility (→) p1 p2 c1 c2 c3

Warehouse (↓)

w1 0 4 3 4 5

w2 5 2 2 1 2

Question: How much quantity must be shipped from each plant → warehouse → market?

8/12/2020 Prof Kalyana C Chejarla Simchi-Levi et al

Heuristic #1

Choose the Cheapest Upstream to Source Demand

Facility (→) p1 p2 c1 c2 c3

Warehouse (↓)

w1 0 4 3 4 5

w2 5 2 2 1 2

p1 w1 c1

D = 50,000

$2 x 50,000

c2

$5 x 140,000 D = 100,000

p2

w2

$1 x 100,000

$2 x 60,000

Cap = 60,000 c3

$2 x 50,000 D = 50,000

Total Costs = $1,120,000

8/12/2020 Prof Kalyana C Chejarla Simchi-Levi et al

Heuristic #2

Choose the warehouse with least total (inbound + outbound)

costs

c1

$0 w1

$3 D = 50,000

p1 p1 →w1 → c1 $3

p1 → w2 → c1 $7

p2 → w1 → c1 $7

$4 $2 c2 p2 → w2 → c1 $4

$5

$5 D = 100,000

p2 $4

p1 →w1 → c2 $4

$1 p1 → w2 → c2 $6

p2 → w1 → c2 $8

$2 p2 → w2 → c2 $3

Cap = 60,000 c3

w2 $2 D = 50,000

p1 →w1 → c3 $5

p1 → w2 → c3 $7

p2 → w1 → c3 $9

p2 → w2 → c3 $4

c1 is served by w1, c2 and c3 are served by w2

8/12/2020 Prof Kalyana C Chejarla Simchi-Levi et al

Heuristic #2 Cont’d

Choose the warehouse with least total (inbound + outbound)

costs

c1 is served by w1, c2 and c3 are served by w2

w1 c1

p1

$0 x 50,000

$3 x 50,000 D = 50,000

p1 →w1 → c1 $3

p1 → w2 → c1 $7

p2 → w1 → c1 $7

c2 p2 → w2 → c1 $4

$5 x 90,000 D = 100,000

p2 w2

p1 →w1 → c2

p1 → w2 → c2

$4

$6

$1 x 100,000

p2 → w1 → c2 $8

$2 x 60,000 p2 → w2 → c2 $3

Cap = 60,000 c3

$2 x 50,000 D = 50,000

p1 →w1 → c3 $5

p1 → w2 → c3 $7

p2 → w1 → c3 $9

p2 → w2 → c3 $4

Total Cost = $920,000

8/12/2020 Prof Kalyana C Chejarla Simchi-Levi et al

The Optimization Model

The problem described earlier can be framed as the

following linear programming problem.

Let

– x(p1,w1), x(p1,w2), x(p2,w1) and x(p2,w2) be the flows from the

plants to the warehouses.

– x(w1,c1), x(w1,c2), x(w1,c3) be the flows from the warehouse w1

to customer zones c1, c2 and c3.

– x(w2,c1), x(w2,c2), x(w2,c3) be the flows from warehouse w2 to

customer zones c1, c2 and c3

8/12/2020 Prof Kalyana C Chejarla Simchi-Levi et al

The Optimization Model

Facility (→) p1 p2 c1 c2 c3

Warehouse (↓)

w1 0 4 3 4 5

w2 5 2 2 1 2

The problem we want to solve is:

minimize {0x(p1,w1) + 5x(p1,w2) + 4x(p2,w1)

+ 2x(p2,w2) + 3x(w1,c1) + 4x(w1,c2)

+ 5x(w1,c3) + 2x(w2,c1) +1x(w2,c2) + 2x(w2,c3)}

subject to the following constraints:

x(p2,w1) + x(p2,w2) 60000 ← Plant 2 capacity constraint

x(p1,w1) + x(p2,w1) = x(w1,c1) + x(w1,c2) + x(w1,c3) ← No inventory @ w1

x(p1,w2) + x(p2,w2) = x(w2,c1) + x(w2,c2) + x(w2,c3) ← No inventory @ w2

x(w1,c1) + x(w2,c1) = 50000 ← c1 is met

x(w1,c2) + x(w2,c2) = 100000 ← c2 is met

x(w1,c3) + x(w2,c3) = 50000 ← c3 is met

all flows greater than or equal to zero.

8/12/2020 Prof Kalyana C Chejarla Simchi-Levi et al

Optimal Solution

Facility p1 p2 c1 c2 c3

warehouse

w1 140,000 0 50,000 40,000 50,000

w2 0 60,000 0 60,000 0

Total cost for the optimal strategy is $740,000

8/12/2020 Prof Kalyana C Chejarla Simchi-Levi et al

Simulation Models

• Useful for a given design and a micro-

level analysis. Examine:

– Individual ordering pattern.

– Specific inventory policies.

– Inventory movements inside the warehouse.

• Not an optimization model

• Can only consider very few alternate

models

8/12/2020 Prof Kalyana C Chejarla Simchi-Levi et al

Which One to Use?

• Use mathematical optimization for static

analysis

• Use a 2-step approach when dynamics in

system must be analyzed:

– Use an optimization model to generate several

least-cost solutions at the macro level,

considering the most important cost

components.

– Use a simulation model to evaluate the

solutions generated in the first phase.

8/12/2020 Prof Kalyana C Chejarla Simchi-Levi et al

1. Facility Location & Capacity (SunOil)

8/12/2020 Prof Kalyana C Chejarla Chopra & Meindl

Capacitated Plant Location Model (General)

Capacity Allocation

n = number of potential plant locations/capacity

m = number of markets or demand points yi = 1 if plant i is open, 0 otherwise

D j = annual demand from market j xij = quantity shipped from plant

i to market j

K i = potential capacity of plant i

f i = annualized fixed cost of keeping plant i open

cij = cost of producing and shipping one unit from plant i to market j (cost

includes production, inventory, transportation, and tariffs)

n n m

Minå f i yi + å åc x ij ij

i=1 i=1 j=1

n

subject to

åx ij

= D j for j = 1,...,m

i=1

m

åx ij

= K i yi for i = 1,...,n

j=1

yi Î {0,1} for i = 1,...,n, x ij ³ 0

8/12/2020 Prof Kalyana C Chejarla Chopra & Meindl

2. Site Selection

Gravity Location Model

xn, yn: Coordinate location of either a market or supply source n

Fn: Cost of shipping one unit for one mile between the facility and

either market or supply source n

Dn: Quantity to be shipped between facility and market or supply

source n

(x, y) is the location selected for the facility, the distance dn between

the facility at location (x, y) and the supply source or market n is given

by

(x – x ) + ( y – y )

2 2

dn = n n

8/12/2020 Prof Kalyana C Chejarla Chopra & Meindl

Gravity Location Model (Steel Appliances)

Transportation Cost Quantity in Tons Coordinates

Sources/Markets $/Ton Mile (Fn) (Dn) xn yn

Supply sources

Buffalo 0.90 500 700 1,200

Memphis 0.95 300 250 600

St. Louis 0.85 700 225 825

Markets

Atlanta 1.50 225 600 500

Boston 1.50 150 1,050 1,200

Jacksonville 1.50 250 800 300

Philadelphia 1.50 175 925 975

New York 1.50 300 1,000 1,080

k

Total transportation cost TC = d n Dn Fn

n =1

8/12/2020 Prof Kalyana C Chejarla Chopra & Meindl

3. Allocate Demand to existing locations

(TelecomOne & HighOptic)

Demand City

Production and Transportation Cost

per Thousand Units (Thousand $) Monthly Monthly

Capacity Fixed Cost

(Thousand (Thousand

Company Supply City Atlanta Boston Chicago Denver Omaha Portland Units) K $) f

TELECOM Baltimore 1,675 400 985 1,630 1,160 2,800 18 7,650

ONE

Memphis 380 1,355 543 1,045 665 2,321 22 4,100

Wichita 922 1,646 700 508 311 1,797 31 2,200

HIGHOPTI Cheyenne 1,460 1,940 970 100 495 1,200 24 3,500

C

Salt Lake 1,925 2,400 1,450 500 950 800 27 5,000

City

Monthly 10 8 14 6 7 11

demand

(thousand

units) Dj

8/12/2020 Prof Kalyana C Chejarla Chopra & Meindl

Demand Allocation (General Model)

Supply > Demand

• Allocating demand to production facilities

n = Number of factory locations

m = Number of markets or demand points xij = Quantity shipped from factory i to

D j = Annual demand from market j market j

K i = Capacity of factory i

cij = Cost of producing and shipping one unit from factory i to market j

n m n

Min cij xij subject to x

i =1

ij = D j for j = 1,..., m

i =1 j =1 m

x

j =1

ij = K i for i = 1,..., n

8/12/2020 Prof Kalyana C Chejarla Chopra & Meindl

Optimal Demand Allocation

Atlanta Boston Chicago Denver Omaha Portland

TelecomOne Baltimore 0 8 2

Memphis 10 0 12

Wichita 0 0 0

HighOptic Salt Lake 0 0 11

Cheyenne 6 7 0

8/12/2020 Prof Kalyana C Chejarla Chopra & Meindl

4. Supply Allocation & facility decision

(General Model)

• Merge the companies

• Solve using location-specific costs

yi = 1 if factory i is open, 0 otherwise

xij = quantity shipped from factory i to market j

n n m

Minå f i yi + å åc x ij ij

i=1 i=1 j=1

8/12/2020 Prof Kalyana C Chejarla Chopra & Meindl

4a. Capacitated Model with Single Sourcing

• Market supplied by only one factory

• Modify decision variables

yi = 1 if factory i is open, 0 otherwise

xij = 1 if market j is supplied by factory i, 0 otherwise

n n m

Minå f i yi + å å D j cij xij

i=1 i=1 j=1

subject to

n

åx ij

= 1 for j = 1,...,m

i=1

m

åD x i ij

£ K i yi for i = 1,...,n

j=1

xij , yi Î {0,1}

8/12/2020 Prof Kalyana C Chejarla Chopra & Meindl

Capacitated Model with Single Sourcing

Open/

Closed Atlanta Boston Chicago Denver Omaha Portland

Baltimore Closed 0 0 0 0 0 0

Cheyenne Closed 0 0 0 0 0 0

Salt Lake Open 0 0 0 6 0 11

Memphis Open 10 8 0 0 0 0

Wichita Open 0 0 14 0 7 0

8/12/2020 Prof Kalyana C Chejarla Chopra & Meindl

Supply Chains of Toyota & Amazon

Toyota ~ 4V & S (12:46 minutes)

https://www.youtube.com/watch?v=IRb4yOKrzs0&list=PLLXjA2RC_qClHMJA

-bh6zX6MBePPql8P6&index=6&t=0s

Behind the scenes of an Amazon Warehouse (Fox News) (4:51 minutes)

https://www.youtube.com/watch?v=Y-lBvI6u_hw

Sinofert Holdings Limited: Urea Distribution Planning

8/12/2020 Prof Kalyana C Chejarla

Q & A / DISCUSSION

8/12/2020 Prof Kalyana C Chejarla

You might also like

- Chapter 6 Answers To ProblemsDocument17 pagesChapter 6 Answers To Problemsjahan0% (1)

- Finals 1: Ritchelle G. Reyes Mr. Maximo Muldong 2.2 Bsa-Cy2 Management Science WED. 5-7 PMDocument7 pagesFinals 1: Ritchelle G. Reyes Mr. Maximo Muldong 2.2 Bsa-Cy2 Management Science WED. 5-7 PMRavena ReyesNo ratings yet

- Operations Management - Section ADocument3 pagesOperations Management - Section Ajoyshree royNo ratings yet

- Chapter 2Document27 pagesChapter 2Chinh Dao QuangNo ratings yet

- Transportation & TranshipmentDocument45 pagesTransportation & TranshipmentsplinterNo ratings yet

- Transportation & TranshipmentDocument47 pagesTransportation & TranshipmentRishabh MishraNo ratings yet

- De LanDocument9 pagesDe Lanlan LanNo ratings yet

- Solution To Solved Problems: 1.S1 Make or BuyDocument3 pagesSolution To Solved Problems: 1.S1 Make or BuyVibhuti BatraNo ratings yet

- Assign 9 Chapter 12 Cash and Marketable Securities Cabrera 2019-2020Document5 pagesAssign 9 Chapter 12 Cash and Marketable Securities Cabrera 2019-2020mhikeedelantar100% (1)

- Break even Analysis Feasibility Study - Chapter 12 - مهمDocument11 pagesBreak even Analysis Feasibility Study - Chapter 12 - مهمwskrebNo ratings yet

- PM BECKER Mock 1 Ans.Document15 pagesPM BECKER Mock 1 Ans.SHIVAM BARANWALNo ratings yet

- Cash Flow Estimation and Risk AnalysisDocument42 pagesCash Flow Estimation and Risk AnalysisdaidainaNo ratings yet

- ECON 453 AssignmentDocument6 pagesECON 453 AssignmentDaniel YuNo ratings yet

- Location Planning & Analysis: OutlineDocument21 pagesLocation Planning & Analysis: OutlineWinter NaiNo ratings yet

- 1.3 - Production Possibilities CurveDocument35 pages1.3 - Production Possibilities CurveMaria FatimaNo ratings yet

- 1.3 - Production Possibilities CurveDocument35 pages1.3 - Production Possibilities CurveMaria FatimaNo ratings yet

- Recitation 2 PDFDocument3 pagesRecitation 2 PDFiNo ratings yet

- CH 18Document1,901 pagesCH 18DavidNo ratings yet

- Value of Flexibility: Dr. Richard de NeufvilleDocument24 pagesValue of Flexibility: Dr. Richard de Neufvillemohamed41988No ratings yet

- Chapter 3 Supply Chain Design Part 2Document22 pagesChapter 3 Supply Chain Design Part 2sadiq-20No ratings yet

- Chapter 4 Network DesignDocument32 pagesChapter 4 Network DesignÂn LêNo ratings yet

- 3b - SESSION - 3b - NETWORK DESIGN DHAKA 2018 PDFDocument4 pages3b - SESSION - 3b - NETWORK DESIGN DHAKA 2018 PDFMohsena MunnaNo ratings yet

- CH 17Document2,828 pagesCH 17DavidNo ratings yet

- Project For SubmissionDocument9 pagesProject For SubmissionDipankar Mukhopadhyay100% (3)

- BBM 1121 Final Exam 2022 S1Document6 pagesBBM 1121 Final Exam 2022 S1bonaventure chipetaNo ratings yet

- Nanyang Business School AB1201 Financial Management Tutorial 8: The Basics of Capital Budgeting (Common Questions)Document4 pagesNanyang Business School AB1201 Financial Management Tutorial 8: The Basics of Capital Budgeting (Common Questions)asdsadsaNo ratings yet

- CH 19Document3,760 pagesCH 19DavidNo ratings yet

- CH 23Document1,409 pagesCH 23DavidNo ratings yet

- Introduction To Network Models & Facility Location ModelsDocument15 pagesIntroduction To Network Models & Facility Location Modelsmohcine zahidNo ratings yet

- Final Exam Practice Papers SolutionsDocument31 pagesFinal Exam Practice Papers Solutionssamuel ngNo ratings yet

- Chapter 01Document2 pagesChapter 01rahulNo ratings yet

- Case Report - Dollar Tree LogisticsDocument4 pagesCase Report - Dollar Tree Logisticsrohitkamath7No ratings yet

- Corporate Finance-AssignmentDocument4 pagesCorporate Finance-AssignmentAssignment HelperNo ratings yet

- Capital BudgetingDocument8 pagesCapital Budgetingneesha0% (1)

- ECO111 Microeconomics Class: Handed Out: Submission Due: Format: Submission Mode: Hardcopy and Softcopy Email ToDocument10 pagesECO111 Microeconomics Class: Handed Out: Submission Due: Format: Submission Mode: Hardcopy and Softcopy Email ToDo Thu Tra50% (2)

- Project Budget Template For Excel - KFqs9Qbrdl52YwdDocument2 pagesProject Budget Template For Excel - KFqs9Qbrdl52YwdAsif SafiNo ratings yet

- Aerocomp, Inc Case Study Week 7Document2 pagesAerocomp, Inc Case Study Week 7John Patrick LaspiñasNo ratings yet

- 2023 2 Linear ProgrammingDocument26 pages2023 2 Linear ProgrammingNatasha Angelica SusantoNo ratings yet

- Inventory Control Models: EPL ModelDocument25 pagesInventory Control Models: EPL ModeldarmianaNo ratings yet

- Location AnalysisDocument7 pagesLocation AnalysisAhmed ElyazidNo ratings yet

- CA-Inter-Costing - Anuj-JalotaDocument17 pagesCA-Inter-Costing - Anuj-JalotaSUMANTO BARMANNo ratings yet

- 10.2.3.2 Capital Budgeting ComputationDocument3 pages10.2.3.2 Capital Budgeting ComputationalliahnahNo ratings yet

- Production Possibilities FrontierDocument23 pagesProduction Possibilities FrontierEl DeeNo ratings yet

- ASSIGNMENT 1 GoravDocument7 pagesASSIGNMENT 1 GoravwqqqNo ratings yet

- Project Budget Template 02Document2 pagesProject Budget Template 02ahmed mostafaNo ratings yet

- Project Budget Template 02Document2 pagesProject Budget Template 02koum juniorNo ratings yet

- Construction Project Budget Tracking by PhaseDocument2 pagesConstruction Project Budget Tracking by PhaseFrancisco SalazarNo ratings yet

- The University of The West IndiesDocument10 pagesThe University of The West IndiesDom PowellNo ratings yet

- Mark Scheme Maximum Mark: 40: International GcseDocument20 pagesMark Scheme Maximum Mark: 40: International GcseKindaNo ratings yet

- L2 Review of DSD1Document11 pagesL2 Review of DSD1madhu ningareddyNo ratings yet

- Chapter 2 - How To Calculate Present ValuesDocument21 pagesChapter 2 - How To Calculate Present ValuesTrọng PhạmNo ratings yet

- P A G e Initial Outlay CF in Year 1 CF I PDFDocument12 pagesP A G e Initial Outlay CF in Year 1 CF I PDFsharlinsdgmailcomNo ratings yet

- F5 - Mock B - QuestionsDocument15 pagesF5 - Mock B - QuestionsUmar AwanNo ratings yet

- Si7 Tarquin 162 198 Solucionario de Ingenieria EconomicaDocument38 pagesSi7 Tarquin 162 198 Solucionario de Ingenieria EconomicaCeleste CasillaNo ratings yet

- Lecture-Leveling - Crashing-2Document30 pagesLecture-Leveling - Crashing-2Ahmed AbdelkariemNo ratings yet

- Advanced Financial Management May 2016 Past Paper and Suggested Answers Wco8ooDocument17 pagesAdvanced Financial Management May 2016 Past Paper and Suggested Answers Wco8ookaragujsNo ratings yet

- Solutions PracProblems Visit 4Document19 pagesSolutions PracProblems Visit 4Falak HanifNo ratings yet

- PM Mock AnswersDocument16 pagesPM Mock AnswersMuhammad HussnainNo ratings yet

- Transportation & Transhipment PDFDocument73 pagesTransportation & Transhipment PDFdeepak kumarNo ratings yet

- SC Strategic Fit PGDM 2019-21 PDFDocument30 pagesSC Strategic Fit PGDM 2019-21 PDFaditya nemaNo ratings yet

- Corporate Governance MiscllaneousDocument14 pagesCorporate Governance Miscllaneousaditya nemaNo ratings yet

- Online Grocery Retailing - Building The Last Mile To The Customer - IMD - Stud...Document16 pagesOnline Grocery Retailing - Building The Last Mile To The Customer - IMD - Stud...ParthNo ratings yet

- Subjective (4 Questions, 4 Marks Each) : Use The Response' Textbox in Wheelbox Window To Type The AnswersDocument1 pageSubjective (4 Questions, 4 Marks Each) : Use The Response' Textbox in Wheelbox Window To Type The Answersaditya nemaNo ratings yet

- Transportation: PGDM (2019-21) : Term IVDocument32 pagesTransportation: PGDM (2019-21) : Term IVaditya nemaNo ratings yet

- Sustainability and Supply Chains - PGDM 2019-21 PDFDocument21 pagesSustainability and Supply Chains - PGDM 2019-21 PDFaditya nemaNo ratings yet

- Agile Operations For Volatile Times - P. 17Document7 pagesAgile Operations For Volatile Times - P. 17Corene Roxy ProNo ratings yet

- Network Design - PGDM 2019-21 PDFDocument19 pagesNetwork Design - PGDM 2019-21 PDFaditya nemaNo ratings yet

- Online Grocery Retailing - Building The Last Mile To The Customer - IMD - Stud...Document16 pagesOnline Grocery Retailing - Building The Last Mile To The Customer - IMD - Stud...ParthNo ratings yet

- 2020 Reimagining Indias Supply Chain - A Bold 2030 vision-CII and ADL PDFDocument8 pages2020 Reimagining Indias Supply Chain - A Bold 2030 vision-CII and ADL PDFaditya nemaNo ratings yet

- 2010 Value Chain Dynamics - Business Business and Supply Chain Strategy in PDFDocument90 pages2010 Value Chain Dynamics - Business Business and Supply Chain Strategy in PDFaditya nemaNo ratings yet

- Angular AccuracyDocument4 pagesAngular AccuracySwatilekha ChowdhuryNo ratings yet

- Dual Inverter Gate: Features DescriptionDocument19 pagesDual Inverter Gate: Features DescriptionYaju JotosNo ratings yet

- Spark: Owner's ManualDocument5 pagesSpark: Owner's Manualjorge medinaNo ratings yet

- 02 Survey Calculations - PpsDocument96 pages02 Survey Calculations - PpsLeo Ivan Aviles RicaldiNo ratings yet

- Systems - of - EquationsDocument39 pagesSystems - of - EquationsAnonymous 5aPb088W100% (1)

- GMS60CSDocument6 pagesGMS60CSAustinNo ratings yet

- P 130881757895329843Document44 pagesP 130881757895329843Vijay MohanNo ratings yet

- Solution To QuestionsDocument76 pagesSolution To QuestionsVipul AggarwalNo ratings yet

- Class - B Complementary Symmetry Power AmplifierDocument3 pagesClass - B Complementary Symmetry Power AmplifierAnonymous SH0A20No ratings yet

- Ergonomic DesignDocument132 pagesErgonomic DesignErin WalkerNo ratings yet

- Solved - Which $1,000 Bond Has The Higher Yield To Maturity, A T...Document4 pagesSolved - Which $1,000 Bond Has The Higher Yield To Maturity, A T...Sanjna ChimnaniNo ratings yet

- PDC NitDocument6 pagesPDC NitrpshvjuNo ratings yet

- Entropy and The Second Law of Thermodynamics Disorder and The Unavailability of Energy 6Document14 pagesEntropy and The Second Law of Thermodynamics Disorder and The Unavailability of Energy 6HarishChoudharyNo ratings yet

- Unit 07 Self-Test Chemistry Self TestDocument2 pagesUnit 07 Self-Test Chemistry Self TestOluwatusin Ayo OluwatobiNo ratings yet

- Microcontroller Based Vehicle Security SystemDocument67 pagesMicrocontroller Based Vehicle Security Systemlokesh_045No ratings yet

- Book Review: Laser Fundamentals, 2nd Edition by William T. SilfvastDocument2 pagesBook Review: Laser Fundamentals, 2nd Edition by William T. SilfvastAbhishekNo ratings yet

- Relay Maintenance and Testing: BenefitsDocument2 pagesRelay Maintenance and Testing: BenefitsojoladapoNo ratings yet

- TMT Boron CoatingDocument6 pagesTMT Boron Coatingcvolkan1100% (2)

- EP 1110-1-8 Vo2 PDFDocument501 pagesEP 1110-1-8 Vo2 PDFyodiumhchltNo ratings yet

- 9Y011-02704 KubotaDocument143 pages9Y011-02704 KubotaZaqi SatchNo ratings yet

- Guide-to-Proficiency-Testing-Australia 2019Document29 pagesGuide-to-Proficiency-Testing-Australia 2019ffatikatuss100% (1)

- Solution Manual For Introductory Statistics 9th Edition by Mann Chapters 1 13 PDFDocument10 pagesSolution Manual For Introductory Statistics 9th Edition by Mann Chapters 1 13 PDFa40095824643% (14)

- Urban Road Types 25.01.2022Document5 pagesUrban Road Types 25.01.2022Balogun IbrahimNo ratings yet

- College of Technology & Engineering: Practical Training at Hindustan Zinc Limited Zinc Smelter, Debari UdaipurDocument24 pagesCollege of Technology & Engineering: Practical Training at Hindustan Zinc Limited Zinc Smelter, Debari UdaipurPooja SahuNo ratings yet

- Chem 1211 Lab ReportDocument9 pagesChem 1211 Lab Reportansleybarfield0% (1)

- Nuclear Fusion EnergyDocument3 pagesNuclear Fusion EnergyAner Labaka UgarteNo ratings yet

- ProjectDocument6 pagesProjecthazimsyakir69No ratings yet

- RespiratorypptDocument69 pagesRespiratorypptMichelle RotairoNo ratings yet

- K46 ManualDocument8 pagesK46 ManualDavid KasaiNo ratings yet

- 002 Ac Yoke B100-ParkerDocument2 pages002 Ac Yoke B100-ParkerNubia BarreraNo ratings yet