Professional Documents

Culture Documents

Pressure Vessels Lectures 93 PDF

Pressure Vessels Lectures 93 PDF

Uploaded by

Adeel NizamiOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Pressure Vessels Lectures 93 PDF

Pressure Vessels Lectures 93 PDF

Uploaded by

Adeel NizamiCopyright:

Available Formats

UG-33 – UG-34 ASME BPVC.VIII.

1-2015

Step 2. Using the value of B obtained in Step 1, calculate

a value P a 1 using the following formula:

(2) For sketch (c) in Figure UG-33.1,

Step 3. Calculate a value P a 2 using the following

formula: (3) For sketch (d) in Figure UG-33.1,

where

(4) For sketch (e) in Figure UG-33.1,

S = the lesser of two times the maximum allowable

stress value in tension at design metal temperature,

from the applicable table referenced by UG-23, or

0.9 times the yield strength of the material at de-

sign temperature

(h) When lap joints are used in formed head construc-

Values of yield strength are obtained from the applic- tion or for longitudinal joints in a conical head under ex-

able external pressure chart as follows. ternal pressure, the thickness shall be determined by the

(a) For a given temperature curve, determine the B va- rules in this paragraph, except that 2P shall be used in-

lue that corresponds to the right hand side termination stead of P in the calculations for the required thickness.

point of the curve. (i) The required length of skirt on heads convex to

(b) The yield strength is twice the B value obtained in pressure shall comply with the provisions of UG-32(k)

(a) above. and UG-32(l) for heads concave to pressure.

Step 4. The smaller of the values of P a 1 calculated in (j) Openings in heads convex to pressure shall comply

Step 2, or P a 2 calculated in Step 3 shall be used for the with the requirements of UG-36 through UG-46.

maximum allowable external working pressure Pa. Com-

pare Pa with P . If Pa is smaller than P , select a larger value UG-34 UNSTAYED FLAT HEADS AND COVERS

for t and repeat the design procedure until a value for Pa

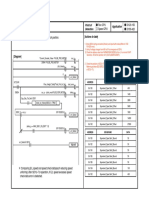

is obtained that is equal to or greater than P. (a) The minimum thickness of unstayed flat heads, cov-

Step 5. Provide adequate moment of inertia and rein- er plates and blind flanges shall conform to the require-

forcement at the cone-to-cylinder junction in accordance ments given in this paragraph. These requirements

with 1-8. For a junction with a knuckle, the reinforcement apply to both circular and noncircular24 heads and covers.

calculation is not required, and the moment of inertia cal- Some acceptable types of flat heads and covers are shown

culation may be performed either by considering the pre- in Figure UG-34. In this figure, the dimensions of the com-

sence of the knuckle or by assuming the knuckle is not ponent parts and the dimensions of the welds are exclu-

present whereby the cone is assumed to intersect the ad- sive of extra metal required for corrosion allowance.

jacent cylinder. (b) The symbols used in this paragraph and in Figure

(2) When α of the cone is greater than 60 deg, the UG-34 are defined as follows:

thickness of the cone shall be the same as the required C = a factor depending upon the method of attachment

thickness for a flat head under external pressure, the dia- of head, shell dimensions, and other items as listed

meter of which equals the largest diameter of the cone in (d) below, dimensionless. The factors for welded

(see UG-34). covers also include a factor of 0.667 that effectively

(3) The thickness of an eccentric cone shall be taken increases the allowable stress for such construc-

as the greater of the two thicknesses obtained using both tions to 1.5S.

the smallest and largest α in the calculations. D = long span of noncircular heads or covers measured

(g) The required thickness of a conical part of a torico- perpendicular to short span

nical head or conical section having pressure on the con- d = diameter, or short span, measured as indicated in

vex side, either seamless or of built‐up construction with Figure UG-34

butt joints within the conical part of a toriconical head or E = joint efficiency, from Table UW-12, of any Category

conical section, shall not be less than that determined A weld as defined in UW-3(a)

from (f) above with the exception that Le shall be deter- h G = gasket moment arm, equal to the radial distance

mined as follows: from the centerline of the bolts to the line of the

(1) For illustrations (a) and (b) in Figure UG-33.1, gasket reaction, as shown in Table 2-5.2

32

You might also like

- On Amanda Tremblay at Citrine Software SolutionsDocument3 pagesOn Amanda Tremblay at Citrine Software SolutionssanjaanNo ratings yet

- Asme BPVC 2021 Section Viii Div. 1-2 - Ug-32Document2 pagesAsme BPVC 2021 Section Viii Div. 1-2 - Ug-32canizales70No ratings yet

- B - Minimum Required Thickness Permanent Blank ASME 304.5.3Document2 pagesB - Minimum Required Thickness Permanent Blank ASME 304.5.3edisjdavNo ratings yet

- UG-23 UG-24 (D) : UG-32 Formed Heads, and Sections, Pressure On Concave SideDocument2 pagesUG-23 UG-24 (D) : UG-32 Formed Heads, and Sections, Pressure On Concave SideLinh0% (1)

- 17 TonsDocument8 pages17 Tonsabuzahrau100% (3)

- Flange Calc Design BasisDocument2 pagesFlange Calc Design BasisfaizalNo ratings yet

- Pressure Vessels Lectures 95Document1 pagePressure Vessels Lectures 95Adeel NizamiNo ratings yet

- 1-6 CUBIERTAS Forma Plana (Cabezas Atornilladas)Document5 pages1-6 CUBIERTAS Forma Plana (Cabezas Atornilladas)Luis EduardoNo ratings yet

- ASME Calc For Blind FlangeDocument2 pagesASME Calc For Blind FlangeAkil PrabhuNo ratings yet

- Reparacion Asme - Viii - Division - IDocument1 pageReparacion Asme - Viii - Division - Ialexis garciaNo ratings yet

- Ug-32 Formed Heads, and Sections, Pressure On Concave Side (A)Document1 pageUg-32 Formed Heads, and Sections, Pressure On Concave Side (A)Shukri NasirNo ratings yet

- Pressure Vessels Lectures 84Document1 pagePressure Vessels Lectures 84Adeel NizamiNo ratings yet

- Ibr BookDocument33 pagesIbr BookRaja JayachandranNo ratings yet

- ASME BPVC - VIII.1-2015 UG-27: UG-27 Thickness of Shells Under Internal PressureDocument2 pagesASME BPVC - VIII.1-2015 UG-27: UG-27 Thickness of Shells Under Internal PressureLinhNo ratings yet

- Asme Secc 8Document9 pagesAsme Secc 8mario valenzuelaNo ratings yet

- Lecture 3 External Pressure C1c8e496 66e8 4086 A720 0e726ced7edfDocument29 pagesLecture 3 External Pressure C1c8e496 66e8 4086 A720 0e726ced7edfAriHara SudhanNo ratings yet

- Anexo A. Parte 2 (Brida Cabezal A)Document2 pagesAnexo A. Parte 2 (Brida Cabezal A)Juan Diego QuevedoNo ratings yet

- Ibr Book PDFDocument33 pagesIbr Book PDFkuldeep mohiteNo ratings yet

- Asme App 2 PDFDocument21 pagesAsme App 2 PDFFabio TemporiniNo ratings yet

- Flange Leakage Test As Per Asme Boiler & Pressure Vessel CodeDocument12 pagesFlange Leakage Test As Per Asme Boiler & Pressure Vessel CoderssambhiNo ratings yet

- Axially Loaded Columns - Base Plate DesignDocument2 pagesAxially Loaded Columns - Base Plate DesignaomareltayebNo ratings yet

- Pressure Vessels Lectures 77Document1 pagePressure Vessels Lectures 77Adeel NizamiNo ratings yet

- ASME Calc For Blind FlangeDocument2 pagesASME Calc For Blind FlangeAkil PrabhuNo ratings yet

- Design Aid For Triangular Bracket Plates Using AISC SpecificationsDocument10 pagesDesign Aid For Triangular Bracket Plates Using AISC Specificationsmaroco1098100% (7)

- Ug-27 Thickness of Shells Under Internal PressureDocument2 pagesUg-27 Thickness of Shells Under Internal PressureJ Angel HdzNo ratings yet

- Asme BPVC 2021 Section Viii Div. 1-2 - Ug-27Document2 pagesAsme BPVC 2021 Section Viii Div. 1-2 - Ug-27canizales70No ratings yet

- Nozzle Design - Codeware-Compress FAQsDocument9 pagesNozzle Design - Codeware-Compress FAQsKashif KaziNo ratings yet

- Appendix A Thickness of Base MetalDocument24 pagesAppendix A Thickness of Base MetalalfonxxlNo ratings yet

- 2010 ASME Section VIII Division 1 Uw-14 (D) Pag 125Document1 page2010 ASME Section VIII Division 1 Uw-14 (D) Pag 125pipochelinNo ratings yet

- b31 3Document1 pageb31 3Hugo OrtegaNo ratings yet

- Pipe Wall THK Calc For External PressureDocument2 pagesPipe Wall THK Calc For External PressurektejankarNo ratings yet

- Homeworks 02 PDFDocument8 pagesHomeworks 02 PDFhoangvanhoakkNo ratings yet

- Asme Sec Viii D1 Ma App 2 Part2 PDFDocument21 pagesAsme Sec Viii D1 Ma App 2 Part2 PDFjuanfco1965No ratings yet

- Lecture 8Document18 pagesLecture 8Cyrus HongNo ratings yet

- Pages From Asme Viii Div 1-2007Document2 pagesPages From Asme Viii Div 1-2007kaustubh_dec17No ratings yet

- Bragg-Reflection Approach For Blazed Dielectric Gratings #Document4 pagesBragg-Reflection Approach For Blazed Dielectric Gratings #nonlinearopticNo ratings yet

- Chapter 2Document8 pagesChapter 2fantaayansa9No ratings yet

- Des 254Document4 pagesDes 254jegadishNo ratings yet

- Sp208-04ex 6Document22 pagesSp208-04ex 6Žarko LazićNo ratings yet

- 45662597562obj CivilEngineering 2006paper IDocument18 pages45662597562obj CivilEngineering 2006paper I94738183No ratings yet

- Design Aids For Tension Members As Per Revised Is: 800-2007Document7 pagesDesign Aids For Tension Members As Per Revised Is: 800-2007dev_1989No ratings yet

- Shear Force and Shear StressDocument3 pagesShear Force and Shear StressAGEGTAMNo ratings yet

- Concrete Technology Homework 2 PDFDocument3 pagesConcrete Technology Homework 2 PDFXiaoman TuNo ratings yet

- Pressure Vessels Lectures 96Document1 pagePressure Vessels Lectures 96Adeel NizamiNo ratings yet

- Technical Note Wall Pier Flexural Design: S W D ACI 318-02Document19 pagesTechnical Note Wall Pier Flexural Design: S W D ACI 318-02tomxxx34No ratings yet

- Design of Single R.C. Beams by Engr. Ben DavidDocument14 pagesDesign of Single R.C. Beams by Engr. Ben DavidElijah Aramburo100% (1)

- Pinned Base Plates 14Document1 pagePinned Base Plates 14pawkomNo ratings yet

- CALCULOS 2 cHOMPI PDFDocument5 pagesCALCULOS 2 cHOMPI PDFOscar Franco MNo ratings yet

- Appendix 9 Jacketed Vessels: 9-1 ScopeDocument9 pagesAppendix 9 Jacketed Vessels: 9-1 ScopeYetkin ErdoğanNo ratings yet

- Pipelines and Buried PipesDocument22 pagesPipelines and Buried PipesjwochNo ratings yet

- Example 6: Prestressed Beam: Adolfo Matamoros Julio RamirezDocument19 pagesExample 6: Prestressed Beam: Adolfo Matamoros Julio RamirezTùng HìNo ratings yet

- Equippment PowerDocument5 pagesEquippment PowerRauf AliyevNo ratings yet

- DomosDocument6 pagesDomosNicolas Leon LunaNo ratings yet

- Design of Tension MembersDocument11 pagesDesign of Tension MembersWilfharry billyNo ratings yet

- Diseño de Atiesador TriangularDocument10 pagesDiseño de Atiesador TriangularMauricio SierraNo ratings yet

- Pressure Vessels Lectures 98Document1 pagePressure Vessels Lectures 98Adeel NizamiNo ratings yet

- Cylindrical Compression Helix Springs For Suspension SystemsFrom EverandCylindrical Compression Helix Springs For Suspension SystemsNo ratings yet

- Composite Structures of Steel and Concrete: Beams, Slabs, Columns and Frames for BuildingsFrom EverandComposite Structures of Steel and Concrete: Beams, Slabs, Columns and Frames for BuildingsNo ratings yet

- Pressure Vessels Lectures 96Document1 pagePressure Vessels Lectures 96Adeel NizamiNo ratings yet

- Pressure Vessels Lectures 95Document1 pagePressure Vessels Lectures 95Adeel NizamiNo ratings yet

- Pressure Vessels Lectures 99Document1 pagePressure Vessels Lectures 99Adeel NizamiNo ratings yet

- Pressure Vessels Lectures 94Document1 pagePressure Vessels Lectures 94Adeel NizamiNo ratings yet

- Pressure Vessels Lectures 88Document1 pagePressure Vessels Lectures 88Adeel NizamiNo ratings yet

- Pressure Vessels Lectures 92Document1 pagePressure Vessels Lectures 92Adeel NizamiNo ratings yet

- Pressure Vessels Lectures 84Document1 pagePressure Vessels Lectures 84Adeel NizamiNo ratings yet

- Pressure Vessels Lectures 98Document1 pagePressure Vessels Lectures 98Adeel NizamiNo ratings yet

- Pressure Vessels Lectures 86Document1 pagePressure Vessels Lectures 86Adeel NizamiNo ratings yet

- Pressure Vessels Lectures 71Document1 pagePressure Vessels Lectures 71Adeel NizamiNo ratings yet

- Pressure Vessels Lectures 85Document1 pagePressure Vessels Lectures 85Adeel NizamiNo ratings yet

- Pressure Vessels Lectures 77Document1 pagePressure Vessels Lectures 77Adeel NizamiNo ratings yet

- Pressure Vessels Lectures 69Document1 pagePressure Vessels Lectures 69Adeel NizamiNo ratings yet

- Pressure Vessels Lectures 63Document1 pagePressure Vessels Lectures 63Adeel NizamiNo ratings yet

- Table U-3 Year of Acceptable Edition of Referenced Standards in This Division (Cont'd)Document1 pageTable U-3 Year of Acceptable Edition of Referenced Standards in This Division (Cont'd)Adeel NizamiNo ratings yet

- Lectures Pressure Vessels 22Document1 pageLectures Pressure Vessels 22Adeel NizamiNo ratings yet

- Pressure Vessels Lectures 70Document1 pagePressure Vessels Lectures 70Adeel NizamiNo ratings yet

- Table U-3 Year of Acceptable Edition of Referenced Standards in This DivisionDocument1 pageTable U-3 Year of Acceptable Edition of Referenced Standards in This DivisionAdeel NizamiNo ratings yet

- Pressure Vessels Lectures 64Document1 pagePressure Vessels Lectures 64Adeel NizamiNo ratings yet

- Lectures Pressure Vessels 30Document1 pageLectures Pressure Vessels 30Adeel NizamiNo ratings yet

- Lectures Pressure Vessels 21Document1 pageLectures Pressure Vessels 21Adeel NizamiNo ratings yet

- Lectures Pressure Vessels 23Document1 pageLectures Pressure Vessels 23Adeel NizamiNo ratings yet

- Win OLSDocument3 pagesWin OLSGospodin Kolev100% (1)

- Indigo NotesDocument7 pagesIndigo NotesDevesh SaiNo ratings yet

- Erased Log by SosDocument3 pagesErased Log by SosJeremy LuriciNo ratings yet

- Presentation PosterDocument1 pagePresentation PosterMihir PatelNo ratings yet

- Design and Analysis of Agriculture SprayersDocument7 pagesDesign and Analysis of Agriculture SprayersIJRASETPublicationsNo ratings yet

- Question of Smart AgricultureDocument3 pagesQuestion of Smart AgricultureEmtronik ClassNo ratings yet

- OG Spec 6R1000Document2 pagesOG Spec 6R1000adlonusNo ratings yet

- Speech ExamplesDocument6 pagesSpeech Examplesjayz_mateo9762100% (1)

- Jinko 250WDocument1 pageJinko 250WCruz López MargaritoNo ratings yet

- SAP BPC Consultant A Leading MNCDocument3 pagesSAP BPC Consultant A Leading MNCSathish SarupuriNo ratings yet

- 2 - Inst Chem Lec Calibration of Instrumental Methods PTTDocument8 pages2 - Inst Chem Lec Calibration of Instrumental Methods PTTJoudNo ratings yet

- Sd3 (U) Over Speed: Application Point of DetectionDocument1 pageSd3 (U) Over Speed: Application Point of DetectionAce Noah SomintacNo ratings yet

- 2-Wheel Profile Measuring System-WPMSDocument19 pages2-Wheel Profile Measuring System-WPMSVictor Manuel BonettoNo ratings yet

- Proposal FarizDocument15 pagesProposal FarizTara ChenqNo ratings yet

- Design For Manufacturing and AssemblyDocument44 pagesDesign For Manufacturing and AssemblyfayuangNo ratings yet

- Chromecore 434N-S: Technical Data SheetDocument1 pageChromecore 434N-S: Technical Data Sheetdneprmt1No ratings yet

- Faculty of Engineering: Answer ALL Questions in The Answer Sheet Provided. Time Allowed: 90 MinutesDocument6 pagesFaculty of Engineering: Answer ALL Questions in The Answer Sheet Provided. Time Allowed: 90 MinutesTharindu AbeykoonNo ratings yet

- Control and Optimization of Distributed Generation Systems: Magdi S. Mahmoud Fouad M. AL-SunniDocument599 pagesControl and Optimization of Distributed Generation Systems: Magdi S. Mahmoud Fouad M. AL-Sunniasad khan100% (1)

- Earth Science: Quarter 2 - Module 6: Seafloor SpreadingDocument23 pagesEarth Science: Quarter 2 - Module 6: Seafloor Spreadingqueancy euleNo ratings yet

- Linguistic Theories of HumorDocument5 pagesLinguistic Theories of HumorNilmalvila Blue Lilies PondNo ratings yet

- Antenna L InEDocument2 pagesAntenna L InERasheed Yaser RabahNo ratings yet

- Photovoltaic Systems-Variation of Efficiency With Band-Gap and TemperatureDocument9 pagesPhotovoltaic Systems-Variation of Efficiency With Band-Gap and TemperatureRaja SekaranNo ratings yet

- Vikram DulloorDocument2 pagesVikram DulloorAjeesh SudevanNo ratings yet

- Experimental and Simulation Study On The Microstructure of TA15 Laser WeldingDocument11 pagesExperimental and Simulation Study On The Microstructure of TA15 Laser Weldingadnan domlogeNo ratings yet

- 50 SoundDocument4 pages50 SoundKer QiNo ratings yet

- Project Management Activity.Document5 pagesProject Management Activity.Kristine Jay AlbertoNo ratings yet

- Support Optimization Tutorial EN LRDocument8 pagesSupport Optimization Tutorial EN LRwdyouQNo ratings yet

- Sensitivity and SpecificityDocument3 pagesSensitivity and SpecificityPrisia AnantamaNo ratings yet

- DEFCON 18 Mage2 Electronic Weapons PDFDocument45 pagesDEFCON 18 Mage2 Electronic Weapons PDFMamy PokoNo ratings yet