Professional Documents

Culture Documents

Download

Uploaded by

anaattiaOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Download

Uploaded by

anaattiaCopyright:

Available Formats

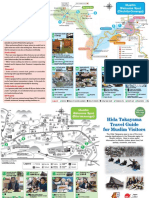

NAGASAKI

WORKS

Matsuura

Saga

Urakami Station

Sasebo Nagasaki Station

Huis Ten Asahi Ohashi

Bosch Bridge

Nagasaki Port Night View 202

aki

Nagasaki

Port

444

206 Nagasaki Akunoura

Saikai Area

Airport Omura

Isahaya

202 251

207

Nagasaki

Unzen 389

251 Megami

Shimabara Bridge

57

Akunoura Area

Minami-

Shimabara

Koyagi Area

499

Koyagi Area

Nagasaki Kunchi Festival (Dragon Dance)

Access

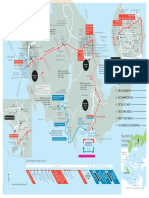

Brief History Akunoura Area

NAGASAKI SINCE 1857

1857 At the request of the Tokugawa Shogunate Government, a group of Dutch 1981 Works were constructed newly in the Fukahori area for the exclusive 1-1, Akunoura-machi, Nagasaki City, Nagasaki 850-8610, Japan Phone: +81-95-828-6003 Area

engineers led by Hendrik Hardes started construction of Nagasaki production of large coal-fired boilers.

[By bus] Take a bus for Tategami, Kaminoshima or Nishidomari from JR Nagasaki Station

Yotetsusho (predecessor of Nagasaki Shipyard & Machinery Works). 547,769 m2

1993 Electronics Shop was built. and get off at Iwasedo (Approximately 20 minutes).

1860 The foundry was renamed Nagasaki Seitetsusho and the ironworks was

MHI Technical Services Corporation (MTS; currently MHI Power Technical [By taxi] Approximately 45 minutes from Nagasaki Airport

opened in March 1861.

Services Corporation) established in the Philippines as an overseas design Approximately 10 minutes from JR Nagasaki Station Creating the Future with

1908 Japan’s first power generating turbine (output 500 kW) was completed company. International Certifications

through a technical tie-up with England-based Parsons & Company and

installed at the central power station of Mitsubishi Shipyard. 2007 Celebration of the 150th Foundation anniversary. Koyagi Area Comprehensive Energy ● ISO 9001 Quality Management System

1911 The first boiler was made following acquisition of boiler production rights

A joint venture was established with Larsen & Toubro Limited (L&T),

a leading construction and heavy machinery company based in India.

180 Koyagi-machi, Nagasaki City, Nagasaki 851-0393, Japan Technology ● ISO 14001 Environmental

Management System

from England-based Nesdrum Boiler Manufacturing Company.

[By bus] Take a bus for Koyagihonmura from JR Nagasaki Station and get off

2010 Joint venture with Larsen & Toubro Limited (L&T) starts local production of

at Nagahama or Koyagiguchi (Approximately 55 minutes).

1934 The works was renamed Nagasaki Shipyard & Machinery Works.

turbines and boilers. Nagasaki Works was established in 1857 as Nagasaki Yotetsusho, or

[By taxi] Approximately 60 minutes from Nagasaki Airport Annual Production Capacity

1963 Production facilities at the Machinery Division were modernized.

steel works, and has developed into a central facility for machinery

2014 Mitsubishi Hitachi Power Systems, Ltd. was established as a joint venture

Approximately 35 minutes from JR Nagasaki Station

Brazil-based CBC Industrias Pesadas S.A. was acquired by three company between Mitsubishi Heavy Industries and Hitachi integrating

manufacturing. Globally, it plays a key role in terms of the innovation and

companies of the Mitsubishi Group (Mitsubishi Heavy Industries, Ltd., thermal power generation systems and other related businesses, therefore

Mitsubishi Corporation and Mitsubishi Electric Corporation) and made into changing the name to Nagasaki Works of Mitsubishi Hitachi Power development of thermal and geothermal power plants, fuel cells, and

the South American boiler production site. Systems. Land Land and

integrated coal gasification combined cycle power plants (IGCC).

SteamTurbines Marine Boilers

1971 Boiler-Tube and Pipe-Header Shops were built in the Fukahori/Koyagi 2020 Renamed Mitsubishi Power, Ltd.

3,000 MW 5,900 MW

areas (Nagasaki City). Mitsubishi Power's Nagasaki Works was formed as a result.

Integrated Coal Gasification Combined Cycle Power Plants (IGCC)

power.mhi.com MP43-05CC05E1-A-0, (3.0)20-9, ZTP

NAGASAKI WORKS

Main Products Outline Combustion Test Facility

Akunoura Area Mitsubishi Power has a combustion test facility that features the world’s largest capacity of coal combustion (4 tons/hr).

The Akunoura Area has a long history dating back to its foundation in 1857 as the Nagasaki Yotetsusho Foundry established by the Tokugawa Shogunate Government. The facility was built to achieve more advanced combustion technologies, the core factor in boilers, particularly in terms of lower

The turbine shop, with an annual production capacity of 3,000 MW, uses highly automated facilities and equipment to manufacture high performance steam turbines, emissions of nitrogen oxides (NOx), less unburned combustibles and lower excess air ratio. The facility can accommodate a wide

ranging from large 1,000 MW operations to those for geothermal power generation, vessels, and other various industrial purposes.

variety of fuels, including bituminous coal, subbituminous coal, lignite, anthracite, biomass, petroleum coke and residual oil. By

The Akunoura Area also has electronics, fuel cell shops and Remote Monitoring Center (RMC) that produce state-of-the-art technological products.

significantly improving combustion evaluation capability, we are pushing ahead with the development of boilers that contribute to

Main Production Facilities further reducing fuel costs, thereby enhancing availability and easing environmental impact.

Akunoura Area

Machining

Large NC combined production milling machine

Facilities

(GANTRY PLANO MILLER):

Misumi Thermal Power Station Unit 1 (Japan),

1,000 MW, The Chugoku Electric Power Co., Inc. 8,500 (W) × 16,000 (L) × 4,200 (H) mm

1 Main Gate Large NC lathe: 4,200 (D) × 14,500 (L) mm

Boiler Selective Catalytic Reduction (SCR)

Large NC vertical lathe: 8,500 (D) × 5,000 (H) mm

2 Main Office

2 3 4 Assembly

1 6 3 Electronics Shop Facilities

Turbine-rotor large high-speed rotation testing machine

Turbine governor test facilities

5 7 4 Turbine Blade Shop

High-Tech

Computer control systems assembling tester,

Facilities

5 Turbine Shop Environmental testing facilities, Simulator training center,

Remote Monitoring Center (RMC)

6 Museum

7 SOFC Shop

Fuel cell manufacturing facilities World Cultural Heritage "Sites of Japan's Meiji Industrial Revolution"

Nakoso Power Station Unit 10 (Japan), Joban Joint Power Co., Ltd.

In 2015, the five facilities in Mitsubishi Heavy Industries Nagasaki Shipyard & Machinery Works were registered as

Gasifier, Heat Recovery Steam Generator Steam Turbine

World Cultural Heritage "Sites of Japan's Meiji Industrial Revolution," which consist of 23 sites located in 8 different

prefectures.

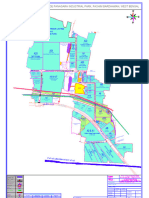

Koyagi Area

The Koyagi Area was founded in 1972. Koyagi Area

The IGCC & Boiler Shop boasts an annual production capacity of 5,900 MW, making it the largest in the country. The shop is equipped with state-of-the-art automated

lines, facilities and equipment capable of manufacturing large 3,800-ton modules to produce massive-sized, high quality and high performance IGCC & boilers. Boiler Production TIG automatic welder, Assembling and

Facilities welding robot

Superheater &

Continuous bender

Reheater Tube Shop

Continuous heat treatment facilities

8 IGCC & Boiler Shop

(Gasifier Pressure Vessel, Gasifier Water Wall, Module Shop) Boiler Production Multiple head panel processing machine,

Facilities capable of 44 welding head simultaneous

Furnace Wall &

Hellisheidi Geothermal Power Plant (Iceland), Reykjavik Energy 9 Module Center welding

Economizer Tube,

Gasifier Water Wall Shop Automatic tube elongation facilities Former Pattern Shop Senshokaku Guest House

Geothermal Power Plant Fuel Cells

Spiral fin tube welder (now used as a museum) (Not open to public)

10 IGCC & Boiler Shop

Assembling and welding robot

11 (Furnace Wall & Economizer Tube, Gasifier Water Wall Shop)

12

Boiler Production High-Frequency pipe bender, NC header boring

14 11 IGCC & Boiler Shop Facilities

10 13 machine, MIG automatic welder, Header nozzle

8 9 (Pipe-Header & Module Shop) Pipe-Header &

welding robot

Module Shop

12 IGCC & Boiler Shop Boiler Production Large sized annealing furnace: 7,500 (W) ×

(Superheater & Reheater Tube Shop) Facilities 13,000 (L) × 7,500 (H) mm

Gasifier Pressure Vessel,

400-ton overhead travelling crane (overhang)

Gasifier Water Wall,

13 IGCC & Boiler Shop Module Shop Welding machine for large sized pressure vessel

(Gasifier Pressure Vessel Shop) 6 MeV “LINAC” Non-Destructive Tester

Axial Flow Fan with Variable No.3 Dry Dock Kosuge Slip Dock Giant Cantilever Crane

MRS Mill Pitch Rotor Blade

14 Mitsubishi Heavy Industries, Ltd. Assembly Facilities Large fan test facilities

(Not open to public) (Abacus Dock) (Not open to public)

Boiler Machinery Plant Control System Research & Innovation Center

You might also like

- Tokyo TrainmapDocument1 pageTokyo Trainmapmaresnia100% (2)

- Kanazawa Bus MapDocument2 pagesKanazawa Bus Mapolivaalessia95No ratings yet

- Guide Map Toyama JapanDocument2 pagesGuide Map Toyama Japankokii_2No ratings yet

- RouteMap MajorrailsubDocument1 pageRouteMap Majorrailsubrlab1000No ratings yet

- RouteMap Majorrailsub-1 PDFDocument1 pageRouteMap Majorrailsub-1 PDFヴェラ 由美No ratings yet

- RouteMap Majorrailsub Simple PDFDocument1 pageRouteMap Majorrailsub Simple PDFapinroseNo ratings yet

- CampusMap Kakuma En2Document1 pageCampusMap Kakuma En2Muhammad Sabirin HadisNo ratings yet

- TLA En0619Document4 pagesTLA En0619Mohammed GallowNo ratings yet

- Guide Kansai AreaDocument8 pagesGuide Kansai AreaKyle Fernando Foster-ElNo ratings yet

- Tenkasi District MapDocument1 pageTenkasi District MapImran Khan100% (1)

- ABSENSI KARYAWAN PT. TRI JOB SITE PPAdasda ABP JEMBAYAN 2021Document12 pagesABSENSI KARYAWAN PT. TRI JOB SITE PPAdasda ABP JEMBAYAN 2021andy setiawanNo ratings yet

- GROUP 4 RAMOS PURGATORIO IMPERIAL GAPpdfDocument1 pageGROUP 4 RAMOS PURGATORIO IMPERIAL GAPpdfLorenceNo ratings yet

- SLD SumbagtengDocument1 pageSLD SumbagtengUlil AlbabNo ratings yet

- Smartworld One DXP BrochureDocument11 pagesSmartworld One DXP BrochureAndlays International RealtyNo ratings yet

- Smartworld One DXP Brochure - CompressedDocument11 pagesSmartworld One DXP Brochure - CompressedAndlays International RealtyNo ratings yet

- Bhagirath Pura Indore Map New Industrial AreaDocument1 pageBhagirath Pura Indore Map New Industrial Areatalreja.jatin25No ratings yet

- Karuizawa: The Highlights: Wedding Literature SportsDocument2 pagesKaruizawa: The Highlights: Wedding Literature Sportsabc2008No ratings yet

- Exb Floor Yokohama enDocument1 pageExb Floor Yokohama enMartin WhiteNo ratings yet

- Ogi-Machi Gassho Style Village Ogi-Machi Gassho Style Village Ogi-Machi Gassho Style VillageDocument1 pageOgi-Machi Gassho Style Village Ogi-Machi Gassho Style Village Ogi-Machi Gassho Style VillageaphinxwuNo ratings yet

- Yogyakarta Metropolitan Area Transit MapDocument1 pageYogyakarta Metropolitan Area Transit MapAgung WidiyantoroNo ratings yet

- Companion 5 - DSP SCH PDFDocument4 pagesCompanion 5 - DSP SCH PDFManimaran MaranNo ratings yet

- 04192018Document12 pages04192018Tammy SchlingmannNo ratings yet

- Mpfdeo 2021 Q4Document1 pageMpfdeo 2021 Q4Aries Falag-eyNo ratings yet

- Sains TrussDocument594 pagesSains TrussJames JoviNo ratings yet

- Kkip Masterplan.Document1 pageKkip Masterplan.yuszriNo ratings yet

- TAKAYAMA Muslim - Pamph PDFDocument4 pagesTAKAYAMA Muslim - Pamph PDFRochamukti RizcanofanaNo ratings yet

- SampleDocument1 pageSamplededi sarifNo ratings yet

- Poster Finale VI IIIDocument1 pagePoster Finale VI IIINajWanNo ratings yet

- Sakura Guide MapDocument2 pagesSakura Guide Mappham KienNo ratings yet

- M318D MH and M322D MH Excavator Hydraulic System: Imp Lock Sol Heavy Lift SolDocument2 pagesM318D MH and M322D MH Excavator Hydraulic System: Imp Lock Sol Heavy Lift SolLuis HernandezNo ratings yet

- Kip D 1001071709 003 PDFDocument1 pageKip D 1001071709 003 PDFHisham AfzalNo ratings yet

- 6186086Document1 page6186086Hamza ShabbirNo ratings yet

- Zoning Plan: Skala 1: 1000Document1 pageZoning Plan: Skala 1: 1000DwiAryantoNo ratings yet

- 2022 - 07 - 27 - 2332 IWTP8-4 Unit 15 SBR - 02 - PRECAST TTS, SECTION & DETAILDocument1 page2022 - 07 - 27 - 2332 IWTP8-4 Unit 15 SBR - 02 - PRECAST TTS, SECTION & DETAILsk mukhtarNo ratings yet

- 772B Tractor & 773B Truck Electrical System: Machine Harness Connector and Component LocationsDocument2 pages772B Tractor & 773B Truck Electrical System: Machine Harness Connector and Component LocationsjesusNo ratings yet

- JRP Japan PDFDocument1 pageJRP Japan PDFcanrullNo ratings yet

- Makkah Makkah: Electrical Shop DrawingDocument1 pageMakkah Makkah: Electrical Shop DrawingkkNo ratings yet

- Parker Fly Schematic PDFDocument1 pageParker Fly Schematic PDFАНДРЕЙ ORLOV0% (1)

- Panagarh Master Plan Northen 2023Document1 pagePanagarh Master Plan Northen 2023Sandeep SinghNo ratings yet

- Manicaland Province - Basemap: MozambiqueDocument1 pageManicaland Province - Basemap: MozambiqueTERRENCE100% (2)

- Asakusa Japan Maps BusDocument1 pageAsakusa Japan Maps BusNoemiCiullaNo ratings yet

- NaoshimaDocument1 pageNaoshimajNo ratings yet

- Cruise Ship Interiors 2023 - Sales PlanDocument1 pageCruise Ship Interiors 2023 - Sales Planpetrasb.amgNo ratings yet

- Muslim Pamph2019Document2 pagesMuslim Pamph2019Swandahru スアンダールNo ratings yet

- 透明な空気、不透明の記憶Document16 pages透明な空気、不透明の記憶佐原 詩音No ratings yet

- Karbala Refinery ProjectDocument5 pagesKarbala Refinery Projectعلاء حسينNo ratings yet

- BBQ CHICKEN VENTILATION 2.1.1-ModelDocument1 pageBBQ CHICKEN VENTILATION 2.1.1-Modelagflamesengineering.salesNo ratings yet

- Kyoto Bus Map 1Document1 pageKyoto Bus Map 1Wahyu SetiawatiNo ratings yet

- Cek Struktur EL 18.5 MeterDocument1 pageCek Struktur EL 18.5 Meterrhp1989No ratings yet

- HS372221 26 Pip Iso 0168 0000 1 - Rm01aDocument1 pageHS372221 26 Pip Iso 0168 0000 1 - Rm01aibrahim qasimovNo ratings yet

- Ac Ac005Document1 pageAc Ac005Afsal JhNo ratings yet

- Httpsuwf - Edumediauniversity of West Floridaacademic Engagement and Student Affairsdepartmentsrecreationimagesoutdoor ADocument1 pageHttpsuwf - Edumediauniversity of West Floridaacademic Engagement and Student Affairsdepartmentsrecreationimagesoutdoor ABeth StageNo ratings yet

- Routemap Retro Omni 2021Document1 pageRoutemap Retro Omni 2021hutchaNo ratings yet

- BANBASA TOWN WATER SUPPLY LAYOUT ZONE - 2 - ModelDocument1 pageBANBASA TOWN WATER SUPPLY LAYOUT ZONE - 2 - Modelshubham kumarNo ratings yet

- Energy Lab: Hawai'i Preparatory AcademyDocument1 pageEnergy Lab: Hawai'i Preparatory AcademySolidr ArchitectsNo ratings yet

- M3M CornerWalkDocument40 pagesM3M CornerWalkNidhi YadavNo ratings yet

- BBC Sky at Night (2017-09)Document110 pagesBBC Sky at Night (2017-09)georgetacaprarescuNo ratings yet

- Math Workshop, Grade 5: A Framework for Guided Math and Independent PracticeFrom EverandMath Workshop, Grade 5: A Framework for Guided Math and Independent PracticeNo ratings yet

- Industry Case Study: Universal Joint For Subsea Valve ActuationDocument1 pageIndustry Case Study: Universal Joint For Subsea Valve ActuationanaattiaNo ratings yet

- Subsea Christmas Tree SystemsDocument13 pagesSubsea Christmas Tree SystemsJefferson SoaresNo ratings yet

- Vam 21Document16 pagesVam 21subodhasinghNo ratings yet

- Subsea Christmas Tree SystemsDocument13 pagesSubsea Christmas Tree SystemsJefferson SoaresNo ratings yet

- Subsea TechnologyDocument23 pagesSubsea TechnologyjujuroyaleNo ratings yet

- Basic Subsea: Course Outline Who Should AttendDocument3 pagesBasic Subsea: Course Outline Who Should AttendanaattiaNo ratings yet

- Technip Subsea Case Study Using Acumen: 11-Sept-13 Presenters: Cesar Ramos & Pat SmithDocument20 pagesTechnip Subsea Case Study Using Acumen: 11-Sept-13 Presenters: Cesar Ramos & Pat SmithanaattiaNo ratings yet

- Subsea Christmas Tree SystemsDocument13 pagesSubsea Christmas Tree SystemsJefferson SoaresNo ratings yet

- 62861135Document46 pages62861135hamedronaldoNo ratings yet

- Gas Engine FundamentalsDocument13 pagesGas Engine Fundamentalsherdin56No ratings yet

- Subsea TechnologyDocument23 pagesSubsea TechnologyjujuroyaleNo ratings yet

- 3066 PDFDocument35 pages3066 PDFstallone21No ratings yet

- Gas Turbines A Manual PDFDocument74 pagesGas Turbines A Manual PDFHenry Pannell100% (1)

- Understanding Gas Turbine PerformanceDocument42 pagesUnderstanding Gas Turbine Performancesenthil03127793% (15)

- Gas Turbines A Manual PDFDocument74 pagesGas Turbines A Manual PDFHenry Pannell100% (1)

- 62861135Document46 pages62861135hamedronaldoNo ratings yet

- 3066 PDFDocument35 pages3066 PDFstallone21No ratings yet

- Generic PfPan Training Manual WebDocument48 pagesGeneric PfPan Training Manual WebBabul KumarNo ratings yet

- Generic PfPan Training Manual WebDocument48 pagesGeneric PfPan Training Manual WebBabul KumarNo ratings yet

- 3066 PDFDocument35 pages3066 PDFstallone21No ratings yet

- Gas Engine FundamentalsDocument13 pagesGas Engine Fundamentalsherdin56No ratings yet

- 3066 PDFDocument35 pages3066 PDFstallone21No ratings yet

- Company ProfileDocument8 pagesCompany ProfileanaattiaNo ratings yet

- Company ProfileDocument8 pagesCompany ProfileanaattiaNo ratings yet

- Company ProfileDocument8 pagesCompany ProfileanaattiaNo ratings yet

- Generic PfPan Training Manual WebDocument48 pagesGeneric PfPan Training Manual WebBabul KumarNo ratings yet

- Induction MotorsDocument28 pagesInduction MotorsMarvin MarcaidaNo ratings yet

- Company ProfileDocument8 pagesCompany ProfileanaattiaNo ratings yet

- Generic PfPan Training Manual WebDocument48 pagesGeneric PfPan Training Manual WebBabul KumarNo ratings yet

- Design and Analysis of Diesel Generator With Battery Storage For Microgrid SystemDocument8 pagesDesign and Analysis of Diesel Generator With Battery Storage For Microgrid SystemMassive MindsNo ratings yet

- Standards Description: 1-American Petroleum Institute (API)Document9 pagesStandards Description: 1-American Petroleum Institute (API)Mohammed Samy DarwishNo ratings yet

- Elpanneteknik Steam Boiler Brochure - ResizedDocument13 pagesElpanneteknik Steam Boiler Brochure - ResizedAhmedNo ratings yet

- Mechatest Grab Sampler Liquid and Gas ConfigurationsDocument1 pageMechatest Grab Sampler Liquid and Gas Configurationsyamen-691904No ratings yet

- RELAP5MOD3 Model and Transient Analyses For The MARIA Research Reactor in PolandDocument9 pagesRELAP5MOD3 Model and Transient Analyses For The MARIA Research Reactor in PolandBambang RiyonoNo ratings yet

- 1106c - Genset Testing Adjusting-System Operation PDFDocument84 pages1106c - Genset Testing Adjusting-System Operation PDFHenryMonteagudoParedes100% (2)

- Quasi Turbine EngineDocument18 pagesQuasi Turbine EngineKailas Sree Chandran100% (2)

- Colibri BV - First Ammonia Absorption in UKDocument3 pagesColibri BV - First Ammonia Absorption in UKEko TjahjantokoNo ratings yet

- EXP-PR-EQ070-R0-EN Support CoursDocument182 pagesEXP-PR-EQ070-R0-EN Support CourshediNo ratings yet

- Required Code Books - ASME - ASMEDocument21 pagesRequired Code Books - ASME - ASMEMichael AngNo ratings yet

- MUN Nuclear DisarmamentDocument3 pagesMUN Nuclear DisarmamentMenna ELAMROUSSYNo ratings yet

- Power System Renewable Energy Source (Hydro Technology)Document9 pagesPower System Renewable Energy Source (Hydro Technology)Amir KhirNo ratings yet

- Test 12Document6 pagesTest 12Nguyệt ChiNo ratings yet

- Compressor Washing PerformanceDocument4 pagesCompressor Washing PerformanceAshraf UddinNo ratings yet

- Wankel EngineDocument8 pagesWankel EngineMuhammad Qasim JameelNo ratings yet

- P2620 CPD SheetDocument1 pageP2620 CPD SheetAlejandra Rodriguez NocuaNo ratings yet

- Grua Liebherr LTM 1095 Motor y Motor Edicion EspecialDocument54 pagesGrua Liebherr LTM 1095 Motor y Motor Edicion Especialcesar alejandro scavo100% (1)

- Ethics Case Study - Three Mile Island Accident ReportDocument8 pagesEthics Case Study - Three Mile Island Accident Reportmprego011100% (1)

- Reciprocating PumpDocument2 pagesReciprocating Pumpmuna222No ratings yet

- Daikin Altherma Air Conditioning Brochure 2008Document13 pagesDaikin Altherma Air Conditioning Brochure 2008Web Design Samui100% (6)

- UNIT V - Reverse Carnot Cycle - COP - Vapor Compression Refrigeration Cycle and Systems (OnlyDocument18 pagesUNIT V - Reverse Carnot Cycle - COP - Vapor Compression Refrigeration Cycle and Systems (OnlyLogesh WaranNo ratings yet

- (2D Simulation) Thermal Power Plant Upgrade Via A Rotating Detonation Combustor andDocument11 pages(2D Simulation) Thermal Power Plant Upgrade Via A Rotating Detonation Combustor andDylan HsiehNo ratings yet

- Objective Question Bank 4 Q MBoiler 1Document2 pagesObjective Question Bank 4 Q MBoiler 1ABHIRAM RNo ratings yet

- Bfs Deaerator RFQDocument2 pagesBfs Deaerator RFQSrinivasa Rao VenkumahanthiNo ratings yet

- Boiler Performance Test ProcedureDocument16 pagesBoiler Performance Test ProceduresuparnabhoseNo ratings yet

- Honeywell RTH8500 Series Quick Installation Guide PDFDocument60 pagesHoneywell RTH8500 Series Quick Installation Guide PDFbandihootNo ratings yet

- Mechanical Engineering For Static and Rotating Equipment: The Delegates Will CoverDocument4 pagesMechanical Engineering For Static and Rotating Equipment: The Delegates Will CoverRashedNo ratings yet

- Benefits & Overview of Single-Shaft Combined Cycle Power PlantsDocument10 pagesBenefits & Overview of Single-Shaft Combined Cycle Power PlantsAhmed Abd El MoatiNo ratings yet

- SAGD For Heavy Oil RecoveryDocument45 pagesSAGD For Heavy Oil RecoveryАлиNo ratings yet

- Mann-Compressor Cross Reference GuideDocument104 pagesMann-Compressor Cross Reference GuideEliasd91% (11)