Professional Documents

Culture Documents

Shafer Paint Specifications

Uploaded by

Rafael Jose Tasco ZabaletaCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Shafer Paint Specifications

Uploaded by

Rafael Jose Tasco ZabaletaCopyright:

Available Formats

Standard/Primer Coating System

SURFACE MINIMUM DRY FILM

COAT PAINT

PREPARATION THICKNESS

Ameron Solvent wash with 63 µm

Primer*

Amercoat® 385 ”d-Limonene®” – Dried 2.5 mils

Ameron 63 µm

Optional second coat Clean-1st coat Dried

Amercoat® 450H 2.5 mils

Two Coat Coating System

SURFACE MINIMUM DRY FILM

COAT PAINT

PREPARATION THICKNESS

Ameron Sandblast to Near- White 63 µm

Primer

Amercoat® 385 (steel parts only) 2.5 mils

Ameron 63 µm

Second coat Clean-1st coat Dried

Amercoat® 450H 2.5 mils

Offshore/3-Coat Coating System

SURFACE MINIMUM DRY FILM

COAT PAINT

PREPARATION THICKNESS

Ameron Sandblast to Near- White 63 µm

Primer

Amercoat® 68HS (steel parts only) 2.5 mils

Ameron Sandblast to Near- White 76 µm

Primer Alternate

Amercoat® 385 (steel parts only) 3 mils

Ameron 76 µm

Intermediate Clean – 1st coat Dried

Amercoat® 385 3 mils

Ameron Amercoat® 385 76 µm

Finish Blue, Pearl Gray Clean – 2nd coat Dried

3 mils

or White

Finish Alternate Ameron Amercoat® 450H Clean – 2nd coat Dried

50 µm

Special Option Customer Color 2 mils

NOTE: Stainless steel or anodized aluminum parts are prepared by washing with “d-Limonene®” solvent and receive one final coat.

* NOTE: It is recommended that a topcoat be applied within 6 months to prevent fading of paint.

AMERON PROTECTIVE COATINGS

AMERCOAT® 68HS: An abrasion resistant zinc rich epoxy primer which provides long lasting cathodic protection to steel

surfaces. The coating has outstanding resistance to chemicals and severe weathering, and exhibits excellent adhesion to

organic and inorganic zinc primers and epoxy topcoats. Low VOC content.

AMERCOAT® 385: A superior rust inhibitive Multi-purpose epoxy primer that provides excellent durability in marine

atmosphere, suitable for immersion service, withstands splash or spillage of solvents, petroleum products, seawater, salt

solutions and sour crude. AMERCOAT® 385 is compatible with a wide range of topcoats including polyurethanes and acrylics,

has excellent adhesion to inorganic zinc silicate. Low VOC content.

AMERCOAT® 450H: A glossy attractive aliphatic polyurethane topcoat used as a finish coat where excellent color retention,

attractive appearance and corrosive resistance are required. Low VOC content.

TECHNICAL BULLETIN PCS-5/06

Subsea Coating System

COAT PAINT SURFACE MINIMUM DRY FILM

PREPARATION THICKNESS

Primer Ameron Sandblast to Near- 76 µm

Amercoat® 68HS White (steel parts only) 3 mils

Intermediate Ameron Clean – 1st Coat Dried 127 µm

Amerlock® 400 5 mils

Finish Ameron Clean – 2nd Coat Dried 127 µm

Amerlock® 400 5 mils

(White)

NOTE: Stainless steel or anodized aluminum parts are prepared by washing with “d-Limonene®” and receive one

coat (only) of Ameron Amerlock® 400.

AMERON PROTECTIVE COATINGS

AMERCOAT® 68HS: An abrasion resistant zinc rich epoxy primer which provides long lasting cathodic protection to steel

surfaces. The coating has outstanding resistance to chemicals and severe weathering, and exhibits excellent adhesion to

organic and inorganic zinc primers and epoxy topcoats. Low VOC content.

AMERLOCK® 400: An optimum performance high solids epoxy coating which provides good chemical resistance to splash /

spillage, fumes and is approved for immersion service. Low VOC content.

TECHNICAL BULLETIN SPCS-9/05

You might also like

- Armstrong Ambience Plus 8 MMDocument30 pagesArmstrong Ambience Plus 8 MMPreethi RajendranNo ratings yet

- Sanding Made Simple Brochure (Hi Res)Document5 pagesSanding Made Simple Brochure (Hi Res)Mayank KakkarNo ratings yet

- H-E Parts Data Sheet PT-95S CeramicDocument1 pageH-E Parts Data Sheet PT-95S CeramicJorge VillalobosNo ratings yet

- H-E Parts Data Sheet PT-92S CeramicDocument1 pageH-E Parts Data Sheet PT-92S CeramicJorge VillalobosNo ratings yet

- Protective Film C 11.6 PDFDocument21 pagesProtective Film C 11.6 PDFherysyam1980No ratings yet

- Finishes for Wood, Wall and Metal SurfacesDocument2 pagesFinishes for Wood, Wall and Metal Surfaceskartick adhikaryNo ratings yet

- Aquaarm Tarmat-P: WaterproofingDocument3 pagesAquaarm Tarmat-P: Waterproofingraviteja036No ratings yet

- E-CR Glass: Chopped Strand Mat (Emulsion) For UP, VE, EPDocument2 pagesE-CR Glass: Chopped Strand Mat (Emulsion) For UP, VE, EPAshit ShahNo ratings yet

- Basf Masterseal m200 TdsDocument2 pagesBasf Masterseal m200 Tdsjuli_radNo ratings yet

- Specification for a 4-coat protective coating systemDocument1 pageSpecification for a 4-coat protective coating systemMaffone NumerounoNo ratings yet

- Change Font Brochure DesignDocument2 pagesChange Font Brochure DesignForeverNo ratings yet

- Ficha Técnica - Amex (Inglés) PDFDocument2 pagesFicha Técnica - Amex (Inglés) PDFPedro Ramos PAchecoNo ratings yet

- Floating Screed System: High Performance Flooring and Tiling ProductsDocument2 pagesFloating Screed System: High Performance Flooring and Tiling ProductsWaled Hantash100% (1)

- Cotton Harvester FEOFMA 000ABC 080514Document6 pagesCotton Harvester FEOFMA 000ABC 080514Juan Alejandro Cañas ColoradoNo ratings yet

- Basf Masterseal m200 TdsDocument2 pagesBasf Masterseal m200 Tdsangelito bernalNo ratings yet

- Waterproofing Handbook HB-1Document172 pagesWaterproofing Handbook HB-1Htun ZarniNo ratings yet

- Premium Satin Enamel for Wood, Wall & MetalDocument6 pagesPremium Satin Enamel for Wood, Wall & MetalAr. Libin K BabyNo ratings yet

- Standard Operating Procedures: Product List Headlight Lens Restoration ProcessDocument2 pagesStandard Operating Procedures: Product List Headlight Lens Restoration ProcessMayank KakkarNo ratings yet

- Schedule of Finishes-Administrative BlockDocument2 pagesSchedule of Finishes-Administrative BlockNainshreeNo ratings yet

- Bitu-Impervi LM Waterproofing MembraneDocument2 pagesBitu-Impervi LM Waterproofing MembraneJoeNo ratings yet

- Cooling Water Towers - Steel Cooling Water Towers - ConcreteDocument2 pagesCooling Water Towers - Steel Cooling Water Towers - ConcreteSai ChaithanyaNo ratings yet

- Materials Preparation For Microstructural Analysis.: MethodDocument1 pageMaterials Preparation For Microstructural Analysis.: MethodRon RonaldsNo ratings yet

- Kingspan Spectrum™: Premium Organic Coating SystemDocument4 pagesKingspan Spectrum™: Premium Organic Coating SystemNikolaNo ratings yet

- Kingspan Spectrum™: Premium Organic Coating SystemDocument4 pagesKingspan Spectrum™: Premium Organic Coating SystemMiso KowacNo ratings yet

- BS - Traffigard Optimize 0Document6 pagesBS - Traffigard Optimize 0TungNo ratings yet

- Coating For Extreme Applications: Hi-Pro ZDocument4 pagesCoating For Extreme Applications: Hi-Pro ZZineddine ALICHENo ratings yet

- Painting cycle technical specificationsDocument1 pagePainting cycle technical specificationsMaffone NumerounoNo ratings yet

- White : Smartcare Crack SealDocument2 pagesWhite : Smartcare Crack Sealpramodyad5810No ratings yet

- Martin Apron Seal Skirting System: 2-Piece 1-Piece Heavy-Duty 1-PieceDocument2 pagesMartin Apron Seal Skirting System: 2-Piece 1-Piece Heavy-Duty 1-Piececristian W. saravia vegaNo ratings yet

- Ultima Protek Duralife NewDocument2 pagesUltima Protek Duralife NewBapun Ben KartikNo ratings yet

- Apex Duracast DholpurtexDocument2 pagesApex Duracast DholpurtexKeyur PatelNo ratings yet

- Large Damage RepairDocument2 pagesLarge Damage RepairQC apollohx100% (1)

- Apcolite Premium Gloss Enamel PDFDocument2 pagesApcolite Premium Gloss Enamel PDFAnand Chavan Projects-QualityNo ratings yet

- Buhler Bead Mills Cenomic - EN2Document4 pagesBuhler Bead Mills Cenomic - EN2Negash JaferNo ratings yet

- Plascoat Ppa 571: Performance Polymer Alloy CoatingDocument2 pagesPlascoat Ppa 571: Performance Polymer Alloy CoatingEidrish ShaikhNo ratings yet

- Abecote 352Document3 pagesAbecote 352engramir07No ratings yet

- Installation Manual for Residential Window and Door ProductsDocument44 pagesInstallation Manual for Residential Window and Door ProductsAymeeenNo ratings yet

- Cleaning PolishingDocument4 pagesCleaning PolishingJose Angel CarrenNo ratings yet

- Global Synthetics Proliner HDPE Smooth DatasheetDocument1 pageGlobal Synthetics Proliner HDPE Smooth DatasheetMatt GhanaviNo ratings yet

- Sri Ramakrishna Building Materials: Quality ReportDocument2 pagesSri Ramakrishna Building Materials: Quality ReportsudhakarthekingNo ratings yet

- Random Orbital Sanding Guide ENDocument12 pagesRandom Orbital Sanding Guide ENidan kahanNo ratings yet

- Trucare Grey 1-Pack Epoxy Primer: Product BenefitsDocument2 pagesTrucare Grey 1-Pack Epoxy Primer: Product BenefitsSakthivelNo ratings yet

- Amercoat 450H: Product Data/ Application InstructionsDocument4 pagesAmercoat 450H: Product Data/ Application InstructionsjoshNo ratings yet

- Carbomastic15BNX EngDocument2 pagesCarbomastic15BNX Engfazeel mohammedNo ratings yet

- AID DS Fans PUBL 7595Document6 pagesAID DS Fans PUBL 7595h1234bNo ratings yet

- Ciclo Di Verniciatura: Painting CycleDocument1 pageCiclo Di Verniciatura: Painting CycleMaffone NumerounoNo ratings yet

- Micro-Ultrafine Finishing with Consistent Grain SizesDocument1 pageMicro-Ultrafine Finishing with Consistent Grain SizesArvin BabuNo ratings yet

- Advance TDSDocument2 pagesAdvance TDSDavid RiceNo ratings yet

- Cement and Pretreatment Guide: 3M Relyx Unicem 2 Self-Adhesive Resin CementDocument1 pageCement and Pretreatment Guide: 3M Relyx Unicem 2 Self-Adhesive Resin CementJH SEBASSNo ratings yet

- 3m Industrial Paint Process Solutions Leaflet LR EnglishDocument8 pages3m Industrial Paint Process Solutions Leaflet LR EnglishYogie YogaswaraNo ratings yet

- Bfma 000 151214Document9 pagesBfma 000 151214Juan Alejandro Cañas ColoradoNo ratings yet

- Surface Treatment20Document2 pagesSurface Treatment20alimesmatparastNo ratings yet

- Apex Duracast SwirlTex NewDocument2 pagesApex Duracast SwirlTex NewPankaj ShirkeNo ratings yet

- FloArm Coat EC Ver 6Document3 pagesFloArm Coat EC Ver 6imsNo ratings yet

- Smartcare Joint Tape (Roof Tape) - Code 5402 5403 5404 PDFDocument2 pagesSmartcare Joint Tape (Roof Tape) - Code 5402 5403 5404 PDFGopal KrishnanNo ratings yet

- Smartcare Joint Tapes: Product BenefitsDocument2 pagesSmartcare Joint Tapes: Product BenefitsRajasekarNo ratings yet

- Cimbar EX TDSDocument2 pagesCimbar EX TDSTarkan AKÇAYNo ratings yet

- Toilet TilesDocument1 pageToilet TilesAshoka MithiranNo ratings yet

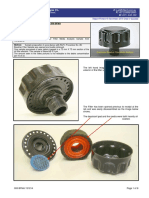

- Reflux 819: Pressure RegulatorDocument20 pagesReflux 819: Pressure RegulatorRafael Jose Tasco ZabaletaNo ratings yet

- Mantenimiento ShaferDocument12 pagesMantenimiento ShaferMauricio RoldanNo ratings yet

- Valve Positioning System PDFDocument8 pagesValve Positioning System PDFRafael Jose Tasco ZabaletaNo ratings yet

- General Training GuideDocument46 pagesGeneral Training GuideRafael Jose Tasco ZabaletaNo ratings yet

- Valve Positioning System PDFDocument8 pagesValve Positioning System PDFRafael Jose Tasco ZabaletaNo ratings yet

- RV-Specifications and Dimensional Data - UsDocument11 pagesRV-Specifications and Dimensional Data - UsRafael Jose Tasco ZabaletaNo ratings yet

- Maintain and service poppet block control valveDocument8 pagesMaintain and service poppet block control valveRafael Jose Tasco ZabaletaNo ratings yet

- Catalogo Paleta RotatoriaDocument8 pagesCatalogo Paleta RotatoriaRafael Jose Tasco ZabaletaNo ratings yet

- PosterDocument1 pagePosterRafael Jose Tasco ZabaletaNo ratings yet

- Spe-059 Reflux 819 Mainteinance New-1Document22 pagesSpe-059 Reflux 819 Mainteinance New-1Rafael Jose Tasco ZabaletaNo ratings yet

- PosterDocument1 pagePosterRafael Jose Tasco ZabaletaNo ratings yet

- Common Control SchematicsDocument22 pagesCommon Control SchematicsRafael Jose Tasco ZabaletaNo ratings yet

- Reflux 819: Pressure RegulatorDocument20 pagesReflux 819: Pressure RegulatorRafael Jose Tasco ZabaletaNo ratings yet

- Catalogo Paleta RotatoriaDocument8 pagesCatalogo Paleta RotatoriaRafael Jose Tasco ZabaletaNo ratings yet

- Modbus Protocol Emulation Program User ManualDocument124 pagesModbus Protocol Emulation Program User ManualRafael Jose Tasco ZabaletaNo ratings yet

- Reflux 819: Pressure RegulatorDocument20 pagesReflux 819: Pressure RegulatorRafael Jose Tasco ZabaletaNo ratings yet

- Optimizing Zinc Oxide and Malic Acid in Sunscreen Cream Combining AvobenzoneDocument7 pagesOptimizing Zinc Oxide and Malic Acid in Sunscreen Cream Combining AvobenzoneNadzirulNo ratings yet

- Understanding Carboxylic Acid DerivativesDocument36 pagesUnderstanding Carboxylic Acid DerivativesArricson HunterNo ratings yet

- Worksheet ElectroChemistry-2Document2 pagesWorksheet ElectroChemistry-2Rishi ChatterjeeNo ratings yet

- Inorganic Qualitative Analysis IdentificationDocument9 pagesInorganic Qualitative Analysis IdentificationShireen SuhailNo ratings yet

- Total Oil DetDocument2 pagesTotal Oil DetAwais A.No ratings yet

- WeldingDocument3 pagesWeldingGregor SamsaNo ratings yet

- Unit-IV Welding Processes of SuperalloysDocument7 pagesUnit-IV Welding Processes of SuperalloysJ Jhansibai100% (1)

- Chem HHW Tip ChartDocument16 pagesChem HHW Tip ChartasdfghNo ratings yet

- 4 BiomoleculesDocument16 pages4 BiomoleculesSajeev S Chadayamangalam SajNo ratings yet

- R FR B1Document39 pagesR FR B1risnasilvi13No ratings yet

- Alkanes worksheet answersDocument3 pagesAlkanes worksheet answerswade aryanNo ratings yet

- Redox Practice Test 1Document21 pagesRedox Practice Test 1Edon BediNo ratings yet

- XI Chemistry Chapter Equilibrium Key ConceptsDocument10 pagesXI Chemistry Chapter Equilibrium Key ConceptsSridhar MarellaNo ratings yet

- Episode 11 - The MoleDocument2 pagesEpisode 11 - The MoleJawadNo ratings yet

- Saacke Gorionici SKVJDocument10 pagesSaacke Gorionici SKVJjalehaNo ratings yet

- Apcs 117Document12 pagesApcs 117Ilyas AhmedNo ratings yet

- RayonDocument9 pagesRayonRahul GuptaNo ratings yet

- DDC SVC Bro 0001 - 2018Document39 pagesDDC SVC Bro 0001 - 2018David PomaNo ratings yet

- CO2 To Methane ElectrochemDocument11 pagesCO2 To Methane ElectrochemalonsoNo ratings yet

- Din en 25817Document1 pageDin en 25817vietduchbkNo ratings yet

- Sugar IndustryDocument50 pagesSugar Industryzohaib ul hassanNo ratings yet

- ASTM A563 - Portland BoltDocument5 pagesASTM A563 - Portland BoltamrNo ratings yet

- SS in Sugar Industry - Mod PDFDocument11 pagesSS in Sugar Industry - Mod PDFNitinNo ratings yet

- Understanding Oil Gas BusinessDocument349 pagesUnderstanding Oil Gas BusinesslogicloverNo ratings yet

- PressureDocument84 pagesPressureHangloque GabanoNo ratings yet

- Experiment 13: Synthesis of Esters Via Nucleophilic Acyl SubstitutionDocument17 pagesExperiment 13: Synthesis of Esters Via Nucleophilic Acyl SubstitutionBianca VirtudasoNo ratings yet

- The Handling Hazards of Propellants Hypergolic With Hydrogen PeroxideDocument11 pagesThe Handling Hazards of Propellants Hypergolic With Hydrogen PeroxideВасилена ГеоргиеваNo ratings yet

- Daftar SingkatanDocument2 pagesDaftar SingkatanRahma YaniNo ratings yet

- Non-Metallic Inclusions in Steel Literature ReviewDocument11 pagesNon-Metallic Inclusions in Steel Literature ReviewPedro Lucas Menezes Lourenço100% (1)

- Carbohydrate Polymers: Feng Jiang, You-Lo HsiehDocument9 pagesCarbohydrate Polymers: Feng Jiang, You-Lo HsiehAaron WongNo ratings yet