Professional Documents

Culture Documents

ABS-M30: Real Production-Grade Thermoplastic

Uploaded by

qualityfreekOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

ABS-M30: Real Production-Grade Thermoplastic

Uploaded by

qualityfreekCopyright:

Available Formats

ABS-M30

for FORTUS 3D Production Systems 3D PRODUCTION SYSTEMS

ABS-M30 is up to 25-70 percent stronger than standard Stratasys ABS and is an

ideal material for conceptual modeling, functional prototyping, manufacturing

tools, and end-use-parts. ABS-M30 has greater tensile, impact, and flexural

strength than standard ABS. Layer bonding is significantly stronger than that of

standard ABS, for a more durable part. This results in more realistic functional

tests and higher quality parts for end use. When combined with a Fortus 3D

Production System, ABS-M30 gives you Real PartsTM that are stronger, smoother, r,

and with better feature detail.

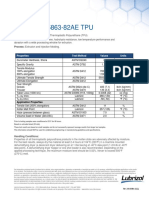

Mechanical Properties1 Test Method English Metric

Tensile Strength (Type 1, 0.125”, 0.2”/min) ASTM D638 5,200 psi 36 MPa

Tensile Modulus (Type 1, 0.125”, 0.2”/min) ASTM D638 350,000 psi 2,413 MPa

Tensile Elongation (Type 1, 0.125”, 0.2”/min) ASTM D638 4% 4%

Flexural Strength (Method 1, 0.05”/min) ASTM D790 8,800 psi 61 MPa

Flexural Modulus (Method 1, 0.05”/min) ASTM D790 336,000 psi 2,317 MPa

IZOD Impact, notched (Method A, 23°C) ASTM D256 2.6 ft-lb/in 139 J/m

IZOD Impact, un-notched (Method A, 23°C) ASTM D256 5.3 ft-lb/in 283 J/m

Thermal Properties3 Test Method English Metric

Heat Deflection (HDT) @ 66 psi, 0.125" unannealed ASTM D648 204°F 96°C

Heat Deflection (HDT) @ 264 psi, 0.125" unannealed ASTM D648 180°F 82°C

Vicat Softening Temp. (Rate B/50) ASTM D1525 210°F 99°C

Coefficient of Thermal Expansion (flow) ASTM E831 4.9E-05 in/in/°F 8.82E-05 mm/mm/°C

Coefficient of Thermal Expansion (xflow) ASTM E831 4.7E-05 in/in/°F 8.46E-05 mm/mm/°C

Glass Transition (Tg) DSC (SSYS) 226°F 108°C

2

Melt Point --------- Not Applicable Not Applicable2

Other3 Test Method Value X See reverse for

color options and

Specific Gravity ASTM D792 1.04

system availability.

Flame Classification UL94 HB (0.06", 1.5 mm)

Rockwell Hardness ASTM D785 109.5

Dielectric Strength IEC 60112 28.0 kV/mm

The information presented are typical values intended for reference and comparison purposes only. They should not be used for design specifications or quality control

purposes. End-use material performance can be impacted (+/-) by, but not limited to, part design, end-use conditions, test conditions, etc. Actual values will vary with build

conditions. Tested parts were built on Fortus 400mc @ 0.010” (0.254 mm) slice. Product specifications are subject to change without notice.

1

Build orientation is on side long edge. 2 Due to amorphous nature, material does not display a melting point. 3 Literature value unless otherwise noted.

REAL PRODUCTION-GRADE THERMOPLASTIC

ABS-M30

At the core:

System Availability Layer Thickness Capability Support Structure Available Colors ®

Advanced FDM technology

Fortus 360mc 0.013 inch (0.330 mm) Soluble Supports Ivory Fortus systems are based on

Fortus 400mc 0.010 inch (0.254 mm) White patented Stratasys FDM —

Fortus 900mc 0.007 inch (0.178 mm) Black Fused Deposition Modeling —

0.005 inch (0.127 mm)1 Dark Grey technology. FDM is the industry’s

Red leading additive fabrication

Blue technology, and the only one

that uses production grade

thermoplastics, enabling the most

1

0.005 inch (0.127 mm) layer thickness not available for Fortus 900mc durable parts.

Fortus systems use a wide range

of thermoplastics with advanced

mechanical properties so your

parts can endure high heat,

caustic chemicals, sterilization,

and high impact applications.

No special facilities needed

You can install a Fortus 3D

Production System just about

anywhere. No special venting

is required because Fortus

systems don’t produce noxious

fumes, chemicals, or waste.

No special skills needed

Fortus 3D Production Systems

are easy to operate and maintain

compared to other additive

fabrication systems because there

are no messy powders or resins

to handle and contain. They’re

so simple, an operator can be

trained to operate a Fortus

system in less than 30 minutes.

Get your benchmark on the

future of manufacturing

Fine details. Smooth surface

finishes. Accuracy. Strength. The

best way to see the advantages of

a Fortus 3D Production System is

to have your own part built on a

Fortus system. Get your free part at:

www.fortus.com/benchmark.

For more information about Fortus systems, materials and applications, call 888.480.3548 or visit www.fortus.com

Fortus 3D Production Systems Fortus 3D Production Systems

Stratasys Incorporated Stratasys GmbH

7665 Commerce Way Weismüllerstrasse 27

Eden Prairie, MN 55344 60314 Frankfurt am Main

+1 888 480 3548 (US Toll Free) Germany

+1 952 937 3000 +49 69 420 994 30 (Tel)

+1 952 937 0070 (Fax) +49 69 420 994 333 (Fax)

www.stratasys.com www.stratasys.com

info@stratasys.com europe@stratasys.com

©2009 Stratasys Inc. All rights reserved. Stratasys and FDM are registered trademarks and Fortus, Real Parts, Fortus 200mc, Fortus 360mc,

Fortus 400mc, Fortus 900mc, Insight, Control Center and FDM TEAM are trademarks of Stratasys Inc., registered in the United States and

other countries. *ULTEM 9085 is a trademark of SABIC Innovative Plastics IP BV. All other trademarks are the property of their respective

owners. Product specifications subject to change without notice. Printed in the USA. MS-ABS-M30 02/09

You might also like

- Microstructure Evolution in Metal Forming Processes (2012)Document2 pagesMicrostructure Evolution in Metal Forming Processes (2012)MedSparkNo ratings yet

- Manufacturing Processes and Materials ExercisesDocument2 pagesManufacturing Processes and Materials ExercisesMedSparkNo ratings yet

- ABS-M30i: Production-Grade Thermoplastic For Fortus 3D PrintersDocument2 pagesABS-M30i: Production-Grade Thermoplastic For Fortus 3D PrinterskaledioskoppNo ratings yet

- PC Abs Spec SheetDocument2 pagesPC Abs Spec SheetAli YudiNo ratings yet

- PC (Polycarbonate) : Production-Grade Thermoplastic For Fortus 3D PrintersDocument2 pagesPC (Polycarbonate) : Production-Grade Thermoplastic For Fortus 3D PrinterskaledioskoppNo ratings yet

- PC (Polycarbonate) : Production-Grade Thermoplastic For Fortus 3D Production SystemsDocument2 pagesPC (Polycarbonate) : Production-Grade Thermoplastic For Fortus 3D Production SystemsvassaNo ratings yet

- Stratasys - MSS FDM ABSplusP430Document2 pagesStratasys - MSS FDM ABSplusP430feltofsnakeNo ratings yet

- ABS-M30: Production-Grade Thermoplastic For FDM 3D PrintersDocument2 pagesABS-M30: Production-Grade Thermoplastic For FDM 3D PrintersSINo ratings yet

- Spec Sheet - ABS-M30 ENDocument2 pagesSpec Sheet - ABS-M30 ENTUSHAR BANGERANo ratings yet

- Absplus-P430: Production-Grade Thermoplastic For 3D PrintersDocument2 pagesAbsplus-P430: Production-Grade Thermoplastic For 3D PrinterscontrolorNo ratings yet

- Polycarbonate-ABS Blend (PC-ABS) : Mechanical Properties Test Method Imperial MetricDocument1 pagePolycarbonate-ABS Blend (PC-ABS) : Mechanical Properties Test Method Imperial MetricIsabel Narloch CardosoNo ratings yet

- ULTEM 9085: Production-Grade Thermoplastic For Fortus 3D PrintersDocument3 pagesULTEM 9085: Production-Grade Thermoplastic For Fortus 3D PrintersRui MatiasNo ratings yet

- Pc-Iso: Mechanical Properties Test Method ValueDocument2 pagesPc-Iso: Mechanical Properties Test Method ValuekaledioskoppNo ratings yet

- Infino Pc-Abs Hp1000xa (Natural)Document1 pageInfino Pc-Abs Hp1000xa (Natural)Rhekron PlasticsNo ratings yet

- 01.03.02.106 Spesifikasi-SOLMAX THA HDPE 2.00mm Black Smooth - 1084285 (HDS-200LM)Document1 page01.03.02.106 Spesifikasi-SOLMAX THA HDPE 2.00mm Black Smooth - 1084285 (HDS-200LM)Aswin MustaminNo ratings yet

- Ninjaflex 3D Printing Filament: Flexible Polyurethane Material For FDM PrintersDocument1 pageNinjaflex 3D Printing Filament: Flexible Polyurethane Material For FDM PrinterssrikanthNo ratings yet

- Delrin100 NC10Document2 pagesDelrin100 NC10avinashchauhan2695No ratings yet

- Tds Ecozen t110gDocument1 pageTds Ecozen t110galfred quinNo ratings yet

- Polygomma EPDM Roofing Membrane CatalogueDocument4 pagesPolygomma EPDM Roofing Membrane Cataloguepolygomma Industries Pvt. LtdNo ratings yet

- Filament Specifications Unit ValueDocument4 pagesFilament Specifications Unit ValueRoberto Gonzalo PelazNo ratings yet

- Performance Test Report - Novaguard 890 PDFDocument2 pagesPerformance Test Report - Novaguard 890 PDFPeter Callán100% (1)

- TPU 95A Technical Data SheetDocument3 pagesTPU 95A Technical Data SheetSteven DonosoNo ratings yet

- POM Delrin 900 HFDocument2 pagesPOM Delrin 900 HFcountzeroaslNo ratings yet

- POM Delrin 500CLDocument2 pagesPOM Delrin 500CLcountzeroaslNo ratings yet

- TDS CPE V3.010-EnDocument3 pagesTDS CPE V3.010-EnspicefooNo ratings yet

- Lexan™ 8010 Uncoated Polished Film DatasheetDocument3 pagesLexan™ 8010 Uncoated Polished Film DatasheetTeng Yan ChanNo ratings yet

- PP Homopolymer for Spunbond FibersDocument1 pagePP Homopolymer for Spunbond FibersMohit MohataNo ratings yet

- Pellethane 5863-82AE TPU: Technical Data SheetDocument2 pagesPellethane 5863-82AE TPU: Technical Data SheetaNo ratings yet

- Ficha Tecnica Um180821 Tds Tough Pla RB v11Document3 pagesFicha Tecnica Um180821 Tds Tough Pla RB v11Servirol CiaNo ratings yet

- PORON 4701-50 Firm - Supported MaterialsDocument2 pagesPORON 4701-50 Firm - Supported MaterialsLayeeq AhmedNo ratings yet

- Dupont Fr50 Nc010 2Document2 pagesDupont Fr50 Nc010 2mariano310570No ratings yet

- PC Lexan 3412R 20% GL - IdesDocument5 pagesPC Lexan 3412R 20% GL - IdescountzeroaslNo ratings yet

- CEFOR™ 1221P: Linear Low Density Polyethylene ResinDocument3 pagesCEFOR™ 1221P: Linear Low Density Polyethylene ResincuppycuppycupNo ratings yet

- PA 66 Zytel 101Document2 pagesPA 66 Zytel 101countzeroaslNo ratings yet

- Estane 58887Document2 pagesEstane 58887M J VoraNo ratings yet

- Mirafi-500X PDSDocument1 pageMirafi-500X PDSLarry Wayne Sumpter, JrNo ratings yet

- Lexan 925u ResinDocument2 pagesLexan 925u ResinAndrNo ratings yet

- Filament Specifications Unit ValueDocument4 pagesFilament Specifications Unit ValueRoberto Gonzalo PelazNo ratings yet

- Propriedades Das Matrizes PolimericasDocument7 pagesPropriedades Das Matrizes PolimericasllepsterlNo ratings yet

- Duraform Pa Plastic: General Properties FeaturesDocument2 pagesDuraform Pa Plastic: General Properties FeaturesMarouane MbarkiNo ratings yet

- Certene™ Llgf-220A: Muehlstein - Linear Low Density PolyethyleneDocument1 pageCertene™ Llgf-220A: Muehlstein - Linear Low Density PolyethyleneRoberto De Mesa PNo ratings yet

- 1120192 Technical Data SheetDocument1 page1120192 Technical Data SheetSilversnape00No ratings yet

- ThermaCool Gap Filler BRO 1372Document8 pagesThermaCool Gap Filler BRO 1372xingdrewNo ratings yet

- Mirafi S800: Gai-LapDocument1 pageMirafi S800: Gai-LapRamiro ChambiNo ratings yet

- Lldpe Series 1.50MM Black TexturedDocument2 pagesLldpe Series 1.50MM Black TexturedBexy Nathaly DiazNo ratings yet

- DOWLEX™ 2038.68G: Polyethylene ResinDocument3 pagesDOWLEX™ 2038.68G: Polyethylene ResinJosé PalmaNo ratings yet

- DOW™ Butene 1220P: Polyethylene ResinDocument1 pageDOW™ Butene 1220P: Polyethylene Resinvantuan17792No ratings yet

- Technical Data Sheet PC: Filament SpecificationsDocument3 pagesTechnical Data Sheet PC: Filament SpecificationsVladimir SarmientoNo ratings yet

- Filament Specifications Unit Value: All 3D Printed Parts Printed at 100% Infill and Annealed at 110ºC/20 MinDocument4 pagesFilament Specifications Unit Value: All 3D Printed Parts Printed at 100% Infill and Annealed at 110ºC/20 MinRoberto Gonzalo PelazNo ratings yet

- Armadillo TDSDocument1 pageArmadillo TDSPIETRO DAVID DE LUCANo ratings yet

- 3M Heavy Wall Heat Shrink Tubing ITCSNDocument4 pages3M Heavy Wall Heat Shrink Tubing ITCSNmuahdibNo ratings yet

- PP PP9074MED DatasheetDocument1 pagePP PP9074MED DatasheetDiogo SouzaNo ratings yet

- Mitsubishi Chemical Advanced Materials Acetron ® LSG POM-C Copolymer Acetal, Porosity-Free, Unfilled, ExtrudedDocument2 pagesMitsubishi Chemical Advanced Materials Acetron ® LSG POM-C Copolymer Acetal, Porosity-Free, Unfilled, ExtrudedJuan Orlando Loaiza MurilloNo ratings yet

- LS PEKK CF HT23 Material Datasheet 201705Document1 pageLS PEKK CF HT23 Material Datasheet 201705Angel LagrañaNo ratings yet

- JUNE2020 Transparent Noise Barrier Technical Datasheet Final ReducedDocument2 pagesJUNE2020 Transparent Noise Barrier Technical Datasheet Final Reducedionut cerneaNo ratings yet

- CPVC Geon PM280Document1 pageCPVC Geon PM280angelokyoNo ratings yet

- Pultruded Composites Material Property ComparisonDocument5 pagesPultruded Composites Material Property ComparisonJohn WycliffeNo ratings yet

- Scotch Heavy Duty Mining Tape 31: Data Sheet June 2013Document2 pagesScotch Heavy Duty Mining Tape 31: Data Sheet June 2013Kishan MohtaNo ratings yet

- Ube Nylon 5034bDocument1 pageUbe Nylon 5034bDiegoTierradentroNo ratings yet

- UntitledDocument78 pagesUntitledqualityfreekNo ratings yet

- Hitepaper: Tooling Applications With Eosint MDocument9 pagesHitepaper: Tooling Applications With Eosint MqualityfreekNo ratings yet

- Ti64 PDFDocument5 pagesTi64 PDFqualityfreekNo ratings yet

- Getting Started With Content Marketing: Year One: EngineersDocument18 pagesGetting Started With Content Marketing: Year One: EngineersGustavo SotoNo ratings yet

- Ninjaflex 3D Printing Filament: Flexible Polyurethane Material For FDM PrintersDocument1 pageNinjaflex 3D Printing Filament: Flexible Polyurethane Material For FDM PrinterssrikanthNo ratings yet

- Ceramics PDFDocument5 pagesCeramics PDFqualityfreekNo ratings yet

- ABS-M30: Production-Grade ThermoplasticDocument2 pagesABS-M30: Production-Grade ThermoplasticqualityfreekNo ratings yet

- NiAll-IN625-M270 Material Data Sheet 10-11 en PDFDocument5 pagesNiAll-IN625-M270 Material Data Sheet 10-11 en PDFqualityfreekNo ratings yet

- Material Data Sheet: ApplicationDocument2 pagesMaterial Data Sheet: ApplicationqualityfreekNo ratings yet

- ABS - P430: Production-Grade Thermoplastic For Design Series 3D PrintersDocument2 pagesABS - P430: Production-Grade Thermoplastic For Design Series 3D PrintersqualityfreekNo ratings yet

- Eosint Technology For Direct Metal Laser-Sintering (DMLS)Document53 pagesEosint Technology For Direct Metal Laser-Sintering (DMLS)qualityfreekNo ratings yet

- Material Data Sheet: ApplicationDocument2 pagesMaterial Data Sheet: ApplicationqualityfreekNo ratings yet

- Lightweight Metal Cellular Structures via 3D Printing and CastingDocument15 pagesLightweight Metal Cellular Structures via 3D Printing and CastingqualityfreekNo ratings yet

- Guidelines-3D DesignDocument3 pagesGuidelines-3D DesignqualityfreekNo ratings yet

- DS Accura 25 USDocument2 pagesDS Accura 25 USqualityfreekNo ratings yet

- Accura Clearvue US PDFDocument2 pagesAccura Clearvue US PDFqualityfreekNo ratings yet

- DMLS AdvantagesDocument7 pagesDMLS AdvantagesqualityfreekNo ratings yet

- KGK Galeta Raos SomolanjiDocument12 pagesKGK Galeta Raos SomolanjiRajeev BujjiNo ratings yet

- A Designer'S Guide For Dimensioning and Tolerancing Sls PartsDocument11 pagesA Designer'S Guide For Dimensioning and Tolerancing Sls PartsqualityfreekNo ratings yet

- Safety Data Sheet Loctite Super Glue Liquid: 1 Identification of The Substance/Preparation and Company/UndertakingDocument4 pagesSafety Data Sheet Loctite Super Glue Liquid: 1 Identification of The Substance/Preparation and Company/UndertakingqualityfreekNo ratings yet

- Zeus Sterilization Parameters Plastic SelectionDocument7 pagesZeus Sterilization Parameters Plastic Selectionjitendertalwar1603No ratings yet

- KGK Galeta Raos SomolanjiDocument12 pagesKGK Galeta Raos SomolanjiRajeev BujjiNo ratings yet

- Optimization of Scale Factors PDFDocument3 pagesOptimization of Scale Factors PDFqualityfreekNo ratings yet

- Improvement of SLS Part AccuracyDocument11 pagesImprovement of SLS Part AccuracyqualityfreekNo ratings yet

- Surface RoughnessDocument14 pagesSurface RoughnessqualityfreekNo ratings yet

- KEENSERT Installation Guide PDFDocument2 pagesKEENSERT Installation Guide PDFqualityfreekNo ratings yet

- Study On Curve of Pe-Heating Temperature Control in Selective Laser SinteringDocument3 pagesStudy On Curve of Pe-Heating Temperature Control in Selective Laser SinteringqualityfreekNo ratings yet

- Ssurface Finish of SLS Using A RobotDocument10 pagesSsurface Finish of SLS Using A RobotqualityfreekNo ratings yet

- First Balfour Silo 2 Proposed CostingDocument6 pagesFirst Balfour Silo 2 Proposed CostingMark Roger II HuberitNo ratings yet

- Bob Engnath On QsteelqDocument6 pagesBob Engnath On QsteelqJason BowmanNo ratings yet

- Time To Failure For Concrete Exposed To Severe Sulfate AttackDocument7 pagesTime To Failure For Concrete Exposed To Severe Sulfate AttackTomás Venegas PardoNo ratings yet

- B111B111M-11 Standard Specification For Copper and Copper-Alloy Seamless Condenser Tubes and Ferrule StockDocument12 pagesB111B111M-11 Standard Specification For Copper and Copper-Alloy Seamless Condenser Tubes and Ferrule StockSalma FarooqNo ratings yet

- BS en 12540-2000 PDFDocument26 pagesBS en 12540-2000 PDFpham khietNo ratings yet

- Metal Finishing Guidebook-08Document772 pagesMetal Finishing Guidebook-08monica100% (1)

- Poultry Cost Estimates - 01Document10 pagesPoultry Cost Estimates - 01Joseph RoyNo ratings yet

- Domestic Cold Water Supply System EssentialsDocument23 pagesDomestic Cold Water Supply System EssentialsRhey LuceroNo ratings yet

- Detailed Cost Breakdown for Irrigation Department Building ProjectDocument7 pagesDetailed Cost Breakdown for Irrigation Department Building ProjectMariam MustafaNo ratings yet

- Transparent Level GaugesDocument4 pagesTransparent Level GaugesAlfonso BlancoNo ratings yet

- Everything You Need to Know About PozzolansDocument19 pagesEverything You Need to Know About Pozzolansdavidborg8No ratings yet

- Study of Cracks in Buildings: January 2009Document15 pagesStudy of Cracks in Buildings: January 2009sharathr22No ratings yet

- Types of Building FramesDocument23 pagesTypes of Building FramesimaniNo ratings yet

- Marces Osmeña General SpecificationsDocument5 pagesMarces Osmeña General SpecificationsAlexander Osmeña IINo ratings yet

- LMI C Series ManualDocument2 pagesLMI C Series ManualBenjamin MillerNo ratings yet

- Stainless Steel Structure Design HandbookDocument20 pagesStainless Steel Structure Design Handbookgnino2No ratings yet

- MS Project 2013Document42 pagesMS Project 2013jasekan.dcNo ratings yet

- DPWH PRICE MATRIX 1st QuarterDocument264 pagesDPWH PRICE MATRIX 1st QuarterLauro LagoNo ratings yet

- Xiameter OFS-6020 Silane: Diaminofunctional Silane Features ApplicationsDocument2 pagesXiameter OFS-6020 Silane: Diaminofunctional Silane Features ApplicationsDelovita GintingNo ratings yet

- UL Listing July 2011Document2 pagesUL Listing July 2011Imran Mughle AzamNo ratings yet

- Wooden Windows CatalogueDocument17 pagesWooden Windows CatalogueVIJAY VATSALNo ratings yet

- TDS Greentech Chemguard 400 Top CoatDocument1 pageTDS Greentech Chemguard 400 Top Coatnguyen hoang AnhNo ratings yet

- BPCL - 221019 PDFDocument55 pagesBPCL - 221019 PDFMaymole Boben100% (1)

- WAHANA wholesale -C- product listingDocument104 pagesWAHANA wholesale -C- product listingLailin Tryskadhana IINo ratings yet

- SV5 Safety Valve-Installation Maintenance ManualDocument12 pagesSV5 Safety Valve-Installation Maintenance ManualGOKUL PRASADNo ratings yet

- ROCA BATHROOM PRODUCTS CATALOGUEDocument87 pagesROCA BATHROOM PRODUCTS CATALOGUEHiland Group100% (1)

- HIgh Strength High-Performance Concrete For Marine EnvironmentDocument8 pagesHIgh Strength High-Performance Concrete For Marine EnvironmentdsmnnangNo ratings yet

- Cement BoardDocument5 pagesCement BoardYsabella May Sarthou CervantesNo ratings yet

- Al Chris BoqDocument35 pagesAl Chris BoqYhan SaludoNo ratings yet

- MS 01 62Document5 pagesMS 01 62Jayesh BaldotaNo ratings yet

- ChatGPT Side Hustles 2024 - Unlock the Digital Goldmine and Get AI Working for You Fast with More Than 85 Side Hustle Ideas to Boost Passive Income, Create New Cash Flow, and Get Ahead of the CurveFrom EverandChatGPT Side Hustles 2024 - Unlock the Digital Goldmine and Get AI Working for You Fast with More Than 85 Side Hustle Ideas to Boost Passive Income, Create New Cash Flow, and Get Ahead of the CurveNo ratings yet

- Algorithms to Live By: The Computer Science of Human DecisionsFrom EverandAlgorithms to Live By: The Computer Science of Human DecisionsRating: 4.5 out of 5 stars4.5/5 (722)

- Defensive Cyber Mastery: Expert Strategies for Unbeatable Personal and Business SecurityFrom EverandDefensive Cyber Mastery: Expert Strategies for Unbeatable Personal and Business SecurityRating: 5 out of 5 stars5/5 (1)

- Cyber War: The Next Threat to National Security and What to Do About ItFrom EverandCyber War: The Next Threat to National Security and What to Do About ItRating: 3.5 out of 5 stars3.5/5 (66)

- CompTIA Security+ Get Certified Get Ahead: SY0-701 Study GuideFrom EverandCompTIA Security+ Get Certified Get Ahead: SY0-701 Study GuideRating: 5 out of 5 stars5/5 (2)

- ChatGPT Millionaire 2024 - Bot-Driven Side Hustles, Prompt Engineering Shortcut Secrets, and Automated Income Streams that Print Money While You Sleep. The Ultimate Beginner’s Guide for AI BusinessFrom EverandChatGPT Millionaire 2024 - Bot-Driven Side Hustles, Prompt Engineering Shortcut Secrets, and Automated Income Streams that Print Money While You Sleep. The Ultimate Beginner’s Guide for AI BusinessNo ratings yet

- Scary Smart: The Future of Artificial Intelligence and How You Can Save Our WorldFrom EverandScary Smart: The Future of Artificial Intelligence and How You Can Save Our WorldRating: 4.5 out of 5 stars4.5/5 (55)

- Chip War: The Quest to Dominate the World's Most Critical TechnologyFrom EverandChip War: The Quest to Dominate the World's Most Critical TechnologyRating: 4.5 out of 5 stars4.5/5 (227)

- Digital Gold: Bitcoin and the Inside Story of the Misfits and Millionaires Trying to Reinvent MoneyFrom EverandDigital Gold: Bitcoin and the Inside Story of the Misfits and Millionaires Trying to Reinvent MoneyRating: 4 out of 5 stars4/5 (51)

- Reality+: Virtual Worlds and the Problems of PhilosophyFrom EverandReality+: Virtual Worlds and the Problems of PhilosophyRating: 4 out of 5 stars4/5 (24)

- Chaos Monkeys: Obscene Fortune and Random Failure in Silicon ValleyFrom EverandChaos Monkeys: Obscene Fortune and Random Failure in Silicon ValleyRating: 3.5 out of 5 stars3.5/5 (111)

- Generative AI: The Insights You Need from Harvard Business ReviewFrom EverandGenerative AI: The Insights You Need from Harvard Business ReviewRating: 4.5 out of 5 stars4.5/5 (2)

- The Infinite Machine: How an Army of Crypto-Hackers Is Building the Next Internet with EthereumFrom EverandThe Infinite Machine: How an Army of Crypto-Hackers Is Building the Next Internet with EthereumRating: 3 out of 5 stars3/5 (12)

- The Intel Trinity: How Robert Noyce, Gordon Moore, and Andy Grove Built the World's Most Important CompanyFrom EverandThe Intel Trinity: How Robert Noyce, Gordon Moore, and Andy Grove Built the World's Most Important CompanyNo ratings yet

- ChatGPT Money Machine 2024 - The Ultimate Chatbot Cheat Sheet to Go From Clueless Noob to Prompt Prodigy Fast! Complete AI Beginner’s Course to Catch the GPT Gold Rush Before It Leaves You BehindFrom EverandChatGPT Money Machine 2024 - The Ultimate Chatbot Cheat Sheet to Go From Clueless Noob to Prompt Prodigy Fast! Complete AI Beginner’s Course to Catch the GPT Gold Rush Before It Leaves You BehindNo ratings yet

- The Simulated Multiverse: An MIT Computer Scientist Explores Parallel Universes, The Simulation Hypothesis, Quantum Computing and the Mandela EffectFrom EverandThe Simulated Multiverse: An MIT Computer Scientist Explores Parallel Universes, The Simulation Hypothesis, Quantum Computing and the Mandela EffectRating: 4.5 out of 5 stars4.5/5 (20)

- The E-Myth Revisited: Why Most Small Businesses Don't Work andFrom EverandThe E-Myth Revisited: Why Most Small Businesses Don't Work andRating: 4.5 out of 5 stars4.5/5 (709)

- Invent and Wander: The Collected Writings of Jeff Bezos, With an Introduction by Walter IsaacsonFrom EverandInvent and Wander: The Collected Writings of Jeff Bezos, With an Introduction by Walter IsaacsonRating: 4.5 out of 5 stars4.5/5 (123)

- AI Superpowers: China, Silicon Valley, and the New World OrderFrom EverandAI Superpowers: China, Silicon Valley, and the New World OrderRating: 4.5 out of 5 stars4.5/5 (398)

- Blood, Sweat, and Pixels: The Triumphant, Turbulent Stories Behind How Video Games Are MadeFrom EverandBlood, Sweat, and Pixels: The Triumphant, Turbulent Stories Behind How Video Games Are MadeRating: 4.5 out of 5 stars4.5/5 (335)