Professional Documents

Culture Documents

Process Evaluation Assignment ISEN4821. F2020: Assignment: A Case Study in Process Analysis and Design

Process Evaluation Assignment ISEN4821. F2020: Assignment: A Case Study in Process Analysis and Design

Uploaded by

Faisal Saleh RazaOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Process Evaluation Assignment ISEN4821. F2020: Assignment: A Case Study in Process Analysis and Design

Process Evaluation Assignment ISEN4821. F2020: Assignment: A Case Study in Process Analysis and Design

Uploaded by

Faisal Saleh RazaCopyright:

Available Formats

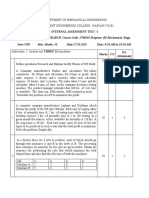

Process Evaluation Assignment

ISEN4821. F2020

Assignment: A case Study in Process Analysis and Design

Product A is formed by assembling three parts (P1, P2, and P3) together. All three

parts are manufactured by Alodine corp. The Co. ships the product unassembled to

the customers. Only three types of machines (M1, M2, and M3) are used in the

manufacturing operations. Parts P1 and P2 are made of plastics and weight 0.8 and

0.4 lbs. each respectively. Part P3 is made of aluminum and weigh 0.5 lbs. Based

on The Sales Department estimates, demand for the product in the next 5 to 10 years

will be about 15000 units per month. In addition, the following manufacturing data

is made available:

Product Sequence of % Scrap % Scrap %Scrap

machines From M1 From M2 From M3

P1 M2➔ M3 3 2 3

P2 M1➔ M3 0.5 1.2 2

P3 M1➔M2➔M3 0.09 0.06 0.04

Standard Time:

Machine ➔ M1 M2 M3

Standard Times (hrs./unit) ➔ 0.04 0.07 0.09

What is needed?

The company intends to produce each product at least once a week. This will avoid buildup of

large inventories of parts. On the basis of the following assumptions determine:

1). Number of machines of each type required.

2). Total amount (lbs) of scrap produced/week.

3). Number of workers required.

4). Bill of Material and a complete process flow chart

ASSUMPTIONS:

a). One year of work means; 8 hrs./day, 5days/week, and 50 weeks/year.

b). Set-up times are: 60 min., 60 min., and 90 min. for M1, M2, and M3 respective

c). Machine availability (for all three machines) is 90% of time.

d). M2 and M3 each need 1 operator, but M1 needs two Operators. The operators are needed only

when machines are operating.

e). The Co. desires to minimize the number of machines required for the operations (minimum

initial investment). On that basis you may plan to use up to 20% overtime.

d). Labor cost per finished unit of the product

You might also like

- Assignment The University of Liverpool Management School: Deadline: Lateness PenaltyDocument4 pagesAssignment The University of Liverpool Management School: Deadline: Lateness PenaltyAnas Hassan0% (1)

- Answer Key - LP-Application - Operations PDFDocument17 pagesAnswer Key - LP-Application - Operations PDFAnand Dharun0% (1)

- Mpy315 FinalDocument21 pagesMpy315 FinalCharles ChivengahNo ratings yet

- OR Assignments 29072018 054510PMDocument26 pagesOR Assignments 29072018 054510PMReema Catherine MathewNo ratings yet

- M/s Ram Krishna CNC Shop Problem Statement: Group AssignmentDocument7 pagesM/s Ram Krishna CNC Shop Problem Statement: Group AssignmentMoidin AfsanNo ratings yet

- PM QBDocument7 pagesPM QBmayur_mechNo ratings yet

- Course: OERATIONS RESEARCH Course Code: 17ME81 Program: BE Mechanical Engg. Sem - VIII Max. Marks: 30 Date:27.05.2020 Time: 9:30 AM To 10:30 AMDocument2 pagesCourse: OERATIONS RESEARCH Course Code: 17ME81 Program: BE Mechanical Engg. Sem - VIII Max. Marks: 30 Date:27.05.2020 Time: 9:30 AM To 10:30 AMLokesh Lokesh D SNo ratings yet

- ME3201Document4 pagesME3201Md. Tariqul Islam MunnaNo ratings yet

- Assignment-1 LPPDocument1 pageAssignment-1 LPPvivek singhNo ratings yet

- On Aggregate PlanningDocument13 pagesOn Aggregate PlanningMahakNo ratings yet

- Assignment 02 Mech495-202428CodingandScheduling29Document3 pagesAssignment 02 Mech495-202428CodingandScheduling29adelNo ratings yet

- AssignmentDocument1 pageAssignmentvivek singhNo ratings yet

- LP Formulation SheetDocument5 pagesLP Formulation Sheetmohamed hossamNo ratings yet

- 1Document5 pages1EndayenewMolla88% (16)

- Manipal Institute of Technology: Department of Printing & Media EngineeringDocument4 pagesManipal Institute of Technology: Department of Printing & Media Engineeringdreamivory29No ratings yet

- B-Tech4191r07i 3Document11 pagesB-Tech4191r07i 3jbj2121No ratings yet

- LP-Application Operations PDFDocument14 pagesLP-Application Operations PDFAnand DharunNo ratings yet

- Production Planning LPP CaseDocument2 pagesProduction Planning LPP Caserinkirola7576No ratings yet

- Lab Evaluation 2019Document2 pagesLab Evaluation 2019divyanshgr07No ratings yet

- Central University of Kerala: "Linear Programming"Document19 pagesCentral University of Kerala: "Linear Programming"Zea ZakeNo ratings yet

- Problems: Section Assigned Problems 8.1 8-1 To 8-11 8.2.1 8-12 To 8-21 8.2.2 8-22 To 8-25Document5 pagesProblems: Section Assigned Problems 8.1 8-1 To 8-11 8.2.1 8-12 To 8-21 8.2.2 8-22 To 8-25siti nurmilaNo ratings yet

- Linear Programming AssignmentDocument5 pagesLinear Programming AssignmentLakshya GargNo ratings yet

- Quantitative Methods For Decision Taking 2023 - Problem Collection (Enunciados)Document6 pagesQuantitative Methods For Decision Taking 2023 - Problem Collection (Enunciados)1537701No ratings yet

- Operations Research QP April 2021Document3 pagesOperations Research QP April 2021Nihar ShahNo ratings yet

- Linear Programming 01Document4 pagesLinear Programming 01Dinesh PriyangaNo ratings yet

- Model Project Proposal3Document21 pagesModel Project Proposal3Suresh AMNo ratings yet

- Master examUE6 2020Document3 pagesMaster examUE6 2020Mohamed LaalouNo ratings yet

- QAMD Tena QuestionsDocument21 pagesQAMD Tena QuestionsCheru TerefeNo ratings yet

- VL2019201001189 DaDocument1 pageVL2019201001189 DaAniket LunkerNo ratings yet

- HW 01Document7 pagesHW 01TibelchNo ratings yet

- Or PracticeProblems 2015Document24 pagesOr PracticeProblems 2015Hi HuNo ratings yet

- Operations Research VII SEMESTER (18ME735) Module - 5: Department of Collegiate and Technical EducationDocument29 pagesOperations Research VII SEMESTER (18ME735) Module - 5: Department of Collegiate and Technical Educationjhansi lakshmiNo ratings yet

- Tutorial Sheet-1 PDFDocument2 pagesTutorial Sheet-1 PDFJapanjOt SinGhNo ratings yet

- SRM Institute of Science and Technology Ramapuram Campus: Even Semester 2021 - 2022Document2 pagesSRM Institute of Science and Technology Ramapuram Campus: Even Semester 2021 - 2022Ramesh RNo ratings yet

- 10 MovementDocument26 pages10 MovementjvanandhNo ratings yet

- CMA Final Paper-9 Study Note 4 & 6: Operations ResearchDocument35 pagesCMA Final Paper-9 Study Note 4 & 6: Operations ResearchSaksham KhuranaNo ratings yet

- DS II Packet 2Document31 pagesDS II Packet 2NitishNo ratings yet

- Production & Operation ManagementDocument8 pagesProduction & Operation ManagementavinashhbeheraNo ratings yet

- An Analysis of Total Productive Maintenance (TPM) Using Total Production Ratio (TPR) Method On Alumuinum Die Casting Products in PT XYZDocument7 pagesAn Analysis of Total Productive Maintenance (TPM) Using Total Production Ratio (TPR) Method On Alumuinum Die Casting Products in PT XYZInternational Journal of Innovative Science and Research TechnologyNo ratings yet

- Project ReportDocument22 pagesProject ReportAnish RohillaNo ratings yet

- SEQUENCINGDocument34 pagesSEQUENCINGmayureshk776No ratings yet

- Final Exam QMS NewDocument2 pagesFinal Exam QMS Newtadesse fissehaNo ratings yet

- Heavy Mechanical ComplexDocument67 pagesHeavy Mechanical ComplexSyed Bukhari100% (1)

- QAMD - Work Sheet (SC)Document19 pagesQAMD - Work Sheet (SC)Tesfu100% (1)

- LP Modelling PbsDocument5 pagesLP Modelling PbsKeith D'souzaNo ratings yet

- Amity University HaryanaDocument3 pagesAmity University Haryananidhi malikNo ratings yet

- Musco StampDocument23 pagesMusco StampRavi UpadhyeNo ratings yet

- Assignment (40%) : A) Formulate The Problem As LPM B) Solve The LPM Using Simplex AlgorithmDocument5 pagesAssignment (40%) : A) Formulate The Problem As LPM B) Solve The LPM Using Simplex Algorithmet100% (1)

- Unit - II: Sequencing Problems Johnson's RuleDocument30 pagesUnit - II: Sequencing Problems Johnson's RuleRakib KhanNo ratings yet

- Perodua Presentation. 26 April 2012Document53 pagesPerodua Presentation. 26 April 2012Nisa Shahril100% (4)

- 302 Decision Science Question - PaperDocument3 pages302 Decision Science Question - Paperajay taleNo ratings yet

- OR Question BankDocument29 pagesOR Question BankSuhas Mv50% (4)

- Sheet 1 PDFDocument2 pagesSheet 1 PDFIniyan I TNo ratings yet

- Training Report 1Document39 pagesTraining Report 1M samirNo ratings yet

- El459 Operations Research 2018 2Document5 pagesEl459 Operations Research 2018 2ChelseaNo ratings yet

- MFS Unit No 4 Numerical FinalDocument2 pagesMFS Unit No 4 Numerical Finalcpt.ghostNo ratings yet

- How Do I Group Them?: E212 - Facilities Planning and DesignDocument51 pagesHow Do I Group Them?: E212 - Facilities Planning and DesignMohamed HassanNo ratings yet

- Shree Swami Atmanand Saraswati Institute of Technology: Subject: OR (2171901) Class: 7 Sem. (Mech)Document7 pagesShree Swami Atmanand Saraswati Institute of Technology: Subject: OR (2171901) Class: 7 Sem. (Mech)VIPULNo ratings yet

- Engineering Applications: A Project Resource BookFrom EverandEngineering Applications: A Project Resource BookRating: 2.5 out of 5 stars2.5/5 (1)

- CIM – Mechanical Aspects: State of the Art ReportFrom EverandCIM – Mechanical Aspects: State of the Art ReportGareth EvansNo ratings yet

- Operations Research 1Document9 pagesOperations Research 1Faisal Saleh RazaNo ratings yet

- Tutorial. Process DesignDocument10 pagesTutorial. Process DesignFaisal Saleh RazaNo ratings yet

- Tutorial & Example. S-Curve Modeling and ApplicationsDocument6 pagesTutorial & Example. S-Curve Modeling and ApplicationsFaisal Saleh RazaNo ratings yet

- S-Curve Modeling AssignmentDocument2 pagesS-Curve Modeling AssignmentFaisal Saleh RazaNo ratings yet

- WTO IMF World Bank No of Members Formation Year Function: International OrganizationsDocument1 pageWTO IMF World Bank No of Members Formation Year Function: International OrganizationsFaisal Saleh RazaNo ratings yet

- Thermodynamics II CompressorsDocument65 pagesThermodynamics II CompressorsFaisal Saleh RazaNo ratings yet

- FYP OrnithopterDocument22 pagesFYP OrnithopterFaisal Saleh RazaNo ratings yet