Professional Documents

Culture Documents

Api 653 Preparatory Course: Exam 4 - Closed Book

Uploaded by

Nuwan RanaweeraOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Api 653 Preparatory Course: Exam 4 - Closed Book

Uploaded by

Nuwan RanaweeraCopyright:

Available Formats

API 653 PREPARATORY COURSE

Exam 4 - Closed Book

Note: Tick only one alternative which you think is most appropriate.

1. A hydrostatic test for a relocated tank:

a. May be waived by the Owner/Operator

b. Is required

c. May be waived by the Inspector

d. Is not necessary

2. Cathodic protection is achieved by directing the flow of current from:

a. A cathode to anode

b. An anode to cathode

c. Both installations are acceptable

d. Neither of a and b

3. During the hydrostatic test, no less than _______ settlement measurement

points shall be surveyed.

a. 8

b. 10

c. 15

d. 5

4. Reinforcement pads shall be tested by applying pressure between the tank

shell and reinforcement plate using the telltale hole. How much pressure is

used to perform this inspection?

a. 15 psig hydrostatic pressure

b. 15 psig pneumatic pressure

c. 5 psig hydrostatic pressure

d. 5 psig pneumatic pressure

5. Which tests are usually conducted to verify acceptability of shell to bottom

plate welds?

a. Diesel test

b. RT

c. Vacuum box test

d. “a” and “c”

6. Except for cast iron parts, internal coils and supports may be:

a dye penetrant tested

b. leak tested

c. hammer tested

d. magnetic particle tested

7. At the next out-of-service inspection on a tank that has had a hot tap

performed, the visual inspection should include:

a. size of the hot tap nozzle holes

b. thickness of the plate at the hot tap

c. height of the hot tap from the tank bottom

d. trimming of the hot tap nozzle holes

8. The term “windgirder” is applicable for which type of tanks?

a. Tanks which a wind measuring device installed at the top of the tank.

b. High octane fuel tanks

c. Tanks with floating roofs

d. None of the above

9. Industry experience and laboratory test have shown that a membrane stress

in tank shell plates of at least _______ is required to cause failure due to

brittle fracture?

a. 500 psi

b. 100 Mpa

c. 7 ksi

d. 18 kg/mm2

10. Which of the following is an advantage of magnetic particle testing over

penetrant testing?

a. it can detect surface discontinuities with foreign material imbedded in

them

b. It is faster on individual parts

c. It can detect near-surface discontinuities

d. All of the above

11. Which of the following types of discontinuities is not normally detected by

radiography?

a. Cracks

b. Incomplete penetration

c. Laminations

d. Slag

12. The reason for periodical inspection of ASTs is to:

a. Determine their physical condition

b. Determine the rate of deterioration

c. Maintain safe operating conditions

d. All of the above

13. Resistance of grounding connection shall not be,

a. more than 25 Ohms

b. less than 1 Meg-Ohm

c. less than 25 Ohms

d. more than 5 Ohms

14. Internal inspection is primarily to:

a. All of the below

b. Ensure that the bottom is not corroded and leaking;

c. Gather data for shell assessment

d. Identify and evaluate bottom settlement.

15. Vacuum box tests require ____ psig of partial vacuum.

a. 3.0 psi

b. 15 psi

c. 21 psi

d. 30 psi

16. The API 653 standard covers the maintenance inspection, repairs,

alteration, relocation and reconstruction of tanks constructed to which

one of the following standards:

a. ASME

b. API 651

c. API 652

d. API 650

17. The complete or partial removal and replacement of more than 12

inches of a vertical weld joining shell plates is considered a :-

a. minor alteration

b. minor repair

c. major alteration

d. major repair

18. The difference between peaking and banding is:

a. peaking pertains to the roof;

b. banding is external to the tank;

c. peaking pertains to vertical weld seams, banding pertains to

horizontal weld seams;

d. peaking pertains to horizontal weld seams, banding pertains to

vertical weld seams.

19. The minimum interval for external inspection by a qualified inspector is ____

years or at the quarter corrosion-rate life of the shell, whichever is less:

a. Twenty

b. Five

c. Ten

d. Fifteen

20. The minimum retirement thickness of an annular plate ring is usually greater

than:

a. 0.10

b. 0.25

c. 0.0625

d. 0.1875

You might also like

- ITP (Inspection Test Plan) For Tank ConstructionDocument6 pagesITP (Inspection Test Plan) For Tank ConstructionNuwan RanaweeraNo ratings yet

- ACMV TrainingDocument227 pagesACMV Traininghbitho100% (3)

- API 510 Closed Questions GuideDocument5 pagesAPI 510 Closed Questions GuideEinsteinw2No ratings yet

- Closed Book API RP 578 Practice QuestionsDocument5 pagesClosed Book API RP 578 Practice QuestionsIsmail Jamaluddin100% (1)

- 653 QB 3Document55 pages653 QB 3Mohamed KHODJA100% (1)

- API 510 PC 20 31 Aug05 Bench MarkDocument4 pagesAPI 510 PC 20 31 Aug05 Bench MarknikafiqNo ratings yet

- API 510 Mid Session Closed0Document10 pagesAPI 510 Mid Session Closed0مبشر أحمد100% (2)

- Study Sheets Based On API 653 Exam InformationDocument7 pagesStudy Sheets Based On API 653 Exam InformationDevin Hardy100% (1)

- Chem 1212 Exam KeyDocument6 pagesChem 1212 Exam KeyChris HeNo ratings yet

- C Closed B Losed B Ook Ook P Practice Que Ractice Questio Stio Ns NsDocument10 pagesC Closed B Losed B Ook Ook P Practice Que Ractice Questio Stio Ns NsElankumaran Periakaruppan100% (1)

- CAIRO INSPECTION COMPANY PT EXAMDocument16 pagesCAIRO INSPECTION COMPANY PT EXAMAhmedNo ratings yet

- Surface Preparation Standards and TechniquesDocument3 pagesSurface Preparation Standards and TechniquesMohamed Reda Hussein80% (5)

- API 653 PC 26feb05 Question BankDocument80 pagesAPI 653 PC 26feb05 Question Bankraobabar21No ratings yet

- Guide Dissolved Oxygen MeasurementDocument40 pagesGuide Dissolved Oxygen Measurementrafael_111No ratings yet

- API-510 Closed Book (Vérifié Lors Du Test) FLASH CARDSDocument31 pagesAPI-510 Closed Book (Vérifié Lors Du Test) FLASH CARDSfathiNo ratings yet

- Welded Tank Oil Storage Inspection StandardDocument106 pagesWelded Tank Oil Storage Inspection StandardiraprobotNo ratings yet

- API 510 ClosedDocument15 pagesAPI 510 ClosedHarmish mewadaNo ratings yet

- Closed Book Questions For Api 575Document25 pagesClosed Book Questions For Api 575vamsikrishna100% (1)

- MSTS Mark's API 510 STUDY GUIDE.Document30 pagesMSTS Mark's API 510 STUDY GUIDE.Hares SlalNo ratings yet

- 510 PC Oct04 Qar-Mid Closed PSJDocument12 pages510 PC Oct04 Qar-Mid Closed PSJCss SfaxienNo ratings yet

- API-510 Exam # 3 2008 Open Book Exam PDFDocument14 pagesAPI-510 Exam # 3 2008 Open Book Exam PDFIslam FawzyNo ratings yet

- 1 API 653 Memories March 2014 ExamDocument16 pages1 API 653 Memories March 2014 ExammajidNo ratings yet

- API 653 PC 15may04 Exam 4 ClosedDocument5 pagesAPI 653 PC 15may04 Exam 4 ClosedShaalan AliNo ratings yet

- API 510 - Book 6Document119 pagesAPI 510 - Book 6nathaniel ekaikoNo ratings yet

- 1.510 Sample QuestionSDocument7 pages1.510 Sample QuestionSvamsikrishnaNo ratings yet

- Ball and Roller BearingsDocument105 pagesBall and Roller Bearingssamurai7_77No ratings yet

- Daily Points To Recall (Day 3) : API 653 PreparatoryDocument2 pagesDaily Points To Recall (Day 3) : API 653 PreparatoryMohammed ShakilNo ratings yet

- Set-C API 510 Preparatory CourseDocument29 pagesSet-C API 510 Preparatory CourseptssoftNo ratings yet

- API 570 DEC 2009 ClosedDocument17 pagesAPI 570 DEC 2009 ClosedMohammedBujairNo ratings yet

- 510 IRS Pune Open Book Questions FinalDocument6 pages510 IRS Pune Open Book Questions Finaljaheer1No ratings yet

- API 653 Tank Inspector Exam Prep Course AnswersDocument5 pagesAPI 653 Tank Inspector Exam Prep Course Answersanisanis100% (1)

- AAPI 510 Serious Examination Questions (80 QB)Document16 pagesAAPI 510 Serious Examination Questions (80 QB)nathaniel ekaikoNo ratings yet

- Api 510 Close Book (Sec Viii & 510) - 17Document12 pagesApi 510 Close Book (Sec Viii & 510) - 17walid walid100% (1)

- 510 Open Exam B. Rev7Document15 pages510 Open Exam B. Rev7yrdna nawaiteosNo ratings yet

- API 510 Preparatory Course GuideDocument7 pagesAPI 510 Preparatory Course GuideRanaweera AriyamanjulaNo ratings yet

- Api 510 Asme PCC2Document1 pageApi 510 Asme PCC2korichiNo ratings yet

- API-653 Homework 1 03 PDFDocument0 pagesAPI-653 Homework 1 03 PDFgurdeepsarora8738100% (1)

- API 510 Final Answer Closed Book1Document1 pageAPI 510 Final Answer Closed Book1Nsidibe Michael EtimNo ratings yet

- API 510 Exam Study GuideDocument6 pagesAPI 510 Exam Study GuidetayyabNo ratings yet

- EXAM 4 CLOSEDDocument5 pagesEXAM 4 CLOSEDmitesh100% (1)

- API 510 QUIZ No.4Document5 pagesAPI 510 QUIZ No.4Hatem RagabNo ratings yet

- Api 577 3 PDFDocument10 pagesApi 577 3 PDFElankumaran Periakaruppan100% (1)

- API Exam Questions from December 2012Document2 pagesAPI Exam Questions from December 2012sureshNo ratings yet

- Api 653 QuestionsDocument28 pagesApi 653 Questionskorichi100% (1)

- API 510 Preparatory Training Exam QuestionsDocument13 pagesAPI 510 Preparatory Training Exam QuestionsCss SfaxienNo ratings yet

- Non-Destructive Evaluation of Corrosion and Corrosion-assisted CrackingFrom EverandNon-Destructive Evaluation of Corrosion and Corrosion-assisted CrackingRaman SinghNo ratings yet

- Boost Your API-570 Piping Inspectors Exam ScoreDocument6 pagesBoost Your API-570 Piping Inspectors Exam Scorejaire esparzaNo ratings yet

- 2-Questions API 650 Question N°02 2022Document3 pages2-Questions API 650 Question N°02 2022korichiNo ratings yet

- 02 API 570 Points To RecallDocument6 pages02 API 570 Points To RecallMohammedBujairNo ratings yet

- API 653 Exam Prep: Key Points for Tank Bottom IntegrityDocument35 pagesAPI 653 Exam Prep: Key Points for Tank Bottom Integritymajdi jerbiNo ratings yet

- Api 510 Q&a-2Document32 pagesApi 510 Q&a-2Mohammed ShakilNo ratings yet

- Api 510 Preparatory Final Exam (Closed Book) : Answers in A Separate Answer SheetDocument14 pagesApi 510 Preparatory Final Exam (Closed Book) : Answers in A Separate Answer SheetCss Sfaxien100% (1)

- API 510 - Question Answer - 2004Document8 pagesAPI 510 - Question Answer - 2004Erick VargasNo ratings yet

- Principles and Application Lithium Secondary BatteriesDocument7 pagesPrinciples and Application Lithium Secondary BatteriesGonzalo Almeida0% (1)

- NPP Education PolicyDocument20 pagesNPP Education PolicyNuwan RanaweeraNo ratings yet

- API 570 Authorized Piping Inspector Preparatory Program: Open Book Mockup ExaminationDocument8 pagesAPI 570 Authorized Piping Inspector Preparatory Program: Open Book Mockup ExaminationmelvinNo ratings yet

- API 510 Inspector Certification RequirementsDocument2 pagesAPI 510 Inspector Certification RequirementsINSTECH ConsultingNo ratings yet

- API 570 Exam Prep TrainingDocument3 pagesAPI 570 Exam Prep Trainingalouis100% (1)

- API 653 PC 15may04 Exam 2 ClosedDocument8 pagesAPI 653 PC 15may04 Exam 2 ClosedShaalan AliNo ratings yet

- Api 653 (CB-109)Document37 pagesApi 653 (CB-109)Naveen RajNo ratings yet

- Api 653 Preparatory Important Closed Book Questions: Professional Training and ConsultationDocument2 pagesApi 653 Preparatory Important Closed Book Questions: Professional Training and ConsultationNuwan RanaweeraNo ratings yet

- API 653 exam sample items guideDocument3 pagesAPI 653 exam sample items guideAbdelhakim MaghnoujNo ratings yet

- Daily Exam 1 (Open) : Professional Training and ConsultationDocument4 pagesDaily Exam 1 (Open) : Professional Training and ConsultationShaalan AliNo ratings yet

- Prep Material QB-576Document5 pagesPrep Material QB-576Raheem Khan100% (1)

- API 510 ApplicationDocument16 pagesAPI 510 ApplicationmalawanyNo ratings yet

- API 510 Section 8 QuizDocument17 pagesAPI 510 Section 8 Quizamalhaj2013No ratings yet

- API 653 PREPARATION/ Question N°06 Close BookDocument3 pagesAPI 653 PREPARATION/ Question N°06 Close BookkorichiNo ratings yet

- Is Living in Sweden A Pleasure or A TormentDocument17 pagesIs Living in Sweden A Pleasure or A TormentNuwan RanaweeraNo ratings yet

- Blushing of Amines in Coal Tar Epoxy (Amine Adduct)Document7 pagesBlushing of Amines in Coal Tar Epoxy (Amine Adduct)Nuwan RanaweeraNo ratings yet

- Relief Valves ProcedureDocument15 pagesRelief Valves ProcedureNuwan RanaweeraNo ratings yet

- Definitions: Source: Australian Pump Technical Handbook 3 Edition and Reproduced in Entirety With Permission From P/ADocument10 pagesDefinitions: Source: Australian Pump Technical Handbook 3 Edition and Reproduced in Entirety With Permission From P/ANuwan RanaweeraNo ratings yet

- Is Living in Sweden A Pleasure or A TormentDocument17 pagesIs Living in Sweden A Pleasure or A TormentNuwan RanaweeraNo ratings yet

- Safety Relief Valve IntroductionDocument7 pagesSafety Relief Valve IntroductionNuwan RanaweeraNo ratings yet

- Why Are Houses in Sweden So CheapDocument8 pagesWhy Are Houses in Sweden So CheapNuwan RanaweeraNo ratings yet

- NPP Health PolicyDocument31 pagesNPP Health PolicyNuwan RanaweeraNo ratings yet

- Why Are Houses in Sweden So CheapDocument8 pagesWhy Are Houses in Sweden So CheapNuwan RanaweeraNo ratings yet

- Tech Brief 2013 - Reading Centrifugal Pump Curves PDFDocument5 pagesTech Brief 2013 - Reading Centrifugal Pump Curves PDFFawaaz KhurwolahNo ratings yet

- NPP Environmental PolicyDocument23 pagesNPP Environmental PolicyNuwan RanaweeraNo ratings yet

- Agri Policy of JVPDocument24 pagesAgri Policy of JVPNebsl KurunegalaNo ratings yet

- Indian Constitution and Separation of PoDocument4 pagesIndian Constitution and Separation of PoNuwan RanaweeraNo ratings yet

- Culture Policy of JVPDocument24 pagesCulture Policy of JVPNebsl KurunegalaNo ratings yet

- Trends in Islamic ExtremismDocument68 pagesTrends in Islamic ExtremismNuwan RanaweeraNo ratings yet

- The Doctrine of Separation of Powers Indian ConstitutionDocument5 pagesThe Doctrine of Separation of Powers Indian ConstitutionNuwan RanaweeraNo ratings yet

- KD Aul Ôú Hla Fkdief, K WD ÓlhlaDocument32 pagesKD Aul Ôú Hla Fkdief, K WD ÓlhlaNuwan RanaweeraNo ratings yet

- Occupational Safety Health - Professional EthicsDocument10 pagesOccupational Safety Health - Professional EthicsNuwan RanaweeraNo ratings yet

- British Labour PartyDocument14 pagesBritish Labour PartyNuwan RanaweeraNo ratings yet

- Occupational Safety & Health - Professional EthicsDocument51 pagesOccupational Safety & Health - Professional EthicsNuwan RanaweeraNo ratings yet

- Basics of Surge Protection SIEMENSDocument44 pagesBasics of Surge Protection SIEMENScleyvasNo ratings yet

- 2018 AKD Nov-23-SpeechDocument40 pages2018 AKD Nov-23-SpeechNuwan RanaweeraNo ratings yet

- Wêrdchjd : Ueèy Aùï Meroùug Kï'''Document50 pagesWêrdchjd : Ueèy Aùï Meroùug Kï'''Jason TaylorNo ratings yet

- Basics of SwitchboardsDocument60 pagesBasics of SwitchboardsRui Pedro SousaNo ratings yet

- Welding Procedure Specification (WPS) : Asme Sec Ix, 2017 Boiler and Pressure Vessel CodeDocument2 pagesWelding Procedure Specification (WPS) : Asme Sec Ix, 2017 Boiler and Pressure Vessel CodeNuwan RanaweeraNo ratings yet

- Experiment 3 FinalDocument13 pagesExperiment 3 FinalRvin OngNo ratings yet

- Diode - Wikipedia, The Free EncyclopediaDocument15 pagesDiode - Wikipedia, The Free EncyclopediamountfestusNo ratings yet

- 1N4148 Diode Pinout, Equivalents & DatasheetDocument3 pages1N4148 Diode Pinout, Equivalents & DatasheetmanguesNo ratings yet

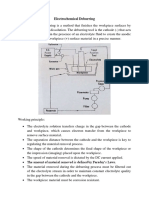

- Electrochemical DeburringDocument3 pagesElectrochemical DeburringAnonymous dL8dsCncNo ratings yet

- Astm G15 - 06Document5 pagesAstm G15 - 06Sofia YuliNo ratings yet

- Physics of Welding Better VersionDocument3 pagesPhysics of Welding Better VersionKhurram RehmanNo ratings yet

- Astm Nace Astmg193 12dDocument10 pagesAstm Nace Astmg193 12dZia ur rehmanNo ratings yet

- Electrochemical Stripping: Dr. Rudolf Keller and Brian J. BarcaDocument5 pagesElectrochemical Stripping: Dr. Rudolf Keller and Brian J. BarcaRinush Fedrikdo Bushido OdaNo ratings yet

- EEC111 PracticalsDocument21 pagesEEC111 PracticalsOreoluwa OmiyaleNo ratings yet

- NCERT Solutions for Class 12 Chemistry Chapter 3Document16 pagesNCERT Solutions for Class 12 Chemistry Chapter 3jiya jainNo ratings yet

- NTB5860NL, NTP5860NL, NVB5860NL N-Channel Power MOSFET: 60 V, 220 A, 3.0 MWDocument9 pagesNTB5860NL, NTP5860NL, NVB5860NL N-Channel Power MOSFET: 60 V, 220 A, 3.0 MWalllim88No ratings yet

- Pacemaker BatteriesDocument12 pagesPacemaker Batteriesrohit860No ratings yet

- Getting Started With Electrochemical Corrosion MeasurementDocument9 pagesGetting Started With Electrochemical Corrosion Measurementa_attarchiNo ratings yet

- NACE 2 BDocument13 pagesNACE 2 BJill MainNo ratings yet

- A Review of Electrochemical Macro To MicDocument16 pagesA Review of Electrochemical Macro To MicGaby AlvarezNo ratings yet

- MaxO2 User ManualDocument18 pagesMaxO2 User ManualfunefoNo ratings yet

- Electrochemistry: 2 303 G - RtlogkDocument7 pagesElectrochemistry: 2 303 G - RtlogkSnehashis BoseNo ratings yet

- Engineering Chemistry NotesDocument99 pagesEngineering Chemistry NotesShivam GuptaNo ratings yet

- Form 5 ElectrolysisDocument2 pagesForm 5 ElectrolysisgrimyNo ratings yet

- Materi Aplikasi Reaksi RedoksDocument28 pagesMateri Aplikasi Reaksi Redokszaharo putriNo ratings yet

- TeDocument36 pagesTeDCNo ratings yet

- Cathodic Protection For MSVDocument17 pagesCathodic Protection For MSVVivek Pandey100% (1)

- CY2161 - Engineering Chemistry - IIDocument186 pagesCY2161 - Engineering Chemistry - IIPushpavalli MohanNo ratings yet

- Gadag R. V., Shetty A. V., Engineering Chemistry (3rd Edition)Document278 pagesGadag R. V., Shetty A. V., Engineering Chemistry (3rd Edition)Prateek sblNo ratings yet

- Discovery of ElectronsDocument3 pagesDiscovery of ElectronsKeiiNo ratings yet

- Computer Graphics Display DevicesDocument21 pagesComputer Graphics Display DevicesrahulNo ratings yet

- MHD GeneratorsDocument19 pagesMHD GeneratorsThejeshwi ReddyNo ratings yet