Professional Documents

Culture Documents

Formation and Stability of C-S-H (I) IN Ca (OH) /Cao-Thermal Silica Densified-H O System

Uploaded by

Ali AddieOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Formation and Stability of C-S-H (I) IN Ca (OH) /Cao-Thermal Silica Densified-H O System

Uploaded by

Ali AddieCopyright:

Available Formats

Original papers

FORMATION AND STABILITY OF C–S–H(I)

IN Ca(OH)2/CaO–THERMAL SILICA DENSIFIED–H2O SYSTEM

KESTUTIS BALTAKYS, RAOUL JAUBERTHIE*, VITA KASPERAVICIUTE

Department of Silicate Technology, Kaunas University of Technology, Radvilenu 19, LT – 50270 Kaunas, Lithuania

*Department of Civil Engineering, INSA, 20 Av. des Buttes de Coësmes, CS 14315, 35043 Rennes, France

E-mail: kestutis.baltakys@ktu.lt

Submitted September 25, 2008; accepted January 30, 2009

Keywords: Calcium silicate hydrates; C–S–H(I); Xonotlite; X-Ray Diffraction

The stability and crystals morphology of C–S–H(I) in the CaO/Ca(OH)2–TSD–H2O systems and a sequence of intermediary

compound formation has been examined. Two series of samples, each being made with different forms of CaO and SiO2, were

used in the experimental tests. The molar ratio of primary mixtures was CaO/SiO2 = 1.0. Hydrothermal synthesis has been

carried out under the saturated steam pressure at temperatures of 90, 110, 130, 150 and 175ºC; the duration of isothermal

curing was 2, 8, 24 or 72 hours. It was determined that thermal silica densified has negative influence on the formation of

calcium silicate hydrates. Ca2+ containing components (Ca(OH)2, CaO) change the composition of intermediate and final

products of the synthesis. In the mixtures with Ca(OH)2, intermediary and final compound is C–S–H(I) in different crystalline

degree. Meanwhile, in the mixtures with CaO, the main intermediary compound is C–S–H(I) and the main product is xonotlite.

It was estimated that the increment of temperature significantly influences the stability, morphology and crystalline degree

of C–S–H(I).

INTRODUCTION of C–S–H(I) and tobermorite [19]. Meanwhile, in the

low base (C/S ~ 0.6) mixtures the initial C–S–H gel

C–S–H is the primary strength-forming phase in transforms to Z-phase and then finally recrystallizes to

Portland cement paste and significantly influences it’s gyrolite [20-25].

mechanical and transport properties. C–S–H has a wide This paper reviews recent results from our laborato-

compositional range, with molar CaO/SiO2 (C/S) ratios ry concerning with the possibility to use more by-pro-

between 0.6 and more than 2. The C/S ratios of C–S–H ducts (especially the compounds which have silicon and

precipitated from aqueous solution depend on the C/S calcium components) as secondary raw materials in the

ratios of starting materials, with higher C/S ratios in the synthesis of calcium silicate hydrates.

starting materials usually resulting in higher C/S ratios The aim of this paper was to examine the stabili-

in the final products. C/S ratios less than 0.6 usually ty and crystals morphology of C–S–H(I) in the CaO/

occur when excess silica is present [1-7]. /Ca(OH)2 and thermal silica densified mixtures as well

There are many proposed structural models for as to analyze and explain the sequence of intermediary

C–S–H, all of which involve some kind of layer structure compound formation.

as revealed by many instrumental analysis methods data.

They differ in the details of the individual layers, how

the layers are connected, and what is in the interlayer EXPERIMENTAL

[8-15].

T. Mitsuda et al. [16] determined that C–S–H(I) The following materials were used in this work:

was always formed as an initial product of crystalline calcium hydroxide Ca(OH)2 (the purity is 98 %, the pro-

phase. These results for crystalline phases formed after duct of ACROS ORGANICS, Belgium), industrial CaO

C–S–H agreed with those reported by many workers. It (loss on ignition 23 %, Manufacturer Pigeon Chaux,

should be underlined that C–S–H(I) phase is metastable Saint Pierre La Cour, FRANCE) and thermal silica densi-

and presents a tendency to crystallization [17-18]. It fied - TSD (amorphous silica > 86 %, carbon content

transforms to tobermorite but this processis very slow, < 5.4 %, pH = 6.3, surface area – 120 m2/g, obtained

probably due to difficulties in nucleation. The elevated from Nantes).

temperatures accelerate the transformation and high Two series of samples, each being made with diffe-

pressure seems to be even more efficient. In the majority rent forms of CaO and SiO2, were used in the experimental

of cases the product of transformation presents a mixture tests. The molar ratio of primary mixtures was CaO/SiO2

Ceramics – Silikáty 53 (2) 81-87 (2009) 81

Baltakys K., Jauberthie R., Kasperaviciute V.

equal to 1.0. Hydrothermal synthesis has been carried RESULTS AND DISCUSSION

out under the saturated steam pressure at temperatures

of 90, 110, 130, 150 and 175°C; the duration of isothermal It was determined that using SiO2 component - ther-

curing was 2, 8, 24 or 72 hours. After synthesis, samples mal silica densified, the formation of calcium silicate hy-

were removed from the teflon cells and were transferred drates proceeds very difficult to compare with amorphous

to an air conditioned chamber with relative humidity of silica [21-24]. In Ca(OH)2–TSD–H2O mixture at 90°C

55 % and temperature of 20°C and sieved through a sieve together with C–S–H(I) (d-spacing: 0.302; 0.179; 0.168

with a mesh width of 50 μm. nm) and CaCO3 (d-spacing: 0.383; 0.302; 0.249; 0.228;

The XRD data were collected with Philips PW 3710 0.209; 0.192; 0.187 nm) as well unreacted Ca(OH)2

X-ray diffractometer with Bragg–Brentano geometry remained (d-spacing: 0.487; 0.310; 0.262; 0.192; 0.179;

using Ni-filtered Cu Kα radiation, operating with the 0.168 nm) (Figure 1, curve 1). It should be underlined

voltage of 30 kV and emission current of 20 mA. The that the carbonation appeared when the products were

step-scan covered the angular range 2–60° (2θ) in steps dryed in air conditionned chamber. It is presumable that

of 2θ = 0.02°. one of the main reasons is that TSD contains quite a large

SEM (JEOL-JSM-6301F) of the samples was per- quantity of carbon which impedes the reaction between

formed using an accelerating voltage of 9 kV and a Ca2+ and Si4+ ions [24].

working distance of 15 mm.

FT–IR spectra has been carried out with the help of

spectrometer Perkin Elmer FT–IR system Spectrum X.

Specimen were prepared by mixing 1 mg of the sample

with 200 mg of KBr. The spectral analysis was perfor-

med in the range of 4000-400 cm-1 with spectral resolu-

tion of 1 cm-1.

a)

b)

Figure 1. X-ray diffraction patterns of synthesis products Figure 2. SEM micrographs of synthesis products in the

at 90°C in the Ca(OH)2–TSD–H2O mixture. Indexes: Ca(OH)2–TSD–H2O mixture when duration of hydrotermal

C - C–S–H(I), P - Ca(OH)2, Ka - calcite. treatment at 90°C, h: a) 2, b) 72.

82 Ceramics – Silikáty 53 (2) 81-87 (2009)

Formation and stability of C–S–H(I) in Ca(OH)2/CaO–thermal silica densified–H2O system

Upon extending the duration of synthesis (till 72 within 72 hours of hydrothermal treatment amorphous,

hours), in the products the quantity of unreacted Ca(OH)2 with no definite crystal structure aggregations typical

decreases because the intensity of the main diffraction for a low crystalline degree C–S–H(I) were already

peak (d-spacing: 0.487) diminishes too (Figure 1, curves identified (Figure 2b).

2-4). By increasing the temperature of synthesis (up to

SEM analysis data show that within 2 h of isother- 150°C), the composition of C–S–H(I) and a sequence

mal curing also silica fume-TSD completely does not of reaction products were not affected in the Ca(OH)2–

react because the irregular plates typical of it dominate –TSD–H2O mixture. At 110, 130 or 150°C the same

in the products (Figure 2a). Meanwhile, in the products compounds were formed as at 90°C: C–S–H(I), CaCO3

and Ca(OH)2 (Figure 3).

SEM analysis showed that by increasing the tem-

perature of isothermal curing, after 72 h at 110–150°C

the stucture of C–S–H(I) vary from the common fibrous

type to irregular grains/aggregates forming a reticular

network (Figure 4).

At 175°C, the XRD data showed that almost all

Ca(OH)2 reacted and well-crystalline C–S–H(I) were

formed (Figure 5a). The results of X-ray diffraction

analysis were confirmed by FT-IR and SEM data.

A broad absorption bands at 475; 673; 976; 1640;

3450 cm-1 are typical for C–S–H(I). The broad band

centered at 1117 cm-1 is attributed to asymmetric stretching

frequency of Si–O–Si, the band centered at 798 cm-1 is

due to symmetric stretching of Si–O–Si, and the band at

475 cm-1 is due to the bending frequency of O–Si–O. The

frequencies of the Si–O–Si bands are an indication of the

overall degree of polymerization of the silica network.

In general, a lower frequency will correspond to a lower

degree of polymerization. Also the presence of calcite

impurities was indentified with an absorption bands at

713; 874; 1428 cm-1 (Figure 5b). In results of scanning

electron micrographs, well-crystalline aggregates of

C–S–H(I) plates can be seen (Figure 6).

Thus, in Ca(OH)2–TSD–H2O mixture, thermal sili-

ca densified grains impeded synthesis of C–S–H(I).

It should be underlined that by increasing synthesis

temperature and prolonging the duration of synthesis,

Figure 3. X-ray diffraction patterns of synthesis products at the quantity of unreacted Ca(OH)2 sligthly decreases. As

150°C in the Ca(OH)2–TSD–H2O mixture. it results from the data shown in Figure 7 at low tem-

Indexes: C - C–S–H(I), P - Ca(OH)2, Ka - calcite. perature (90°C) almost half of Ca(OH)2 does react during

a) b) c)

Figure 4. SEM micrographs of synthesis products in the Ca(OH)2–TSD–H2O mixture when duration of hydrotermal treatment at

110°C (a), 130°C (b) and 150°C (c) is 72 h.

Ceramics – Silikáty 53 (2) 81-87 (2009) 83

Baltakys K., Jauberthie R., Kasperaviciute V.

72 hours. The further reduction of its quantity depends The data of SEM analysis presented that in the tem-

on temperature of hydrothermal curing. At higher tempe- perature range from 90°C to 150°C the overal morphology

ratures (175°C), Ca(OH)2 reacts considerably more of C–S–H(I) varies from the common fibrous type to

quickly and about 75–80 % of it is bound during 72 irregular plates (Figure 9).

hours of isothermal curing. It was noticed that the last

amount of Ca(OH)2 reacts very slowly.

Meanwhile, it is known that CaO reacts more

quickly with amorphous SiO2 components than Ca(OH)2.

It is possible that formation process of C–S–H proceeds

better in CaO–TSD–H2O system than in Ca(OH)2–TSD–

–H2O.

It was determined that formation process of calcium

silicate hydrates proceeds faster in CaO–TSD–H2O

system than in Ca(OH)2–TSD–H2O only at higher tem-

perature because curves of the X-ray diffraction analysis

of the synthesized compounds show that similar amounts

of C–S–H(I), portlandite and CaCO3 formed irrespective

of synthesis temperature (90, 110, 130, 150°C) and

duration (4, 8, 24, 72 h) because the intensities of the

main diffraction peaks typical for them are almost ana-

logous (Figure 8). Moreover, upon extending the duration

or temperature of synthesis, in the products the quantity

of unreacted Ca(OH)2 sligthly decreases because the Figure 6. SEM micrographs of synthesis products in the

intensity of the main diffraction peak (d-spacing: 0.490) Ca(OH)2–TSD–H2O mixture when duration of hydrotermal

decreases too (Figure 8). curing at 175°C is 72 h.

θ

a) b)

Figure 5. X-ray diffraction patterns (a) and FT-IR spectra (b) of synthesis products at 175°C in the Ca(OH)2–TSD–H2O mixture.

Indexes: C - C–S–H(I), P - Ca(OH)2, Ka - calcite.

84 Ceramics – Silikáty 53 (2) 81-87 (2009)

Formation and stability of C–S–H(I) in Ca(OH)2/CaO–thermal silica densified–H2O system

It should be underlined that at 175°C unexpected CONCLUSIONS

results were obtained. The accumulation of two mor-

phologous crystals can be seen in SEM micrographs: 1. It was determined that SiO2 component – thermal silica

C–S–H(I) characteristic irregular shape crystals and long, densified has negative influence on the formation of

needle/plate shape xonotlite crystals that are formed as calcium silicate hydrates. It should be underlined that

on C–S–H(I) grains and in the interlayers between them CaO reacts more quickly with thermal silica densified

(Figure10). than Ca(OH)2. Moreover, the reactivity of Ca(OH)2

The formation of xonotlite is confirmed by XRD depends on temperature of hydrothermal curing.

studies only after 72 h at 175°C: the main peak with 2. It was estimated that the increment of temperature

d-spacing: 0.703 nm which is specific to xonotlite was significantly influences the stability, morphology and

identified (Figure 11, curve 4, d-spacing: 0.703; 0.426; crystalline degree of C–S–H(I) in the temperature

0.364; 0.271; 0.250; 0.228 nm). range from 90°C to 175°C. The overall morphology of

Obtained results confirmed that CaO reacts more C–S–H vary from the common fibrous type to irregular

quickly with amorphous SiO2 component (TSD) than grains forming a reticular network.

Ca(OH)2. It should be underlined that dissociation of 3. Ca2+ containing component (Ca(OH)2, CaO) change the

Ca(OH)2 depends on temperature of hydrothermal curing. composition of intermediate and final products of the

At 175°C, Ca(OH)2 reacts considerably rapidly and synthesis. In the mixtures with Ca(OH)2, intermediary

about 90 % of it is bound during 72 hours of isothermal and final compound is C–S–H(I) in different crystalline

curing (Figure 12). degree. Meanwhile, in the mixtures with CaO, the

Thus, in CaO–TSD–H2O system at the temperature main intermediary compound is C–S–H(I) and the

range from 90°C to 175°C, the sequence of compounds main product is xonotlite. Moreover, in both mixtures

to be formed during the synthesis looks as follows: calcite prevails at the beginning of the synthesis

and remains in the products almost in all explored

conditions.

Figure 7. Intensity of main peak (d-spacing: 0.490 nm) of Figure 8. X-ray diffraction patterns of synthesis products at

Ca(OH)2 at different temperature and duration of synthesis in 150°C in the CaO–TSD–H2O mixture. Indexes: C - C–S–H(I),

the Ca(OH)2–TSD–H2O mixture. P - Ca(OH)2, Ka - calcite.

Ceramics – Silikáty 53 (2) 81-87 (2009) 85

Baltakys K., Jauberthie R., Kasperaviciute V.

a) b)

c) d)

Figure 9. SEM micrographs of synthesis products in the CaO–TSD–H2O mixture when duration of hydrotermal treatment at

90°C (a), 110°C (b), 130°C (c) and 150°C (d) is 72 h.

Acknowledgement

The authors express their thanks to Joseph Le

Lannic, CMEBA Universite de Rennes, for his assistance

with scanning electron microscopy.

References

1. Richardson I. G.: Cem.Concr.Res. 38, 137 (2008).

2. Chen J. J., Thomas J.J., Taylor H. F. W., Jennings H. M.:

Cem.Concr.Res. 34, 1499 (2004).

3. Nonat A.: Cem.Concr.Res. 34, 1521 (2004).

4. Black L., Garbev K., Beuchle G., Stemmermann P., Schild

D.: Cem.Concr.Res. 36, 1023 (2006).

5. Hartmann A., Buhl J.-Ch., Breugel K.: Cem.Concr.Res. 37,

21 (2007).

6. Garbev K.: Ph. D. Thesis, Forschungszentrum Karlsuhe

GmbH, Karlsruhe, (2004) (In German).

7. Zhang X., Chang W., Zhang T., Ong C.K.: J. Am. Ceram.

Figure 10. SEM micrographs of synthesis products in the Soc. 83, 2600 (2000).

CaO–TSD–H2O mixture when duration of hydrotermal curing 8. Richardson, I.G.: Cem.Concr.Res., 34, 1733 (2004).

at 175°C is 72 h. 9. Taylor H. F. W.: J.Chem.Soc. 36, 82 (1950).

86 Ceramics – Silikáty 53 (2) 81-87 (2009)

Formation and stability of C–S–H(I) in Ca(OH)2/CaO–thermal silica densified–H2O system

10. Sun G. K., Young J. F., Kirkpatrick R. J.: Cem.Concr.Res. 17. Sugiyama D., Fujita T.: Cem.Concr.Res., 36, 227 (2006).

36, 18 (2006). 18. Babushkin V. I., Matveev G. M., Mchedlow-Petrossyan O.

11. Jennings H.M.: Cem.Concr.Res. 38, 275 (2008). P.: Thermodynamics of Silicates (in Russian), Stroyizdat,

12. Constantinides G., Ulm F. J.: J.Mech.Phys.Solids 55, 64 Moscow, Russia, 1962.

(2007). 19. Kurdowski W., Nguyen T. T., Proceedings 9th ICCC, Natio-

13. Pellenq R. J. M., Lequeux N., Van Damme H.: Cem.Concr. nal Council for Cement and Building Materials, New Delhi

Res., 38, 159 (2008). 1992.

14. Mohan K., Taylor H. F. W.: J.Am.Ceram.Soc. 64, 177 20. Shaw S., Henderson C. M. B., Clark S. M.: Amer.Mineral.

(1981). 87, 553 (2002).

15. Gard J. A., Howison J. W., Taylor H. F. W.: Mag.Concr. 21. Jauberthie R., Temimi M., Laquerbe M.: Cem.Concr.Res.

Res., 11, 151 (1959). 26, 1335 (1996).

16. Mitsuda T., Kobayakawa S., Toraya H.: Proc. 8th International 22. Siauciunas R., Baltakys K.: Cem. Concr. Res. 34, 2029

Congress on the Chemistry of Cement, Vol. 2, p. 160, Rio de (2004).

Janeiro 1986. 23. Shaw S.: Ph. D. Thesis, University of Manchester, 1999.

24. Baltakys K., Jauberthie R. Siauciunas R., Kaminskas R.:

Materials Science-Poland 25, 663 (2007).

25. Baltakys K., Siauciunas R.: Ceramics-Silikáty 51, 106

(2007).

Figure 11. X-ray diffraction patterns of synthesis products at Figure 12. Intensity of main peak (d-spacing: 0.490 nm) of

175°C in the CaO–TSD–H2O mixture. Indexes: C - C–S–H(I), Ca(OH)2 at different temperature and duration of synthesis in

P - Ca(OH)2, Ka - calcite, X - xonotlite. the CaO–TSD–H2O mixture.

Ceramics – Silikáty 53 (2) 81-87 (2009) 87

You might also like

- Wu and Ye 2020, Study of Carbonation Rate of Synthetic C-S-H by XRD, NMR and FTIRDocument18 pagesWu and Ye 2020, Study of Carbonation Rate of Synthetic C-S-H by XRD, NMR and FTIRLeoNo ratings yet

- Samuneva 1990Document6 pagesSamuneva 1990kawmokNo ratings yet

- Cesium SubstitutionDocument6 pagesCesium SubstitutionMadihah Wan RazaliNo ratings yet

- Dehydration and Rehydration Processes of Cement Paste Exposed To High Temperature EnvironmentsDocument11 pagesDehydration and Rehydration Processes of Cement Paste Exposed To High Temperature EnvironmentsMatheus CiveiraNo ratings yet

- Sol-Gel Synthesis and Structure of Cordieritetialite Glass-CeramicsDocument6 pagesSol-Gel Synthesis and Structure of Cordieritetialite Glass-CeramicsahadsajjadiNo ratings yet

- Oxidation CO Over CuODocument4 pagesOxidation CO Over CuOncaothachNo ratings yet

- Course: Heterogenous Reaction Systems Topic: Heterogeneous Ag-Tio - Sio Composite Materials As Novel Catalytic Systems For Selective Epoxidation of Cyclohexene by H ODocument17 pagesCourse: Heterogenous Reaction Systems Topic: Heterogeneous Ag-Tio - Sio Composite Materials As Novel Catalytic Systems For Selective Epoxidation of Cyclohexene by H OParidhi GargNo ratings yet

- Procesos de Deshidratacion Del Cemento Pasta Expuesta Ambientes de Alta TemperaturaDocument10 pagesProcesos de Deshidratacion Del Cemento Pasta Expuesta Ambientes de Alta TemperaturaYoselin Medina FonsecaNo ratings yet

- E-Mail: Ribeiroc@iq - Unesp.br: QUÍMICA NOVA, 22 (1) (1999) 41Document6 pagesE-Mail: Ribeiroc@iq - Unesp.br: QUÍMICA NOVA, 22 (1) (1999) 41Siva RamNo ratings yet

- Crystallization of Belite - Melilite Clinker Minerals in The Presence of Liquid PhaseDocument5 pagesCrystallization of Belite - Melilite Clinker Minerals in The Presence of Liquid PhaseAnonymous NxpnI6jCNo ratings yet

- Mg (OH) 2 + MgSO4 + H2O体系的相关系和热力学建模及其对氢氧化镁硫酸盐水泥的影响Document14 pagesMg (OH) 2 + MgSO4 + H2O体系的相关系和热力学建模及其对氢氧化镁硫酸盐水泥的影响jordan jackNo ratings yet

- Thermal and Spectral Properties of Halogenosalicylato-Cu (Ii) ComplexesDocument10 pagesThermal and Spectral Properties of Halogenosalicylato-Cu (Ii) ComplexesBagus Taufiq ANo ratings yet

- 0040 6031 (84) 87153 1Document10 pages0040 6031 (84) 87153 1gauravNo ratings yet

- Synthesis of Sulfated Silica-Doped Tin Oxides and Their High Activities in TransesterificationDocument6 pagesSynthesis of Sulfated Silica-Doped Tin Oxides and Their High Activities in Transesterificationchaitu49No ratings yet

- Diagram MeDocument22 pagesDiagram MeAkira SaidNo ratings yet

- Phase Diagram of Cao-Al2O3 System: Ceramics International December 2001Document5 pagesPhase Diagram of Cao-Al2O3 System: Ceramics International December 2001rogerioNo ratings yet

- Cobre SelenioDocument5 pagesCobre SelenioMauricio E JimenezNo ratings yet

- IR Ni LanthanaDocument6 pagesIR Ni LanthanaNelly RojasNo ratings yet

- Ye (2020) Transições de Fase de Cério Dopado Com Sm2O3Document8 pagesYe (2020) Transições de Fase de Cério Dopado Com Sm2O3Emerson SilvaNo ratings yet

- Effect of Curing Temperature On Cement Hydration: Imad Elkhadiri, Marta Palacios, Francisca PuertasDocument11 pagesEffect of Curing Temperature On Cement Hydration: Imad Elkhadiri, Marta Palacios, Francisca PuertasHisham MohamedNo ratings yet

- Hydrogenation of Ethyl Acetate To Ethanol Over Bimetallic Cu-Zn/Sio Catalysts Prepared by Means of CoprecipitationDocument6 pagesHydrogenation of Ethyl Acetate To Ethanol Over Bimetallic Cu-Zn/Sio Catalysts Prepared by Means of CoprecipitationAtul TripathiNo ratings yet

- The Hydration Products of A Refractory Calcium Aluminate Cement at Intermediate TemperaturesDocument6 pagesThe Hydration Products of A Refractory Calcium Aluminate Cement at Intermediate TemperaturesLenia LuciaNo ratings yet

- Characterization of CuO Species and Thermal Solid-Solid Interaction in CuO-CeO2-Al2O3 Catalyst by In-Situ XRD, Raman Spectroscopy and TPRDocument5 pagesCharacterization of CuO Species and Thermal Solid-Solid Interaction in CuO-CeO2-Al2O3 Catalyst by In-Situ XRD, Raman Spectroscopy and TPRDiego CarvalhoNo ratings yet

- Ferdian 14060Document7 pagesFerdian 14060Marko JukićNo ratings yet

- Differential Scanning Calorimetry Study of Ordinary Portland Cements Mixed With Fly Ash and SlagDocument10 pagesDifferential Scanning Calorimetry Study of Ordinary Portland Cements Mixed With Fly Ash and Slageid elsayedNo ratings yet

- Thermalmagneticinvestigationofthedecomp CuOxalate-precursorforCuO J Mater Sci v402005Document7 pagesThermalmagneticinvestigationofthedecomp CuOxalate-precursorforCuO J Mater Sci v402005Vítězslav HegerNo ratings yet

- 1415 Exam 1 Answers (ICP) (EN)Document8 pages1415 Exam 1 Answers (ICP) (EN)김하은No ratings yet

- 1 s2.0 S0010938X18305274 MainDocument9 pages1 s2.0 S0010938X18305274 MainHilios MonosNo ratings yet

- Jihai Cheng, Weitao Bao, Dechun Zhu, Changan Tian, Qiyi Yin, Ming DingDocument3 pagesJihai Cheng, Weitao Bao, Dechun Zhu, Changan Tian, Qiyi Yin, Ming DingkinecamposNo ratings yet

- Nanoparticles of The Giant Dielectric Material, Cacu Ti O From A Precursor RouteDocument47 pagesNanoparticles of The Giant Dielectric Material, Cacu Ti O From A Precursor RouteNguyen Thi Thuy TienNo ratings yet

- Cheng 2011Document4 pagesCheng 2011Hoa Sầu ĐâuNo ratings yet

- Electrodeposition of Copper From Non-Cyanide AlkalineDocument20 pagesElectrodeposition of Copper From Non-Cyanide AlkalineDerdo ZulmuNo ratings yet

- Boosting Hydrogen Production From Steam Reforming of Ethanol On NickelDocument13 pagesBoosting Hydrogen Production From Steam Reforming of Ethanol On NickelDana MateiNo ratings yet

- Method For Free Lime Estimation PDFDocument5 pagesMethod For Free Lime Estimation PDFfaheemqcNo ratings yet

- Alkali Activation of Fly Ashes, Part 1Document7 pagesAlkali Activation of Fly Ashes, Part 1Tan Khoa NguyenNo ratings yet

- Ni-Schiff 2Document10 pagesNi-Schiff 2Danesh AzNo ratings yet

- (Ba0 85ca0 15) (Ti0 9Zr0 1) O3-CeO2Document4 pages(Ba0 85ca0 15) (Ti0 9Zr0 1) O3-CeO2Soni PrayogiNo ratings yet

- 8 Data Selection CimentsDocument27 pages8 Data Selection Cimentssukanta60No ratings yet

- Minerals: Ffect of Quartz On The Preparation of SodiumDocument13 pagesMinerals: Ffect of Quartz On The Preparation of Sodiumjeremy parkerNo ratings yet

- Luis F. D'Elia Camacho, Jorge A. Moncada Vivas: SciencedirectDocument5 pagesLuis F. D'Elia Camacho, Jorge A. Moncada Vivas: SciencedirectMONCADAJANo ratings yet

- Dekomposisi H2o2 DG CobaltDocument4 pagesDekomposisi H2o2 DG CobaltAndrea Rizky Sabrina HarahapNo ratings yet

- Jiang - Plasma Methane Conversion Using DBD Zeolite ADocument7 pagesJiang - Plasma Methane Conversion Using DBD Zeolite Aapi-3728640100% (1)

- Blue Coal O Spinel Via Complexation Method: Materials Chemistry and PhysicsDocument7 pagesBlue Coal O Spinel Via Complexation Method: Materials Chemistry and PhysicsAlin CamarăNo ratings yet

- Calcium Carbonate (PCC)Document15 pagesCalcium Carbonate (PCC)Huyentrang NguyenNo ratings yet

- Ker Ridge 1982Document6 pagesKer Ridge 1982laura preciadoNo ratings yet

- Synthesis, Characterization and Catalytic Properties of PtCeO2-Al2O3 and PtLa2O3-Al2O3 Sol-Gel Derived CatalystsDocument9 pagesSynthesis, Characterization and Catalytic Properties of PtCeO2-Al2O3 and PtLa2O3-Al2O3 Sol-Gel Derived CatalystsSangHao NgNo ratings yet

- Enhanced Catalytic Performance of Cr-Inserted Hydrotalcites in TheDocument12 pagesEnhanced Catalytic Performance of Cr-Inserted Hydrotalcites in TheAlexa RiveraNo ratings yet

- Materials Science & Engineering BDocument7 pagesMaterials Science & Engineering BS I DesaiNo ratings yet

- Gasification of CoalDocument28 pagesGasification of CoalAris Raymond GirsangNo ratings yet

- GasifierDocument67 pagesGasifierAris Raymond GirsangNo ratings yet

- AmoolDocument12 pagesAmoolirfan k shahNo ratings yet

- ArticleDocument8 pagesArticleemperor_vamsiNo ratings yet

- Guevara & Irons (2011) Part IDocument12 pagesGuevara & Irons (2011) Part IaarondenboerNo ratings yet

- Thermodynamic Evaluation and Optimization of The (Na SO + K SO + Na S O + K S O) SystemDocument16 pagesThermodynamic Evaluation and Optimization of The (Na SO + K SO + Na S O + K S O) SystemJhoselin Guisela ContrerasNo ratings yet

- Author's Accepted Manuscript: Ceramics InternationalDocument40 pagesAuthor's Accepted Manuscript: Ceramics Internationalhanifa16No ratings yet

- Fabrication of High-Entropy Carbide Ceramics (Ti, ZR, HF, NB, Ta) C Through Low-Temperature Calcium-Hydride Reduction of OxidesDocument9 pagesFabrication of High-Entropy Carbide Ceramics (Ti, ZR, HF, NB, Ta) C Through Low-Temperature Calcium-Hydride Reduction of OxidesShirazEinstineNo ratings yet

- Materials 12 00702Document16 pagesMaterials 12 00702Manish ShrungareNo ratings yet

- Gas Hydrates 1: Fundamentals, Characterization and ModelingFrom EverandGas Hydrates 1: Fundamentals, Characterization and ModelingDaniel BrosetaNo ratings yet

- Investigation of Dissolution of Aluminosilicates in Aqueous Alkaline Solution Under Laboratory ConditionsDocument7 pagesInvestigation of Dissolution of Aluminosilicates in Aqueous Alkaline Solution Under Laboratory ConditionsAli AddieNo ratings yet

- Hydration and Pore Structure Characteristics of Superplasticized Hardened Slag Cement PastesDocument5 pagesHydration and Pore Structure Characteristics of Superplasticized Hardened Slag Cement PastesAli AddieNo ratings yet

- Spinel Crystal Distribution and Settling in A High-Level Waste Melter Working As A Perfect MixerDocument5 pagesSpinel Crystal Distribution and Settling in A High-Level Waste Melter Working As A Perfect MixerAli AddieNo ratings yet

- Natural Corrosion of Old Potash Glass Coloured With Uranium CompoundsDocument11 pagesNatural Corrosion of Old Potash Glass Coloured With Uranium CompoundsAli AddieNo ratings yet

- Stabilizing The High-Temperature Properties of Gypsum-Free Portland Cement by Al O AdditionsDocument6 pagesStabilizing The High-Temperature Properties of Gypsum-Free Portland Cement by Al O AdditionsAli AddieNo ratings yet

- Measurement of Optical Transmittance - A Novel Method For Determination of The Glass Transition Temperature of Transparent GlassesDocument5 pagesMeasurement of Optical Transmittance - A Novel Method For Determination of The Glass Transition Temperature of Transparent GlassesAli AddieNo ratings yet

- Nitric Acid Attack On Hardened Paste of Geopolymeric CementsDocument7 pagesNitric Acid Attack On Hardened Paste of Geopolymeric CementsAli AddieNo ratings yet

- Sulphide Glasses Doped With Rare Earth Elements: Dimitrij Ležal, Marcel Poulain, Jiří ZavadilDocument6 pagesSulphide Glasses Doped With Rare Earth Elements: Dimitrij Ležal, Marcel Poulain, Jiří ZavadilAli AddieNo ratings yet

- Miscibility of Cuo, Nio, and Zno in Their Binary Mixtures and Its Impact For Reprocessing Industrial WastesDocument7 pagesMiscibility of Cuo, Nio, and Zno in Their Binary Mixtures and Its Impact For Reprocessing Industrial WastesAli AddieNo ratings yet

- High-Temperature Properties of A Binder Based On Gypsum-Free Portland Cement Over The Temperature Range of 20 To 1200 °CDocument7 pagesHigh-Temperature Properties of A Binder Based On Gypsum-Free Portland Cement Over The Temperature Range of 20 To 1200 °CAli AddieNo ratings yet

- Evaporation of Pbo-Sio and K O-Pbo-Sio MeltsDocument5 pagesEvaporation of Pbo-Sio and K O-Pbo-Sio MeltsAli AddieNo ratings yet

- The Impact of Bubble Arrays On Glass Flow and Redox State of Glass During Glass MeltingDocument8 pagesThe Impact of Bubble Arrays On Glass Flow and Redox State of Glass During Glass MeltingAli AddieNo ratings yet

- Glasses in The B O - V O System Obtained by Fast QuenchingDocument4 pagesGlasses in The B O - V O System Obtained by Fast QuenchingAli AddieNo ratings yet

- 2002 02 056 PDFDocument7 pages2002 02 056 PDFAli AddieNo ratings yet

- Effects of Host Micas, Interlayer Cations and The Addition of Pva On Formation and Porous Properties of Fluorine Mica - Iron (Iii) Oxide CompositesDocument7 pagesEffects of Host Micas, Interlayer Cations and The Addition of Pva On Formation and Porous Properties of Fluorine Mica - Iron (Iii) Oxide CompositesAli AddieNo ratings yet

- Prospects of Novel Macro-Defect-Free Cements For The New MillenniumDocument6 pagesProspects of Novel Macro-Defect-Free Cements For The New MillenniumAli AddieNo ratings yet

- Liquid Phase Separation in The Systems Teo - B O - M O (M O Al O, Ga O, SC O, La O, Bi O)Document4 pagesLiquid Phase Separation in The Systems Teo - B O - M O (M O Al O, Ga O, SC O, La O, Bi O)Ali AddieNo ratings yet

- Reprocessing of Zinc Galvanic Waste Sludge by Selective PrecipitationDocument4 pagesReprocessing of Zinc Galvanic Waste Sludge by Selective PrecipitationAli AddieNo ratings yet

- Preparation and Microstructure of Na-Psds Geopolymeric MatrixDocument10 pagesPreparation and Microstructure of Na-Psds Geopolymeric MatrixAli AddieNo ratings yet

- Corrosion of Sio and Tio Sol-Gel Layers in Water and Diluted HCLDocument3 pagesCorrosion of Sio and Tio Sol-Gel Layers in Water and Diluted HCLAli AddieNo ratings yet

- An Estimate of Orientation Effects On The Results of Size Distribution Measurements For Oblate ParticlesDocument8 pagesAn Estimate of Orientation Effects On The Results of Size Distribution Measurements For Oblate ParticlesAli AddieNo ratings yet

- Crystallization Behaviour of Fluorphlogopite Glass Ceramics: Received February 7, 2000 Accepted February 20, 2001Document8 pagesCrystallization Behaviour of Fluorphlogopite Glass Ceramics: Received February 7, 2000 Accepted February 20, 2001Ali AddieNo ratings yet

- The Influence of Simulated Body Fluid Composition On Carbonated Hydroxyapatite FormationDocument6 pagesThe Influence of Simulated Body Fluid Composition On Carbonated Hydroxyapatite FormationAli AddieNo ratings yet

- Characterization of Silica Sorbents by SansDocument3 pagesCharacterization of Silica Sorbents by SansAli AddieNo ratings yet

- 2002 01 015 PDFDocument9 pages2002 01 015 PDFAli AddieNo ratings yet

- Leucite Porcelain: E-Mail: Lezal@iic - Cas.czDocument4 pagesLeucite Porcelain: E-Mail: Lezal@iic - Cas.czAli AddieNo ratings yet

- What Is The True Kramers-Kronig Transform?Document3 pagesWhat Is The True Kramers-Kronig Transform?Ali AddieNo ratings yet

- Structural and Mechnical Response To A Thermo-Rheologic History of Spinel Sludge in High-Level Waste GlassDocument7 pagesStructural and Mechnical Response To A Thermo-Rheologic History of Spinel Sludge in High-Level Waste GlassAli AddieNo ratings yet

- Morphology and Chemical Composition of Minerals Inside The Phase Assemblage C - C S - C A S - C Af - Cs Relevant To Sulphoaluminate Belite CementsDocument9 pagesMorphology and Chemical Composition of Minerals Inside The Phase Assemblage C - C S - C A S - C Af - Cs Relevant To Sulphoaluminate Belite CementsAli AddieNo ratings yet

- Foc Data Sheet-U M CablesDocument4 pagesFoc Data Sheet-U M CablesKAVIYARASAN SNo ratings yet

- Myanmar National Building Code 2012: MaterialDocument35 pagesMyanmar National Building Code 2012: MaterialHeinMinn AungNo ratings yet

- OSG Promotie HYPRO 14.01 - 30.06.13Document20 pagesOSG Promotie HYPRO 14.01 - 30.06.13Vlad MiticaNo ratings yet

- Specification of Gabion WallsDocument2 pagesSpecification of Gabion WallsAnam JabbarNo ratings yet

- Manzil Coordination Compound: Please Fill in Your JEE Application Details by Clicking On Link BelowDocument4 pagesManzil Coordination Compound: Please Fill in Your JEE Application Details by Clicking On Link BelowAbhi kumarNo ratings yet

- Localised Corrosion and Atmospheric Corrosion of Stainless SteelsDocument131 pagesLocalised Corrosion and Atmospheric Corrosion of Stainless Steelsxia luoNo ratings yet

- Joining Process Ghosh and MalikDocument8 pagesJoining Process Ghosh and MalikPKNo ratings yet

- TLE - Information and Communication Technology Tle 8 Second Quarterly AssessmentDocument4 pagesTLE - Information and Communication Technology Tle 8 Second Quarterly AssessmentVincent Rivac100% (1)

- PE RT For Industrial and Oil Gas Applications TotalDocument7 pagesPE RT For Industrial and Oil Gas Applications TotalAlexNo ratings yet

- Halocarbon Compound: Presented By: Santos, John Merwin S. Pagdanganan, John Del C. Sanchez, Ronn Andrew EDocument10 pagesHalocarbon Compound: Presented By: Santos, John Merwin S. Pagdanganan, John Del C. Sanchez, Ronn Andrew ERalph Bernard Dela RosaNo ratings yet

- Adipic Acid Dihydrazide - A Unique Crosslinking Agent and CurativeDocument4 pagesAdipic Acid Dihydrazide - A Unique Crosslinking Agent and CurativeSuharti RifaiNo ratings yet

- CBSE Class 10 Chemistry WorksheetDocument1 pageCBSE Class 10 Chemistry WorksheetPragathi ShanmugamNo ratings yet

- SRF Pre-Feasibility Report DahejDocument66 pagesSRF Pre-Feasibility Report DahejPrashant SinghNo ratings yet

- 7.2 - Lindberg - Melting PropertiesDocument26 pages7.2 - Lindberg - Melting PropertiesHuy NguyenNo ratings yet

- Jss 1 Basic Technology Week 4 - 10Document9 pagesJss 1 Basic Technology Week 4 - 10Victory OjugbaNo ratings yet

- Fiber Manufacturing & ProcessDocument19 pagesFiber Manufacturing & ProcessJuddis JNo ratings yet

- Pet Coke Gasification - InfoDocument12 pagesPet Coke Gasification - Inforaj355No ratings yet

- Polymer Processing Assignment-5 (11,20,25,45,51)Document3 pagesPolymer Processing Assignment-5 (11,20,25,45,51)Eshan BhatNo ratings yet

- Product Form: Api 6A LT ASTM A694 F60Document5 pagesProduct Form: Api 6A LT ASTM A694 F60Ejaz KNo ratings yet

- Jawapan Modul SN T4 B5 PDFDocument16 pagesJawapan Modul SN T4 B5 PDFqq235No ratings yet

- Cambridge O Level: Chemistry 5070/12Document16 pagesCambridge O Level: Chemistry 5070/12Islamabad ALMA SchoolNo ratings yet

- Polymer: Adil Sultan, Faiz MohammadDocument12 pagesPolymer: Adil Sultan, Faiz MohammadenggsantuNo ratings yet

- The Safe Use of Cationic Flocculants With Reverse Osmosis MembranesDocument8 pagesThe Safe Use of Cationic Flocculants With Reverse Osmosis Membranesalexmuchmure2158No ratings yet

- Iran Polym J 2010, 19, 853 Compositos de NR-SBR en Nylon Propiedades Mecanicas y MorfologicasDocument9 pagesIran Polym J 2010, 19, 853 Compositos de NR-SBR en Nylon Propiedades Mecanicas y MorfologicasDavid ContrerasNo ratings yet

- A Kinetic Study of Copper Cementation With Zinc in Aqueous SolutionsDocument6 pagesA Kinetic Study of Copper Cementation With Zinc in Aqueous SolutionsIbrahim MücahitNo ratings yet

- Technical Information Surface Chemistry - Akzo NobelDocument15 pagesTechnical Information Surface Chemistry - Akzo NobelAlfredo MéndezNo ratings yet

- Cast Iron Weld RepairDocument1 pageCast Iron Weld RepairssNo ratings yet

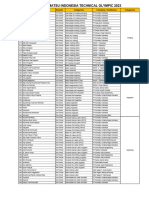

- 12th All Komatsu Indonesia Technical Olympic 2022 Official ResultDocument2 pages12th All Komatsu Indonesia Technical Olympic 2022 Official ResultMarchal KawengianNo ratings yet

- ABB FURSE SHORT FORM 2016 UK AnayaDocument22 pagesABB FURSE SHORT FORM 2016 UK AnayaIndra WanNo ratings yet

- AQA GCSE Combined C3 Reacting Masses 2 MSDocument6 pagesAQA GCSE Combined C3 Reacting Masses 2 MSHamdi AhmedNo ratings yet