Professional Documents

Culture Documents

Prospects of Novel Macro-Defect-Free Cements For The New Millennium

Uploaded by

Ali AddieOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Prospects of Novel Macro-Defect-Free Cements For The New Millennium

Uploaded by

Ali AddieCopyright:

Available Formats

Review papers

PROSPECTS OF NOVEL MACRO-DEFECT-FREE CEMENTS

FOR THE NEW MILLENNIUM

MILAN DRÁBIK, SUBHASH C. MOJUMDAR, ROBERT C. T. SLADE*

Institute of Inorganic Chemistry, Slovak Academy of Sciences

Dúbravská Cesta 9, 842 36 Bratislava, Slovak Republic

E-mail: uachmdra@savba.sk

*Department of Chemistry, University of Surrey

Guildford GU2 7XH, United Kingdom

Submitted July 13, 2001; accepted October 27, 2001

Keywords: MDF cement, Polymer grafting, Moisture resistance

INTRODUCTION aluminateferrite belite (SAFB) clinker, Portland cement

(OPC), and hydroxy-propylmethyl cellulose (HPMC) or

High strength cement-based materials developed polyphospate glass (poly-P). The incorporation of poly-

recently are being used to explore new applications mer by grafting polymer chains onto the surface of

which have not been possible with traditional cement grains and the concomitant modification of the bulk

and concrete technology. High flexural strength has not properties are briefly discussed in terms of the theory of

been a property typical of conventional cements, and functional polymers.

thus there is no established position for cement technol-

ogy in many modern industries. The relatively high cost

of these materials has limited their uses in civil and CURRENT STATUS

architectural applications, which are very common for

cements. Searching for new applications in areas cur- Following the initial invention and basic findings

rently dominated by metals, plastics and ceramics is a of Birchall and co-workers, there are an increasing

challenging task for cement scientists and engineers. number of reports that the polymer plays a more active

Macrodefect-free (MDF) cement is a polymer- role than simply being a rheological aid. These reports

cement composite at the micrometer and nanometer include [3-5]: (i) series of flexural vs. compressive

levels. In these materials the polymer and cement react strength values, the ratio of these values being much

synergistically to create a unique microstructure with higher than typical of hydraulic cements; (ii) the com-

distinct characteristics. MDF cements were first repor- position of cement as well as polymer is crucial for

ted [1,2] by the research group of Birchall at Imperial material performance; (iii) removal of polymer reduces

Chemical Industries plc (ICI, United Kingdom). They the strength by 90 % and, if the porosity created by that

are characterized by very high flexural strength and removal is filled by subsequent hydration, the strength

high modulus of elasticity. Kendall and co-workers [1] returns to only one third of the original value of MDF

attributed the high strength of these materials to the cement; (iv) dramatic loss of strength occurs on pro-

elimination of large critical flaws, which reduce the longed exposure to water. It has been concluded [3] that

strength of cast hydraulic cement pastes. The name MDF cements have a microstructure with close packed

Macro-Defect-Free cements was adopted for the new unreacted cement particles (consequent on a low w/s

materials, but alternative names such as MDF materials, ratio) acting as a filler within the binding matrix. The

organo-cement composites, and high flexural strength matrix itself consists of two interpenetrating phases, a

cement-polymer composites can be also found in the lit- cross-linked polymer and a nanocomposite interphase

erature. region around the cement particles. Several models for

Recently Young [3] and Odler [5] have given the local atomic-level structures are reviewed in [5], a

reviews on the chemical and mechano-chemical aspects significant aspect of the models essentially corresponds

of MDF cements. These reviews are updated here by to grafting of functional polymers to solid surfaces as

our findings on the future potential of blends of sulfo- presented in [6].

68 Ceramics − Silikáty 46 (2) 68-73 (2002)

Prospect of novel macro-defect-free cements for the new millennium

The monitoring of the synthetic sequence by a list, but illustrate the range of potential uses that exist

Banbury-type rheometer [7] (which mimics a twin roll for high flexural strength polymer-cement composites

mill) suggests that the formation of microstructure in or, at least, provide guidelines for application-oriented

MDF materials is a mechanochemical process, and both experiments. A comprehensive overview of potential

chemical reactions and mechanical effects are involved market applications for MDF materials (cf. table 1) has

to create a highly filled, cross-linked viscoelastic poly- been given by the Maeta Techno-Research Inc. in a mar-

mer system. The mechanical effects are postulated to be ket survey of Japanese and European manufacturing

due to fission of polymer chains during high shear mix- industries [11].

ing, creating fragments which subsequently react to

form cross-links. The chemical effects arise from

release of ionic species from the hydrating cement, MDF CEMENT IN THE SYSTEM

which participate in controlled cross-linking reactions OF LOW-ENERGY SAFB CLINKER -

that do not proceed as rapidly as the mechanical mixing. - OPC - HPMC - poly-P

The time dependence of the increase in the cross-link

density results in a characteristic plateau in torque vs. Both chemical and materials science approaches

mixing time plot, referred to as the window of process- have contributed to progress in control and improve-

ability. Crucial aspects of the microstructure are the ment of moisture resistance of MDF cements. Our

binding of the matrix with cement particles (formed due research is focused on the relationship of local atomic

to the mechanochemical process) and the grafting of structure (cross-links) to the moisture resistance of

cross-linked polymer chains to the surface of cement MDF cements in systems with SAFB clinker (and

grains. blends with OPC) with HPMC and/or poly-P. Details of

The control and improvement of the moisture a model for the local atomic structure, as assigned in our

resistance is a strategic target for MDF materials. Mois- magnetic resonance studies [12-14] and cited by Odler

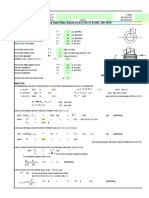

ture enters an MDF material by diffusion through the [5], are summarised in figure 1 (below). The cross-link-

polymer-containing phase, the residual cement particles ing volume and its bonding to the AFm skeleton serve as

hydrate destroying the interphase region and ultimately an example of the grafting of polymer chains to the

degrading the original binding matrix [3,5]. The extent grain surface through specific bonding interactions

of moisture absorption of high aluminium MDF cement

test pieces at ambient humidity and on immersion in

water has been reported [8-10], with the consequent

effects on the performance and phase composition [10].

Since the polymer is the conduit for moisture uptake,

resistance should be enhanced by increasing the

hydrophobicity of the polymer matrix itself. Studies of

the control/improvement of moisture resistance

(referred to in [3,5,8,11] and discussed further below)

rely on up to two of the following methods: (i) removal

of unreacted cement (reduction of the concentration of

active clinker); (ii) improved cross-linking by increas-

ing the amount of water soluble polymer in cross linked

component; (iii) substitution of the water soluble poly-

mer by a hydrophobic polymer.

A few potential applications of MDF materials

have been examined, with a view to meeting specific

market needs. Thermal and sound insulators for specif-

ic applications, reinforcement for ordinary cement

pastes or mortars, and formed body shells for specific

applications are promising. The technology utilized in

making a cement shell for a solar powered car can be

easily applied to form armours also. Loudspeaker cabi-

nets were also considered by Alford and Birchall [4];

generally a material higher in damping (tan δ), Young's

modulus and density has good acoustic properties. Figure 1. Diagrammatic representation of Al(Fe)-O-C(P)

These applications are by no means a comprehensive cross-links in the structure of an AFm-like skeleton.

Ceramics − Silikáty 46 (2) 68-73 (2002) 69

M. Drábik, S. C. Mojumdar, R. C. T. Slade

Table 1. Information on market needs, adapted from [11].

field intended applications required performance

roofing (tiles), permanent lightweight, durability, fire-

formwork, fire resistant doors proofing, impact resistance,

cover for underfloor cable pits, smaller deflection,

construction OA floor, Sewage pipe, productivity, possible size,

airport bridge, monument, cost, workability, maximum

electric poles in coastal area, angle sheet folded without

partition panel, door or damage, nailing

window shutters

replacement for angle steel, thermal resistance, acoustic

replacement for steel towers damping, incombustibility,

moulds for plastics or leather insulating properties, high

steel, machinery industry, printing rollers for strength, hardness, cost,

newspapers, repairing material machineability, ability to

for moulds, thermal insulators apply colours, dimensional

for injection molds, tube, accuracy, ability to process by

exhaust, handgrips for iron pots injection moulding

chemical corrosion - resistant tanks, corrosion resistance, setting

engineering oil tank shrinkage, cost

cover for cable ducts, globe lightweight, thermal

electrical insulators, propellers in resistance, dimensional stability,

engineering electrical generators, pipe, shaping, machineability,

housing for rotators, ability to apply colours, surface

electrical parts roughness, adhesion

tyre wheel, yacht, airplane, thermal and chemical

frame for motorcycle, boat deck, resistance, outdoor stability,

transportation interior panel for train, thermal acoustic damping, stiffness,

insulation, stiffening plate for dimensional accuracy,

outer shell of cars, brake shaping, mixing with powders

lining, pallets from waste FRP products

toy, swing, playground slide, low thermal conductivity,

model plane, model house, outdoor stability, non-toxicity,

miscellaneous signboard, pipe, fireproof safety cost, smaller in deflection,

box, cooler box, artificial teeth, productivity, strength equal

handicraft material for children to steel

(functional groups of the polymer participate in the for- increase the concentration of polymer, water soluble

mation of Al and Fe oxycation polyhedra). polymers which do not decompose during MDF pro-

The sensitivity of MDF samples to relative humid- cessing are tested. We have demonstrated [12-16] the

ity (RH) limits the moisture resistance and use of these potential of these low-energy clinkers and cements for

materials. Thus, a very important task, not only for sci- the MDF process, in particular (a) the involvement of

entists but also for technologists, is to minimize the Al, Fe, P, C and O atoms in Al(Fe)-O-C(P) cross-links

negative influence of high RH on MDF materials. The within amorphous AFm-like reaction product/intergran-

origins of moisture sensitivity are principally discussed ular gel, (b) thermoanalytical characteristics of cross-

by Young, Lewis, Igarashi and Pushpalal [3,8,9,11]. links, giving the temperature of cross-link decomposi-

Our studies are aimed at (i) reduction of the concentra- tion and partial degradation of polymeric phase at 250-

tion of the active clinker component, (ii) increase of the 450°C and (c) the influence of cross-link chemistry on

content of water soluble polymer in cross-linked section porosity, electrical impedance and microstructure, as

of the product matrix. To decrease the concentration of well as on bulk moisture resistance. We have proposed

reactive clinker, SAFB clinkers are used in which C2S an impregnation effect incorporating Al(Fe)-O-C(P)

phase is passive under MDF synthesis conditions. To cross-links [14,15].

70 Ceramics − Silikáty 46 (2) 68-73 (2002)

Prospect of novel macro-defect-free cements for the new millennium

The raw materials for MDF cement processing and ground powders; both these series were stored in desic-

subsequent moisture treatment were: SAFB clinker cators at controlled relative humidity (RH) values of 52

blended with OPC (CEM I 42.5) in the mass ratio 85:15, % and 100 %, and subsequently at ambient laboratory

HPMC {corresponding to the viscosity of a 2 % aque- conditions. Mass changes were recorded periodically

ous solution 80-120 cP}, poly-P of formula (NaPO3)n until constant mass defined equilibrium at the given

(used in solution) and Na5P3O10 (used as powder). Pro- RH. Data obtained are summarised in figure 2 (vide

cessing was as follows: (i) initial dry premixing of the infra); figure 2a shows equilibrium data after storage at

cement blends was followed by either (a) addition of RH = 100 %, and figure 2b shows equilibrium data for

HPMC or poly-P powders (5 % of total mass) and water the same samples subsequently stored under ambient

to give w/s = 0.2 or (b) addition of an aqueous solution laboratory conditions (and defines the irreversible mass

of poly-P to incorporate 5 % (by mass) of poly-P and to change). TG/DTA studies (TA Instruments SDT 2960)

give w/s = 0.2; (ii) twin-rolling until the mixture on materials after the moisture resistance tests are com-

reached the consistency of dense dough (up to 5 min); pared with data for virgin MDF cements (table 2) in

(iii) static 5 MPa pressure in a pellet die (10 mm diam- order to highlight the chemical/phase changes occurring

eter) applied for 30 min ≤ t ≤ 5 h; (iv) chemical reac- during moisture attack. Further methodological details

tions were kinetically frozen by air drying. Moisture are given in [11-16].

resistance was tested for cylindrical tablets and for

Table 2. Summary of TG mass change intervals (°C) and DTA peak temperatures (°C) for MDF cement samples derived from blends

of SAFB clinker and Portland cement.

MDF cement samples

polymer as synthesized after attack at RH = 100% and storage

additive (virgin) under ambient conditions

TG DTA TG DTA

20-250 190 20-250 92, 180

HPMC 250-500 * 282 * 250-500 * 295*

500-600 (CH) 500-700 (CH) (Cc) 680 (Cc)

20-250 181 20-250 76, 180

poly-P 250-500 * 308 * 250-500 * 315 *

500-600 * (CH) 500-720 * (CH) (Cc) 667 (Cc)

Thermal events are assigned as follows: * - decomposition of the cross-linked volume of MDF cement; CH - decomposition of portlandite,

Ca(OH)2; Cc - decomposition of CaCO3. Values in the presence of poly-P appear independent of whether (NaPO3)n or Na5P3O10 is used in the

synthesis.

a) b)

Figure 2. Moisture sensitivity expressed as a) ∆m (%) (total mass increase at RH = 100%) and b) ∆mir (irreversible mass change)

of individual MDF compositions. Left-hand columns give the values for powders, right-hand columns for tablets of the same com-

position. Compositions C are specified in the text. Compositions P (pressed without twin-rolling) illustrate the adverse effects of

an incomplete synthesis procedure.

Ceramics − Silikáty 46 (2) 68-73 (2002) 71

M. Drábik, S. C. Mojumdar, R. C. T. Slade

TESTS OF MOISTURE RESISTANCE tem against moisture sensitivity. In terms of a function-

AND THERMAL STABILITY al polymers approach [6], the intensity of grafting of

IN THE SYSTEM SAFB CLINKER - polymer chains to the surface and the impregnation of

- OPC - HPMC - poly-P MDF cement itself increase if poly-P alone is used and

with prolonged processing (delayed drying of samples).

The moisture and thermal stabilities of MDF The phenomenological link between functional poly-

cements were investigated in this system. A consider- mers and MDF cements is further technologically rele-

able volume of information arose from (i) mass changes vant evidence of the grafting effect of functional poly-

(totals ∆m at a given RH and irreversible components mers bonding to the surface of particles.

∆mir, the latter as a measure of moisture resistance, c.f. The chemical changes after moisture attack are a

figure 2) and (ii) thermoanalytical traces of powdered further important topic [19]. These can be deduced from

MDF cements showing cross-links and phase changes thermoanalytical traces for "fresh" and moisture-

during moisture attack in air. attacked samples (summarised in table 2) by analysis of

MDF materials synthesized with w/s = 0.2 and characteristic decomposition temperatures [12, 16, 17].

HPMC showed at RH = 100 % a total equilibrium mass After moisture attack phases with Tdecomp < 250°C are

increase ∆m ≈ 13 %, with the irreversible component present at higher mass percentage, the decomposition of

∆mir ≈ 6 % (C51, C52, C52` in figure 2). The samples the constant amount of cross-linked material occurs at

made with poly-P as the only polymer (C31(.1) and 250 < Tdecomp < 500°C, and a new CaCO3 phase with 500

C31(.2) in figure 2) gave equilibrium ∆m ≈ 5 % and ∆mir < Tdecomp < 750°C is detected. Considering the details of

≈ 3 %. Poly-P appears a better polymer than HPMC for the local structure of MDF cements based on SAFB

processing in this system, and this result is very impor- clinker [12-15], and the diagram in figure 1, there are

tant from the point of view of the prospects for MDF two inequivalent volumes with respect to moisture

technology. Partial reversibility of moisture uptake is resistance; the more resistant volume has a cross-linked

similarly reported in [10] for MDF cements based on Al(Fe)-O-C(P) skeleton and the second, less resistant,

high aluminium cement sequentially placed in the envi- volume is composed of cementitious hydraulic phases

ronments of high/low humidity. (cf. chapters by Odler and Lawrence in Lea's Chemistry

The mass increases for powdered samples at RH = of Cement and Concrete, 4th Edn, 1998). Moisture attack

100 % are very high, achieving the range ∆m ≈ 39-75 %. also results in the formation of some CaCO3 [16-18].

∆mir values are ca. 50 % of the total mass change in

every case. Both partial conversion of clinkers during

the original MDF syntheses and disruption of cross- CONCLUSIONS

links are indirectly responsible for the observed mass

increase when powdered samples are compared to Cements and cement-based advanced materials,

tablets. Due to the formation of cross-linked volumes, including MDF cements, have potential for a healthy

the unreacted clinker grains are partially prevented from long-term future with research and development provid-

the secondary interactions [14-15] in tablets. This type ing better quality products. New niche market products

of surface impregnation is removed by grinding, which could serve mankind, if industry grasps the benefits

consequently enables the completion of conversion due available. Universities and research institutes have an

to the secondary hydration and carbonation reactions in important function here in playing an increasing role in

moist atmospheres. The materials studied showed sig- fundamental understanding related to technical prob-

nificant differences also in equilibration times on expo- lems encountered in the field.

sure to high relative humidity; tablets required treat- Our studies have displayed the advantages and

ment in a moist atmosphere for up to 25 days, whereas potential of polyphosphate (poly-P) polymers for the

powders needed ca. 35 days for equilibration. MDF cements synthesized from SAFB clinker, and for

Comparison of data for tablets and powdered MDF blends of these with OPC; compact Al(Fe)-O-P cross-

cements show that the level of moisture resistance is links increase the intrinsic density and impregnate the

determined by the atomic structure of cross-links. Fur- system against the uptake of moisture. A preliminary

ther improvement is achieved by delayed drying of the model of functional polymers is directly relevant, func-

samples after the original syntheses [20]. When com- tional groups from the polymer participating in the for-

paring the effects of HPMC and poly-P, our studies mation of Al/Fe oxycation polyhedra. The density of

show the advantage and potential of poly-P for the MDF this mode of grafting the polymer to the surface of

cements; the compactness of Al(Fe)-O-P cross-links cement grains increases when poly-P is used and with a

increases the intrinsic density and impregnates the sys- prolonged processing time.

72 Ceramics − Silikáty 46 (2) 68-73 (2002)

Prospect of novel macro-defect-free cements for the new millennium

Fundamental chemical and materials science 7. McHugh A.J., Tan L.S., Gulgun M.A., Kriven W.M.

research is necessary in tackling the long-desired strate- in: MAETA Workshop on High Flexural Polymer-

gic goal for the application of MDF cements i.e control Cement Composite, p. 59-68, Sakata, 3-4 October

and improvement of moisture resistance. The phenome- 1996.

nological link between functional polymers and MDF 8. Igarashi H., Takarashi T.: Mat. Res. Soc. Symp. 245,

cements, especially in the bonding/grafting of polymer 173 (1992).

chains to grain surfaces and the concomitant modifica- 9. Lewis J.A. and Desai P.G.: MAETA Workshop on

tion/improvement in mechanical properties, will ulti- High Flexural Polymer-Cement Composite, p. 49-58,

mately provide control of fabrication and use for MDF Sakata, 3-4 October 1996.

cements. 10. Harsh S., Handoo S.K., Ahluwalia S.C.: Procee-

dings of 10th International Congress on the Chem-

istry of Cement (Ed.: H. Justnes), paper 4iv013,

Acknowledgements: Goteborg, 2-6 June 1997.

11. Pushpalal G.K., Maeda N., Kawano T., Kojimi H.:

A joint program linking the research groups of the Insti- MAETA Workshop on High Flexural Polymer-

tute of Inorganic Chemistry (SASci, Slovak Republic) Cement Composite, p. 35-48, Sakata, 3-4 October

and the University of Surrey (UK) is funded by the Slo- 1996.

vak Grant Agency for Science (project VEGA 12. Drabik M., Galikova L., Kubranova M., Slade

2/2073/22) and the Royal Society. R.C.T.: J. Mater. Chem. 4, 265 (1994).

13. Drabik M., Slade R.C.T.: British Ceramic Transac-

tions 94, 242 (1995).

14. Drabik M., Galikova L., Slade R.C.T.: MAETA

References Workshop on High Flexural Polymer-Cement Com-

posite, p. 107-118, Sakata, 3-4 October 1996.

1. Kendall K., Howard A.J., Birchall J.D.: Philos. 15. Drabik M., Zimermann P., Slade R.C.T.: Advances

Trans. R. Soc. London, A 310, 139 (1983). in Cement Research 10, 129 (1998).

2. Birchall J.D., Howard A.J., Kendall K., Raistrick 16. Drabik M., Galikova L., Zimermann P.: J.Therm.

J.H.: European Pat. Specification, June 1988, B1, Anal. & Calor. 56, 117 (1999).

No. 0055035, 1-17. 17. Strydom A., Potgieter J.H.: Proceedings of 10th

3. Young J.F. in: MAETA Workshop on High Flexural International Congress on the Chemistry of Cement

Polymer-Cement Composite, p. 1-12, Sakata, 3-4 (Ed.: H. Justnes), paper 2ii049, Goteborg, 2-6 Juni

October 1996. 1997.

4. Alford N.M., Birchall J.D.: Mat.Res.Soc.Symp. 42, 18. Drabik M., Galikova L., Hanic F., Sharp J.H.: Chem.

265 (1985). Papers 51, 363 (1997).

5. Odler I.: Special Inorganic Cements, Chpt. 13. 3. 19. Drabik M., Mojumdar S.C., Galikova L.: Cement &

MDF cements, E & FN Spon, London, New York Concrete Research 31, 743 (2001).

2000. 20. Mojumdar S.C.: J.Therm.Anal.&Calor. 64, 1133

6. Wegner G.: Acta Materialia 48, 253 (2000). (2001).

Ceramics − Silikáty 46 (2) 68-73 (2002) 73

You might also like

- Mechanical Strength and Water Resistance of Magnesium Oxysulfate CementDocument11 pagesMechanical Strength and Water Resistance of Magnesium Oxysulfate CementArlen Gutierrez100% (1)

- Nanoparticles Effect On FRP Filament-Winded Composites PerformanceDocument13 pagesNanoparticles Effect On FRP Filament-Winded Composites PerformanceUday MavooriNo ratings yet

- Composites Part B: Krzysztof Majerski, Barbara Surowska, Jaroslaw BieniasDocument9 pagesComposites Part B: Krzysztof Majerski, Barbara Surowska, Jaroslaw BieniasFilipe RibeiroNo ratings yet

- Construction and Building Materials: Martin Jasso, Dusan Bakos, Daryl Macleod, Ludo ZanzottoDocument7 pagesConstruction and Building Materials: Martin Jasso, Dusan Bakos, Daryl Macleod, Ludo ZanzottoRavichandran.PNo ratings yet

- Microstructural and Mechanical Characteristics of in Situ MetalDocument65 pagesMicrostructural and Mechanical Characteristics of in Situ MetalSegovia PerezNo ratings yet

- A Comparative Study of Mechanical Properties of Zinc Acrylate Epoxy nanocomposites Reinforced by AL2O3 and Cloisite®30B and Their Mixture: Tensile Strength and Fracture Toughness: A Comparative Study of Mechanical Properties of Zinc Acrylate Epoxy nanocomposites Reinforced by AL2O3 and Cloisite®30B and Their Mixture: Tensile Strength and Fracture ToughnessFrom EverandA Comparative Study of Mechanical Properties of Zinc Acrylate Epoxy nanocomposites Reinforced by AL2O3 and Cloisite®30B and Their Mixture: Tensile Strength and Fracture Toughness: A Comparative Study of Mechanical Properties of Zinc Acrylate Epoxy nanocomposites Reinforced by AL2O3 and Cloisite®30B and Their Mixture: Tensile Strength and Fracture ToughnessNo ratings yet

- Baldan2004a Article Adhesively-bondedJointsAndRepaDocument49 pagesBaldan2004a Article Adhesively-bondedJointsAndRepamastourNo ratings yet

- 1 s2.0 S0261306911001907 MainDocument9 pages1 s2.0 S0261306911001907 MainPratul DesouzaNo ratings yet

- SAP - Mechanical Properties, Drying Shrinkage, Microstructure of Modified Cement Mortar Based On Poly (Acrylamide-Co-Methacrylic Acid) MicrogelDocument12 pagesSAP - Mechanical Properties, Drying Shrinkage, Microstructure of Modified Cement Mortar Based On Poly (Acrylamide-Co-Methacrylic Acid) MicrogelNicolle Paredes ReyesNo ratings yet

- Research ArticleDocument9 pagesResearch ArticleGufran AhmadNo ratings yet

- Performance Enhancement of Concrete Through Waste PelletsDocument13 pagesPerformance Enhancement of Concrete Through Waste PelletsIrina RomanNo ratings yet

- 4096-Article Text-20292-1-10-20210531Document11 pages4096-Article Text-20292-1-10-20210531janhvi muleNo ratings yet

- Materials Today: Proceedings: Balu Maloth, N.V. Srinivasulu, R. RajendraDocument6 pagesMaterials Today: Proceedings: Balu Maloth, N.V. Srinivasulu, R. RajendraJúlia NogueiraNo ratings yet

- Research Article A Combined Experimental and First-Principle Calculation (DFT Study) For in Situ Polymer Inclusion Membrane-Assisted Growth of Metal-Organic Frameworks (Mofs)Document12 pagesResearch Article A Combined Experimental and First-Principle Calculation (DFT Study) For in Situ Polymer Inclusion Membrane-Assisted Growth of Metal-Organic Frameworks (Mofs)Shivansh MishraNo ratings yet

- Nanomaterials 11 01003Document19 pagesNanomaterials 11 01003Kuah LaksanNo ratings yet

- Jcs 04 00148Document19 pagesJcs 04 00148HARSHIT MAITHILNo ratings yet

- 1 s2.0 S004316481100634X Main PDFDocument11 pages1 s2.0 S004316481100634X Main PDFVignesh RajaNo ratings yet

- Effect of Nanoparticles On Tensile, Impact and Fatigue Properties of Fibre Reinforced PlasticsDocument4 pagesEffect of Nanoparticles On Tensile, Impact and Fatigue Properties of Fibre Reinforced PlasticsOliver RisteskiNo ratings yet

- Epoxy, Polyester and Vinyl Ester Based Polymer Concrete A ReviewDocument25 pagesEpoxy, Polyester and Vinyl Ester Based Polymer Concrete A Reviewwmh280815459No ratings yet

- Construction and Building MaterialsDocument8 pagesConstruction and Building MaterialsVeronika PrymNo ratings yet

- Evaluations of SomeDocument11 pagesEvaluations of SomeEris DNo ratings yet

- Journal of Inorganic and Organometallic Polymers and MaterialsDocument14 pagesJournal of Inorganic and Organometallic Polymers and MaterialsShaik KaleemullaNo ratings yet

- Chapter 05Document8 pagesChapter 05vishal teraiyaNo ratings yet

- Separation and Puri Fication Technology: SciencedirectDocument9 pagesSeparation and Puri Fication Technology: SciencedirectMarcela JaimesNo ratings yet

- HdpeDocument9 pagesHdpeXuân Giang NguyễnNo ratings yet

- 47 Impact Resistance To Polypropylene PrepegsDocument12 pages47 Impact Resistance To Polypropylene PrepegsAfsar HusainNo ratings yet

- Concreto Polimérico Reforzado Con Fibras: Efecto de La Radiación GammaDocument11 pagesConcreto Polimérico Reforzado Con Fibras: Efecto de La Radiación GammaLuisCarlosNo ratings yet

- Badry 2021 IOP Conf. Ser. Mater. Sci. Eng. 1090 012032Document17 pagesBadry 2021 IOP Conf. Ser. Mater. Sci. Eng. 1090 012032rahul kumarNo ratings yet

- Polymer/Clay NanocompositesDocument27 pagesPolymer/Clay NanocompositesBbaPbaNo ratings yet

- Buildings: Physical and Mechanical Properties of Fly Ash Based Geopolymer Concrete Compared To Conventional ConcreteDocument14 pagesBuildings: Physical and Mechanical Properties of Fly Ash Based Geopolymer Concrete Compared To Conventional ConcreteSrToshiNo ratings yet

- Effect of Nano Clay Mechanical Behaviour On Nano ClayDocument5 pagesEffect of Nano Clay Mechanical Behaviour On Nano ClayHari PrasadNo ratings yet

- PolymersDocument14 pagesPolymersJuan RochaNo ratings yet

- Construction and Building MaterialsDocument13 pagesConstruction and Building MaterialsAshfaq AhmedNo ratings yet

- A Critical Review On Erosion Wear Characteristics of Polymer Matrix CompositesDocument18 pagesA Critical Review On Erosion Wear Characteristics of Polymer Matrix CompositesankushNo ratings yet

- Mechanical Properties of Cement-Bitumen Composites For Semi-Flexible Pavement SurfacingDocument9 pagesMechanical Properties of Cement-Bitumen Composites For Semi-Flexible Pavement SurfacingMuslim AFHNo ratings yet

- Polymer Concrete and Its Potential in The Construction IndustryDocument3 pagesPolymer Concrete and Its Potential in The Construction Industrylavanya_prabhaNo ratings yet

- 1 s2.0 S0958946520302638 MainDocument12 pages1 s2.0 S0958946520302638 MainArunNo ratings yet

- Polymers 14 04777 v2Document15 pagesPolymers 14 04777 v2mohamed aliNo ratings yet

- Al-Mulla 2020 IOP Conf. Ser. Mater. Sci. Eng. 671 012131Document13 pagesAl-Mulla 2020 IOP Conf. Ser. Mater. Sci. Eng. 671 012131THORAVI SARODENo ratings yet

- Untitled PDFDocument7 pagesUntitled PDFVansala GanesanNo ratings yet

- Untitled PDFDocument7 pagesUntitled PDFVansala GanesanNo ratings yet

- Investigations On The Mechanical Properties of Conducting Polymer Coating-Substrate Structures and Their Influencing FactorsDocument28 pagesInvestigations On The Mechanical Properties of Conducting Polymer Coating-Substrate Structures and Their Influencing FactorsAldo Córdoba GuerreroNo ratings yet

- Mechanical Characterization of Sheet Moulding Composites For The Automotive IndustryDocument6 pagesMechanical Characterization of Sheet Moulding Composites For The Automotive IndustryCaio OliveiraNo ratings yet

- Geopolymeric Composite CementDocument8 pagesGeopolymeric Composite CementJoão RicardoNo ratings yet

- 2003 - PM Aluminum Matrix Composites - An OverviewDocument4 pages2003 - PM Aluminum Matrix Composites - An OverviewakjeevananthamNo ratings yet

- Polymer/Clay Nanocomposites: A ReviewDocument26 pagesPolymer/Clay Nanocomposites: A ReviewmajeedssmNo ratings yet

- Composites: Part B: Guo-Ming Lin, Guang-You Xie, Guo-Xin Sui, Rui YangDocument6 pagesComposites: Part B: Guo-Ming Lin, Guang-You Xie, Guo-Xin Sui, Rui YangFabian MelinaoNo ratings yet

- 2 67 1588053965 13.ijmperdjun202013Document10 pages2 67 1588053965 13.ijmperdjun202013TJPRC PublicationsNo ratings yet

- Super PlastiDocument8 pagesSuper PlastiBEN NARENDRANNo ratings yet

- Degradation Rate of Natural Fiber in Cement Composites Exposed To Various Accelerated Aging Environment Conditions PDFDocument15 pagesDegradation Rate of Natural Fiber in Cement Composites Exposed To Various Accelerated Aging Environment Conditions PDFJosé Antonio Cruz DíazNo ratings yet

- Nano Metal Matrix Composites Fabrication MethodsDocument13 pagesNano Metal Matrix Composites Fabrication MethodsWaseem ShameerNo ratings yet

- A Guide For Analysis and Comparative Study On Conductive ConcreteDocument4 pagesA Guide For Analysis and Comparative Study On Conductive ConcreteLavanyaNo ratings yet

- Different-2D-materials-based-polyetherimide-mixed-matrix-membranes-for-CON-separation2020Journal-of-Industrial-and-Engineering-ChemistryDocument13 pagesDifferent-2D-materials-based-polyetherimide-mixed-matrix-membranes-for-CON-separation2020Journal-of-Industrial-and-Engineering-ChemistryDarwin ZuluagaNo ratings yet

- Ceramic vs Polymeric Membranes for Cadmium RemovalDocument2 pagesCeramic vs Polymeric Membranes for Cadmium RemovalOrlando BernalNo ratings yet

- The Preparation and Properties Study of Polydimethylsiloxane-Based Coatings Modified by Epoxy ResinDocument10 pagesThe Preparation and Properties Study of Polydimethylsiloxane-Based Coatings Modified by Epoxy ResinjahhanshirNo ratings yet

- Construction and Building MaterialsDocument16 pagesConstruction and Building MaterialsNasir ShafiqNo ratings yet

- Properties of Concrete Incorporating Nano-SilicaDocument7 pagesProperties of Concrete Incorporating Nano-SilicaChan NovNo ratings yet

- FRC Blast ResistanceDocument16 pagesFRC Blast ResistanceAamirKhattakNo ratings yet

- True Kramer-Kronig TransformDocument3 pagesTrue Kramer-Kronig TransformAli AddieNo ratings yet

- The Influence of Simulated Body Fluid Composition On Carbonated Hydroxyapatite FormationDocument6 pagesThe Influence of Simulated Body Fluid Composition On Carbonated Hydroxyapatite FormationAli AddieNo ratings yet

- Prediction of Heat Capacities of Solid Binary Oxides Using Group Contribution MethodDocument4 pagesPrediction of Heat Capacities of Solid Binary Oxides Using Group Contribution MethodAnggita SpNo ratings yet

- Measuring Glass Transition via Optical TransmittanceDocument5 pagesMeasuring Glass Transition via Optical TransmittanceAli AddieNo ratings yet

- Natural Corrosion of Old Potash Glass Coloured With Uranium CompoundsDocument11 pagesNatural Corrosion of Old Potash Glass Coloured With Uranium CompoundsAli AddieNo ratings yet

- The Effect of Nucleation Catalysts on CrystallizationDocument9 pagesThe Effect of Nucleation Catalysts on CrystallizationAli AddieNo ratings yet

- Spinel Crystal Distribution and Settling in A High-Level Waste Melter Working As A Perfect MixerDocument5 pagesSpinel Crystal Distribution and Settling in A High-Level Waste Melter Working As A Perfect MixerAli AddieNo ratings yet

- Investigation of Dissolution of Aluminosilicates in Aqueous Alkaline Solution Under Laboratory ConditionsDocument7 pagesInvestigation of Dissolution of Aluminosilicates in Aqueous Alkaline Solution Under Laboratory ConditionsAli AddieNo ratings yet

- Characterization of Silica Sorbents by SansDocument3 pagesCharacterization of Silica Sorbents by SansAli AddieNo ratings yet

- Stabilizing The High-Temperature Properties of Gypsum-Free Portland Cement by Al O AdditionsDocument6 pagesStabilizing The High-Temperature Properties of Gypsum-Free Portland Cement by Al O AdditionsAli AddieNo ratings yet

- Reprocessing zinc galvanic sludge selective precipitationDocument4 pagesReprocessing zinc galvanic sludge selective precipitationAli AddieNo ratings yet

- White Cement Review - Properties, Manufacture and ProspectsDocument6 pagesWhite Cement Review - Properties, Manufacture and ProspectsMiguel SegundoNo ratings yet

- CuO, NiO, ZnO miscibility limits impact industrial waste reprocessingDocument7 pagesCuO, NiO, ZnO miscibility limits impact industrial waste reprocessingAli AddieNo ratings yet

- Hydration and Pore Structure Characteristics of Superplasticized Hardened Slag Cement PastesDocument5 pagesHydration and Pore Structure Characteristics of Superplasticized Hardened Slag Cement PastesAli AddieNo ratings yet

- 2002 02 056 PDFDocument7 pages2002 02 056 PDFAli AddieNo ratings yet

- Corrosion of Sio and Tio Sol-Gel Layers in Water and Diluted HCLDocument3 pagesCorrosion of Sio and Tio Sol-Gel Layers in Water and Diluted HCLAli AddieNo ratings yet

- Leucite Porcelain: E-Mail: Lezal@iic - Cas.czDocument4 pagesLeucite Porcelain: E-Mail: Lezal@iic - Cas.czAli AddieNo ratings yet

- Glasses in the B2O3-V2O5 SystemDocument4 pagesGlasses in the B2O3-V2O5 SystemAli AddieNo ratings yet

- Nitric Acid Attack On Hardened Paste of Geopolymeric CementsDocument7 pagesNitric Acid Attack On Hardened Paste of Geopolymeric CementsAli AddieNo ratings yet

- High-Temperature Properties of A Binder Based On Gypsum-Free Portland Cement Over The Temperature Range of 20 To 1200 °CDocument7 pagesHigh-Temperature Properties of A Binder Based On Gypsum-Free Portland Cement Over The Temperature Range of 20 To 1200 °CAli AddieNo ratings yet

- The Impact of Bubble Arrays On Glass Flow and Redox State of Glass During Glass MeltingDocument8 pagesThe Impact of Bubble Arrays On Glass Flow and Redox State of Glass During Glass MeltingAli AddieNo ratings yet

- Evaporation of Pbo-Sio and K O-Pbo-Sio MeltsDocument5 pagesEvaporation of Pbo-Sio and K O-Pbo-Sio MeltsAli AddieNo ratings yet

- Structural and Mechnical Response To A Thermo-Rheologic History of Spinel Sludge in High-Level Waste GlassDocument7 pagesStructural and Mechnical Response To A Thermo-Rheologic History of Spinel Sludge in High-Level Waste GlassAli AddieNo ratings yet

- An Estimate of Orientation Effects On The Results of Size Distribution Measurements For Oblate ParticlesDocument8 pagesAn Estimate of Orientation Effects On The Results of Size Distribution Measurements For Oblate ParticlesAli AddieNo ratings yet

- Sulphide Glasses Doped With Rare Earth Elements: Dimitrij Ležal, Marcel Poulain, Jiří ZavadilDocument6 pagesSulphide Glasses Doped With Rare Earth Elements: Dimitrij Ležal, Marcel Poulain, Jiří ZavadilAli AddieNo ratings yet

- Effects of host micas and PVA on porous Fe2O3-fluorine mica compositesDocument7 pagesEffects of host micas and PVA on porous Fe2O3-fluorine mica compositesAli AddieNo ratings yet

- Crystallization Behaviour of Fluorphlogopite Glass Ceramics: Received February 7, 2000 Accepted February 20, 2001Document8 pagesCrystallization Behaviour of Fluorphlogopite Glass Ceramics: Received February 7, 2000 Accepted February 20, 2001Ali AddieNo ratings yet

- Preparation and Microstructure of Na-Psds Geopolymeric MatrixDocument10 pagesPreparation and Microstructure of Na-Psds Geopolymeric MatrixAli AddieNo ratings yet

- Liquid Phase Separation in The Systems Teo - B O - M O (M O Al O, Ga O, SC O, La O, Bi O)Document4 pagesLiquid Phase Separation in The Systems Teo - B O - M O (M O Al O, Ga O, SC O, La O, Bi O)Ali AddieNo ratings yet

- Chemical Engineering Process in Cement ProductionDocument18 pagesChemical Engineering Process in Cement ProductionNeeraj SharmaNo ratings yet

- 222 Poplar DriveDocument21 pages222 Poplar DrivelkdalksndNo ratings yet

- Sikabond® T-100: Product Data SheetDocument5 pagesSikabond® T-100: Product Data Sheetemre sönmezNo ratings yet

- Influence of Silica Fume On High Strength Lightweight ConcreteDocument8 pagesInfluence of Silica Fume On High Strength Lightweight ConcretePhanHathamNo ratings yet

- Appendix J3 Preliminary Design Report Retaining WallsDocument50 pagesAppendix J3 Preliminary Design Report Retaining WallsKhalilNo ratings yet

- Slef Cleaning Concrete PDFDocument9 pagesSlef Cleaning Concrete PDFP Guru RajuNo ratings yet

- 6.1 Steel Structures Design L T P Period/Week 6 0 0 RationaleDocument23 pages6.1 Steel Structures Design L T P Period/Week 6 0 0 RationaleVishakha PatelNo ratings yet

- Larsen & Toubro Limited FCCE List of Construction CodesDocument3 pagesLarsen & Toubro Limited FCCE List of Construction CodesShikhin GargNo ratings yet

- Area Wise Structure Package SummaryDocument476 pagesArea Wise Structure Package SummaryNurseha FaridNo ratings yet

- Section 2Document6 pagesSection 2Marcos AmorimNo ratings yet

- Basf 9665 Conipur M 865 Z enDocument3 pagesBasf 9665 Conipur M 865 Z enMarijana JukicNo ratings yet

- Comparison of Structural Behaviour of Flat Plate and Flat Slab RC BuildingsDocument5 pagesComparison of Structural Behaviour of Flat Plate and Flat Slab RC BuildingsNan Shwe Kyi HtweNo ratings yet

- Forsa Formwork System PresentationsDocument45 pagesForsa Formwork System PresentationsAhmedAliKhaskayaNo ratings yet

- Creep and Shrinkage - KhouryDocument12 pagesCreep and Shrinkage - KhouryMouhaNo ratings yet

- Preservation ManualDocument159 pagesPreservation ManualPedro Troncoso Acuña100% (1)

- 4 Design Considerations For Steel Fiber Reinforced ConcreteDocument18 pages4 Design Considerations For Steel Fiber Reinforced Concretesochiva pramesti100% (2)

- Mdterm Comprehensive QuizDocument2 pagesMdterm Comprehensive QuizMac KYNo ratings yet

- Development of Tall Buildings in JakartaDocument11 pagesDevelopment of Tall Buildings in JakartaponyochanNo ratings yet

- JSCE 1997 (B)Document170 pagesJSCE 1997 (B)Victor Calvet RodriguezNo ratings yet

- Anchorage Design with Circular Base PlateDocument5 pagesAnchorage Design with Circular Base PlateGabbo pnukNo ratings yet

- Concrete Cube Test Report: Cast Laboratories Pte LTDDocument1 pageConcrete Cube Test Report: Cast Laboratories Pte LTDsawwahwahNo ratings yet

- Sikafloor 2530 W-LP, 18kg (Ab)Document4 pagesSikafloor 2530 W-LP, 18kg (Ab)azheminNo ratings yet

- High Strength Recycled Aggregate Concrete using MetakaolinDocument64 pagesHigh Strength Recycled Aggregate Concrete using MetakaolinAbhishekNo ratings yet

- Ug BreakwatersDocument34 pagesUg BreakwatersMahiba Shalon100% (1)

- Design of Prestressed Concrete ElementsDocument20 pagesDesign of Prestressed Concrete ElementsCivil EngineeringNo ratings yet

- Comparative Analysis of A Tall Structure PDFDocument8 pagesComparative Analysis of A Tall Structure PDFHugo MeloNo ratings yet

- Method Statement - Post Tensioning WorksDocument15 pagesMethod Statement - Post Tensioning WorksMirzojon MirzoevNo ratings yet

- Drop Weight Impact On Hybrid-Fiber ECC Blast Panels-ZhangDocument10 pagesDrop Weight Impact On Hybrid-Fiber ECC Blast Panels-ZhangsardarumersialNo ratings yet

- TDS - MasterFlow 718 Plus V1Document2 pagesTDS - MasterFlow 718 Plus V1Erection DepartmentNo ratings yet

- MCGM Usor - BLD - 2013Document201 pagesMCGM Usor - BLD - 2013Abhijeet Vardhe100% (1)