Professional Documents

Culture Documents

Mill Questionnaire - Rev0

Uploaded by

samuel libseworkOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Mill Questionnaire - Rev0

Uploaded by

samuel libseworkCopyright:

Available Formats

Questionnaire for complete grinding circuits

Please select language: English

Please select type of modernisation: Complete grinding circuits

Type of product: cement

Company:

Plant:

Contact:

Address:

Christian Pfeiffer Maschinenfabrik GmbH

Sudhofer Weg 110-112

59269 Beckum

phone: +49 (0)2521 - 849 - 00

fax: +49 (0)2521 - 849 - 123

e-mail: office@christianpfeiffer.de

homepage:http://www.christianpfeiffer.de

495046714.xls Rev.: 0 page 1 of 13

Christian Pfeiffer Maschinenfabrik GmbH

Sudhofer Weg 110-112

59269 Beckum

phone: +49 (0)2521 - 849 - 00

fax: +49 (0)2521 - 849 - 123

e-mail: office@christianpfeiffer.de

homepage:http://www.christianpfeiffer.de

GENERAL DATA OF PLANT

Country:

Elevation above sea level: m

Ambient temperatures: min: °C

max: °C

average: °C

Air humidity at average ambient temperature: %

Power supply: Frequency: Hz

Medium voltage: V

>= kW

Low voltage: V

>= kW

Control voltage: V / DC

V / AC

Control system (PLC): yes

Brand:

Type:

Year of installation:

analog signals: 1

current

range: mA

Remarks:

GENERAL DATA OF GRINDING CIRCUIT

Name of mill circuit:

Grinding process: dry

Grinding circuit: closed

Pre-grinding system: none

Feed to mill: gravimetric

automatic

495046714.xls Rev.: 0 page 2 of 13

Control concept: automatic

###

feed to mill = constant

Current of bucket elevator: no max. A

Weighing of separator rejects: no

Mill power: no 2

Sound level (electrical ear): no 2

Other: no

DATA OF MILL

GENERAL DATA

Brand of mill:

Year of construction:

Number of grinding chambers two2

Material discharge end discharge

Rotation of mill counter-clockwise looking from inlet to discharge

number of rotations: min-1

GEOMETRICAL DATA

Length of mill shell: mm

Inside diameter of mill shell: mm

Diameter of material inlet: mm

Clearance 1st compartment: mm

Effective grinding length 1st chamber: mm

Clearance 2nd compartment: mm

Effective grinding length 2nd chamber: mm

Diameter of material outlet: mm

MILL DRIVE / MILL BEARING

Type of drive: Central drive

Type of mill bearing: Trunnion bearing

495046714.xls Rev.: 0 page 3 of 13

Installed motor power: kW

Absorbed motor power (counter reading): kW

Voltage: V

Frequency: Hz

Current: A

Power factor of motor: cos j

GRINDING MEDIA

Actual grinding media composition

Brand:

Manufacturing method cast

1st compartment 2nd compartment 3rd compartment

Ø [mm] Mass [t] Ø [mm] Mass [t] Ø [mm] Mass [t]

Total mass: 0.0 t Total mass: 0.0 t Total mass: 0.0 t

Volume load: Volume load: Volume load:

Wear rate: Wear rate: Wear rate:

MILL HEAD LINING - INLET

Brand:

Filling piece: no

Mill head: straight

Number of rings: 5 5

outer ring 2. ring 3. ring 4. ring inner ring

[1] [2] [3] [4] [5]

Number of plates [-]:

Nominal thickness [mm]:

Actual average thickness [m

Highest wear rate at ring: 4

495046714.xls Rev.: 0 page 4 of 13

4

Material:

Manufacturing method: cast

Date of commissioning:

Operating time: h

Expected life time: h

Remarks: Please attach picture / sketch of wear

INTERMEDIATE DIAPHRAGM - ÜTW

between first and second grinding chamber

DIAPHRAGM STRUCTURE

Type/ Generation:

Brand:

Date of commissioning:

Material flow control no

Operating time: h

Width of diaphragm on mill shell: mm

Diameter of center opening: mm

SLOTTED PLATES

Brand:

Filling piece: no

Number of rings: 5 5

outer ring 2. ring 3. ring 4. ring inner ring

[1] [2] [3] [4] [5]

Number of plates [-]:

Nominal thickness [mm]:

Actual average thickness [m

Highest wear rate at ring: 4

Slot width: mm

Direction of slots: radial

Material:

cast

495046714.xls Rev.: 0 page 5 of 13

Manufacturing method: cast

Date of commissioning:

Operating time: h

Expected life time: h

Remarks: Please attach pictures / sketch / drawing

BACKSIDE PLATES

Brand:

Filling piece: no

Number of rings: 5 5

outer ring 2. ring 3. ring 4. ring inner ring

[1] [2] [3] [4] [5]

Number of plates [-]:

Nominal thickness [mm]:

Actual average thickness [m

Slot width [mm]:

Highest wear rate at ring: 4

Material:

Manufacturing method: cast

Date of commissioning:

Operating time: h

Expected life time: h

Remarks: Please attach pictures / sketch / drawing

DISCHARGE DIAPHRAGM - ATW

DIAPHRAGM STRUCTURE

Type/ Generation:

Brand:

Date of commissioning:

495046714.xls Rev.: 0 page 6 of 13

Operating time: h

Width of diaphragm on mill shell: mm

Diameter of center opening: mm

SLOTTED PLATES

Brand:

Filling piece: no

Number of rings: 5 5

outer ring 2. ring 3. ring 4. ring inner ring

[1] [2] [3] [4] [5]

Number of plates [-]:

Nominal thickness [mm]:

Actual average thickness [m

Highest wear rate at ring: 4

Slot width: mm

Direction of slots: radial

Material:

Manufacturing method: cast

Date of commissioning:

Operating time: h

Expected life time: h

Remarks: Please attach pictures / sketch / drawing

LINING 1st COMPARTMENT

grinding chamber

Brand:

Type:

Design:

Fastening system: bolted

Effective grinding length: m

Number of lining plates - mill axial direction:

495046714.xls Rev.: 0 page 7 of 13

Number of plates per ring:

Number of lifter plates per ring:

Special plates at first ring: no

Special plates at manhole: no

Other special plates: no

Backing: other

Nominal thickness of plates: mm

Actual thickness at chamber inlet: mm

Actual thickness at middle of chamber: mm

Actual thickness at end of chamber: mm

Average height of lifters: mm

Material:

Date of commissioning:

Operating time: h

Expected life time: h

Remarks: Please attach pictures / sketch / drawing

LINING 2nd COMPARTMENT

grinding chamber

Brand:

Type:

Design:

Fastening system: bolted

Effective grinding length: m

Number of lining plates - mill axial direction:

Number of plates per ring:

Number of lifter plates per ring:

Special plates at first ring: no

Special plates at manhole: no

Other special plates: no

Backing: rubber

495046714.xls Rev.: 0 page 8 of 13

rubber

Nominal thickness of plates: mm

Actual thickness at chamber inlet: mm

Actual thickness at middle of chamber: mm

Actual thickness at end of chamber: mm

Average height of lifters: mm

Material:

Date of commissioning:

Operating time: h

Expected life time: h

Remarks: Please attach pictures / sketch / drawing

MILL FILTER

Type of filter:

Brand:

Date of commissioning:

Design filter size: Nm³/h

Am³/h

at operating temperature: °C

Pre-collector: no2

Filterproduct to: 2 elevator

Bucket

Suction at: [daPa] [°C]

Mill inlet:

Mill outlet:

Filter inlet:

Filter outlet:

Fan inlet:

Designed pressure drop of fan: daPa

Designed air flow of fan: Am³/h

at temperature: °C

Installed motor power of fan: kW

495046714.xls Rev.: 0 page 9 of 13

Remarks:

DATA SEPARATOR

Type:

Brand:

Design air flow: Am³/h

at temperature: °C

Date of commissioning:

Collection of fines: Cyclone

Type of filter:

Brand:

Design filter size: Am³/h

at operating temperature: °C

Suction at filter inlet: daPa

Suction at filter outlet daPa

Designed pressure drop of fan: daPa

Designed air flow of fan: Am³/h

at temperature: °C

Installed motor power of fan: kW

Date of commissioning:

Separation air circuit: 1

closed

Production rate Fineness / Blaine Feed to separator:

[t/h] [cm²/g] [t/h]

Actual production:

Max. production:

Separation air flow: Am³/h

at operating temperature: °C

Specific load [fines [kg] / air flow [Am³]): kg/Am³

Installed motor power separator: kW

Absorbed motor power separator: kW

495046714.xls Rev.: 0 page 10 of 13

Installed motor power fan: kW

Absorbed motor power fan: kW

Residue: Fineness / Blaine

Fineness of:

90µm 63µm 45µm [cm²/g]

Separator feed:

Separator rejects:

Separator fines:

Finish product:

Mill filter discharge:

Separator filter discharge:

Remarks: Please attach flow sheet / tromp-curve analysis

MILL FEEDING MATERIAL

Cement types:

Product: 1 2 3 4 5

[%] [%] [%] [%] [%]

Type:

Clinker:

Gypsum:

Limestone:

Puzzolana:

Slag:

Standard:

Feed properties

Feed properties

Average Max. Average Max. Max. feed

moisture moisture temperature temperature size

[M%] [M%] [°C] [°C] [mm]

Clinker:

Gypsum:

Limestone:

Puzzolana:

Slag:

0

0

495046714.xls Rev.: 0 page 11 of 13

Specific parameter

Feed properties

Grindability Bulk density Quartz -

acc. Zeisel content

at

3000cm²/g

Component: [kWh/t] [t/m³] [M%]

0

0

0

0

0

0

Transport equipment

CIRCULATING BUCKET ELEVATOR

Max. conveying capacity: t/h

Installed power: kW

Absorbed power: kW

FINISH PRODUCT TRANSPORT

Max. conveying capacity: t/h

Finish Product

Product: 1 2 3 4 5

Type: 0 0 0 0 0

Percent of Total Production [%]:

Production rate [t/h]:

Fineness acc. Blaine: [cm²/g]

Residue on 45µm: [m%]:

Circulation load (Sep.-Feed/Sep.- ###

Fines):

Spec. energy consumption (mill counter) [kWh/t]:

Product temperature mill outlet [°C]:

Product temperature cooler outlet [°C]:

Water spray [l/h]:

Grinding aid:

ml/t

495046714.xls Rev.: 0 page 12 of 13

Grinding aid consumption: ml/t ###

495046714.xls Rev.: 0 page 13 of 13

You might also like

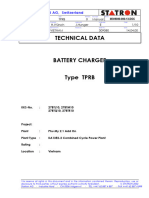

- Technical Data Battery ChargerDocument10 pagesTechnical Data Battery ChargerPhiNo ratings yet

- Fiche Technique Transfo France Transfo PDFDocument3 pagesFiche Technique Transfo France Transfo PDFKDANo ratings yet

- Refrigeration Industries & Storage Co.: PackageDocument3 pagesRefrigeration Industries & Storage Co.: PackageWaheed MidoNo ratings yet

- Welding Technology Corporation: Is A New Concept in Weld MonitorsDocument2 pagesWelding Technology Corporation: Is A New Concept in Weld MonitorsCHRISTIAN ZAVALANo ratings yet

- Electrical Data General Data: Order NumberDocument1 pageElectrical Data General Data: Order Numberandri putrantoNo ratings yet

- Inquiry/Order: Your Contact Partner at SEWDocument3 pagesInquiry/Order: Your Contact Partner at SEWAnonymous 9ZSghmNo ratings yet

- Siemens: Electrical Data General DataDocument1 pageSiemens: Electrical Data General Dataadefaizalmaizar12No ratings yet

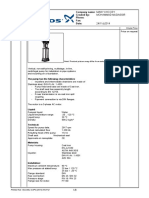

- CRN 57 AcaaehqqeDocument6 pagesCRN 57 AcaaehqqeDiannita CarrolinaNo ratings yet

- 4HCH007690 - Commissioning Report - 1491-HYM-002Document16 pages4HCH007690 - Commissioning Report - 1491-HYM-002leonardo rinconNo ratings yet

- Gildemeister N.E.F. CT 40Document1 pageGildemeister N.E.F. CT 40aleksataman510No ratings yet

- Fisa Tehnica Pompe SPAUDocument4 pagesFisa Tehnica Pompe SPAUciui_ionelNo ratings yet

- Technical Data Sheet For Avk-Alternators: Unsaturated Saturated Unsaturated SaturatedDocument9 pagesTechnical Data Sheet For Avk-Alternators: Unsaturated Saturated Unsaturated SaturatedTariqMaqsoodNo ratings yet

- Qty. Description CR 255-3-2 A-F-A-E-HQQE: Company Name: Created By: Phone: DateDocument6 pagesQty. Description CR 255-3-2 A-F-A-E-HQQE: Company Name: Created By: Phone: DateAriesNo ratings yet

- Recirculation Pump CalculationDocument4 pagesRecirculation Pump Calculationsenthilkumar_5425717No ratings yet

- Qty. Description NB 65-160/173 DF2BBAQE: Company Name: Created By: Phone: DateDocument5 pagesQty. Description NB 65-160/173 DF2BBAQE: Company Name: Created By: Phone: DatePriyanka KumariNo ratings yet

- Cooling - Furrer Industriekühlung GMBH Technical Data: DescriptionDocument8 pagesCooling - Furrer Industriekühlung GMBH Technical Data: DescriptionRangaNo ratings yet

- Qty. Description CRE 45-2-2 A-F-A-E-HQQE: Company Name: Created By: Phone: DateDocument2 pagesQty. Description CRE 45-2-2 A-F-A-E-HQQE: Company Name: Created By: Phone: DateVitor AntunesNo ratings yet

- Ets 15Document2 pagesEts 15abdalazeez20122013No ratings yet

- DS 4013 Rev-0Document4 pagesDS 4013 Rev-0Dinesh RajNo ratings yet

- Electrical Data General Data: Datasheet For Three-Phase Squirrel-Cage-Motors Order Number: 1LE0102-1DB23-4AA4Document1 pageElectrical Data General Data: Datasheet For Three-Phase Squirrel-Cage-Motors Order Number: 1LE0102-1DB23-4AA4abdulloh_99No ratings yet

- Siemens: Electrical Data General DataDocument1 pageSiemens: Electrical Data General Datasergio cabezaNo ratings yet

- Kessel - 93001 - 120B K DS P1Document4 pagesKessel - 93001 - 120B K DS P1rennes desamparadoNo ratings yet

- 30 KW - 1450 RPMDocument1 page30 KW - 1450 RPMTalha YousufNo ratings yet

- Qty. Description CR 45-7-2A-F-A-E-HQQE: Company Name: Created By: Phone: DateDocument10 pagesQty. Description CR 45-7-2A-F-A-E-HQQE: Company Name: Created By: Phone: DateSyamsirAlamNo ratings yet

- Data Sheet For ClarifierDocument2 pagesData Sheet For ClarifiergffNo ratings yet

- Pump Solidc-2 - 170 5.5kw 50hz Tech SpecDocument2 pagesPump Solidc-2 - 170 5.5kw 50hz Tech SpecHakan TekelNo ratings yet

- CM10-2 A-R-G-V-AQQV: Position Qty. Description Single PriceDocument7 pagesCM10-2 A-R-G-V-AQQV: Position Qty. Description Single PricehatkaraokequamangNo ratings yet

- 02 - 2technical Data of The GeneratorDocument16 pages02 - 2technical Data of The GeneratorJŐn PardédéNo ratings yet

- Olukunle Afeni - Datasheet Refrigerative ChillerDocument2 pagesOlukunle Afeni - Datasheet Refrigerative ChillerBolakale UthmanNo ratings yet

- Qty. Description CR 64-3-2 A-F-A-E-HQQE: Company Name: Created By: Phone: DateDocument6 pagesQty. Description CR 64-3-2 A-F-A-E-HQQE: Company Name: Created By: Phone: DateMilihane Adelino da SilvaNo ratings yet

- CRN 952 Afavhqqv PDFDocument8 pagesCRN 952 Afavhqqv PDFRisal RNo ratings yet

- Doc-20230818-Wa0021 231204 143641Document1 pageDoc-20230818-Wa0021 231204 143641leivaperalesNo ratings yet

- Arburg 270M 350-90Document2 pagesArburg 270M 350-90deadskinmask6660% (1)

- FichaTécnicaMotor200KW PDFDocument1 pageFichaTécnicaMotor200KW PDFEdward Jr ChapetonNo ratings yet

- Data Sheet MVC-25 06-3, 3.0HP, 1 1 4x1 1 4 Pump 60 HZDocument4 pagesData Sheet MVC-25 06-3, 3.0HP, 1 1 4x1 1 4 Pump 60 HZluis alberto macedoNo ratings yet

- Dimensioning of POLFLAME VN: Basis DataDocument3 pagesDimensioning of POLFLAME VN: Basis DataIrshad HussainNo ratings yet

- Qty. Description HS 65-50-242 5/1-F-B-BBVP: Company Name: Created By: Phone: DateDocument2 pagesQty. Description HS 65-50-242 5/1-F-B-BBVP: Company Name: Created By: Phone: DateZain ShariffNo ratings yet

- Technical Datasheet - DWK.O.10.100.37.5.0D.RDocument4 pagesTechnical Datasheet - DWK.O.10.100.37.5.0D.RsubhashsomaNo ratings yet

- Motor DatasheetDocument1 pageMotor DatasheetMuzzamilNo ratings yet

- Transformer Rectifiers PDFDocument29 pagesTransformer Rectifiers PDFSoltani AliNo ratings yet

- TC 2212921 - Washtech Industries - 20.02 PDFDocument1 pageTC 2212921 - Washtech Industries - 20.02 PDFDevesh PathakNo ratings yet

- CRN - 45 3 - A F G V HQQVDocument2 pagesCRN - 45 3 - A F G V HQQVWendyNo ratings yet

- CR 5-29Document8 pagesCR 5-29azam razzaqNo ratings yet

- Capacity Calculation IPB CapacitanceDocument1 pageCapacity Calculation IPB CapacitanceArthurNo ratings yet

- Bvi Man Marc2-C10 Used Machine For Sale No. 138468526Document5 pagesBvi Man Marc2-C10 Used Machine For Sale No. 138468526Aaron GamezNo ratings yet

- 11 AppendixDocument11 pages11 AppendixLOKESHNo ratings yet

- 02E CTP 100 Portable Profi Serie V1Document4 pages02E CTP 100 Portable Profi Serie V1bmxmmxNo ratings yet

- Product Info PacketDocument8 pagesProduct Info PacketMuhammad Rinaldy RinaldyNo ratings yet

- A 694Document2 pagesA 694zayerirezaNo ratings yet

- Grundfos Ups 2580 180Document2 pagesGrundfos Ups 2580 180SAURABH PRADHANNo ratings yet

- Armstrong VSD Pump 563397.2.2 SubmittalDocument6 pagesArmstrong VSD Pump 563397.2.2 Submittalckyee88-1No ratings yet

- Submittal: Ref. #: SQP001392 - 1 Design Envelope Split-Coupled Vertical In-Line PumpDocument4 pagesSubmittal: Ref. #: SQP001392 - 1 Design Envelope Split-Coupled Vertical In-Line PumpOmar MuqtharNo ratings yet

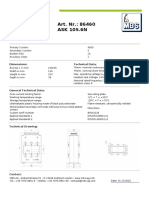

- Ask 1056nDocument1 pageAsk 1056nriver karimNo ratings yet

- Pump Data - J1-MET-WWT-DAS-R00-0304 - R0Document4 pagesPump Data - J1-MET-WWT-DAS-R00-0304 - R0Andrew LabitoNo ratings yet

- Grundfos Pupm Siemens, Felm Motor Data SheetDocument11 pagesGrundfos Pupm Siemens, Felm Motor Data SheetMohamed GassemNo ratings yet

- Data Sheet For SINAMICS G120 Power Module PM240: Rated Data General Tech. SpecificationsDocument2 pagesData Sheet For SINAMICS G120 Power Module PM240: Rated Data General Tech. SpecificationstrynoskNo ratings yet

- 03-Motor JP-DF180MA 18.5KW 4P B3Document2 pages03-Motor JP-DF180MA 18.5KW 4P B3Ahmed Mahmoud AliNo ratings yet

- 12-Motor - JPU-DF315MA - 132KW - 4P - B3Document2 pages12-Motor - JPU-DF315MA - 132KW - 4P - B3Ahmed Mahmoud AliNo ratings yet

- QDK187 Z in A German Cement PlantDocument2 pagesQDK187 Z in A German Cement Plantsamuel libseworkNo ratings yet

- Dry Process KilnDocument20 pagesDry Process KilnISLAM I. Fekry100% (8)

- Fuels and CombustionDocument29 pagesFuels and Combustionsamuel libseworkNo ratings yet

- Duoflex BurnerDocument6 pagesDuoflex Burnersinghite100% (1)

- Duoflex BurnerDocument6 pagesDuoflex Burnersinghite100% (1)

- Kiln Heat and Mass Balance September 2010Document20 pagesKiln Heat and Mass Balance September 2010samuel libsework50% (2)

- Massive X-16x9 Version 5.0 - 5.3 (Latest New Updates in Here!!!)Document158 pagesMassive X-16x9 Version 5.0 - 5.3 (Latest New Updates in Here!!!)JF DVNo ratings yet

- TRX Documentation20130403 PDFDocument49 pagesTRX Documentation20130403 PDFakasameNo ratings yet

- Volvo B13R Data SheetDocument2 pagesVolvo B13R Data Sheetarunkdevassy100% (1)

- S SSB29 - Alternator Cables PM: WARNING: This Equipment Contains Hazardous VoltagesDocument3 pagesS SSB29 - Alternator Cables PM: WARNING: This Equipment Contains Hazardous VoltagesMohan PreethNo ratings yet

- Expected MCQs CompressedDocument31 pagesExpected MCQs CompressedAdithya kesavNo ratings yet

- Brand Guidelines Oracle PDFDocument39 pagesBrand Guidelines Oracle PDFMarco CanoNo ratings yet

- List of Light Commercial LED CodesDocument8 pagesList of Light Commercial LED CodesRenan GonzalezNo ratings yet

- Software Testing Notes Prepared by Mrs. R. Swetha M.E Unit I - Introduction at The End of This Unit, The Student Will Be Able ToDocument30 pagesSoftware Testing Notes Prepared by Mrs. R. Swetha M.E Unit I - Introduction at The End of This Unit, The Student Will Be Able ToKabilan NarashimhanNo ratings yet

- Applications of MathematicsDocument35 pagesApplications of MathematicsRamdas Sonawane100% (1)

- จัดตารางสอบกลางภาคภาคต้น53Document332 pagesจัดตารางสอบกลางภาคภาคต้น53Yuwarath SuktrakoonNo ratings yet

- CPM W1.1Document19 pagesCPM W1.1HARIJITH K SNo ratings yet

- 1.2 The Main Components of Computer SystemsDocument11 pages1.2 The Main Components of Computer SystemsAdithya ShettyNo ratings yet

- R 18 Model B Installation of TC Auxiliary Lights and WingletsDocument29 pagesR 18 Model B Installation of TC Auxiliary Lights and WingletsAlejandro RodríguezNo ratings yet

- Key Features of A Company 1. Artificial PersonDocument19 pagesKey Features of A Company 1. Artificial PersonVijayaragavan MNo ratings yet

- DTMF Controlled Robot Without Microcontroller (Aranju Peter)Document10 pagesDTMF Controlled Robot Without Microcontroller (Aranju Peter)adebayo gabrielNo ratings yet

- WPGPipingIndex Form 167 PDFDocument201 pagesWPGPipingIndex Form 167 PDFRaj AryanNo ratings yet

- SEBI Circular Dated 22.08.2011 (Cirmirsd162011)Document3 pagesSEBI Circular Dated 22.08.2011 (Cirmirsd162011)anantNo ratings yet

- Qualifi Level 6 Diploma in Occupational Health and Safety Management Specification October 2019Document23 pagesQualifi Level 6 Diploma in Occupational Health and Safety Management Specification October 2019Saqlain Siddiquie100% (1)

- Database Management System and SQL CommandsDocument3 pagesDatabase Management System and SQL Commandsdev guptaNo ratings yet

- Nasoya FoodsDocument2 pagesNasoya Foodsanamta100% (1)

- For Exam ReviewerDocument5 pagesFor Exam ReviewerGelyn Cruz67% (3)

- VB 850Document333 pagesVB 850Laura ValentinaNo ratings yet

- Civil NatureDocument3 pagesCivil NatureZ_Jahangeer100% (4)

- Ss1169 - Telecom Frameworx l1TMFDocument65 pagesSs1169 - Telecom Frameworx l1TMFPrince SinghNo ratings yet

- Attachment BinaryDocument5 pagesAttachment BinaryMonali PawarNo ratings yet

- Chapter 123 RevisedDocument23 pagesChapter 123 RevisedCristy Ann BallanNo ratings yet

- Mathematical Geophysics: Class One Amin KhalilDocument13 pagesMathematical Geophysics: Class One Amin KhalilAmin KhalilNo ratings yet

- G JaxDocument4 pagesG Jaxlevin696No ratings yet

- Hoja Tecnica Item 2 DRC-9-04X12-D-H-D UV BK LSZH - F904804Q6B PDFDocument2 pagesHoja Tecnica Item 2 DRC-9-04X12-D-H-D UV BK LSZH - F904804Q6B PDFMarco Antonio Gutierrez PulchaNo ratings yet

- SKF LGMT-2 Data SheetDocument2 pagesSKF LGMT-2 Data SheetRahul SharmaNo ratings yet