Professional Documents

Culture Documents

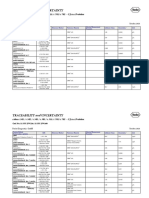

Austenitic and Martensitic Steel Chemical Compositions

Uploaded by

Tommy CamposOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Austenitic and Martensitic Steel Chemical Compositions

Uploaded by

Tommy CamposCopyright:

Available Formats

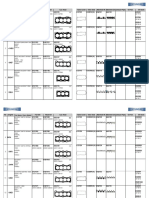

BACK TO INDEX

MATERIAL & SPECIFICATION

Chemical composition

C Si Mn P S Ni Cr Mo Cu WW Co Fe

SUHI 0.40-0.50 3.00-3.5 ≦0.60 ≦0.030 ≦0.030 ≦0.5 7.50-9.50 - - - Bal.

Austenitic Steel Martensitic Steel

SUH11 0.45-0.55 1.00-2.00 ≦0.60 ≦0.030 ≦0.030 - 7.50-9.50 - - - Bal.

SUH3 0.30-0.45 1.80-2.50 ≦0.60 ≦0.030 ≦0.030 ≦0.6 10.00-12.00 0.70-1.30 ≦0.3 - Bal.

SUH4

0.75-0.85 1.75-2.25 0.20-0.60 ≦0.030 ≦0.030 1.15-1.65 19.00-20.50 - ≦0.3 - Bal.

(XB)

SUH31 0.30-0.45 1.50-2.50 ≦0.60 ≦0.040 ≦0.030 13.00-15.00 14.00-16.00 - ≦0.30 2.00-3.00 Bal.

SUH36

0.475-0.575 ≦0.25 8.00-10.00 ≦0.030 ≦0.040 3.25-4.50 20.00-22.00 - ≦0.30 - Bal.

(21-4N)

SUH37

0.15-0.25 0.75-1.00 1.00-1.50 ≦0.025 ≦0.025 10.50-12.50 20.00-22.00 - ≦0.30 - Bal.

(21-12N)

Facing Material

STL #6 1.2 1.1 <0.5 - - <3.0 28 <1.0 - 4.5 Bal.(65) <3.0

STL #12 1.4 1.0 <1.5 - - <3.0 30 <1.0 - 8.3 Bal.(60) <3.0

STL #32 1.7 1.1 <0.3 - - 22 26 <0.6 - 12.3 Bal.(36) 1.1

*SUH3: Magnetic Material STOCK No. REFERENCE

MARTENSITIC STEEL (STOCK NO. ONLY)

Ordinary heat-resistance alloy, which has magnetism and is *One-piece Martensitic Steel

widely applied to Intale Valve for internal combustion engine.

(Magnetic)

(Example: TON-49)

*21-4N: Anti-Magnetic Material

AUSENTIC STEEL (STOCK No. + A) *One-piece Austenitic Steel

High quality heat-resistance alloy (non-magnetic), that is (Non-Magnetic)

excellent in wear and corrosion resistance under high (Example: TOX-49A)

temperature and applicable to Exhaust Valve for heavy duty

engine use.

*Stellite facing on Top

*TUFFTRIDE (STOCK No. + T) (Example: TOX-49AW)

The TUFFTRIDE is a molten salt heat treetment at 570-580 ℃.

After this process the surface of the steel material is carbonized *Stellite facing on Seat

and nitrided by CO and N. An Engine valve face after (Example: TOX-49AV)

TUFFTRIDE process has abrasion resistance four times

stronger than conventional valves.

The TUFFTRIDE is a highly efficient and less costly method for *Surface Treatment

engine valves. (1) Hard-chromium plating

Today, more than 90% of the O.E.M. car engine valves in Japan (Example: TOX-49C)

are treated with TUFFTRIDE.. (2) Nitriding-TUFFTRIDE

(Example: TOX-49T)

Note: Greater share TUFFTRIDE is expected in after market......

1) The increasing number of high performance car engines will push up demand for TUFFTRIDE-treated valves to

repair these engines.

2) The adoption of TUFFTRIDE treatment for engine valves is expected to start with Exhaust Valves, which must

withstand high temperature, and then proceed to Intake Valves.

MOTORIX INTERNATIONAL, INC.

You might also like

- Alternator Catalog ReferenceDocument102 pagesAlternator Catalog Referencemikec101100% (3)

- Ben Brand PDFDocument80 pagesBen Brand PDFrojasautoparts24100% (1)

- EP82 Starlet Wiring and ConnectorsDocument19 pagesEP82 Starlet Wiring and ConnectorsIndar Nunik Cahya100% (2)

- Hot-rolled carbon steel data sheetDocument7 pagesHot-rolled carbon steel data sheetwulfgang66No ratings yet

- Semiconductor Data Book: Characteristics of approx. 10,000 Transistors, FETs, UJTs, Diodes, Rectifiers, Optical Semiconductors, Triacs and SCRsFrom EverandSemiconductor Data Book: Characteristics of approx. 10,000 Transistors, FETs, UJTs, Diodes, Rectifiers, Optical Semiconductors, Triacs and SCRsNo ratings yet

- Gabriel Product CatalogueDocument156 pagesGabriel Product CatalogueFrancisco Salvador Mondlane50% (2)

- Liquid Penetrant Inspection 50 Question QuizDocument10 pagesLiquid Penetrant Inspection 50 Question QuizAnonymous gFcnQ4go100% (6)

- BearingDocument326 pagesBearingdhirajchhetri2010100% (1)

- SA/AS1548 - 7 - 460R: XlerplateDocument3 pagesSA/AS1548 - 7 - 460R: XlerplatenavNo ratings yet

- 2011 - SANDIA - Steam Cycles For Molten Salt Plants PDFDocument121 pages2011 - SANDIA - Steam Cycles For Molten Salt Plants PDFDavide FranziniNo ratings yet

- Materials Data for Cyclic Loading: Aluminium and Titanium AlloysFrom EverandMaterials Data for Cyclic Loading: Aluminium and Titanium AlloysRating: 1 out of 5 stars1/5 (1)

- Nozzle Part Numbers GuideDocument35 pagesNozzle Part Numbers Guideali4299No ratings yet

- ASTM A335 Pipe Specification1 PDFDocument8 pagesASTM A335 Pipe Specification1 PDFRoberto EliasNo ratings yet

- Din 17102 PDFDocument10 pagesDin 17102 PDFEvriMert RüzgArdaNo ratings yet

- Equivalent TableDocument1 pageEquivalent Tableliamcs88% (8)

- Assessment of Welding ConsumablesDocument17 pagesAssessment of Welding Consumablesmahmoud_allam3No ratings yet

- Syllabus PDFDocument253 pagesSyllabus PDFVivek KumarNo ratings yet

- Victor-Reinz PKW Mitsubishi PDFDocument15 pagesVictor-Reinz PKW Mitsubishi PDFTommy CamposNo ratings yet

- Test Methodology FORD TM 00.00 L 467 2 PDFDocument5 pagesTest Methodology FORD TM 00.00 L 467 2 PDFFadi MagdyNo ratings yet

- Motorix International Valve Guide Catalog for Japanese Vehicle EnginesDocument79 pagesMotorix International Valve Guide Catalog for Japanese Vehicle EnginesgaelNo ratings yet

- ASTM-A240-A240M-23Document7 pagesASTM-A240-A240M-23Venkatesh KumarNo ratings yet

- Weld Consumable SelectionDocument25 pagesWeld Consumable SelectionNisarg PandyaNo ratings yet

- Properties of Engineering Material - Waleed NassefDocument1 pageProperties of Engineering Material - Waleed NassefWaleed NassefNo ratings yet

- A N D High-Cycle Fatigue Properties of Various Steels Specified in Jis For Machine Structural USEDocument12 pagesA N D High-Cycle Fatigue Properties of Various Steels Specified in Jis For Machine Structural USEKadek Santiari DewiNo ratings yet

- Compositon of Martensitic SteelDocument1 pageCompositon of Martensitic SteelMahesh PandyaNo ratings yet

- Astm A493 16Document2 pagesAstm A493 16wongNo ratings yet

- Ferritic Stainless Steel Core 441/4509 GuideDocument5 pagesFerritic Stainless Steel Core 441/4509 GuideEnrique Ruiz HonoratoNo ratings yet

- A 213 Â " A 213M Â " 03 - QTIXMY9BMJEZTS1SRUQDocument14 pagesA 213 Â " A 213M Â " 03 - QTIXMY9BMJEZTS1SRUQhNo ratings yet

- Material delivery specificationsDocument2 pagesMaterial delivery specificationsviyfNo ratings yet

- Vulcan Industrial Engineering Co. Pvt. LTDDocument3 pagesVulcan Industrial Engineering Co. Pvt. LTDk koradiaNo ratings yet

- Swagelok TubingDocument1 pageSwagelok TubingMmstevens00No ratings yet

- Welding Filler Metals For Power Plant EngineeringDocument20 pagesWelding Filler Metals For Power Plant EngineeringShoaib AhmedNo ratings yet

- S460M Steel Plates. Thermomechanical Rolled Weldable Fine Grain Structural SteelDocument2 pagesS460M Steel Plates. Thermomechanical Rolled Weldable Fine Grain Structural SteelrichadNo ratings yet

- Product Data Sheet OK 61.30: E 'Manual Metal-Arc Welding'Document2 pagesProduct Data Sheet OK 61.30: E 'Manual Metal-Arc Welding'Bayu RahmanNo ratings yet

- Duplex SSDocument2 pagesDuplex SSsjk_akolNo ratings yet

- Aerospace Material Specification: Nickel, Sheet and Strip Low (0.02 Max) Carbon AnnealedDocument5 pagesAerospace Material Specification: Nickel, Sheet and Strip Low (0.02 Max) Carbon AnnealedMehdi MokhtariNo ratings yet

- ASTM A335 Pipe Specification1Document8 pagesASTM A335 Pipe Specification1Rupam BaruahNo ratings yet

- As1548 Pt46onrlo l20 August2010bDocument3 pagesAs1548 Pt46onrlo l20 August2010bchoopoNo ratings yet

- Pipe & Tube SpecificationsDocument3 pagesPipe & Tube SpecificationsIbrahim Ali100% (1)

- Fatigue Behavior of Carbon Composite MaterialsDocument11 pagesFatigue Behavior of Carbon Composite MaterialsCroitoru GeorgeNo ratings yet

- Hot-Rolled - Plate: Data SheetDocument2 pagesHot-Rolled - Plate: Data SheetRichard Vica CalvoNo ratings yet

- Astm A269 A269mDocument5 pagesAstm A269 A269mwataneta valveNo ratings yet

- Vulcan steel alloy specificationsDocument4 pagesVulcan steel alloy specificationsk koradiaNo ratings yet

- S-777Q X M-12K H-14 L-8: Hyundai Welding Co., LTDDocument6 pagesS-777Q X M-12K H-14 L-8: Hyundai Welding Co., LTDSergio AlejandroNo ratings yet

- S275NLDocument1 pageS275NLMukesh ShettyNo ratings yet

- Hot-Rolled Steel FL AtsDocument3 pagesHot-Rolled Steel FL AtsĐình Khoa PhanNo ratings yet

- Thyssenkrupp Materials (UK) LTD Stainless Steel 1.4307 - 304LDocument3 pagesThyssenkrupp Materials (UK) LTD Stainless Steel 1.4307 - 304LpabloNo ratings yet

- Buderus Edelstahl Presentation PDFDocument15 pagesBuderus Edelstahl Presentation PDFMustafa Mert SAMLINo ratings yet

- CastMaterials E00510Document6 pagesCastMaterials E00510samir basuniNo ratings yet

- ZXDocument6 pagesZXPedro SilvaNo ratings yet

- Cold Rolled Sheets HINDALCODocument3 pagesCold Rolled Sheets HINDALCOADIPESHNo ratings yet

- NI-182 Victory ENICRFE-3 Electrode Data SheetDocument1 pageNI-182 Victory ENICRFE-3 Electrode Data SheetgianNo ratings yet

- Specification for Precipitation-Hardening Nickel Alloy BarsDocument9 pagesSpecification for Precipitation-Hardening Nickel Alloy BarsrbagriNo ratings yet

- ASTM A830 Steel Grades: General Product DescriptionDocument2 pagesASTM A830 Steel Grades: General Product DescriptionsachedalNo ratings yet

- ALCOA 7075 ALLOY SHEET AND PLATE PRODUCTSDocument4 pagesALCOA 7075 ALLOY SHEET AND PLATE PRODUCTSSarat SrinivasNo ratings yet

- Amecoil InsertDocument2 pagesAmecoil InsertyauctionNo ratings yet

- Mould SteelsDocument32 pagesMould SteelsAnonymous B3I6zYNhqdNo ratings yet

- A 249 - A 249m - 03 Qti0os9bmjq5ts1sruqDocument11 pagesA 249 - A 249m - 03 Qti0os9bmjq5ts1sruqAntonio ChangNo ratings yet

- Pinnacle Alloys ENiCrFe 3 12.16Document2 pagesPinnacle Alloys ENiCrFe 3 12.16satnamNo ratings yet

- Duplex Ss Welding PDF FreeDocument8 pagesDuplex Ss Welding PDF Freeel_sharkawy2011No ratings yet

- Core 321/4541: EN 1.4541, ASTM TYPE 321 / UNS S32100Document8 pagesCore 321/4541: EN 1.4541, ASTM TYPE 321 / UNS S32100Nguyen03No ratings yet

- Hindalco Cold Rolled CoilsDocument3 pagesHindalco Cold Rolled CoilsRoshan ShanmughanNo ratings yet

- Experimental Investigation For Welding Aspects of Stainless Steel 310 For The Process of TIG Welding PDFDocument7 pagesExperimental Investigation For Welding Aspects of Stainless Steel 310 For The Process of TIG Welding PDFfaisalNo ratings yet

- Supranox Rs 309L: MMA Electrodes Stainless and Heat Resistant SteelsDocument1 pageSupranox Rs 309L: MMA Electrodes Stainless and Heat Resistant SteelsbrunizzaNo ratings yet

- Weldeability Offshore SteelDocument12 pagesWeldeability Offshore Steelcarrotiron100% (1)

- Ferritic and Martensitic Casting Materials SpecificationsDocument2 pagesFerritic and Martensitic Casting Materials SpecificationsSinan YıldızNo ratings yet

- Rules For Materials and Welding 2021 AmendmentsDocument29 pagesRules For Materials and Welding 2021 AmendmentsSUEZSHIPYARD QCNo ratings yet

- AWS A5.1 E6010 SC-10 Mild Steel Electrodes SpecificationsDocument56 pagesAWS A5.1 E6010 SC-10 Mild Steel Electrodes SpecificationsFakhar WindratamaNo ratings yet

- Alloy 6082 - Rev2012Document2 pagesAlloy 6082 - Rev2012Ysraels Santisteban DurandNo ratings yet

- 04 Ben Valve Guide PohtoDocument1 page04 Ben Valve Guide PohtoTommy CamposNo ratings yet

- 02 Daihatsu PDFDocument4 pages02 Daihatsu PDFTommy CamposNo ratings yet

- Catalogo de Fajas de Tiempo Gates PDFDocument28 pagesCatalogo de Fajas de Tiempo Gates PDFTommy CamposNo ratings yet

- 02 Daihatsu PDFDocument4 pages02 Daihatsu PDFTommy CamposNo ratings yet

- Austenitic and Martensitic Steel Chemical CompositionsDocument1 pageAustenitic and Martensitic Steel Chemical CompositionsTommy CamposNo ratings yet

- A-Gatez Faja de Tiempo - Faja Del Alternador PDFDocument342 pagesA-Gatez Faja de Tiempo - Faja Del Alternador PDFTommy CamposNo ratings yet

- 02 Daihatsu PDFDocument4 pages02 Daihatsu PDFTommy CamposNo ratings yet

- Auto Wheel/Brake Cylinder PartsDocument9 pagesAuto Wheel/Brake Cylinder PartsTommy CamposNo ratings yet

- Kyb EXEL PDFDocument172 pagesKyb EXEL PDFTommy CamposNo ratings yet

- Catalogo de Fajas de Tiempo Gates PDFDocument28 pagesCatalogo de Fajas de Tiempo Gates PDFTommy CamposNo ratings yet

- Catalogo de Fajas de Tiempo Gates PDFDocument28 pagesCatalogo de Fajas de Tiempo Gates PDFTommy CamposNo ratings yet

- KYBJ 2015 LatinoamericaDocument297 pagesKYBJ 2015 LatinoamericaBeto MerizaldeNo ratings yet

- Kyb EXEL PDFDocument172 pagesKyb EXEL PDFTommy CamposNo ratings yet

- (-) (-) (-) (-) (Hyundai New Items)Document7 pages(-) (-) (-) (-) (Hyundai New Items)Tommy CamposNo ratings yet

- KYB - Maz PDFDocument1 pageKYB - Maz PDFTommy CamposNo ratings yet

- Gabriel newsletter provides shock absorber specificationsDocument1 pageGabriel newsletter provides shock absorber specificationsTommy CamposNo ratings yet

- Lista de ProductosDocument53 pagesLista de ProductosTommy CamposNo ratings yet

- Aumark FL PDFDocument4 pagesAumark FL PDFTommy CamposNo ratings yet

- Kyb Codigo de BarrasDocument124 pagesKyb Codigo de BarrasTommy CamposNo ratings yet

- Toyota engine codes reference guideDocument37 pagesToyota engine codes reference guideTommy CamposNo ratings yet

- Catalogue For Auto PDFDocument22 pagesCatalogue For Auto PDFali4299No ratings yet

- HDK CATALOGUE Vo.,11 INDEXDocument121 pagesHDK CATALOGUE Vo.,11 INDEXTommy CamposNo ratings yet

- MEYA BEARING Wheel Hub Bearing - ABS Sensor - Center Support Bearing - Clutch Release Bearing ApplicationDocument67 pagesMEYA BEARING Wheel Hub Bearing - ABS Sensor - Center Support Bearing - Clutch Release Bearing ApplicationTommy CamposNo ratings yet

- Bcga Code of Practice CP 20: Bulk Liquid Oxygen Storage at Production SitesDocument55 pagesBcga Code of Practice CP 20: Bulk Liquid Oxygen Storage at Production Sitesfadlul akbar herfiantoNo ratings yet

- Food BiochemistryDocument48 pagesFood BiochemistryFombang AtamNo ratings yet

- Environmental and health risks of Granuflex rubber tilesDocument19 pagesEnvironmental and health risks of Granuflex rubber tilesCristian-Alexandru JiteaNo ratings yet

- Common Header Line For Pump TestingDocument8 pagesCommon Header Line For Pump TestingNovesa NurgirisiaNo ratings yet

- VinnapasDocument2 pagesVinnapasNguyễn Quốc TiếnNo ratings yet

- Internship Report on Ghee Manufacturing ProcessDocument36 pagesInternship Report on Ghee Manufacturing ProcessNuman TariqNo ratings yet

- Daftar PustakaDocument3 pagesDaftar PustakaPutri Meylia An NajiyahNo ratings yet

- Triple Q WatersDocument4 pagesTriple Q Watersendalehadgu2866No ratings yet

- 15-5 PH Data Bulletin PDFDocument12 pages15-5 PH Data Bulletin PDFAndres Camilo BenitezNo ratings yet

- Clobazam EP 11.0Document2 pagesClobazam EP 11.0Alejandro RestrepoNo ratings yet

- Resonance StructuresDocument4 pagesResonance StructuresSmyra100% (1)

- Brochure - Genuine Oil SPECIFICATIONS OILDocument14 pagesBrochure - Genuine Oil SPECIFICATIONS OILBouslimi SouhaibNo ratings yet

- Nuclear ChemistryDocument42 pagesNuclear ChemistryneerajNo ratings yet

- Perpindahan Panas: Tugas 3 (Double PipeDocument4 pagesPerpindahan Panas: Tugas 3 (Double Pipeiim252575% (4)

- Nonferrous Metals and Alloys: Production, General Properties, and ApplicationsDocument13 pagesNonferrous Metals and Alloys: Production, General Properties, and Applicationsvicki20julyNo ratings yet

- Fundamentals and Applications of 3D Printing For Novel MaterialsDocument14 pagesFundamentals and Applications of 3D Printing For Novel MaterialsOrranaNo ratings yet

- Argan Oil MSDSDocument10 pagesArgan Oil MSDSCrina BanuNo ratings yet

- Ocy751 Waste Water TreatmentDocument13 pagesOcy751 Waste Water TreatmentDivyadharshinisekarNo ratings yet

- Traceability and Uncertainty: Cobas C 501 / C 502 / C 503 / C 303 / C 311/ C 701/ C 702 - C.F.A.S. ProteinsDocument3 pagesTraceability and Uncertainty: Cobas C 501 / C 502 / C 503 / C 303 / C 311/ C 701/ C 702 - C.F.A.S. ProteinsLaura Puentes JiménezNo ratings yet

- Radon PowerpointDocument23 pagesRadon Powerpointokejomail100% (1)

- Prevent From Flower and Fruit DroppingDocument2 pagesPrevent From Flower and Fruit DroppingRachel BiostimulantsNo ratings yet

- Henk Multicore Macromelt Mm6208s TdsDocument2 pagesHenk Multicore Macromelt Mm6208s TdsAbohicham AbhNo ratings yet

- Gupta (2010)Document42 pagesGupta (2010)x raysNo ratings yet

- What Is Activation OverpotentialDocument1 pageWhat Is Activation OverpotentialMuhammad RiaanNo ratings yet

- Bacteria Nutrition RequirementsDocument14 pagesBacteria Nutrition RequirementsFuad Hasan Pranto 1921147049No ratings yet

- Astm G 145 - 96Document10 pagesAstm G 145 - 96AL DOMANo ratings yet