Professional Documents

Culture Documents

IEC 61439 Mystery of Temperature Rise Limits

Uploaded by

Kuljinder VirdiOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

IEC 61439 Mystery of Temperature Rise Limits

Uploaded by

Kuljinder VirdiCopyright:

Available Formats

Consultancy, R&D and Training Ltd

IEC 61439: The Mystery of the Temperature Rise Limits

• Was your low voltage switchgear approved in the temperature rise test?

• Is this written in the test report or you have a “quality system” weak point?

• An alert to low-voltage switchgear buyers

http://www.cognitor.com.br/TemperatureRise_IEC61439Mistery.pdf

Author name: Affiliation:

Sergio Feitoza Costa COGNITOR – Consultancy, Research and Training Ltd.

Email: sergiofeitoza@cognitor.com.br Site : http://www.cognitor.com.br

Keywords: IEC standards, CIGRÈ, Simulations, High Power Tests, Switchgear, Switchboards, Bus-bar systems, Testing Laboratory, Internal Arcs, Overpressure,

Temperature rise, Electrodynamic forces, stresses, Short time currents, EMC, Magnetic fields, Electric Fields, Substations, certification, Quality System.

------------------------------------------------------------------------------------------------------------

1. AN ALERT TO LOW-VOLTAGE SWITCHGEAR BUYERS

From 2016 I have been writing articles about a clear, old and strange deficiency in IEC 61439 standard that impact the

worldwide market of low-voltage switchgear. I will not repeat here, the contents of these articles but you may read

them freely in the links:

• http://www.cognitor.com.br/TemperatureRise_IEC61439_2019.pdf

• http://www.cognitor.com.br/TempRise_IEC61439_07112018.pdf

• More information: http://www.cognitor.com.br/downloads1.html

The facts motivating this, and previous articles are:

a) Low-voltage switchgear (LV) (IEC 61439) is a piece of equipment basically equal to medium voltage switchgear

(MV) (IEC 62271-1 , IEC 62271-200 and IEC 62271-307). Both are metallic boxes enclosing electrical conductors

and insulators, made of the same materials. They have the same basic operational functions and so, it is

reasonable to expect that both would have the same life expectancy.

b) The only difference between LV and MV switchgear is the rated voltage, which is not relevant for temperature

rise tests. You may do the tests at any convenient (low) voltage for both medium and low voltage switchgear.

c) To attend the temperature rise requirements specified in the IEC standard is the predominating aspect that

defines the design and cost of such equipment. Other things like electrodynamic forces, mechanical and

electrical endurance and supportability to internal arcs are important but at a lower level.

d) For MV switchgear, the temperature rise test limits are clear and well defined (see table 1 below). If a testing

laboratory does a test, it is easy for the testing teams to state in the test report if the equipment passed or

failed in the test. In my opinion, if they do not include these statements (approved or not) they are being

Cell phone. 55-21-9 88874600

E-mail: sergiofeitoza@cognitor.com.br Site: http://www.cognitor.com.br

Consultancy, R&D and Training Ltd

omitted in their neutral laboratory role. The omission is because they are leaving to the user, the task of

interpreting well the IEC standards, when it seems they are not skilled enough to do it.

e) For LV switchgear, the temperature rise test limits of connections and contacts are not defined in a clear table

to be used by the testing lab. So, most of the testing laboratories simply present the test results but do not

state if the equipment passed or not. Labs also do not usually include in the test reports the alerts to the reader

already mentioned. Not passing, in the sense of the text of this article, means that the temperature was above

table 1. For values higher than table 1 there will be accelerated aging in daily life the greater are the differences

to the values of table 1 as explained in the previous articles .

f) In my 40+ years of experience as a testing lab expert and a designer of switchgear for companies all over the

world the majority of the testing lab reports of low-voltage switchgear do not present (approved or not)

statements and the temperature rise values presented for the connections like busbar to circuit breaker are

higher than the ones in Table 1. This means that by MV standards parameters they did not pass in the test.

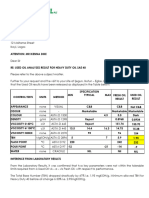

Table 1 – Values extracted from Table 14 of IEC 62271-1 (2017)) for temperature rise limits of MV switchgear

Nature of the part, of the material and of the dielectric Maximum value

Temperature Temperature rise at

ambient temperature not

exceeding 40°C

°C K

Contacts

Bare-copper or bare-copper alloy

- in OG 75 35

- in NOG 115 75

- in Oil 80 40

Silver-coated or nickel-coated

- in OG 115 75

- in NOG 15 75

- in Oil 90 50

Tin-coated

- in OG 90 50

- in NOG 90 50

- in Oil 90 50

Connections, bolted or the equivalent

Bare-copper or bare-copper alloy or bare-aluminium alloy

- in OG 100 60

- in NOG 115 75

- in Oil 100 60

Silver-coated or nickel-coated

- in OG 115 75

- in NOG 115 75

- in Oil 100 60

Tin-coated

- in OG 105 65

- in NOG 105 65

- in Oil 100 60

Terminals for the connection to external conductors by

screws or bolts (refer to points 8 and 14)

- bare 100 60

- silver or nickel coated 115 75

- tin-coated 105 65

Accessible surfaces

Surfaces of manual control components to be touched in

normal operation:

- Uncoated metal 55 15

- Coated metal 55 15

- Non metal 65 25

Other surfaces to be touched in normal operation but

not to be held continuously in the hand:

- Uncoated metal 65 25

- Coated metal 70 30

- Non metal 80 40

Surfaces not to be touched in normal operation:

- Uncoated metal 80 40

- Coated metal 80 40

- Non metal 90 50

Cell phone. 55-21-9 88874600

E-mail: sergiofeitoza@cognitor.com.br Site: http://www.cognitor.com.br

Consultancy, R&D and Training Ltd

2. THE MARKET ISSUE CAUSED BY NOT HAVING THE LIMITS CLEARLY DEFINED IN THE IEC 61439 STANDARDS

IEC technical standards are powerful documents providing directions for specifications, tests, and types of equipment

which will be commercialized in the Worldwide market. What is written in IEC standards will influence what will

happen all over the world in developed and developing countries.

What is written in the IEC standards is seen around the world as unquestionable and the vast majority of buyers,

manufacturers and testing labs follow it fully.

If the temperature rise limits define a considerable part of the project and its cost, there will be a big difference

between someone designing the equipment considering the values in Table 1 or considering values far higher since

IEC 61439 doesn't define them as it should.

.

This creates unfair competition in the market as LV manufacturers aiming to meet Table 1 will possibly have a design

of higher cost. They will be penalized for trying to do what is technically correct.

As a suggestion to the IEC committee preparing the IEC 61439 series, I suggest including in the next revision the phrase

"Temperature Elevation Limits are shown in IEC 62271-1”. Doing this the problem is solved.

The author of this paper is Mr. Sergio Feitoza Costa. Sergio is an electrical engineer, M. Sc in Power Systems and

director of COGNITOR. Sergio has 35+ years of experience in design, operation and management of high power, high

voltage and other testing laboratories. After leaving the activities in testing labs Sergio acquired considerable

experience in the use of testing simulations to support manufacturers and certification companies.

Sergio is the author of the simulation software SwitchgearDesign and provides consultancy services for the

development of innovative equipment

Cognitor site: http://www.cognitor.com.br

CV and publications: http://ec09e43.contato.site/trainings

• Sergio Feitoza provides consultancy studies for extrapolation of test results, to verify, based on the

test report of an already tested equipment, whether or not another untested equipment would be

approved in the same tests. More and more companies are accepting these studies to avoid expensive

high-power tests.

• Sergio helps to develop innovative substation equipment designs.

Cell phone. 55-21-9 88874600

E-mail: sergiofeitoza@cognitor.com.br Site: http://www.cognitor.com.br

You might also like

- Service Manual Selenia Dimensions V1.8 Rev 3Document418 pagesService Manual Selenia Dimensions V1.8 Rev 3IMEEDCO SRL100% (1)

- Marriott Fire ProtectionDocument19 pagesMarriott Fire ProtectionjulchabNo ratings yet

- TDS - NP505-HR Solder PasteDocument2 pagesTDS - NP505-HR Solder PasteChoice OrganoNo ratings yet

- IEC 61439: The Mystery of The Temperature Rise Limits: An Alert To Low-Voltage Switchgear BuyersDocument3 pagesIEC 61439: The Mystery of The Temperature Rise Limits: An Alert To Low-Voltage Switchgear BuyersAbdul Mohid SheikhNo ratings yet

- What Is The Temperature Rise Permitted in A Silver Coated Connection?Document6 pagesWhat Is The Temperature Rise Permitted in A Silver Coated Connection?Hà Huy TấnNo ratings yet

- Valvoline Heavy Duty Synthetic Gear Lubricant 75w90 DR 74130700260Document1 pageValvoline Heavy Duty Synthetic Gear Lubricant 75w90 DR 74130700260CarlosNo ratings yet

- Planned Maintenance Manual: GEK-75889J SUP. 2, REV. 1Document2 pagesPlanned Maintenance Manual: GEK-75889J SUP. 2, REV. 1ait mimouneNo ratings yet

- Hydraulic CoolersDocument12 pagesHydraulic Coolersarpit.vNo ratings yet

- Electronic Oil Level Indicator With Magnetic JointDocument12 pagesElectronic Oil Level Indicator With Magnetic JointJOSE DANIEL PEREZNo ratings yet

- ValvolineSYNGARDIS_75W80_ATF_HD_EN (1)Document1 pageValvolineSYNGARDIS_75W80_ATF_HD_EN (1)JUAN BAUTISTANo ratings yet

- Galden SV Fluids CFC Free Solvents For Safer Operations - EN 220549Document2 pagesGalden SV Fluids CFC Free Solvents For Safer Operations - EN 220549AlexandreNo ratings yet

- Huf75344G3, Huf75344P3: N-Channel Ultrafet Power Mosfet FeaturesDocument10 pagesHuf75344G3, Huf75344P3: N-Channel Ultrafet Power Mosfet FeaturesChristina MullinsNo ratings yet

- RAYCLAD 80/120: Heat Shrinkable Two Layer Pipeline CoatingDocument2 pagesRAYCLAD 80/120: Heat Shrinkable Two Layer Pipeline CoatingHamza GhaniNo ratings yet

- General Discussions On Lubricating OilsDocument59 pagesGeneral Discussions On Lubricating OilsHari PurwadiNo ratings yet

- Typical Tests Lubriplate 105Document2 pagesTypical Tests Lubriplate 105KeinerNo ratings yet

- Engine Oil Test Results and Recommendations To Interkels - 07082019Document2 pagesEngine Oil Test Results and Recommendations To Interkels - 07082019Georgina SuleNo ratings yet

- Selector ValvesDocument23 pagesSelector Valveswalk111No ratings yet

- Insulating Oils: by Santosh.N Engineer/HosurDocument19 pagesInsulating Oils: by Santosh.N Engineer/Hosursantoshnarinoi241No ratings yet

- Gengear SPL A-SeriesDocument1 pageGengear SPL A-SeriesHakim AmmorNo ratings yet

- Chevron Open Gear NC PDFDocument2 pagesChevron Open Gear NC PDFDavid Hinostroza IbarraNo ratings yet

- 6.1 - SL2006-469 PDFDocument15 pages6.1 - SL2006-469 PDFValeriy DomashenkoNo ratings yet

- NL Corporation M3611-M3651 175w MV R40 Cylinder Spec Sheet 10-75Document2 pagesNL Corporation M3611-M3651 175w MV R40 Cylinder Spec Sheet 10-75Alan MastersNo ratings yet

- 15.3 MVA - 15kV Rev 09 04 2012Document5 pages15.3 MVA - 15kV Rev 09 04 2012Eléctrico EléctricoNo ratings yet

- Meiden Singapore Site Investigation ReportDocument9 pagesMeiden Singapore Site Investigation ReportSurendran RadhakrishnanNo ratings yet

- Thermal Switch: 17AME-H Series: FeaturesDocument2 pagesThermal Switch: 17AME-H Series: FeaturesHotel WijayaNo ratings yet

- 325-340W 120-cell 9BB solar moduleDocument2 pages325-340W 120-cell 9BB solar moduleServicios Ingeniería Test LabNo ratings yet

- THIELE Grade80 A5 EnglishDocument53 pagesTHIELE Grade80 A5 EnglishAlberth Mauricio Casteblanco GomezNo ratings yet

- 44-5800 Series: SpecificationsDocument4 pages44-5800 Series: SpecificationsMFERRNo ratings yet

- Guía de Resistencia de MaterialesDocument36 pagesGuía de Resistencia de MaterialesFelix AlorNo ratings yet

- Led Canopy Light Generation 2 - VENAS-2022Document2 pagesLed Canopy Light Generation 2 - VENAS-2022Johana GuerreroNo ratings yet

- 95026Document4 pages95026Samuel Mur BonifacioNo ratings yet

- AEO-04B-48Document4 pagesAEO-04B-48zaur.bNo ratings yet

- Long-duration thermal stress test verifies coil resistance at high heatDocument4 pagesLong-duration thermal stress test verifies coil resistance at high heatAddul Omman NailNo ratings yet

- Gear Oils: Axle & Manual TransmissionsDocument4 pagesGear Oils: Axle & Manual TransmissionsAli ShokoohiNo ratings yet

- valvoline-syn-gard-is-75w-80-bulkDocument1 pagevalvoline-syn-gard-is-75w-80-bulkJUAN BAUTISTANo ratings yet

- Data Bulletin: Wiring Conductor Ampacity To Temperature RatingDocument2 pagesData Bulletin: Wiring Conductor Ampacity To Temperature RatingAdam BehielsNo ratings yet

- Coating product and application guideDocument3 pagesCoating product and application guideMegan BrewerNo ratings yet

- Magnetic Oil Level Gauges SpecsDocument6 pagesMagnetic Oil Level Gauges SpecsHarish Kumar GNo ratings yet

- Solar CellDocument20 pagesSolar Cellaisya mutia syafiiNo ratings yet

- Epact MotorsDocument11 pagesEpact MotorsfrancoghoshNo ratings yet

- Proimage - Crane ScaleDocument2 pagesProimage - Crane ScaleBAPTU MAJUMDERNo ratings yet

- Whitmore GF-Series Synthetic Blend Gear OilDocument1 pageWhitmore GF-Series Synthetic Blend Gear OilDon HowardNo ratings yet

- Viat Product BriefDocument12 pagesViat Product BrieftanniayulianaNo ratings yet

- Surface Vehicle Standard: Rev. JUN2005Document4 pagesSurface Vehicle Standard: Rev. JUN2005JOSE ANDRES OCHOA ORELLANANo ratings yet

- Engine Oil Viscosity and SAE GradesDocument2 pagesEngine Oil Viscosity and SAE Gradeschandra BandaraNo ratings yet

- BGA ReballingDocument10 pagesBGA ReballingdhulandharNo ratings yet

- Littelfuse ATOF DatasheetDocument2 pagesLittelfuse ATOF DatasheetnobrainnopaingkNo ratings yet

- MXB-E, MJB, MJH Generator product catalogueDocument44 pagesMXB-E, MJB, MJH Generator product catalogueMohmad HajNo ratings yet

- Kitz Cryoegenic Valve Catalogue PDFDocument36 pagesKitz Cryoegenic Valve Catalogue PDFAnonymous DB81HnTD49No ratings yet

- LEAFLETS For Lighting FittingsDocument28 pagesLEAFLETS For Lighting FittingsFarid GergesNo ratings yet

- 90°C Panel Discussion: Safety Codes Council Conference Banff 2014Document51 pages90°C Panel Discussion: Safety Codes Council Conference Banff 2014Camilo FeijooNo ratings yet

- Brochure - Valco - Presentatation For Export - EnglishDocument2 pagesBrochure - Valco - Presentatation For Export - EnglishMeet JaniNo ratings yet

- GE Tetra PowerGridDocument2 pagesGE Tetra PowerGridPatrick MorcosNo ratings yet

- Terman - WTI - MSRT150-WDocument9 pagesTerman - WTI - MSRT150-Waimiza100% (2)

- Absolute Maximum Ratings Maximum Power Dissipation: Temperature Package Package Model Range Description Option BrandingDocument1 pageAbsolute Maximum Ratings Maximum Power Dissipation: Temperature Package Package Model Range Description Option BrandingmhasansharifiNo ratings yet

- Technical Data: Technical Data For Release Times Up To 10 S According To PN-EN 60947-1Document5 pagesTechnical Data: Technical Data For Release Times Up To 10 S According To PN-EN 60947-1QasimNo ratings yet

- Breaker THED136100Document4 pagesBreaker THED136100leonelgonzalezNo ratings yet

- WOLVER Multipurpose Gear Oil GL-4 75W-90 PDFDocument2 pagesWOLVER Multipurpose Gear Oil GL-4 75W-90 PDFMeza GalleguillosNo ratings yet

- L1 - ZALUX - BST 1.5 55-840 ET BPC 3x1,5Document2 pagesL1 - ZALUX - BST 1.5 55-840 ET BPC 3x1,5luxcontrolsystems.geralNo ratings yet

- Three-Phase Pad-Mounted TransformersDocument2 pagesThree-Phase Pad-Mounted TransformersmarkfoyNo ratings yet

- Datasheet ThermistorDocument5 pagesDatasheet ThermistorwaniabuNo ratings yet

- Heat Transfer: Non-Stationary Heat Transfer Through Walls, Measurement of Thermal Conductivity, Heat Transfer with Two Phase RefrigerantsFrom EverandHeat Transfer: Non-Stationary Heat Transfer Through Walls, Measurement of Thermal Conductivity, Heat Transfer with Two Phase RefrigerantsRating: 5 out of 5 stars5/5 (1)

- Concealed Ceiling Unit with DCBL Motor for Energy Saving and Quiet ComfortDocument6 pagesConcealed Ceiling Unit with DCBL Motor for Energy Saving and Quiet ComfortKuljinder VirdiNo ratings yet

- Rj45 Socket Arteor - Category 6A STP - 1 Module - Magnesium: CAT. #5 728 06Document1 pageRj45 Socket Arteor - Category 6A STP - 1 Module - Magnesium: CAT. #5 728 06Kuljinder VirdiNo ratings yet

- MK Pds Catalogue Ukmk467-0520-En FinalDocument46 pagesMK Pds Catalogue Ukmk467-0520-En FinalKuljinder VirdiNo ratings yet

- 2022 Top Tips To Solve Situational Questions in PMP ExamDocument10 pages2022 Top Tips To Solve Situational Questions in PMP ExamKuljinder Virdi100% (1)

- MILLENIUM Catalogue 2017-Low ResolutionDocument56 pagesMILLENIUM Catalogue 2017-Low ResolutionKuljinder VirdiNo ratings yet

- Denveâ Wateâ - Engineering: TransmittalDocument1 pageDenveâ Wateâ - Engineering: TransmittalKuljinder VirdiNo ratings yet

- IEC System for Conformity Testing and Certification of Electrotechnical EquipmentDocument4 pagesIEC System for Conformity Testing and Certification of Electrotechnical EquipmentKuljinder VirdiNo ratings yet

- IEC System for Conformity Testing and Certification of Electrotechnical EquipmentDocument4 pagesIEC System for Conformity Testing and Certification of Electrotechnical EquipmentKuljinder VirdiNo ratings yet

- 2021 Millenium CatalogueDocument66 pages2021 Millenium CatalogueKuljinder VirdiNo ratings yet

- Lovag 60439-1Document12 pagesLovag 60439-1Ivana Parčina DjirlićNo ratings yet

- Handicap Toilet AlarmDocument2 pagesHandicap Toilet AlarmKuljinder VirdiNo ratings yet

- 17 Jul 19 Lightning Protection Checklist For Explosives Safety Site Plan 3.1Document6 pages17 Jul 19 Lightning Protection Checklist For Explosives Safety Site Plan 3.1Kuljinder VirdiNo ratings yet

- Overnight Thaw Technical Datasheet: S1Ot-Ss Overnight Thaw S2Ot-Ss Overnight ThawDocument2 pagesOvernight Thaw Technical Datasheet: S1Ot-Ss Overnight Thaw S2Ot-Ss Overnight ThawKuljinder VirdiNo ratings yet

- Temperature Rise of Power Transformers: Comments and PROPOSALS TO IEC 60076-2:2011Document11 pagesTemperature Rise of Power Transformers: Comments and PROPOSALS TO IEC 60076-2:2011Kuljinder VirdiNo ratings yet

- Time Delay Switch Arteor - With Led - 2 Modules - White: CAT. #5 720 55Document1 pageTime Delay Switch Arteor - With Led - 2 Modules - White: CAT. #5 720 55Kuljinder VirdiNo ratings yet

- Generic EICRDocument6 pagesGeneric EICRKuljinder VirdiNo ratings yet

- High-Voltage Switchgear and ControlgearDocument11 pagesHigh-Voltage Switchgear and Controlgearashish sahaNo ratings yet

- High-Voltage Switchgear and ControlgearDocument11 pagesHigh-Voltage Switchgear and Controlgearashish sahaNo ratings yet

- Instructions For Use and Installation Contact Grills Savoye / Panini / Majesctic / Panini DoubleDocument10 pagesInstructions For Use and Installation Contact Grills Savoye / Panini / Majesctic / Panini DoubleKuljinder VirdiNo ratings yet

- Configurable Network Paging Console Product Instructions: Model: X-NPMIDocument9 pagesConfigurable Network Paging Console Product Instructions: Model: X-NPMIKuljinder VirdiNo ratings yet

- Electrical Installation Certificate GuideDocument6 pagesElectrical Installation Certificate GuideKuljinder VirdiNo ratings yet

- Hotplate SOP GuideDocument2 pagesHotplate SOP GuidefathuldewaNo ratings yet

- BS 5499-1:2002 Graphical Symbols and Signs - Safety Signs, Including Fire Safety SignsDocument1 pageBS 5499-1:2002 Graphical Symbols and Signs - Safety Signs, Including Fire Safety SignsKuljinder VirdiNo ratings yet

- Study of Compliance To Prescribed Lighting Standards in Hospitals of Delhi NCR, IndiaDocument5 pagesStudy of Compliance To Prescribed Lighting Standards in Hospitals of Delhi NCR, IndiaKuljinder VirdiNo ratings yet

- Lighting I Course TranscriptDocument23 pagesLighting I Course Transcriptler_ntNo ratings yet

- Hotplate Stirrer PDFDocument1 pageHotplate Stirrer PDFKuljinder VirdiNo ratings yet

- Power Transformers - Part 2 Temperature PDFDocument11 pagesPower Transformers - Part 2 Temperature PDFKuljinder VirdiNo ratings yet

- IELTS preparation writing sample essay on graduate unemploymentDocument2 pagesIELTS preparation writing sample essay on graduate unemploymentmohammed jebreelNo ratings yet

- Compare formal and informal essay stylesDocument1 pageCompare formal and informal essay stylesLyka Nicole DoradoNo ratings yet

- Strength of Materials - II (CE-8402) UNIT-3Document29 pagesStrength of Materials - II (CE-8402) UNIT-3Janarthanan BalakrishnasamyNo ratings yet

- Lesson Plan: Industrial University of Ho Chi Minh CityDocument10 pagesLesson Plan: Industrial University of Ho Chi Minh CityNguyễn TrangNo ratings yet

- TAU 2 Course Material v2.1Document40 pagesTAU 2 Course Material v2.1sreenathNo ratings yet

- Activities guide and evaluation rubric - Unit 3 - Task 4 - Oral Production - Voices in Motion (1)Document7 pagesActivities guide and evaluation rubric - Unit 3 - Task 4 - Oral Production - Voices in Motion (1)Darleison VergelNo ratings yet

- Valvoline Lithium Ep2 GreaseDocument1 pageValvoline Lithium Ep2 GreaseDicky PratamaNo ratings yet

- Lesson 2: Writing Thesis StatementsDocument32 pagesLesson 2: Writing Thesis StatementsUnknownNo ratings yet

- Seismic Force CANADA Code - CNBC2005-V421Document7 pagesSeismic Force CANADA Code - CNBC2005-V421Niko NištićNo ratings yet

- 3rd Year Exam Schedule RegularDocument3 pages3rd Year Exam Schedule RegularHACHALU FAYENo ratings yet

- Kajian Pengaruh Variasi Penambahan Bahan Accelerator Terhadap Parameter Beton Memadat Mandiri Dan Kuat Tekan Beton Mutu TinggiDocument7 pagesKajian Pengaruh Variasi Penambahan Bahan Accelerator Terhadap Parameter Beton Memadat Mandiri Dan Kuat Tekan Beton Mutu TinggiHilda NurhelfitrianingsihNo ratings yet

- Teachers Without Borders Programme: Brought To You byDocument5 pagesTeachers Without Borders Programme: Brought To You bynyashadzashe munyatiNo ratings yet

- Student's Book Unit 4Document9 pagesStudent's Book Unit 4Pau FlurscheimNo ratings yet

- GRC/SPE Workshop: High-Temperature Well Cementing and IntegrityDocument6 pagesGRC/SPE Workshop: High-Temperature Well Cementing and IntegrityesyNo ratings yet

- Automotive Lighting System SimulatorDocument14 pagesAutomotive Lighting System SimulatorAllan LariosaNo ratings yet

- Understanding Faults and EarthquakesDocument8 pagesUnderstanding Faults and EarthquakesJerome CastilloNo ratings yet

- Kelas Xii - May I Help You - Chapter 1Document2 pagesKelas Xii - May I Help You - Chapter 1Syifa Fauziah50% (2)

- Probability and Statistics ExamDocument4 pagesProbability and Statistics ExamLeul SolomonNo ratings yet

- Beneficial Utilisation of Sasol Coal Gasification Ash: Martin Ginster and Ratale H. MatjieDocument5 pagesBeneficial Utilisation of Sasol Coal Gasification Ash: Martin Ginster and Ratale H. MatjieAnonymous fS6Znc9No ratings yet

- Assignmnet, Textile PhysicsDocument6 pagesAssignmnet, Textile PhysicsAbu Mukarram AZADNo ratings yet

- Passage A-1Document6 pagesPassage A-1Natalia VonnyNo ratings yet

- Metrology and Measurement SystemsDocument18 pagesMetrology and Measurement SystemssalemNo ratings yet

- AP Greenfield Electronics Cluster EIA ReportDocument283 pagesAP Greenfield Electronics Cluster EIA ReportNUTHI SIVA SANTHANNo ratings yet

- ACIC - The Professional Criminal Intelligence PractitionerDocument15 pagesACIC - The Professional Criminal Intelligence PractitionerWendell Miles De ArmasNo ratings yet

- Spiral Spring ApparatusDocument3 pagesSpiral Spring ApparatusaqibNo ratings yet

- 71 International Astronautical Congress (Iac) - The Cyberspace Edition, 12-14 October 2020Document8 pages71 International Astronautical Congress (Iac) - The Cyberspace Edition, 12-14 October 2020John DoeNo ratings yet

- GSS Open RecruitmentDocument3 pagesGSS Open RecruitmentFazrie AkbarNo ratings yet

- Explains The Indicators For FitnessDocument7 pagesExplains The Indicators For FitnessCHITO PENJIE ODUYANo ratings yet

- Sample Narrative Report and Documentation 2024 InsetDocument3 pagesSample Narrative Report and Documentation 2024 InsetWILSON CASTRONo ratings yet

- Topic For The Class:: Knowledge and ReasoningDocument41 pagesTopic For The Class:: Knowledge and ReasoningVamshidhar ReddyNo ratings yet