Professional Documents

Culture Documents

Test Results MVSG (1VC1BB00000166)

Uploaded by

CarlCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Test Results MVSG (1VC1BB00000166)

Uploaded by

CarlCopyright:

Available Formats

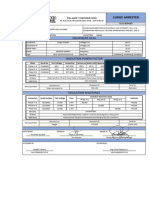

B SCANNER MAGNEDYNE, INC.

SMI Building, Tres de Mayo, Ward IV, Minglanilla, Cebu, 6046

Telefax (032) 236 – 0753 / Tel. No. (032) 490 – 0708

SEC Reg. No. CS200529237 / PCAB Lic. No. 32522

Email address: scannermagnedyne@yahoo.com.ph

Date : September 28, 2020

To : Mr. Jeffrey Inigo

FSG Manager

Tsuneishi Heavy Industries, Cebu Inc.

Subject: TEST REPORT

Test Item Vacuum Circuit Breaker Serial No. 1VC1BB00000166

Code PC-NO.1 & PC-NO.2 Type VMAX 17.06.25

Voltage Rating 17.5 kV Test Site Phase 1 Tsuneishi

Current Rating 630 A Date of Test September 13, 2020

Maker ABB Weather Fair

Test Equipment Model Maker S/N

Contact Resistance TRM-10 Teldar Instruments 0845

Insulation Resistance Teraohm 10kV Metrel 14220160

Prepared by: Conducted by:

_________________________ ________________________

Engr. Carl Anthony Bequilla Engr. Wilfred Medil

Technical Services Engineer Engineering Manager

Checked by: Noted by:

_________________________ ________________________

Engr. Joseph Fortunate Gerona Engr. Mario Gabunilas

Technical Services Engineer Assistant General Manager

SCANNER MAGNEDYNE, INC.

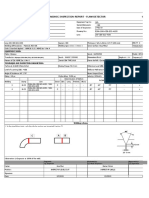

SUMMARY OF TEST DATA

Contact Resistance Test @1 Amp

Phase Result

A 1.501 mΩ

B 1.669 mΩ

C 1.741 mΩ

In accordance with ANSI/NETA MTS-2015 standards, micro-ohm or millivolt drop values should not exceed the high levels of

the normal range as indicated in the manufacturer’s published data. If manufacturer’s data is not available, investigate any

values which deviate from adjacent poles or similar switches by more than 50% of the lowest value.

Remarks: Satisfactory

Insulation Resistance Test @ 2500VDC

Close Contact

Line Line

30°C *20°C 30°C *20°C

to to

(GΩ) (GΩ) (GΩ) (GΩ)

Line Ground

A–B 4.75 7.51 A–G 1.49 2.35

B–C 4.47 7.06 B–G 1.95 3.08

C–A 3.73 5.89 C–G 1.43 2.26

Open Contact

Lineside Loadside

30°C *20°C 30°C *20°C

to to

(GΩ) (GΩ) (GΩ) (GΩ)

Ground Ground

1–G 196 310 2–G 1.64 2.59

3–G 159 251 4–G 2.08 3.29

5–G 231 365 6–G 1.43 2.26

Lineside to Loadside

30°C *20°C

(GΩ) (GΩ)

1–2 176 278

3–4 187 295

5–6 170 269

Recommended minimum Insulation Resistance based on ANSI/NETA MTS-2015 Standards for Electrical apparatus and

systems other than transformer and motor windings (20°C)

2500 VDC = 5000 MΩ

*Correction factors used are based on ANSI/NETA MTS-2015 Table 100.14.1: Insulation Resistance Conversion Factors

Test results are dependent on the temperature of the insulating material and the humidity of the surrounding environment at

the time of the test. Insulation-resistance test data may be used to establish a trending pattern. Deviations from the baseline

information permit evaluation of the insulation.

Remarks: Values marked in red font did not reach the minimum standard set by ANSI/NETA MTS-2015.

Operational Test

Operation Remarks

Circuit Breaker Open Passed

Circuit Breaker Close Passed

Manual Charging, Closing and Tripping Passed

Counter Reading

As – Found 315

As – Left 315

SCANNER MAGNEDYNE, INC.

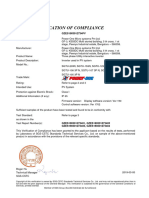

FINDINGS

Physical inspection indicates that there are no noticeable signs of corrosion or dents.

During the testing, it was observed that the counter reading did not change after the unit was operated, which is the

reason for the same AS-FOUND and AS-LEFT reading in this report.

SUMMARY OF TEST RESULTS

Test Conducted Standard Used Remarks Notes

Contact Resistance Test ANSI/NETA MTS-2015 Satisfactory ---

Insulation resistance is

Values marked in red font

affected by temperature,

did not reach the minimum

Insulation Resistance Test ANSI/NETA MTS-2015 humidity, as well as the

standard set by

aging of the installed

ANSI/NETA MTS-2015.

unit.

Operational Tests ANSI/NETA MTS-2015 Satisfactory ---

RECOMMENDATIONS

Based on the satisfactory results of contact resistance test and circuit breaker operational tests which are in line

with the standards set by ANSI/NETA MTS-2015, we conclude that the circuit breaker can be safely energized and

operated.

On the case of some values of insulation resistance not meeting the standard set by ANSI/NETA MTS-2015, further

evaluation and investigation through the analysis of the insulation resistance trend is advised. However, since we

have no previous insulation resistance test results for this particular unit, trend analysis is not possible and we can

only use the current values as baseline for future tests.

It is recommended to conduct periodic electrical testing on the unit to prevent potential problems from happening.

Generally, conducting annual electrical testing on vacuum circuit breakers is considered as good practice.

SCANNER MAGNEDYNE, INC.

You might also like

- Constellation Pharma (CNST) ThesisDocument17 pagesConstellation Pharma (CNST) Thesisjulia skripka-serry100% (2)

- MDR - Conformity AssessmentDocument8 pagesMDR - Conformity AssessmentNathan LabordeNo ratings yet

- Method Statement - Foul Drainage DiversionDocument4 pagesMethod Statement - Foul Drainage DiversionBNo ratings yet

- Handout IV: DSM-5 ASD Checklist: Making An Autism Spectrum Disorder DiagnosisDocument2 pagesHandout IV: DSM-5 ASD Checklist: Making An Autism Spectrum Disorder DiagnosisValentina IerotheouNo ratings yet

- Antenna Datasheet Am 2 Freq CircDocument9 pagesAntenna Datasheet Am 2 Freq CircĐỗ Quang HuyNo ratings yet

- Electrode Test Record E6010Document9 pagesElectrode Test Record E6010Veeraraghavan GuruNo ratings yet

- Semiconductor Data Book: Characteristics of approx. 10,000 Transistors, FETs, UJTs, Diodes, Rectifiers, Optical Semiconductors, Triacs and SCRsFrom EverandSemiconductor Data Book: Characteristics of approx. 10,000 Transistors, FETs, UJTs, Diodes, Rectifiers, Optical Semiconductors, Triacs and SCRsNo ratings yet

- in This Photograph, The Issue or Problem Depicted Is That We Became The Slaves of Science andDocument1 pagein This Photograph, The Issue or Problem Depicted Is That We Became The Slaves of Science andClarisse Angela Postre50% (2)

- 1N5231B T Diodes Inc.Document4 pages1N5231B T Diodes Inc.cossagenioNo ratings yet

- 75 kVA Single Phase Distribution Transformer Test ResultDocument9 pages75 kVA Single Phase Distribution Transformer Test ResultCarlNo ratings yet

- 201 - M CVTDocument3 pages201 - M CVTAshutosh KumarNo ratings yet

- Transformer Testing For New 10mva Power Transfomer: Batangas Ii Electric Cooperative (Batelec Ii)Document4 pagesTransformer Testing For New 10mva Power Transfomer: Batangas Ii Electric Cooperative (Batelec Ii)Edmar BataqueNo ratings yet

- 01 1MVA Transformer Test Results First Farmers L247979CDocument5 pages01 1MVA Transformer Test Results First Farmers L247979CMario GabunilasNo ratings yet

- Thermocouple Amplifier - Dual Ga 112Document3 pagesThermocouple Amplifier - Dual Ga 112SUVENDU ADHIKARYNo ratings yet

- ArresterDocument1 pageArresterrey pamelo navarroNo ratings yet

- 7191088490-01-Pne Translite Pte Ltd-Emergency Luminaires-Test Report Ss263Document14 pages7191088490-01-Pne Translite Pte Ltd-Emergency Luminaires-Test Report Ss263Justin NgNo ratings yet

- Ca Abc-Semca: Temperature ProbeDocument7 pagesCa Abc-Semca: Temperature ProbejackNo ratings yet

- B320/A/B - B360/A/B: 3.0A Surface Mount Schottky Barrier RectifierDocument4 pagesB320/A/B - B360/A/B: 3.0A Surface Mount Schottky Barrier RectifierGustavo Alberto Jaramillo RuedaNo ratings yet

- 8015-0151-00-Al-Cd 1133-19-Gf-Ogf4-J-Vd-9506-00001 - 00 - RT ProcedureDocument20 pages8015-0151-00-Al-Cd 1133-19-Gf-Ogf4-J-Vd-9506-00001 - 00 - RT ProcedureRami KsidaNo ratings yet

- Test Certificate For Current TransformerDocument1 pageTest Certificate For Current Transformersanjayprakash1979No ratings yet

- Site Test Report: Under Ground Cables Precommissioning Test SheetDocument1 pageSite Test Report: Under Ground Cables Precommissioning Test SheetNaser Mahamid100% (1)

- HRSG 21 Sump Pumps 20GMA31AP001, 20GMA32AP002 (Motor Datasheet, Drawing)Document5 pagesHRSG 21 Sump Pumps 20GMA31AP001, 20GMA32AP002 (Motor Datasheet, Drawing)Anibal QuezadaNo ratings yet

- Jelf243c 0031-1569892Document11 pagesJelf243c 0031-1569892PIER ANGEL SUAREZ GUTIERREZNo ratings yet

- GoldyDocument1 pageGoldyAniket DubeNo ratings yet

- Lightning Arrester 2Document1 pageLightning Arrester 2Noel SantosNo ratings yet

- Contactor Ac-6b Capacitor CJ19Document2 pagesContactor Ac-6b Capacitor CJ19ChangKhenNo ratings yet

- Test Report 2.2 - Type Test (EN 10204) : 1 Rated Motor DataDocument9 pagesTest Report 2.2 - Type Test (EN 10204) : 1 Rated Motor DatazsmithNo ratings yet

- Anti Pumping Device / Relay (APD or APC) : Inventa Electro Systems (Nasik) PVT .LTDDocument7 pagesAnti Pumping Device / Relay (APD or APC) : Inventa Electro Systems (Nasik) PVT .LTDragab abulmagdNo ratings yet

- Anti Pumping Device / Relay (APD or APC) : Inventa Electro Systems (Nasik) PVT .LTDDocument7 pagesAnti Pumping Device / Relay (APD or APC) : Inventa Electro Systems (Nasik) PVT .LTDArunava BasakNo ratings yet

- SMAJ5.0 (C) A - SMAJ170 (C) A: 400W Surface Mount Transient Voltage Suppressor FeaturesDocument4 pagesSMAJ5.0 (C) A - SMAJ170 (C) A: 400W Surface Mount Transient Voltage Suppressor Featuresedi purwantoNo ratings yet

- Specification: KJ Lian JieDocument6 pagesSpecification: KJ Lian Jiericmf89No ratings yet

- Mmbta92lt1g en 10043876Document5 pagesMmbta92lt1g en 10043876Janos NagyNo ratings yet

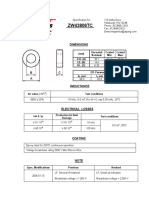

- 250w Core ZW43806TCDocument1 page250w Core ZW43806TCErkanNo ratings yet

- Bus-1 VTDocument2 pagesBus-1 VTGajendran SriramNo ratings yet

- Diodes MMBZ5226BDocument3 pagesDiodes MMBZ5226BErasmo Franco SNo ratings yet

- ZF40907TCDocument1 pageZF40907TCMurugan AlbumsNo ratings yet

- Ut ProcedureDocument2 pagesUt ProcedureJJ WeldingNo ratings yet

- ALL-TEST Pro, LLC Case Study: Dynamometers 012002Document3 pagesALL-TEST Pro, LLC Case Study: Dynamometers 012002RM HaroonNo ratings yet

- 33 KV CT Straton Make 400Document5 pages33 KV CT Straton Make 400Anand SharmaNo ratings yet

- Current Sensitivity of A Galvanometer: Mustafa Anwar & Ahmed Ali - Electronic Measurements LabDocument4 pagesCurrent Sensitivity of A Galvanometer: Mustafa Anwar & Ahmed Ali - Electronic Measurements LabMustafa AnwarNo ratings yet

- Uss 105Document12 pagesUss 105Soumya BhowmickNo ratings yet

- Sr. No. Equipment Equipment ID Location Calibration Due DateDocument16 pagesSr. No. Equipment Equipment ID Location Calibration Due DateGURINo ratings yet

- RT Duroid 5870 5880 Data Sheet PDFDocument2 pagesRT Duroid 5870 5880 Data Sheet PDFNom MonNo ratings yet

- GOLDI - 72GN1 Monocrystalline Module (PERC) : Key FeaturesDocument1 pageGOLDI - 72GN1 Monocrystalline Module (PERC) : Key Featuresklp_kedarpNo ratings yet

- 5KW-20KW AllDocument3 pages5KW-20KW Allsol indiaNo ratings yet

- HT Panel Test ReportDocument4 pagesHT Panel Test ReportItx Adi0% (1)

- Gpti Qicl J931 Mut 019Document3 pagesGpti Qicl J931 Mut 019uselessinstaid52No ratings yet

- B - S-1W & B - D-1W Series: 1W, Fixed Input Isolated & Unregulated Single Output Miniature Sip/Dip PackageDocument5 pagesB - S-1W & B - D-1W Series: 1W, Fixed Input Isolated & Unregulated Single Output Miniature Sip/Dip PackagecesarNo ratings yet

- Kiem Tra Thiet Bi Truoc Khi Dong Dien (E-Ver RC2) - 2Document5 pagesKiem Tra Thiet Bi Truoc Khi Dong Dien (E-Ver RC2) - 2Thái TrầnNo ratings yet

- Iso Thermal Relaxation ReportDocument5 pagesIso Thermal Relaxation ReportKit AnnoncerNo ratings yet

- 06 - Fire Resistant CablesDocument13 pages06 - Fire Resistant CablesmlutfimaNo ratings yet

- A1X3R1 - 2d - EPI-08-WP5-TW PDFDocument10 pagesA1X3R1 - 2d - EPI-08-WP5-TW PDFJose Anisio SilvaNo ratings yet

- Lightning Arrester 1Document1 pageLightning Arrester 1Noel SantosNo ratings yet

- WAGO 750-602enDocument6 pagesWAGO 750-602enFirmanNo ratings yet

- Surge Protector and Filter Specifications: Technical DataDocument16 pagesSurge Protector and Filter Specifications: Technical DataJuan Esteban Benjumea BenjumeaNo ratings yet

- 132 HiDocument6 pages132 HiNiteen S. RathodNo ratings yet

- AEC Q200 Rev D Table7Document2 pagesAEC Q200 Rev D Table7Michael PengNo ratings yet

- Red670 AcceptanceDocument12 pagesRed670 AcceptancewazakifyNo ratings yet

- Welding Procedure Specification No. Epi-11-Wp10 BW Rev. 1Document15 pagesWelding Procedure Specification No. Epi-11-Wp10 BW Rev. 1Felipe Vásquez ArribasplataNo ratings yet

- N Sschou JDocument3 pagesN Sschou JdraganbabicNo ratings yet

- Example of Inspection Report 3Document11 pagesExample of Inspection Report 3SAIFUDDIN NUR AKMALNo ratings yet

- GW gm1000gm3000gm1000d Quick Installation Guide-EnDocument10 pagesGW gm1000gm3000gm1000d Quick Installation Guide-EnJakub BohdálekNo ratings yet

- DHHDFDocument1 pageDHHDFTTIPLNo ratings yet

- Test ReportDocument40 pagesTest ReportMourad BenderradjiNo ratings yet

- Test Results MVSG (1VC1BB00000163)Document3 pagesTest Results MVSG (1VC1BB00000163)CarlNo ratings yet

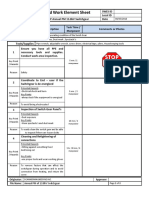

- Standard Work Element Sheet: 5 Min / 1 ManpowerDocument2 pagesStandard Work Element Sheet: 5 Min / 1 ManpowerCarlNo ratings yet

- EasyLogic PM1000 Series - METSEDM6000Document2 pagesEasyLogic PM1000 Series - METSEDM6000CarlNo ratings yet

- Fundamentals of Preventive MaintenanceDocument21 pagesFundamentals of Preventive MaintenanceCarlNo ratings yet

- Carbohydrate NotesDocument5 pagesCarbohydrate NotesdrewNo ratings yet

- Delight in Sight: Corneal Topographer Tms-4NDocument2 pagesDelight in Sight: Corneal Topographer Tms-4NWaleed Ah-DhaifiNo ratings yet

- KFCDocument41 pagesKFCSumit Kumar100% (1)

- Pressure Vessel Hydrotest Procedure - Google SearchDocument3 pagesPressure Vessel Hydrotest Procedure - Google SearchAsad KhanNo ratings yet

- Profit and Loss Statement TemplateDocument2 pagesProfit and Loss Statement TemplateAlisa VisanNo ratings yet

- Solid Waste Management PDFDocument3 pagesSolid Waste Management PDFGanga Dhar Chaudhary0% (1)

- Hildegard PeplauDocument7 pagesHildegard PeplauCarmenchuParraNo ratings yet

- PROYECTO DE INGLES CITRULINA FinalDocument60 pagesPROYECTO DE INGLES CITRULINA FinalBoris V ZuloetaNo ratings yet

- Architecture: Passive Design With ClimateDocument39 pagesArchitecture: Passive Design With ClimateamenrareptNo ratings yet

- Body Systems TestDocument6 pagesBody Systems TestIRENE DÁVALOS SMILGNo ratings yet

- OS Prosthetics Orthotics, L3, L4 & L5Document144 pagesOS Prosthetics Orthotics, L3, L4 & L5MaxNo ratings yet

- Case Session - 5Document3 pagesCase Session - 5Ruthwick GowdaNo ratings yet

- SubseaLV DatasheetDocument1 pageSubseaLV DatasheetPablo TorresNo ratings yet

- Calibration of Portable Hardness TesterDocument4 pagesCalibration of Portable Hardness Testerashishchandan13No ratings yet

- Bio 11.1 LE 2 NotesDocument7 pagesBio 11.1 LE 2 NotesCode BlueNo ratings yet

- Reaction PaperDocument3 pagesReaction PaperMondejar KhriziaNo ratings yet

- Pry LiteDocument1 pagePry LiteTere_insaNo ratings yet

- 3rd - Sem-Ct-23-Chemical EngineeringDocument3 pages3rd - Sem-Ct-23-Chemical EngineeringJay RanjanNo ratings yet

- Emersus Brochure PDFDocument11 pagesEmersus Brochure PDFDevagaran GunasekaranNo ratings yet

- Eudrabook - Epub - en - European Commission - HealthDocument826 pagesEudrabook - Epub - en - European Commission - Healthpr1asdNo ratings yet

- Golf Pei Course Comparison ChartDocument1 pageGolf Pei Course Comparison ChartSteve DimondNo ratings yet

- Psychiatric Nurse's Role As Member of The Research TeamDocument3 pagesPsychiatric Nurse's Role As Member of The Research TeamKim Tango100% (1)

- Lymph Node - Any of The Small, Oval or Round Bodies, Located Along The Lymphatic VesselsDocument2 pagesLymph Node - Any of The Small, Oval or Round Bodies, Located Along The Lymphatic VesselsKaren ParraNo ratings yet

- Digi-Flex v. Gripmaster PDFDocument12 pagesDigi-Flex v. Gripmaster PDFMark JaffeNo ratings yet

- NEOTHERM 70 EVO - 60V Manual - P1600 PDFDocument23 pagesNEOTHERM 70 EVO - 60V Manual - P1600 PDFm_armouti100% (1)