Professional Documents

Culture Documents

Air Permeability Method

Uploaded by

muralidharanOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Air Permeability Method

Uploaded by

muralidharanCopyright:

Available Formats

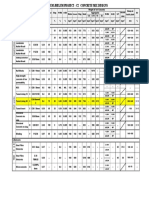

AIR PERMEABILITY METHOD ( BLAINE METHOD )

The fineness of cement is measured as specific surface. Specific surface is expressed as

the total surface area in square metres of all the cement particles in one kilogram of

cement. The higher the specific surface is, the finer cement will be. Principle of air

permeability method is in observing the time taken for a fixed quantity of air to flow

through compacted cement bed of specified dimension and porosity. Under

standardised conditions the specific surface of cement is proportional to where t is the

time for given quantity of air to flow through the compacted cement bed. The number

and size range of individual pores in the specified bed are determined by the cement

particle size distribution which also determined the time for the specified air flow. The

method is comparative rather than absolute and therefore a reference sample of known

specific surface is required for calibration of the apparatus.

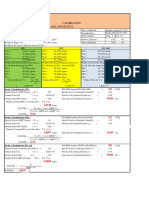

A bed of cement is prepared in special permeability cell and have exact porosity e =

0,500 weight a quantity of cement. The weight of the cement is calculated from

Where

ρ is the density of the cement [g.cm-3]

V volume of the cement bed [cm3 ]

Specific surface S is expressed as

Where

K is the apparatus constant

e porosity of the bed

t the measured time [s]

ρ density of cement [g.cm-3]

η the viscosity of air at the test temperature taken from Tab.:27

The apparatus constant is determinate by measuring permeability of reference cement

of known specific surface. The procedure repeats three times for three samples of

cement bed. For each sample is calculated constant K from formula:

where

S0 is the specific surface of the reference cement [cm2 .g-1]

ρ0 density of the reference cement [g.cm-3]

t0 measured time [s]

η0 air viscosity at the test temperature [Pa.s]

With the specified porosity of e = 0,500

The mean of three values of K is the constant K for the apparatus

TESTING PROCEDURE :

1.Place the perforated disc on the ledge at the bottom of the cell and place on it a new

filter paper disc. Place the weighed quantity of cement, m1, in the cell. Place a second

new filter paper disc on the levelled cement. Insert the plunger and press it gently but

firmly until the lower face of the cap is in contact with the cell. Slowly withdraw the

plunger, rotate it through 90 ° and press once again. The bed is now compacted and

ready for the permeability test.

2. Test is performed on the Blaine apparatus (see Fig.:30). It is practically manometer in

the U-tube form. One arm of the manometer is provided at the top with conical socket

to form an airtight fit with the conical surface of the cell. The same arm has four etched

lines M1 to M4 and T-joint, which lead to an airtight stopcock beyond which is attached

aspiration rubber bulb.

3. Manometer is filled to the level of the lowest etched line with non-volatile, non-

hygroscopic liquid of low viscosity and density (such as dibutylphthalate or light

mineral oil).

4.Insert the conical surface of the cell into the socket at the top of the manometer.

5. Open the stopcock and with gentle aspiration raise the level of the manometer liquid

to that of the highest etched line. Close the stopcock and the manometer liquid will

begins to flow. Start the timer as the liquid reaches the second etched line and stop it

when the liquid reaches the third etched line. Record the time, t, and the temperature, T.

6. The procedure repeats three times

7. Calculate three values of the specific surface and the mean of them.

Temperature ° C Air viscosity η [Pa.s] Sq .rt 0,1 η

16 0.00001800 0.001342

17 0.00001805 0.001344

18 0.00001810 0.001345

19 0.00001815 0.001347

20 0.00001819 0.001349

21 0.00001824 0.001351

22 0.00001829 0.001353

23 0.00001834 0.001354

24 0.00001839 0.001356

You might also like

- Plastic Injection Mold Design for Toolmakers - Volume II: Plastic Injection Mold Design for Toolmakers, #2From EverandPlastic Injection Mold Design for Toolmakers - Volume II: Plastic Injection Mold Design for Toolmakers, #2No ratings yet

- Various Lab Test On CementDocument4 pagesVarious Lab Test On Cementhncc ghazniNo ratings yet

- The Book of the Singer Junior - Written by an Owner-Driver for Owners and Prospective Owners of the Car - Including the 1931 SupplementFrom EverandThe Book of the Singer Junior - Written by an Owner-Driver for Owners and Prospective Owners of the Car - Including the 1931 SupplementNo ratings yet

- IS 4031 - Part15Document8 pagesIS 4031 - Part15Nagaraju ChintaNo ratings yet

- Mix Design CalculationDocument8 pagesMix Design CalculationEr Digvijay SinghNo ratings yet

- ASTM C618.18780 Fly Ash in ConcreteDocument5 pagesASTM C618.18780 Fly Ash in Concreteskhan247No ratings yet

- D3796-90 S-Pitot TubeDocument13 pagesD3796-90 S-Pitot Tubeonline account0% (1)

- Specification For 53 Grade Ordinary Portland CementDocument7 pagesSpecification For 53 Grade Ordinary Portland Cementsukanta420No ratings yet

- Bitumen Viscosity Testing Equipment and Test ProceduresDocument6 pagesBitumen Viscosity Testing Equipment and Test ProceduresDani MarineloNo ratings yet

- CementDocument28 pagesCementhboespn100% (1)

- IRS T-39 6th Revision March 2021 - With Corrigendum No - 1Document41 pagesIRS T-39 6th Revision March 2021 - With Corrigendum No - 1Raja SandakaNo ratings yet

- Gap Analysis For ASTM D7928Document9 pagesGap Analysis For ASTM D7928Kim Yuen Wong100% (1)

- Air Permeability Test PDFDocument1 pageAir Permeability Test PDFEhsaan Raahi RihaanNo ratings yet

- Experiment No 3a Sieve Analysis of SoilDocument7 pagesExperiment No 3a Sieve Analysis of Soillance adrian del rosarioNo ratings yet

- White CementDocument11 pagesWhite CementLdiabiNo ratings yet

- Viscosity TestDocument1 pageViscosity TestDeven PatleNo ratings yet

- Setting & Soundness Tests for CementDocument13 pagesSetting & Soundness Tests for CementGanesh.RajanNo ratings yet

- List of Referred Indian Standard Codes For Civil EngineersDocument5 pagesList of Referred Indian Standard Codes For Civil EngineersDarshan M MNo ratings yet

- 03 SOLVED Gravity Settling Chamber Problem 2016-17 PDFDocument6 pages03 SOLVED Gravity Settling Chamber Problem 2016-17 PDFmanelNo ratings yet

- BEE Cement Plant Code FinalDocument4 pagesBEE Cement Plant Code FinalHazem DiabNo ratings yet

- Determining Soundness and Impact Value of Concrete MaterialsDocument61 pagesDetermining Soundness and Impact Value of Concrete MaterialsUbaid RajputNo ratings yet

- Planetary Ball Mill Process in Aspect of Milling EnergyDocument11 pagesPlanetary Ball Mill Process in Aspect of Milling EnergyJesús IbarraNo ratings yet

- Is 1489 Part 1 Final Product ManualDocument16 pagesIs 1489 Part 1 Final Product ManualBAl MURUGANNo ratings yet

- List of Standards Edit 2Document5 pagesList of Standards Edit 2volminkNo ratings yet

- Astm C 186-2017Document7 pagesAstm C 186-2017Mohammed AliNo ratings yet

- Free Lime Determination ClinkerDocument2 pagesFree Lime Determination ClinkerfoxmancementNo ratings yet

- Cement Classification BDPDocument26 pagesCement Classification BDPkonstantasNo ratings yet

- California Bearing Ratio Test Data Sheets & GraphsDocument4 pagesCalifornia Bearing Ratio Test Data Sheets & GraphsSaad JuventinoNo ratings yet

- Is 1448 16 1990 PDFDocument10 pagesIs 1448 16 1990 PDFDario de SantiagoNo ratings yet

- Asphalt Tests PDFDocument9 pagesAsphalt Tests PDFdishkuNo ratings yet

- Astm Ac20Document3 pagesAstm Ac20Juan QuiñonesNo ratings yet

- Cement Testing ReportsDocument29 pagesCement Testing ReportstejakandulaNo ratings yet

- 75 81 EngDocument84 pages75 81 Engmehrdad_so1981No ratings yet

- Calibration Report CTMDocument2 pagesCalibration Report CTMSuresh RajuNo ratings yet

- Mix DesignDocument1 pageMix Designfaizankhan23No ratings yet

- Construction and Quality Control of Flexible PavementsDocument83 pagesConstruction and Quality Control of Flexible PavementsSayan GharNo ratings yet

- Vicatronic Automatic Recording Apparatus ManualDocument22 pagesVicatronic Automatic Recording Apparatus ManualAhmed Azad100% (1)

- Cement Tests GuideDocument10 pagesCement Tests GuideAbhishek SharmaNo ratings yet

- TE Lab Manual - 2017 New - 2.1 LatestDocument94 pagesTE Lab Manual - 2017 New - 2.1 LatestArundhathi PushpagaranNo ratings yet

- DBM Dencity CalculationDocument3 pagesDBM Dencity Calculationer_kenedyNo ratings yet

- Is 8887 (2004) - Bitumen Emulsion For Roads (Cationic Type)Document17 pagesIs 8887 (2004) - Bitumen Emulsion For Roads (Cationic Type)arjun kumar50% (2)

- California Bearing Ratio Testing ReportsDocument42 pagesCalifornia Bearing Ratio Testing ReportsNurhalizah PutriNo ratings yet

- A Study of Intergrinding and Separate Grinding of Blast Furnace Slag CementDocument8 pagesA Study of Intergrinding and Separate Grinding of Blast Furnace Slag CementAbd El-nour RamdNo ratings yet

- Presentation on Bitumen Properties and TestsDocument54 pagesPresentation on Bitumen Properties and TestsSavitha PradeepNo ratings yet

- .Methods of Physical Tests For Hydraulic Cement: Indian StandardDocument8 pages.Methods of Physical Tests For Hydraulic Cement: Indian StandardRS EngineeringNo ratings yet

- Determination of Pack-Set Index of Portland Cement: Standard Test Method ForDocument5 pagesDetermination of Pack-Set Index of Portland Cement: Standard Test Method ForINARQ1979No ratings yet

- IS-8042-Product-Manual-WHITE CEMENTDocument14 pagesIS-8042-Product-Manual-WHITE CEMENTSauravTekriwalNo ratings yet

- CIVL354 Notes 1 Soil CompactionDocument20 pagesCIVL354 Notes 1 Soil Compactionmusiomi2005No ratings yet

- CALIBRATION RESULTSDocument1 pageCALIBRATION RESULTSKuldeep UpadhyayNo ratings yet

- Better ETP Performance with Zinc TechnologyDocument31 pagesBetter ETP Performance with Zinc Technologyदीपक कश्यपNo ratings yet

- Is 73-2013 Paving Bitumen - SpecificationsDocument6 pagesIs 73-2013 Paving Bitumen - Specificationsyash_monu05No ratings yet

- Is Concrete Mix DesignDocument21 pagesIs Concrete Mix DesignahmedanyNo ratings yet

- Is 269 Final Product ManualDocument14 pagesIs 269 Final Product ManualBiswajit MansinghNo ratings yet

- ASTM C-1356, Quantitative Determination of Phases in Portland Cement PDFDocument5 pagesASTM C-1356, Quantitative Determination of Phases in Portland Cement PDFsaeedhoseini100% (1)

- Air Permeability MethodDocument4 pagesAir Permeability MethodgowricivilNo ratings yet

- Blaine Apparatus ProcedureDocument7 pagesBlaine Apparatus ProcedureVivek Pandey100% (3)

- Cement Testing MethodsDocument7 pagesCement Testing MethodspiratekANo ratings yet

- Tests On CementDocument24 pagesTests On CementIan BondocNo ratings yet

- Specific: Experiment No. 02: Determination of Gravity of Soil by Water Pycnometer. 2.1. DesignationDocument8 pagesSpecific: Experiment No. 02: Determination of Gravity of Soil by Water Pycnometer. 2.1. DesignationAbdullah qureshiNo ratings yet

- Sci1103 Unit 4notesDocument84 pagesSci1103 Unit 4notesSalin RajNo ratings yet

- Determination of Aggregate Crushing Value TestDocument3 pagesDetermination of Aggregate Crushing Value TestmuralidharanNo ratings yet

- Tool Makers MicroscopeDocument9 pagesTool Makers MicroscopemuralidharanNo ratings yet

- Surface Roughness TesterDocument7 pagesSurface Roughness TestermuralidharanNo ratings yet

- Aggregate Impact ValueDocument5 pagesAggregate Impact ValuemuralidharanNo ratings yet

- New No. 3, Old No. 2, S.V. Koil Street, Sekar Nagar, Ashok Nagar, Chennai - 60083 Phone: +91 (044 43518677 - Cell: (+91) 9789976777, 9940077338 EmailDocument4 pagesNew No. 3, Old No. 2, S.V. Koil Street, Sekar Nagar, Ashok Nagar, Chennai - 60083 Phone: +91 (044 43518677 - Cell: (+91) 9789976777, 9940077338 EmailmuralidharanNo ratings yet

- Cyclone SeparatorDocument7 pagesCyclone SeparatormuralidharanNo ratings yet

- Cooling Tower Test Rig (Fluidised Bed)Document5 pagesCooling Tower Test Rig (Fluidised Bed)muralidharanNo ratings yet

- Air Permeability MethodDocument4 pagesAir Permeability MethodmuralidharanNo ratings yet

- Drop Weight CrusherDocument2 pagesDrop Weight CrushermuralidharanNo ratings yet

- Cyclone SeparatorDocument7 pagesCyclone SeparatormuralidharanNo ratings yet

- Cooling Tower Test Rig (Fluidised Bed)Document5 pagesCooling Tower Test Rig (Fluidised Bed)muralidharanNo ratings yet

- Bare and Finned Tube Heat ExchangerDocument5 pagesBare and Finned Tube Heat ExchangermuralidharanNo ratings yet

- Drop Weight Crusher Aim: Apparatus Required: ProcedureDocument2 pagesDrop Weight Crusher Aim: Apparatus Required: ProceduremuralidharanNo ratings yet

- Drop Weight CrusherDocument2 pagesDrop Weight CrushermuralidharanNo ratings yet

- Air Permeability MethodDocument4 pagesAir Permeability MethodmuralidharanNo ratings yet

- Drop Weight CrusherDocument2 pagesDrop Weight CrushermuralidharanNo ratings yet

- Bare and Finned Tube Heat ExchangerDocument5 pagesBare and Finned Tube Heat ExchangermuralidharanNo ratings yet

- Cooling Tower Test Rig (Fluidised Bed)Document5 pagesCooling Tower Test Rig (Fluidised Bed)muralidharanNo ratings yet

- Air Permeability MethodDocument4 pagesAir Permeability MethodmuralidharanNo ratings yet

- Cyclone SeparatorDocument7 pagesCyclone SeparatormuralidharanNo ratings yet

- Cooling Tower Test Rig (Fluidised Bed)Document5 pagesCooling Tower Test Rig (Fluidised Bed)muralidharanNo ratings yet

- 6.load Test On Petrol EngineDocument3 pages6.load Test On Petrol Enginemuralidharan100% (1)

- Bare and Finned Tube Heat ExchangerDocument5 pagesBare and Finned Tube Heat ExchangermuralidharanNo ratings yet

- METALLOGRAPHIC PROPERTIES: MILD STEELS TO BRASSDocument4 pagesMETALLOGRAPHIC PROPERTIES: MILD STEELS TO BRASSmuralidharanNo ratings yet

- Metallographic Structures of Common AlloysDocument2 pagesMetallographic Structures of Common AlloysmuralidharanNo ratings yet

- Bare and Finned Tube Heat ExchangerDocument5 pagesBare and Finned Tube Heat ExchangermuralidharanNo ratings yet

- Transverse Cantiliver, Free, Simply SupportedDocument3 pagesTransverse Cantiliver, Free, Simply SupportedmuralidharanNo ratings yet

- Whirling Shaft ManualDocument3 pagesWhirling Shaft ManualmuralidharanNo ratings yet

- Sta.& Dy. - Balancing PDFDocument8 pagesSta.& Dy. - Balancing PDFGurmeet MehmaNo ratings yet

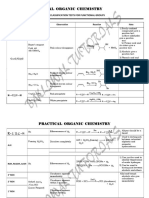

- General Organic Chemistry - Sheet - 10 - 11 & 12) (Hyperconjugation & Aromaticity) Level - 1 1Document10 pagesGeneral Organic Chemistry - Sheet - 10 - 11 & 12) (Hyperconjugation & Aromaticity) Level - 1 1IznnxxkozsksnndNo ratings yet

- Corrosion InhibitorDocument6 pagesCorrosion Inhibitorpadmesh awasthiNo ratings yet

- Atomic and Molecular Structure ExplainedDocument20 pagesAtomic and Molecular Structure Explainedke.No ratings yet

- Volume Measurement TechniquesDocument3 pagesVolume Measurement TechniquesKim Arthur CruzNo ratings yet

- Measurement and Prediction of Hydrate-Phase Equilibria For Reservoir FluidsDocument8 pagesMeasurement and Prediction of Hydrate-Phase Equilibria For Reservoir FluidsThevaruban RagunathanNo ratings yet

- Practical Organic Chemistry Classification TestsDocument19 pagesPractical Organic Chemistry Classification TestsJonathan ParkerNo ratings yet

- Extrusion and Wire Drawing 2020 PDFDocument64 pagesExtrusion and Wire Drawing 2020 PDFChand PatelNo ratings yet

- TDS - Bronco Cemgrout SP75Document4 pagesTDS - Bronco Cemgrout SP75Jignessh JoshiNo ratings yet

- 54TMSS01R1 - Mineral Insulating OilDocument11 pages54TMSS01R1 - Mineral Insulating OilGardellNo ratings yet

- Thesis About Rachel CarsonDocument8 pagesThesis About Rachel CarsonHelpWithPaperCanada100% (2)

- Word DocumentDocument7 pagesWord DocumentHlumelo SompondoNo ratings yet

- 18BCH010 Termpaper PPTDocument25 pages18BCH010 Termpaper PPTFake accNo ratings yet

- (Chapter 1 and 2) : Anaphy Quiz Reviewer (Chapters 1-3)Document20 pages(Chapter 1 and 2) : Anaphy Quiz Reviewer (Chapters 1-3)Mariam GamosNo ratings yet

- Non Conventional Machining ProcessesDocument65 pagesNon Conventional Machining ProcessesRenjith Rajendraprasad100% (1)

- Shieldmaster Brochure by Manuli HydraulicsDocument12 pagesShieldmaster Brochure by Manuli HydraulicsPawan ChaturvediNo ratings yet

- Distillation of Creosote and Creosote-Coal Tar Solutions: Standard Test Method ForDocument5 pagesDistillation of Creosote and Creosote-Coal Tar Solutions: Standard Test Method ForCasey RybackNo ratings yet

- Selective Post-Emergence Herbicide for Soybeans and Other CropsDocument21 pagesSelective Post-Emergence Herbicide for Soybeans and Other CropsMunish ParasharNo ratings yet

- Disinfectant TypesDocument6 pagesDisinfectant TypesshrutiNo ratings yet

- MPHARM QA 1Y 2S 202T Pharm - ValidationDocument562 pagesMPHARM QA 1Y 2S 202T Pharm - Validationhosein bagheriNo ratings yet

- Grade 10 Terms and DefinitionsDocument11 pagesGrade 10 Terms and Definitionskhotso100% (6)

- Isonem Thermal Paint: Technical Data SheetDocument4 pagesIsonem Thermal Paint: Technical Data SheetRodolvano EmilianoNo ratings yet

- 20 eDocument57 pages20 eakanksha vermaNo ratings yet

- Algae - InformationDocument13 pagesAlgae - InformationPreNo ratings yet

- Update DeailsDocument75 pagesUpdate DeailsNehalNo ratings yet

- HORIBA Emission Monitoring Solutions For Power PlantsDocument1 pageHORIBA Emission Monitoring Solutions For Power PlantsmrafigNo ratings yet

- General Piping Design: Document No. Rev.: A BMR-PIP-DBS-ST-0001 Page 1 of 20Document20 pagesGeneral Piping Design: Document No. Rev.: A BMR-PIP-DBS-ST-0001 Page 1 of 20Agus SupriadiNo ratings yet

- (X:1 3) Xoxtcuz1-K (As+) : Toxfree Marine PlusDocument2 pages(X:1 3) Xoxtcuz1-K (As+) : Toxfree Marine PlusomarNo ratings yet

- On-Line XRF Analysis of Phosphate Materials at VarDocument7 pagesOn-Line XRF Analysis of Phosphate Materials at Varabrahamsrs72No ratings yet

- Introduction of CarbohydratesDocument28 pagesIntroduction of CarbohydratesShahzad BashirNo ratings yet

- Jobm 201800252Document14 pagesJobm 201800252leilany casillasNo ratings yet

- Process Plant Equipment: Operation, Control, and ReliabilityFrom EverandProcess Plant Equipment: Operation, Control, and ReliabilityRating: 5 out of 5 stars5/5 (1)

- Artificial Intelligence Revolution: How AI Will Change our Society, Economy, and CultureFrom EverandArtificial Intelligence Revolution: How AI Will Change our Society, Economy, and CultureRating: 4.5 out of 5 stars4.5/5 (2)

- Transformed: Moving to the Product Operating ModelFrom EverandTransformed: Moving to the Product Operating ModelRating: 4 out of 5 stars4/5 (1)

- Pharmaceutical Blending and MixingFrom EverandPharmaceutical Blending and MixingP. J. CullenRating: 5 out of 5 stars5/5 (1)

- Physical and Chemical Equilibrium for Chemical EngineersFrom EverandPhysical and Chemical Equilibrium for Chemical EngineersRating: 5 out of 5 stars5/5 (1)

- Process Steam Systems: A Practical Guide for Operators, Maintainers, and DesignersFrom EverandProcess Steam Systems: A Practical Guide for Operators, Maintainers, and DesignersNo ratings yet

- Piping and Pipeline Calculations Manual: Construction, Design Fabrication and ExaminationFrom EverandPiping and Pipeline Calculations Manual: Construction, Design Fabrication and ExaminationRating: 4 out of 5 stars4/5 (18)

- Functional Safety from Scratch: A Practical Guide to Process Industry ApplicationsFrom EverandFunctional Safety from Scratch: A Practical Guide to Process Industry ApplicationsNo ratings yet

- The User's Journey: Storymapping Products That People LoveFrom EverandThe User's Journey: Storymapping Products That People LoveRating: 3.5 out of 5 stars3.5/5 (8)

- Nuclear Energy in the 21st Century: World Nuclear University PressFrom EverandNuclear Energy in the 21st Century: World Nuclear University PressRating: 4.5 out of 5 stars4.5/5 (3)

- Guidelines for Engineering Design for Process SafetyFrom EverandGuidelines for Engineering Design for Process SafetyNo ratings yet

- An Applied Guide to Water and Effluent Treatment Plant DesignFrom EverandAn Applied Guide to Water and Effluent Treatment Plant DesignRating: 5 out of 5 stars5/5 (4)

- Practical Troubleshooting of Electrical Equipment and Control CircuitsFrom EverandPractical Troubleshooting of Electrical Equipment and Control CircuitsRating: 4 out of 5 stars4/5 (5)

- 507 Mechanical Movements: Mechanisms and DevicesFrom Everand507 Mechanical Movements: Mechanisms and DevicesRating: 4 out of 5 stars4/5 (28)

- Gas-Liquid And Liquid-Liquid SeparatorsFrom EverandGas-Liquid And Liquid-Liquid SeparatorsRating: 3.5 out of 5 stars3.5/5 (3)

- The Design Thinking Playbook: Mindful Digital Transformation of Teams, Products, Services, Businesses and EcosystemsFrom EverandThe Design Thinking Playbook: Mindful Digital Transformation of Teams, Products, Services, Businesses and EcosystemsNo ratings yet

- Design for How People Think: Using Brain Science to Build Better ProductsFrom EverandDesign for How People Think: Using Brain Science to Build Better ProductsRating: 4 out of 5 stars4/5 (8)

- Guidelines for the Management of Change for Process SafetyFrom EverandGuidelines for the Management of Change for Process SafetyNo ratings yet

- Guidelines for Chemical Process Quantitative Risk AnalysisFrom EverandGuidelines for Chemical Process Quantitative Risk AnalysisRating: 5 out of 5 stars5/5 (1)