Professional Documents

Culture Documents

Install and Maintain High Intensity Strobe Light System

Uploaded by

প্রসূন মজুমদারOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Install and Maintain High Intensity Strobe Light System

Uploaded by

প্রসূন মজুমদারCopyright:

Available Formats

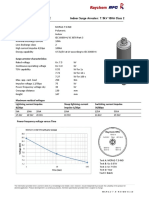

Document: 9100-127-2905-99

Revision B

Release Date: 1/23/2017

INSTALLATION AND MAINTENANCE MANUAL

FOR

L-856 / L-864 High Intensity Strobe

D266-A57-CTR-AC

(Base Controller)

D266-A57-270 (Power Supply and Flash Head)

Diali gh t Corp orat io n 1501 Route 34 South F armingda le NJ 07727

Tel: 732.919.3119 F ax: 732.751.5778 Web: www.diali gh t.com

Document: 9100-127-2905-99

Revision B

Release Date: 1/23/2017

C O NTEN TS PAGE

Notice and Warnings --------------------------------------------------------------------------------- 3

Product Overview -------------------------------------------------------------------------------------- 4

Terminology --------------------------------------------------------------------------------------------- 6

Getting Started ----------------------------------------------------------------------------------------- 7

Section 1.0: Tower Preparation ------------------------------------------------------------------ 7

Section 2.0: Choosing a circuit breaker ------------------------------------------------------- 8

Section 3.0: Base Controller Preparation ---------------------------------------------------- 9

Section 4.0: Photocell Installation ------------------------------------------------------------- 11

Section 5.0: OB or L810 Connections --------------------------------------------------------- 12

Section 6.0: Sync Input (with Optional GPS Hardware) -------------------------------- 12

Section 7.0: Sync Output (with Optional GPS Hardware) ------------------------------ 13

Section 8.0: AOL Enable / Disable ------------------------------------------------------------- 13

Section 9.0: Adding Additional Interfaces -------------------------------------------------- 13

Section 10.0: Photocell Validation ------------------------------------------------------------- 14

Section 11.0: Initial Power Supply Preparation ------------------------------------------- 15

Section 12.0: Power Supply Addressing ---------------------------------------------------- 16

Section 13.0: Power Supply Cable Definition & DC Connections------------------- 18

Section 14.0: Flash Head Communication Connections ------------------------------- 22

Section 15.0: Other Power Supply Preparation ------------------------------------------- 22

Section 17.0: Mounting Power Supply Enclosures -------------------------------------- 25

Section 18.0: Mounting Flash Heads ---------------------------------------------------------- 27

Section 20.0: System Power Up ---------------------------------------------------------------- 31

Section 21.0: Alarm Relays ----------------------------------------------------------------------- 31

Section 22.0: Additional Information ---------------------------------------------------------- 33

Section 23.0: Troubleshooting ------------------------------------------------------------------- 33

Section 24.0: System Specifications----------------------------------------------------------- 38

Dialight Corporation 1501 Route 34 South Farmingdale, NJ 07727

Tel: 732.919.3119 Fax: 732.751.5778 Web: www.dialight.com

Page 2 of 40

Document: 9100-127-2905-99

Revision B

Release Date: 1/23/2017

Notice and Warnings

This manual contains important information regarding the proper installation, operation, and

maintenance of this product. Before using the product, read and understand all instructions,

cautions, and warnings; as well as all of the labels affixed to the product. Failure to do so

could result in personal injury or damage to the equipment, and/or void the product warranty.

FAILURE TO LEAVE THE ENCLOSURES FREE FROM DEBRIS UPON COMPLETION OF

INSTALLATION MAY CAUSE SHORT CIRCUITS AND VOID THE SYSTEM WARRANY.

FAILURE TO TIGHTEN DOWN CLAMP WASHERS WILL MAKE INTERNAL COMPONENTS

VULNERABLE TO SURGE OR LIGHTNING DAMAGE AND VOID THE SYSTEM WARRANY.

FAILURE TO PROPERLY BOND THE EARTH GROUND WIRE TO THE JUNCTION BOX WILL

RESULT IN EVENTUAL LIGHTNING DAMAGE OF THIS SYSTEM. TO AVOID WARRANTY

NULLIFICATION, FOLLOW ALL DIRECTIONS IN THEIR ENTIRETY.

CAUTION: PHOTOCELL ONLY TO BE CONNECTED TO MONITOR BOARD USING

TERMINAL BLOCKS PROVIDED

WARNING: FAILURE TO PROPERLY BOND THE FLASH HEADS AND POWER SUPPLY

ENCLOSURES TO THE TOWER STRUCTURE WILL RESULT IN EVENTUAL LIGHTNING

DAMAGE OF THIS SYSTEM. THE SYSTEM’S WARRANTY SHALL BE VOID IF ALL FLASH

HEADS AND POWER SUPPLY ENCLOSURES ARE NOT PROPERLY BONDED TO THE TOWER

STRUCTURE. TO AVOID WARRANTY NULLIFICATION, FOLLOW ALL DIRECTIONS IN

THEIR ENTIRETY.

CAUTION: NEVER LOOK AT THE FRONT OF A FLASH HEAD WHILE THE SYSTEM IS

ENERGIZED. THE FLASH HEAD COULD START FLASHING CAUSING TEMPORARY

BLINDNESS WHICH WOULD BE DANGEROUS AT HIGH ELEVATIONS.

Dialight Corporation 1501 Route 34 South Farmingdale, NJ 07727

Tel: 732.919.3119 Fax: 732.751.5778 Web: www.dialight.com

Page 3 of 40

Document: 9100-127-2905-99

Revision B

Release Date: 1/23/2017

FAILURE TO SET UP SYSTEM CORRECTLY DURING START UP WILL RESULT IN THE

TOWER HAVING TO BE CLIMBED AGAIN TO PERFORM TROUBLESHOOTING.

DIALIGHT CORPORTATION DOES NOT WARANTEE THE HIGH INTENSITY SYSTEM WHEN

USING IT WITH A TEMPORARY POWER SOURCE.

DIALIGHT CORPORTATION DOES REQUIRE PICTURES OF THE INSTALLATION FOR

COMMISIONING PURPOSES. FAILURE TO DO WILL VOID ALL ALL WARRANTIES.

THE SITE MANAGER OR OWNER MUST SUPPLY RECENT PICTURES OF THE STRUCTURE

TO ENSURE ACCURACY OF THE LIGHTING SYSTEM AND HARDWARE SUPPLIED.

ADEQUATE WIRING GAUGES AND BREAKER SIZES ARE THE RESPONSIBILITY OF THE

SUPPLIER OF THE SYSTEM.

SPECIAL CONSIDERATIONS ARE REQUIRED FOR INSTALLING ON HOT AM TOWERS.

CONTACT THE SUPPLIER OF THE SYSTEM WHEN IN DOUBT.

AC INPUT TOLERANCES ARE A MAXIMUM OF +/-10% OF THE NOMINAL VOLTAGES

SHOWN IN THE MANUAL

Dialight Corporation 1501 Route 34 South Farmingdale, NJ 07727

Tel: 732.919.3119 Fax: 732.751.5778 Web: www.dialight.com

Page 4 of 40

Document: 9100-127-2905-99

Revision B

Release Date: 1/23/2017

Product Overview

The Dialight L-856 / L-864 High Intensity White / Red Strobe System, herein referred

to as the System, is designed to for the lighting of tall structures such as television and radio

towers, chimneys, cooling towers, tall buildings, wind generators and other obstructions to

aerial navigation, per specification by the FAA.

This product uses LED technology within each Flash Head to produce white strobe

light. Unlike conventional xenon flashtube technology, little or no maintenance is required

during the lifetime of this System. Working voltages within this System never exceed 200

Volts DC. Therefore by significantly lowering the working voltage with respect to Xenon white

strobes, this System represents an advance in obstruction lighting safety and efficiency.

One Base Controller Enclosure is required to enable the System regardless of system

scale. For example a System with three Flash Heads and a System with eighteen Flash

Heads both need the same Base Controller Enclosure to operate.

With the use and proper setup of the Base Controller each of the below systems can

be configured through the LCD display.

White Only System

The System may comprise up to eighteen L-856 High Intensity White Strobe Flash

Heads; each with a corresponding Power Supply Enclosure, e.g. one Power Supply

Enclosure per Flash Head. The Flash Heads are typically distributed as three per level on up

to six levels, for a maximum of eighteen Flash Heads.

Red/White System

The System may comprise up to eighteen L-856/864 High Intensity White Strobe Flash

Heads which have the RED L-864 included in each of the LED modules. Each has a

corresponding Power Supply Enclosure, e.g. one Power Supply Enclosure per Flash Head.

The Flash Heads are typically distributed as three per level on up to six levels, for a maximum

of eighteen Flash Heads. L810 Marker Lights are also monitored through the base controller.

AOL Strobe

Additionally, one L-864/L-865 Medium Intensity Strobe may be integrated into the

system as an Antenna Obstruction Light (AOL). The Base Controller will synchronize,

monitor, and control the entire System, as well the Antenna Obstruction Lights.

Dialight Corporation 1501 Route 34 South Farmingdale, NJ 07727

Tel: 732.919.3119 Fax: 732.751.5778 Web: www.dialight.com

Page 5 of 40

Document: 9100-127-2905-99

Revision B

Release Date: 1/23/2017

Terminology

The following definitions apply to the System:

L856 FAA classification of a flashing white High Intensity Obstruction Light, 40 FPM

L864 FAA classification of a flashing Red Medium Intensity Obstruction Light, 20-30 FPM

L810 FAA classification of a Red Steady Burning Obstruction Light

Base Controller Master Control Cabinet

LCD Screen Liquid Crystal Display; forty character module

Micro Board Printed circuit board with onboard micro controller

Relay Board Provides 8 external connections for alarm status and monitoring

Alarms Alarm faults that need to verified and corrected, NOTAM must be reported

Events are notice to the site manager that an “event” occurred but has NOT caused

Events an alarm. I.E. power on, Power Supply was turned off. These are also used to

troubleshoot alarms.

Power Supply Enclosure mounted to the tower controlling the individual Flash Head

Dip Switches Located in Power Supplies to assign addresses to Flash Heads

Flash Head The 3 individual Flash LED Modules mounted together

Flash “LED” Module The individual module numbered 1, 2or 3 containing the LED’s and reflectors

PEC Mode Flash intensity based on outdoor ambient light condition

Blinking LED which indicates a Micro Board is healthy. NOTE: Located in both the

Heartbeat

Base Controller and Power Supply

Red System When properly configured through the main micro provides RED at night operation

AOL Antenna Obstruction Light, also can be added through the Base Controller

Synchronization All lights flash simultaneously to the human eye

Communication RS485 signals between Controller, Power Supply and Flash Head

Alarm occurs when greater than 25% of a single Flash Head is out, monitors for

25% Failure

both in Red operation and white operation

The lighting, hardware, wiring and any other materials required for installing the

The System

system.

Dialight Corporation 1501 Route 34 South Farmingdale, NJ 07727

Tel: 732.919.3119 Fax: 732.751.5778 Web: www.dialight.com

Page 6 of 40

Document: 9100-127-2905-99

Revision B

Release Date: 1/23/2017

Getting Started

Carefully unpack and take inventory of all system components before beginning the

following steps. Flash Heads and Power Supply Enclosures come in separate boxes. They

must be paired together and laid out in a clean work area.

Parts Typically Supplied:

1: 1 Base Controller

2: 3 or More LED Flash Heads (Consisting of 3 modules factory secured together)

3: 3 or More Flash Head Power Supply enclosures

4: Spare Parts Kit(s)

5: This manual

6: Quick start Manual (For configuring the Base Controller)

NOT Supplied with this Manual is the site specific wiring diagram. This is supplied by the

seller of the system.

Section 1.0: Tower Preparation

It is recommended that the tower on which the System is to be installed be inspected

prior the installation.

1: If using existing junction boxes, they should be opened and checked for leaks.

2: If re-using wiring from an existing system it must be checked at this time for ratings, breaks,

oxidation and other damage that could cause electrical issues during the installation and

operation. Failures in the wiring during or after the installation are the responsibility of the Site

Manager and the owner of the structure.

NOTE: It is recommended that any reused existing cable has the bare wire cut far enough

back to expose clean copper. If this is not possible then the cabling MUST be replaced.

3: The Dialight High Intensity system uses RS485 for communications. The signal integrity,

ratings and wire gauge should be verified before installing this system.

4: The Base Controller and Power Supply enclosures have terminal blocks for AC wiring that

can accept up to 8 gauge (8AWG) wires.

NOTE: Do not use less than 14 gauge (14AWG) mains cord for powering the system. Refer

to electrical specifications below for further details.

Dialight Corporation 1501 Route 34 South Farmingdale, NJ 07727

Tel: 732.919.3119 Fax: 732.751.5778 Web: www.dialight.com

Page 7 of 40

Document: 9100-127-2905-99

Revision B

Release Date: 1/23/2017

Section 2.0: Choosing a circuit breaker

Also refer to the wiring diagram that is sent with the cables and hardware for site

specific information. This information is required to be sent by the system provider or the

hardware provider.

For the purpose of sizing tower conductor gauges and circuit breakers follow the table

and formula below. Input current is inversely proportional to supply voltage, so low supply

voltages result in higher input currents. It is the responsibility of the system supplier to

calculate the required cable gauges and breaker sizes.

All tolerances are +/- 10% from nominal voltages shown below.

Measurements are actual measurements and not scaled in any matter

Nominal Supply Voltage /Freq RMS Current (A) per Flash Peak Current (A) per Flash

(VAC)/Hz Head Head

208 / 60Hz 1.12 2.18

240 /50Hz .96 1.98

277 /60Hz .87 1.68

Table 1 - High Intensity Strobe Current Ratings

Find the voltage you are planning to run the System in the table above; then multiply

the number of Flash Heads on the System times the RMS current to find the total operating

current. Also multiply the number of Flash Heads on the System times the peak current to

find the total peak current.

If using a Dialight DR1W strobe as an AOL, then you must add the current of the AOL

to the total calculated below if the AOL is to be powered off the same breaker.

Nominal Supply Voltage RMS Current (A) for AOL Peak Current (A) for AOL

(VAC)

208 0.8 1.3

240 0.50 0.8

277 0.50 0.8

Table 2 - AOL (D1RW) Current Ratings

WARNING: The above tables are for individual Flash Heads and the AOL. The system power

requirements must be calculated.

WARNING: It is recommended that no more than 80% of the breaker rating is used.

Dialight Corporation 1501 Route 34 South Farmingdale, NJ 07727

Tel: 732.919.3119 Fax: 732.751.5778 Web: www.dialight.com

Page 8 of 40

Document: 9100-127-2905-99

Revision B

Release Date: 1/23/2017

Section 3.0: Base Controller Preparation

The Base Controller should be permanently mounted in a location which has easy

access for inspections or upgrades.

The Base Controller can be energized from the same circuit breaker as the Power

Supply Enclosures, or it can be run from a different voltage or breaker. In the case of different

voltages and breakers, it is recommended that the Power Supplies be powered up first, then

the Base Controller. This will only be required during the installation process and configuring

the system. Thus it is preferred that the Base Controller be on its own breaker.

Base Controller Electrical Parameters:

NOTE: This is only for the High Intensity Base Controller

NOTE: Only the Base controller can run from 120Vac

WARNING: Power Supplies/Flash Heads can NOT properly operate from 120VAC.

Nominal Supply Voltage Watts Information

(VAC) Hz

120 +/-10% Max 50/60Hz 6.5 Can only be used if Controller

has its own power

208 +/-10% Max 50/60Hz 6.5

240 +/-10% Max 50/60Hz 6.5

277 +/-10% Max 50/60Hz 6.5

Table 3 - AOL (D1RW) Base Controller Electrical Parameters

The following steps are recommended for a successful installation:

The Base Controller can be mounted to any sufficient location the installer/electrician

sees fit. The dimensions are given below. If the Base Controller is to be mounted to an exterior

structure such as the tower, then special grounding considerations must be adhered to avoid

voided warranties. See Section 17.0 for further details.

For exterior mounting it is suggested that the conduit or glands be mounted on the

bottom of the enclosure using holes provided by Dialight to ensure a weather tight seal for

the life of the product.

Dialight Corporation 1501 Route 34 South Farmingdale, NJ 07727

Tel: 732.919.3119 Fax: 732.751.5778 Web: www.dialight.com

Page 9 of 40

Document: 9100-127-2905-99

Revision B

Release Date: 1/23/2017

NOTE: If there is a possibility of water or condensation entering through the conduit or cables,

the installer must take all necessary precautions to prevent water entering the enclosure.

Failure to do so will void all warranties. Cable loops and drain plugs must be added to the

system as seen fit. If in doubt, please contact www.dialight.com or the system provider.

For cable loops it is suggested that a minimum of 3 to 4 loops with a diameter of 12

inches are used.

Drain plugs should be located at the bottom of any conduit run and or at the lowest

point of the conduit run.

For horizontal conduit runs it is required that the conduit be tilted or angled toward

junction boxes that have drain plugs. Conduit should not tilt downwards to un-drained

enclosures or to breaker panels.

Refer to the Quick Start Manual for information regarding connection of AC power and

RS485 Communications.

Spacing of the mounting tabs is shown below:

Open the Base Controller enclosure and set aside any spare parts bags.

Dialight Corporation 1501 Route 34 South Farmingdale, NJ 07727

Tel: 732.919.3119 Fax: 732.751.5778 Web: www.dialight.com

Page 10 of 40

Document: 9100-127-2905-99

Revision B

Release Date: 1/23/2017

NOTE: Some spare parts included in this bag may be required for the fixtures being

mounted on the structure

L810 Monitor & Photocell

Main Controller Board

Control Board

RS485

Junction Board 48V Power Supply

Filter / Surge Board

Dry Contact Relay

Board

Section 4.0: Photocell Installation

NOTE: See the Photocell manual included in its packaging box for connections and additional

information.

Cable Requirements:

NOTE: The connection cord to the photocell is required to be 3 conductors of 18 to 14

gauge stranded wire. Refer to structure’s wiring diagram supplied with the hardware kit.

A separate ¾” conduit must be run for the Photocell to connect to the Base Controller.

A single Photocell is required for transitioning between day, twilight and night modes. The

Photocell is pre-calibrated to the correct trigger light intensity. No additional adjustments are

required.

When mounting, it is important to orientate the Photocell so that it faces north with no

obstructions. The Photocell is powered by the Base Controller through the Monitor Board

and no additional power is required as shown below.

Dialight Corporation 1501 Route 34 South Farmingdale, NJ 07727

Tel: 732.919.3119 Fax: 732.751.5778 Web: www.dialight.com

Page 11 of 40

Document: 9100-127-2905-99

Revision B

Release Date: 1/23/2017

NOTE: Only Dialight Photocells can be used with this system

NOTE: Additional Photocell relay testing will be included in Section 10.0 of this manual.

CAUTION: PHOTOCELLS ARE TO BE CONNECTED TO J4 OF THE MONITOR BOARD ONLY

USING THE DIN RAIL TERMINAL BLOCKS IN THE CONTROLLER ENCLOSURE

Section 5.0: RED Side lights (OB) or L810 Connections

Refer to Quick Start manual for instructions to calibrate and connect side lights to the

System.

Section 6.0: Sync Input (with Optional GPS Hardware)

This connection will synchronize the System with either a GPS controller or another

local Base Controller. The contact looks for a pulsed signal with a period of 1,500

milliseconds, where the leading edge to falling edge of the pulse is greater than 100

milliseconds. This will trigger forty flashes per minute synchronized with the other system’s

output.

In order for the system to work with a GPS controller the Base Controller must be

configured through the “config” setup screens. See the Quick Start Manual for details and set

up.

NOTE: The maximum distance between the Base Controller and the device receiving the

sync signal is 50 feet. If longer distances are required please contact www.dialight.com.

Dialight Corporation 1501 Route 34 South Farmingdale, NJ 07727

Tel: 732.919.3119 Fax: 732.751.5778 Web: www.dialight.com

Page 12 of 40

Document: 9100-127-2905-99

Revision B

Release Date: 1/23/2017

NOTE: Be sure the GPS antenna is located at an adequate height and does not have

obstructed views of the sky when selecting a location.

Section 7.0: Sync Output (with Optional GPS Hardware)

This connection will synchronize the System to another local Base Controller. The

contact generates a pulsed signal with a period of 1,500 milliseconds, where the leading edge

to falling edge of the pulse is approximately 100 milliseconds.

The System generates this output in all operational modes after startup.

This connection would be typically used when 2 structures are situated side by side and

requires both structures to flash simultaneously.

NOTE: 2 Base Controllers are required for this option

NOTE: If a single Base Controller is used then the RS485 or a sync cable can be ran between

structures. There are no further details in this manual for this connection, please contact

www.dialight.com for connections, maximum distances and more information.

Section 8.0: AOL Enable / Disable

An AOL light can be added to the System at anytime by way of RS485

communications. By connecting RS485 from the AOL Power Supply to the last junction box

and the Base Controller configured for the AOL, the system then will control the AOL.

WARNING: The AOL must be an approved Dialight version or delivered from one of their

partners.

WARNING: Refer to the AOL instruction manual for wiring and mounting.

To enable the use of an AOL requires configuration through the config screen. See the Quick

Start Manual for setup.

Section 9.0: Adding Additional Interfaces

If at a later date an AOL is required for the structure that has this system already

installed then just the AC connection and a link in to the RS485 bus is required for connecting.

Once installed the Base Controller requires configuring for AOL. Only a single AOL can be

added to the system. Multiple AOL’s can not be added. The AOL must be fed from the same

AC power source as feeding the lights.

Dialight Corporation 1501 Route 34 South Farmingdale, NJ 07727

Tel: 732.919.3119 Fax: 732.751.5778 Web: www.dialight.com

Page 13 of 40

Document: 9100-127-2905-99

Revision B

Release Date: 1/23/2017

Section 10.0: Photocell Validation

Perform the following to make sure the Photocell is correctly connected and controlling the

System mode.

1. NOTE: This can be done as a stand alone test; no Flash Heads are required to be

powered.

2. Turn on the Base Controller, and using the up/down arrows go to the “alarm screen”

3. On the Monitor Board confirm LED Photo_Fault is not lit.

If the LED is lit RED then the Photocell is not being detected and wiring and

connections must be confirmed before continuing the testing of the Photocell.

4. Remove the Phoenix connector that connects the 3 wires that go to the Photocell.

Located on the Monitor Board J4.

5. The status alarm must go from “normal” to alarm and by selecting the “ent” button the

last alarm will be PEC lost “act”.

6. A red LED labeled LED Photo_Fault on the monitor board will be turned on this

indicates there is no Photocell detected.

7. Re-install the Photocell J4 and the LED will be turned off and then by pressing the up

arrow the next entry will be PEC lost “Clr” which means the Photocell is detected.

For testing the actual operation of the Photocell it is required that the Photocell be

covered to indicate night mode operation.

NOTE: Since twilight mode is triggered between day and night mode, only day and night

mode are required to be tested to ensure proper operation of the Photocell.

1: With the Base Controller powered on, using the up/down arrows select the Mode screen.

2: Verify the present mode which will be day, twilight or night

NOTE: If the present mode is not shown it is due to the connections of the Photocell not being

correct.

3: If the System mode is day then simply covering the Photocell with a glove will change the

state of the Photocell to twilight then night.

NOTE: There is a factory default setting of approximately 1 minute before switching modes.

If the system mode is shown as night then a flash light focused on the Photocell can be used

to change the state of the system to day.

Dialight Corporation 1501 Route 34 South Farmingdale, NJ 07727

Tel: 732.919.3119 Fax: 732.751.5778 Web: www.dialight.com

Page 14 of 40

Document: 9100-127-2905-99

Revision B

Release Date: 1/23/2017

WARNING: If Flash Heads are connected then the structure will go to 270,000cd day mode

and changing back has a 1 minute delay.

WARNING: If the Photocell is removed or not connected properly all Flash Heads will operate

in night mode based on if the system is set for red night or white night.

Section 11.0: Initial Power Supply Preparation

The Power Supply Enclosure requires the most field wiring and should be configured

and reviewed before being brought up the tower.

At the bottom of the enclosure there are six factory installed holes. 3 of these

are for connection to the Flash Head and 1 for AC mains and RS485 communications

cable. The AC and RS485 can be run together and must be in seal tight or conduit.

Unused holes must remain plugged to maintain ingress protection ratings.

NOTE: If for some un-foreseen reason additional holes are required for the

installation. Contact the seller of the system or Dialight for instructions.

NOTE: The AC and RS485 can be run together and must be in seal tight or conduit.

The enclosure comes with mounting tabs that are to be joined to the body of the

tower.

Dialight Corporation 1501 Route 34 South Farmingdale, NJ 07727

Tel: 732.919.3119 Fax: 732.751.5778 Web: www.dialight.com

Page 15 of 40

Document: 9100-127-2905-99

Revision B

Release Date: 1/23/2017

Section 12.0: Power Supply Addressing

Open the enclosure and orientate your view to match the illustration shown below. On

the Micro Board there is a DIP switch array designated as SW1. This is the addressing switch

used to identify this Power Supply Enclosure / Flash Head on the system.

P/S Micro Board

DIP switch SW1 for

setting addresses of

the Power Supply

150V

Power

Supplies

Filter/Surge Board

Dialight Corporation 1501 Route 34 South Farmingdale, NJ 07727

Tel: 732.919.3119 Fax: 732.751.5778 Web: www.dialight.com

Page 16 of 40

Document: 9100-127-2905-99

Revision B

Release Date: 1/23/2017

The default factory address is 1. One of the Power Supply Enclosures must be

set as address 1. The addresses of all other Power Supply Enclosures must be

changed. The inside of the enclosure will have a sticker showing all the possible

address positions for switch SW1.

WARNING: No two Power Supplies can have the same address setting.

If duplicate settings are made then configuration errors will be shown in the event

log.

Flip the DIP switches on SW1 to match the desired address for that Power

Supply location, as shown below, and then immediately mark the inner label with an

X in permanent marker as to which address was set. The enclosure should be closed

up tightly before being lifted to the mounting location. Therefore before mounting the

address should also be written on the outside of the enclosure with a grease pencil

or marker.

NOTE: Typical installations are that Power Supply #1 is located on the lowest level

and mounted to the Northern most leg. Looking down from the top of the structure

counting clockwise the next is 2 and the next is 3. So that above #1 is #4 and above

that is #7 and so one.

NOTE: This is required unless the Site manager wants something different than the

above states.

NOTE: Refer to the below and section 23.0 for additional information.

Dialight Corporation 1501 Route 34 South Farmingdale, NJ 07727

Tel: 732.919.3119 Fax: 732.751.5778 Web: www.dialight.com

Page 17 of 40

Document: 9100-127-2905-99

Revision B

Release Date: 1/23/2017

Level 6

Level 5

Level 4

Level 3

Level 2

Level 1

Section 13.0: Power Supply Cable Definition & DC Connections

The Flash Head cable is supplied factory installed into each of the modules that make

up the Flash Head.

Connect the Flash Head cables to the Power Supply Enclosure so that the electrical

connections can be tested on the ground. Each of three red cables should be passed through

a corresponding cable grip. All cables and cable grips are numerically labeled for easy match

up.

The ends of each cable have been prepared for connections within the enclosure. The

triad of blue, yellow, and gray wires is for communication. The pair of black and red wires is

for DC power from the Power Supply Enclosure to the Flash Head. Do not alter the length of

these wires or attempt to cut back or modify the exposed braided shield. The picture below

shows the prepared cable end.

Dialight Corporation 1501 Route 34 South Farmingdale, NJ 07727

Tel: 732.919.3119 Fax: 732.751.5778 Web: www.dialight.com

Page 18 of 40

Document: 9100-127-2905-99

Revision B

Release Date: 1/23/2017

NOTE: The cable grip has been pre installed on to the cable. The nut must first be removed

after securing the cable grip to the enclosure.

Land the exposed braid underneath one of two large clamp washers (whichever one which

lines up with that cable grip position). Two cable braids can be landed side by side on the

clamp washers as shown below. Pull enough of the cable length through to reach all

connections before tightening down the washers.

FAILURE TO PROPERLYTIGHTEN DOWN CLAMP WASHERS WILL MAKE INTERNAL

COMPONENTS VULNERABLE TO SURGE OR LIGHTNING DAMAGE AND VOID THE SYSTEM

WARRANY

NOTE: If the Red and Black wires need to be cut and re stripped then ¾” of insulation

should be removed. The wires must be neatly twisted before inserting in to the terminal

blocks.

Dialight Corporation 1501 Route 34 South Farmingdale, NJ 07727

Tel: 732.919.3119 Fax: 732.751.5778 Web: www.dialight.com

Page 19 of 40

Document: 9100-127-2905-99

Revision B

Release Date: 1/23/2017

Steps for inserting the Red and Black wires:

The DC power wiring needs to be terminated on the DIN rail terminal blocks connected

to J2 of the Filter / Surge board as shown in Figure xx below. The DIN rail terminal blocks are

labeled appropriately for each module.

NOTE: Module #1 gets connected to pins 1 and 2 of J2 (left), Module #2 gets connected to

pins 3 and 4 of J2 (middle), & Module #3 gets connected to pins 5 and 6 (right).

NOTE: It is recommended that each Red and Black wire gets twisted on the exposed copper

before inserting into the terminal block.

Use a small flathead screwdriver to terminate by inserting the blade in to the slot and

easily lifting the screwdriver, then inserting the wire. The wire must go in easily and must not

be forced into the terminal bock.

If it is forced then the wire should be removed re-twisted and inserted again.

NOTE: Tug on these connections to ensure the wire ends were landed properly.

Drain wires from all three Module cables must be terminated on the grounding bus. This

connection is for lightning / surge protection and should be double checked like all other

wiring discussed above. Since the drain wire is a bare wire, extra attention should be placed

on routing these connections neatly.

Dialight Corporation 1501 Route 34 South Farmingdale, NJ 07727

Tel: 732.919.3119 Fax: 732.751.5778 Web: www.dialight.com

Page 20 of 40

Document: 9100-127-2905-99

Revision B

Release Date: 1/23/2017

1: Take all 3 drain wires from the modules and twist them together at the end, a minimum of

1”.

2: Insert the twisted cable in the ground terminal and tighten the screw securely.

NOTE: It is recommended that the twisted wire be slightly extended beyond the screw so

the installer can see that it is not bunching and making a poor ground connection.

DC Connection

points Drain wires

twisted and fed

under screw.

Screw to be

secured tightly.

Dialight Corporation 1501 Route 34 South Farmingdale, NJ 07727

Tel: 732.919.3119 Fax: 732.751.5778 Web: www.dialight.com

Page 21 of 40

Document: 9100-127-2905-99

Revision B

Release Date: 1/23/2017

Section 14.0: Flash Head Communication Connections

RS485 connections must now be terminated to the DIN rail terminal blocks wired to

the correct socket on the Micro Board. In front of each terminal will be a label for clear

identification of landing positions. It is very important to land these connections on the correct

terminal for proper function of the Flash Head.

Module #1

Module #2

Module #3

Section 15.0: Other Power Supply Preparation

If running new cable from each Power Supply Enclosure to their respective junction

boxes on the tower, now would be the time to attach these relatively short runs. Even if not

running new cable in these positions, it is recommended to do a dry run of terminating these

Dialight Corporation 1501 Route 34 South Farmingdale, NJ 07727

Tel: 732.919.3119 Fax: 732.751.5778 Web: www.dialight.com

Page 22 of 40

Document: 9100-127-2905-99

Revision B

Release Date: 1/23/2017

connections. The end of the cable needs to have the outer jacket stripped back to allow for

routing of the communication and AC power wires. Like with the Flash Head cables, the wires

are to be connected to a pre-wired labeled terminal block inside the enclosure. These

locations are shown below in Figure 11.

Communication wires could be various colors and gauges depending on cable

manufacturer. Also, the common wire may be a bare wire similar to a drain wire. They will

always be a group of three and must be terminated on the terminal block pre-wired to the

same green pluggable connector used for the Flash Head communication wires. If using a

Dialight junction box, the junction board has markings for which wire is the “A” wire and which

is the “B” wire. The Micro Board in the Power Supply Enclosure has the same markings next

to its sockets. Both ends of the cable must be wired the same.

AC CONNECTION to Power Supply Enclosure:

Feed the cable through the hole not numbered on the enclosure and connect to the terminal

blocks located on the right side of the Power supply (Marked L and N).

NOTE: This feeds power to both LED Drivers that are mounted to each side of the

enclosure. There are small Green LED’s located on each to show that they are powered.

WARNING: Earth ground must be connected for SAFE and proper operation of the Power

Supply Enclosure.

NOTE: It is recommended that 277Vac, 240Vac or 208Vac (2 hot Lines of 120Vac) is to be

used to power the power supplies. When 3 phases are used, all the phases must be

balanced though out the system. See the wiring diagrams for connections.

WARNING: Operating the power supplies and flash heads from single phase 120Vac (Live

and Neutral) is NOT permitted. Contact www.dialight.com for more information.

AC Input,

Ground

terminal

on right

RS485 Input

coming from

level junction

box.

Dialight Corporation 1501 Route 34 South Farmingdale, NJ 07727

Tel: 732.919.3119 Fax: 732.751.5778 Web: www.dialight.com

Page 23 of 40

Document: 9100-127-2905-99

Revision B

Release Date: 1/23/2017

Section 16.0: Junction Preparation

NOTE: For commissioning purposes pictures are required of the wiring and mounting of

all the junction boxes to the structure. They MUST be reviewed and verified before de

rigging.

Located in the Junction box that was supplied with the kit is a surge protection board for

the RS 485 communications. These connections are vitally important for proper operation of

the system and the communications for controlling the lights and there functions. The surge

board has 3 ports J2, J3 and J4 that provide communications to the lights on each level of

the structure. J1 is the Input from wither the Base controller or the lower level of lights. J5 is

the output that would feed the next higher level of lights or the AOL if installed.

The installer will need to strip and connect all necessary cables to these ports. Care must

be taken when connecting these cables to avoid un-necessary troubleshooting later.

NOTE: The installer must make sure that all the A and B ports have the same color wire

attached.

NOTE: it is recommended that J2 be beacon #1 J3 be beacon #2 and J4 be beacon #3.

This will make any troubleshooting required later easier.

It is recommended that

J2 be connected to Power supply

#1,

J3 to power supply #2

J4 to power supply #3 3 RS485 Outputs to

power supplies

Next level enclosures that control

J2 to #4 the Flashheads

J3 to #5

J4 to #6

And so on up the structure

Output to next

higher level of

Input from the

lights or AOL if

Base

installed

Controller

Dialight Corporation 1501 Route 34 South Farmingdale, NJ 07727

Tel: 732.919.3119 Fax: 732.751.5778 Web: www.dialight.com

Page 24 of 40

Document: 9100-127-2905-99

Revision B

Release Date: 1/23/2017

FAILURE TO PROPERLY BOND THE EARTH GROUND WIRE TO THE JUNCTION BOX WILL

RESULT IN EVENTUAL LIGHTNING DAMAGE OF THIS SYSTEM. TO AVOID WARRANTY

NULLIFICATION, FOLLOW THE ABOVE DIRECTIONS IN THEIR ENTIRETY.

NOTE: If there is a question if the protection board is operating correctly, verify by using a

multi-meter set to ohms. By connecting the multi-meter from “A” to “A” and then “B” to “B” the

meter must measure a very low resistance, which should be less than 10 ohms. If an “OL” or

open load is measured than the protection board is bad or there is a bad connection. This

test should be conducted for each of the colored wires. The Green wire is the Earth ground

connection.

Section 17.0: Mounting Power Supply Enclosures

This section is also required when the Base controller is mounted to the exterior structure.

NOTE: For commissioning purposes pictures are required of the wiring and mounting of

the power supplies to the structure. They MUST be reviewed and verified before de

rigging.

Power Supply Enclosures must be mounted to the tower structure. This may require

the addition of rails welded into the tower structure to create a more narrow spacing to line

up with the enclosure mounting tabs. Spacing of the mounting tabs is shown below.

Dialight Corporation 1501 Route 34 South Farmingdale, NJ 07727

Tel: 732.919.3119 Fax: 732.751.5778 Web: www.dialight.com

Page 25 of 40

Document: 9100-127-2905-99

Revision B

Release Date: 1/23/2017

The additional use of a grounding strap between each Power Supply Enclosure and

the tower structure may be required to ensure proper grounding. If the Ground strap is added

then it is recommended that the ground strap is located on the front of one of the four

mounting tabs before bolting.

The installer should avoid using numerous bolt-through connections when bonding the

Power Supply Enclosure to the Tower. The use of prefabricated lug bonds made from

annealed size #1 copper cable joined at both ends with tinned copper lugs conforming to

ASTM B-187 is recommended. The lug should be permanently bonded to cable via

exothermic welding i.e. CADWELD.

Dialight Corporation 1501 Route 34 South Farmingdale, NJ 07727

Tel: 732.919.3119 Fax: 732.751.5778 Web: www.dialight.com

Page 26 of 40

Document: 9100-127-2905-99

Revision B

Release Date: 1/23/2017

WARNING: FAILURE TO PROPERLY BOND THE ENCLOSURES TO THE TOWER STRUCTURE

WILL RESULT IN EVENTUAL LIGHTNING DAMAGE OF THIS SYSTEM. THE SYSTEM’S

WARRANTY SHALL BE VOID IF ALL ENCLOSURES S ARE NOT PROPERLY BONDED TO THE

TOWER STRUCTURE. TO AVOID WARRANTY NULLIFICATION, FOLLOW THE ABOVE

DIRECTIONS IN THEIR ENTIRETY.

Section 18.0: Mounting Flash Heads

For Brackets and Mounting instructions refer to the Structures wiring diagram.

NOTE: For commissioning purposes pictures are required of the wiring and mounting of

the Flashheads to the structure. They MUST be reviewed and verified before de rigging.

Flash Heads must be mounted to brackets permanently mounted to the tower

structure. Some brackets will have a mechanism for slight pitch adjustment (zero to eight

degrees). Since there could be a mechanical hinge in the bracket, there is not sufficient metal

contact to ensure proper bonding between the Flash Head and the tower structure. Therefore,

use of a grounding strap between each Flash Head and the tower structure is required. Each

Flash Head has Aluminum housing with extra M8x1.25 threaded holes for the purpose of

adding such a strap. After selecting a hole on the Flash Head to use, the installer must grind

the flat surfaces on both sides to expose metal.

Although this one bonding connection will be made with an M8 nut and bolt, the

installer should avoid using numerous bolt-through connections when bonding to the Tower.

See Section 17.0 for additional ground information.

NOTE: Module “#1” MUST be positioned on the bottom bracket due to the orientation of the

optics. The modules are factory marked on the backside.

NOTE: The Flash Head is designed to be mounted parallel to the ground.

NOTE: The installer must level the Flash Head in both orientations to ensure minimal ground

scatter. It is recommended that it is mounted level within 0.25º of zero.

Dialight Corporation 1501 Route 34 South Farmingdale, NJ 07727

Tel: 732.919.3119 Fax: 732.751.5778 Web: www.dialight.com

Page 27 of 40

Document: 9100-127-2905-99

Revision B

Release Date: 1/23/2017

Table 4 – Light Unit Elevation above the Horizontal

Complete 3 Level Flashhead: (3 Modules make a Flashhead)

Individual Flash Module: Wire Colors coming from Module

Flash Module Power Supply

(Factory Wired) Locations

Drain Wire Ground Lug

RS485 “A” “A” RS485

RS485 ”GND” “GND RS485

RS485 “B” “B” RS485

+150Volts (RED) Terminal B

- 150Volts Gnd (Black) Terminal B

NOTE: The LED Module is factory sealed and no user access is required.

The module comes with a factory installed 7 to 10 feet of cable.

Dialight Corporation 1501 Route 34 South Farmingdale, NJ 07727

Tel: 732.919.3119 Fax: 732.751.5778 Web: www.dialight.com

Page 28 of 40

Document: 9100-127-2905-99

Revision B

Release Date: 1/23/2017

SECTION 19.0: Final System Checks

Perform the following before applying power to the System!!!

FAILURE TO SET UP THE SYSTEM CORRECTLY DURING START UP WILL RESULT IN THE

TOWER HAVING TO BE CLIMBED AGAIN TO PERFORM TROUBLESHOOTING.

Grounding:

The primary goal of grounding this System is to maintain a low resistance level

between the electrical sub components and the tower structure. Improved lightning immunity

results as this resistance is reduced. For comparison, the National Electrical Code requires

the resistance value between the earth and a grounding bus to not exceed 25 ohms, however

for this application lowering ground resistance values to levels as close to 0 ohms as possible

is the only way to prevent lightning related damage.

It is compulsory for the installer to use an Ohm meter to check the resistance after all

bonding is complete. A normal value range to see between the inside of a Power Supply

Enclosure and the bare metal of the tower structure is 0.3 to 1.3 Ohms. Check each Power

Supply enclosure with a Multimeter set on Resistance/Ohms measurement to ensure the

grounding was done properly.

Communication:

A termination resistor is factory installed in the Base controller. Depending on the type

of tower and the size of the structure (typically larger than 1200 foot structures or 4 levels of

lights an additional termination is required. This can done by adding a jumper to the last power

supply (for example #12 of a 4 level system) on location “terminator” located in the power

supply enclosure.

NOTE: Do not add

jumpers to any

2 pin header, other Power

when supplies for the

required. highest number.

NOTE: By tying or

jumpering the 2

pins together the

terminating resistor

will be added.

Dialight Corporation 1501 Route 34 South Farmingdale, NJ 07727

Tel: 732.919.3119 Fax: 732.751.5778 Web: www.dialight.com

Page 29 of 40

Document: 9100-127-2905-99

Revision B

Release Date: 1/23/2017

Back probe all of the RS485 ports on each Power Supply Enclosure and the one going

out of the Base Controller with a Multimeter set on Resistance/Ohms. Place one probe where

the “A” wire terminates in the back of the plug and the other probe firmly on the ground bus

of the backplane. Be sure to press firmly. Depending on the model meter you should see an

open circuit symbol, OL, or a value exceeding 20 mega Ohms. Repeat this process by back

probing for the Common wire (middle) and the “B” wire. Then, repeat all of the steps for each

communication port. This step will confirm there are no shorted communication wires within

the System.

Figure 18 - Back Probing Connections

DC Wiring:

Check terminal block J2 on the Filter/Surge board by performing short circuit check

with a Multimeter. Back probe the terminals and ensure that positive terminal positions have

no continuity with negative terminal positions. Perform this check for each Power Supply

Enclosure.

AC Wiring:

On the Base Controller ensure that the Hot and Neutral wires are landed correctly on

the AC connection terminal block.

WARNING: Power Supplies require a minimum of 208vac and a maximum voltage of 305Vac

from live to ground.

Dialight Corporation 1501 Route 34 South Farmingdale, NJ 07727

Tel: 732.919.3119 Fax: 732.751.5778 Web: www.dialight.com

Page 30 of 40

Document: 9100-127-2905-99

Revision B

Release Date: 1/23/2017

Section 20.0: System Power Up

All Power Supply Enclosures must be completely closed with door clamps before

proceeding. Interlock switches inside these enclosures will not make contact unless a good

seal is established.

NOTE: It is highly recommended that upon initial powering of the system that individual levels

be tested as the system is being installed. For example once a level is installed this level

should be tested and verified before adding additional levels.

It is recommended to have one installer stand near a Flash Head, and one installer

near the Base Controller. Energize the System from the circuit breaker. You will see the LCD

Screen illuminate at the Base Controller; displaying the text “please wait.” The next screen

will begin counting down from 15 and once complete the display will be in the main screens

for system setup. See the quick start manual for configuring the system. If the countdown

from 15 does not happen and the screen just stays at 15 then the Base Controller does not

see any Flash Heads on the RS485 communications line. Please check that the

communications is connected and that no wires have been reversed. At the back of the Flash

Head it is possible to see small green and yellow LED’s light up.

CAUTION: NEVER LOOK AT THE FRONT OF A FLASH HEAD WHILE THE SYSTEM IS

ENERGIZED. THE FLASH HEAD COULD START FLASHING CAUSING TEMPORARY

BLINDNESS WHICH WOULD BE DANGEROUS AT HIGH ELEVATIONS.

Section 21.0: Alarm Relays

Eight relay outputs are provided as a means to externally monitor alarms from the

System. Refer to the Quick Start Manual for relay definitions.

To interface outside of the Base Controller, the installer must choose either to use the

Normally Open, or Normally Closed contacts on the relay board depending on the

installation’s requirements. Using the 3-position Phoenix on the header allows for any

combination of normally open and normally closed contacts to be utilized. To wire the dry

contacts it is recommended to use 18-22 AWG wire. The preferred strip length for the Phoenix

connector is ¼ inch.

NOTE: If the existing monitoring system does not have 8 alarm ports than multiple relays can

be multiplexed together.

Dialight Corporation 1501 Route 34 South Farmingdale, NJ 07727

Tel: 732.919.3119 Fax: 732.751.5778 Web: www.dialight.com

Page 31 of 40

Document: 9100-127-2905-99

Revision B

Release Date: 1/23/2017

NOTE: If a single monitoring port exists than all 8 relays can be multiplexed together.

NOTE: If the monitor monitoring system has 8 ports than each of the dry contacts should

have its own monitoring port.

Section 22.0: Maintenance

There is no regular maintenance required for this System.

Dialight recommends the following spare parts be purchased for emergency replacement.

Description Dialight Part Number

Complete Flash Head D266-1019FH

Flash Head Module D266-1019MOD

Table 5 – System Part Numbers

Dialight Corporation 1501 Route 34 South Farmingdale, NJ 07727

Tel: 732.919.3119 Fax: 732.751.5778 Web: www.dialight.com

Page 32 of 40

Document: 9100-127-2905-99

Revision B

Release Date: 1/23/2017

Section 23.0: Additional Information

For clarification purposes the addressing scheme is provided below with binary

format.

Address Number Binary Number Drawing

־ Switch position 1 2 3 4 5 1 = ON, 0 = OFF

1 10000

2 01000

3 11000

4 00100

5 10100

6 01100

7 11100

8 00010

9 10010

Table 6- Power Supply Address Table (1 through 9)

Dialight Corporation 1501 Route 34 South Farmingdale, NJ 07727

Tel: 732.919.3119 Fax: 732.751.5778 Web: www.dialight.com

Page 33 of 40

Document: 9100-127-2905-99

Revision B

Release Date: 1/23/2017

Address Number Binary Number Drawing

־ Switch position 1 2 3 4 5 1 = ON, 0 = OFF

10 01010

11 11010

12 00110

13 10110

14 01110

15 11110

16 00001

17 10001

18 01001

Table 7 - Power Supply Address Table (10 through 18)

Dialight Corporation 1501 Route 34 South Farmingdale, NJ 07727

Tel: 732.919.3119 Fax: 732.751.5778 Web: www.dialight.com

Page 34 of 40

Document: 9100-127-2905-99

Revision B

Release Date: 1/23/2017

Section 24.0: Troubleshooting

PROBLEM CAUSE SOLUTION

1. Diagnostic and Display Board There were no devices detected Make sure communication cable is

in the Base Controller reads on the network during startup. wired correctly at all ends. Check the

“Tower Style : _____ ” “config” screen to make the correct

(blank) selections are made

2. Diagnostic and Display Board There is either an electrical or The missing addresses should be

correctly displays tower style, communication problem with checked for wiring issues while the

but the Power Supply map has the Power Supply Enclosure(s) System is off. If more than one is bad,

missing addresses. at the missing address. proceed by isolating power to just a

single bad address. Observe that

address power up by pulling the

interlock switch outward. This will

allow the Power Supply Enclosure to

power up with the door opened. Wait a

minute after startup. Observe if the

Micro Board powers up correctly.

3. Heartbeat on a Power Supply Communication to this address Observe the RX (receive) and TX

Enclosure Micro Board comes was never established. (transmit) LED indicators on the Micro

on, but other status lights do Board for pulsing. If the RX light

not. comes on every 1.5 seconds then there

is at least a connection to the Base

Controller. If the RX or TX lights are

hanging solid, there are crossed

communication wires, or shorted

communication wires somewhere in

the network. This could be anywhere

and every junction box and Power

Supply Enclosure must be checked.

Dialight Corporation 1501 Route 34 South Farmingdale, NJ 07727

Tel: 732.919.3119 Fax: 732.751.5778 Web: www.dialight.com

Page 35 of 40

Document: 9100-127-2905-99

Revision B

Release Date: 1/23/2017

PROBLEM CAUSE SOLUTION

4. Adding an AOL interface to the There are crossed The junction box preceding the AOL

System caused the whole communication wires, or must be checked as well as the AOL

system to go down. shorted communication wires enclosure.

inside the AOL enclosure.

5. The Flash Heads are not There is too much RS-485 bias Verify the communications

flashing in sync. Addresses are on the network, or too many connections at the missing Power

missing or dropping on and off termination resistors on the Supplies, Verify the addresses have

the map. network. Weak RS-485 signal. been set correct. Check the level

junction boxes for proper

connections.

Remove good Power Supplies by

unplugging outgoing

communications to the rest of the

tower and individually test the

problematic Power Supplies.

6. A Flash Head appears on the 25% of the lighting in that There is a problem inside the sealed

network but after 25 flashes it Flash Head has failed. Flash Head. Further visual evaluation

appears to shut down and drops should be done. Verify the LED’s on

off the Power Supply map. the driver cards in the Power Supplies

Reappears when the System is are illuminated. Check the red and

restarted. black wires going in to the terminals

wired to J2.

7. A Flash Head will only flash in The Flash Head is in stand Something has changed since startup.

Day mode; eventually looses alone mode. Meaning, it was There is either a loose wire

sync with the rest of the successfully started up but lost intermittently loosing contact or a

System. communication at a later time. similar problem. Check all

communication wiring to the bad

address.

Dialight Corporation 1501 Route 34 South Farmingdale, NJ 07727

Tel: 732.919.3119 Fax: 732.751.5778 Web: www.dialight.com

Page 36 of 40

Document: 9100-127-2905-99

Revision B

Release Date: 1/23/2017

PROBLEM CAUSE SOLUTION

8. Entire System will only flash in Photocell and its respective Check the connections on the Monitor

a certain mode. i.e. Night mode wiring has a problem. Board. Verify that the Photocell

all the time. Regardless of Failure alarm indicators are not lit. If

outdoor light conditions. they are lit, check Photocell

connections.

9. In a style C tower, the AOL is The sync output from the AOL The problem will be located in the

not in sync with the rest of the Interface kit is not being Power Supply enclosure of the AOL.

System. The tower type is accepted by the DR1W Micro Verify by opening the enclosure that

displayed correctly and the Board. all the connections are made correctly

AOL is listed under active and the RS485 communications is

interfaces. attached.

10. In a style C tower, the AOL is The AOL Interface kit is not Use the AOL / Red System manual to

flashing RED. wired correctly to the DR1W troubleshoot the wiring connection

Micro Board. between the AOL Interface kit and the

DR1W Micro Board.

11. In a style F tower, after 100 There is a RED light fault from There is a red fault input being sent to

flashes in NIGHT mode, then the AOL. Which means the the Base Controller. The problem

system behaves like a style C system will go to white night would be either in the Power Supply

tower. by per FAA requirements. where there is a bad red driver or in the

Flash Head.

Dialight Corporation 1501 Route 34 South Farmingdale, NJ 07727

Tel: 732.919.3119 Fax: 732.751.5778 Web: www.dialight.com

Page 37 of 40

Document: 9100-127-2905-99

Revision B

Release Date: 1/23/2017

Section 25.0: System Specifications

The following physical specifications apply to the System:

Flash Head Weight: 67.5 pounds (40.8 kg)

Flash Head Dimensions:

Dialight Corporation 1501 Route 34 South Farmingdale, NJ 07727

Tel: 732.919.3119 Fax: 732.751.5778 Web: www.dialight.com

Page 38 of 40

Document: 9100-127-2905-99

Revision B

Release Date: 1/23/2017

Module Weight ( 3 per Flash Head ): 22.5 pounds (10.2 kg)

Flash Head Cable Length ( 3 per Flash Head ): 9 feet (3.66 m)

Flash Head Mounting Holes: Clearance for M8x1.25 thread

Power Supply Enclosure Weight: 40 pounds (18.1 kg)

Base Controller Weight: 40 pounds (18.1 kg)

Table 8 – Mechanical Specifications

The following operational specifications apply to the System:

Flash Head Voltage: 135 - 165 VDC (150 VDC nominal)

Power Supply Enclosure Voltage: 208 - 277 VAC, +/- 10% 50/60 Hz

Base Controller Voltage: 120 - 277 VAC, +/- 10% 50/60 Hz

Day mode: 160 W

Power Supply Enclosure Wattage: Twilight mode: 30 W

White Night mode: 23 W

Red Night Mode 30W

Base Controller Wattage (all modes): 6.5 W Maximum

System Operating Temperature Range: – 40°C to 55°C

Day: 40 FPM

Flash Rate: Twilight: 40 FPM

Night: 40 FPM

RED night: 40FPM

Day: 270,000 Candela ( ± 25% )

Flash Intensity: Twilight: 20,000 Candela ( ± 25% )

Night: 2,000 Candela ( ± 25% )

Light Pattern (all modes): Horizontal plane: 120°

Vertical plane: 3°- 7°

Table 9 – System Specifications

Dialight Corporation 1501 Route 34 South Farmingdale, NJ 07727

Tel: 732.919.3119 Fax: 732.751.5778 Web: www.dialight.com

Page 39 of 40

Document: 9100-127-2905-99

Revision B

Release Date: 1/23/2017

REVISION HISTORY

REV ECO No. DRN CKD APP QA CM DATE

A 38371 CAG SA BAM YS JN 9/9/16

B 41842 SA EK KH YS JN 1/23/17

Dialight Corporation 1501 Route 34 South Farmingdale, NJ 07727

Tel: 732.919.3119 Fax: 732.751.5778 Web: www.dialight.com

Page 40 of 40

You might also like

- 16th Edition IEE Wiring Regulations: Design and Verification of Electrical InstallationsFrom Everand16th Edition IEE Wiring Regulations: Design and Verification of Electrical InstallationsRating: 4 out of 5 stars4/5 (1)

- Practical, Made Easy Guide To Building, Office And Home Automation Systems - Part OneFrom EverandPractical, Made Easy Guide To Building, Office And Home Automation Systems - Part OneNo ratings yet

- Orbit AL-7103 M & T - PrintDocument124 pagesOrbit AL-7103 M & T - PrintKarl LinderNo ratings yet

- Metallic BondingDocument6 pagesMetallic Bonding胡佳玲No ratings yet

- FBB150 Installation Manual 2014Document88 pagesFBB150 Installation Manual 2014Yanko150No ratings yet

- Agrokid 210 220 230 240 WSM PDFDocument488 pagesAgrokid 210 220 230 240 WSM PDFjwd80% (5)

- Transmission Installation and ConfigurationsDocument29 pagesTransmission Installation and Configurationsoliv1912100% (5)

- DECS 250 ManualsDocument374 pagesDECS 250 ManualsPhước Khang NguyễnNo ratings yet

- DOC-01-031 - AFP-3030 Installation Manual (AUS) Rev ADocument52 pagesDOC-01-031 - AFP-3030 Installation Manual (AUS) Rev AMohamed RafihNo ratings yet

- Introduction to Machine Protection FunctionsDocument14 pagesIntroduction to Machine Protection FunctionsAbdelsalam ElhaffarNo ratings yet

- 93P Endress HauserDocument32 pages93P Endress HauserMario GuzmanNo ratings yet

- SB 7-4-106Document4 pagesSB 7-4-106jussmeeeNo ratings yet

- DVD Home Theatre SystemDocument84 pagesDVD Home Theatre SystemGeorgio HabibNo ratings yet

- DVD Home Theatre System: HT-7000DHDocument84 pagesDVD Home Theatre System: HT-7000DHJuan de Dios HernandezNo ratings yet

- E500 Router ManualDocument107 pagesE500 Router ManualBogaManNo ratings yet

- Multi Channel AV Receiver: STR-DG910Document100 pagesMulti Channel AV Receiver: STR-DG910Walter Alexandre dos Santos Silva100% (1)

- Installation sheet for WSE 81 PLUS and WSE 155 PLUS light curtain systemsDocument5 pagesInstallation sheet for WSE 81 PLUS and WSE 155 PLUS light curtain systemskizonimeisterNo ratings yet

- Sailor900ka ManualDocument195 pagesSailor900ka ManualNazrulNo ratings yet

- FCS-930 FCS-960 User's ManualDocument26 pagesFCS-930 FCS-960 User's Manualssking1No ratings yet

- 71 Busbar PowerDocument6 pages71 Busbar PowerMevlüt GünaydınNo ratings yet

- Manual Instalacion 900CRDocument16 pagesManual Instalacion 900CRgeovanyhazellopezsixtosNo ratings yet

- TW500A Linear Amplifier - Operator and Technical ManualDocument33 pagesTW500A Linear Amplifier - Operator and Technical ManualAlexander J Rokowetz100% (2)

- DECS450 ManualDocument356 pagesDECS450 ManualНиколай МухаNo ratings yet

- 876-0255-000 - b1 (Install Procedure, Bantam)Document16 pages876-0255-000 - b1 (Install Procedure, Bantam)mglemNo ratings yet

- 4100-6068 4100U/4100Es or TSW To Tfxnet Interface Installation and Programming InstructionsDocument24 pages4100-6068 4100U/4100Es or TSW To Tfxnet Interface Installation and Programming InstructionsAsif Uz ZamanNo ratings yet

- PCE-N15: Wireless Local Area Network Card (For 802.11 G/B/N Wireless Networks)Document35 pagesPCE-N15: Wireless Local Area Network Card (For 802.11 G/B/N Wireless Networks)Robert MurrayNo ratings yet

- Sunny Boy SWR 1100 LVDocument79 pagesSunny Boy SWR 1100 LVjonathan dacumosNo ratings yet

- 200WB7EB 27 chassis+UH7Document72 pages200WB7EB 27 chassis+UH7RogeriotabiraNo ratings yet

- PCS-9611S Feeder RelayDocument197 pagesPCS-9611S Feeder RelayMarkusKunNo ratings yet

- DSEP100 Mains (Utility) Protection Relays & Power Meters DSEGenset Deep Sea ElectronicsDocument1 pageDSEP100 Mains (Utility) Protection Relays & Power Meters DSEGenset Deep Sea ElectronicsEdinson Carrillo BeltranNo ratings yet

- TI-500E Plus UG 12Document22 pagesTI-500E Plus UG 12Miguel Angel Molotla BernalNo ratings yet

- DOC-01-038 - F - Notifier AFP-3030 NZ Programming Manual - Rev FDocument124 pagesDOC-01-038 - F - Notifier AFP-3030 NZ Programming Manual - Rev FMauricioDinizNo ratings yet

- Rca ctc-175 - 176 - 177 Training PDFDocument91 pagesRca ctc-175 - 176 - 177 Training PDFJesus Garcia Hernandez100% (1)

- Sailor 900 Installation and User Manual 133400 CDocument216 pagesSailor 900 Installation and User Manual 133400 CLeo BolqvadzeNo ratings yet

- 2097 In002 - en PDocument8 pages2097 In002 - en PCarlosOtinianoNo ratings yet

- 9504000990Document330 pages9504000990Venkata Madhav ModugaNo ratings yet

- Orbit Man26 1327 User GuideDocument116 pagesOrbit Man26 1327 User Guidelams_21No ratings yet

- AFP-3030 Operations Manual_RevCDocument62 pagesAFP-3030 Operations Manual_RevCalberttaladrogomeraNo ratings yet

- Kinetix 3 Component Servo Drives: Installation InstructionsDocument20 pagesKinetix 3 Component Servo Drives: Installation InstructionsJefferson BentesNo ratings yet

- Operation and Maintenance Manual For The 7200 Antenna Control SystemDocument250 pagesOperation and Maintenance Manual For The 7200 Antenna Control SystemIrancell TellNo ratings yet

- Manuel Point D'acces ALTAIDocument65 pagesManuel Point D'acces ALTAIMohamed HIRINo ratings yet

- Powershift V2: Manual Resistance Installation GuidelineDocument27 pagesPowershift V2: Manual Resistance Installation GuidelinedklnfsdNo ratings yet

- Color TV Service Manual for Daewoo CN-201A/B ModelsDocument74 pagesColor TV Service Manual for Daewoo CN-201A/B ModelsJairo PadronNo ratings yet

- 74 3441Document104 pages74 3441GUZMANNo ratings yet

- Multilin 8 Series Retrofit Kit: Instruction ManualDocument36 pagesMultilin 8 Series Retrofit Kit: Instruction ManualiskaadityaNo ratings yet

- Sailor600 - Vsat - Ka Im 98 148248 CDocument192 pagesSailor600 - Vsat - Ka Im 98 148248 CBruno MirandaNo ratings yet

- Rosemount 3051 Press. FieldBusDocument20 pagesRosemount 3051 Press. FieldBusQuynhtnNo ratings yet

- ics_triplex_t8314_Trusted Fibre TX_RX UnitDocument23 pagesics_triplex_t8314_Trusted Fibre TX_RX Unit朱迎安No ratings yet

- Nexus 7000 Site PrepDocument56 pagesNexus 7000 Site PrepaarnulfoNo ratings yet

- Va2016w 20 LCD MonitorDocument79 pagesVa2016w 20 LCD MonitorFABRI311No ratings yet

- VR-606 VR-616: Instruction ManualDocument36 pagesVR-606 VR-616: Instruction Manualrodax4No ratings yet

- Seatel XX98 PCU Upgrade ProcessDocument8 pagesSeatel XX98 PCU Upgrade ProcessmikeNo ratings yet

- Manual Basler Avr Decs250Document344 pagesManual Basler Avr Decs250dhinakaranNo ratings yet

- New-BCU-PCS-9705 - X - Instruction Manual - EN - Overseas General - X - R2.32 PDFDocument267 pagesNew-BCU-PCS-9705 - X - Instruction Manual - EN - Overseas General - X - R2.32 PDFLê Công TuấnNo ratings yet

- AL-7108 MAN29-0820_ADocument215 pagesAL-7108 MAN29-0820_AAntonio Bragança MartinsNo ratings yet

- COIT-000.812.62.01.02 C867VAE-K9 CRSP Installation GuideDocument26 pagesCOIT-000.812.62.01.02 C867VAE-K9 CRSP Installation GuidenlevenzonNo ratings yet

- 145eDocument6 pages145eWendy CassidyNo ratings yet

- SLSLX-6RS Series Installation GuideDocument30 pagesSLSLX-6RS Series Installation GuideQuân BùiNo ratings yet

- C460 DatasheetDocument114 pagesC460 Datasheetmountaineer07No ratings yet

- Sunny Boy SB2500 Tech ManualDocument33 pagesSunny Boy SB2500 Tech ManualCJ10aNo ratings yet

- 700 Series Page/Party Systems: Confidentiality NoticeDocument10 pages700 Series Page/Party Systems: Confidentiality NoticeTiagoNo ratings yet

- Catalyst 3560-C and 2960-C Switch Hardware Installation GuideDocument92 pagesCatalyst 3560-C and 2960-C Switch Hardware Installation Guide830139No ratings yet

- Service Manual Trucks: Delco Audio System, Troubleshooting VNDocument146 pagesService Manual Trucks: Delco Audio System, Troubleshooting VNsetiup holjiNo ratings yet

- Pioneer Deh p8650mp EspDocument154 pagesPioneer Deh p8650mp Espjupablo23No ratings yet

- NORDEX Fire Protection ConceptDocument3 pagesNORDEX Fire Protection Conceptpayamsa0% (1)

- Dynamometer and Power MeasurementDocument44 pagesDynamometer and Power MeasurementAndrei NobleNo ratings yet

- Flexim F704 PDFDocument257 pagesFlexim F704 PDFMarcelo OlivaresNo ratings yet

- Digital Dual-Axis Line-Of-sight Los DefensetechsDocument2 pagesDigital Dual-Axis Line-Of-sight Los DefensetechsdefensetechsNo ratings yet

- Meitrack t1 User Guide v1.8Document22 pagesMeitrack t1 User Guide v1.8Khor Su HakNo ratings yet

- Ingecon Sun Storage 1play TL M: List of Approved Power MetersDocument6 pagesIngecon Sun Storage 1play TL M: List of Approved Power MetersalarmaNo ratings yet

- As 4024.3-1998 Safeguarding of Machinery Manufacturing and Testing Requirements For Electro-Sensitive SystemsDocument7 pagesAs 4024.3-1998 Safeguarding of Machinery Manufacturing and Testing Requirements For Electro-Sensitive SystemsSAI Global - APACNo ratings yet

- Janitza BHB Umg96rm Etl 95 240V enDocument104 pagesJanitza BHB Umg96rm Etl 95 240V enM HuzaifaNo ratings yet

- Progress of Phased Array Systems in JapanDocument10 pagesProgress of Phased Array Systems in JapanDhimas AfihandarinNo ratings yet

- HW 8 3 Series ParallelDocument4 pagesHW 8 3 Series ParallelRona Patricia MacabugaoNo ratings yet

- Yamaha C-70Document6 pagesYamaha C-70orioncap33No ratings yet

- GSM ProtocolsDocument11 pagesGSM ProtocolsMohammed RiyazNo ratings yet

- 3 Final Four TG Reading SupportsDocument11 pages3 Final Four TG Reading SupportsadriannatsNo ratings yet

- Current ElectricityDocument3 pagesCurrent ElectricityWild RaptorNo ratings yet

- Installation Manual: FX - 4ADDocument3 pagesInstallation Manual: FX - 4ADbenzNo ratings yet

- University of Cambridge International Examinations International General Certificate of Secondary EducationDocument12 pagesUniversity of Cambridge International Examinations International General Certificate of Secondary EducationHany ElGezawyNo ratings yet

- Elec P CDocument31 pagesElec P CKria Vora100% (1)

- Low Power VLSI Circuits and Systems Prof. Ajit Pal Department of Computer Science and Engineering Indian Institute of Technology, KharagpurDocument23 pagesLow Power VLSI Circuits and Systems Prof. Ajit Pal Department of Computer Science and Engineering Indian Institute of Technology, KharagpurHimaja DasariNo ratings yet

- Metrel D.D. - MI 3295 Step Contact Voltage Measuring SystemDocument3 pagesMetrel D.D. - MI 3295 Step Contact Voltage Measuring SystemCatalina CocoşNo ratings yet

- Activated script manipulates numbers on websiteDocument4 pagesActivated script manipulates numbers on websiteJosgenda ClatituaNo ratings yet

- Pioneer AVH-P4100DVD Installation ManualDocument15 pagesPioneer AVH-P4100DVD Installation ManualCELDesignNo ratings yet

- Flyer Mach2 en 02Document2 pagesFlyer Mach2 en 02Abdelhamid Chergui0% (1)

- Mcpa2-7.5-Ind - Rev 1Document1 pageMcpa2-7.5-Ind - Rev 1ttaauuNo ratings yet

- XK3101 (KM05) User ManualDocument17 pagesXK3101 (KM05) User ManualmanhNo ratings yet

- Pipper Navajo ElectricSystem PDFDocument163 pagesPipper Navajo ElectricSystem PDFMonica EninNo ratings yet