Professional Documents

Culture Documents

Omni Sleeve Wall Pipe Penetration Sleeve: SIGMA Corporation

Omni Sleeve Wall Pipe Penetration Sleeve: SIGMA Corporation

Uploaded by

JojolasOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Omni Sleeve Wall Pipe Penetration Sleeve: SIGMA Corporation

Omni Sleeve Wall Pipe Penetration Sleeve: SIGMA Corporation

Uploaded by

JojolasCopyright:

Available Formats

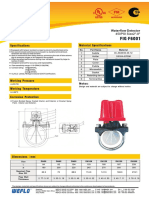

OMNI SLEEVE™ Wall Pipe Penetration Sleeve

HUB:

Manufactured from Ductile Iron, ASTM A536, in conformance with

ANSI/AWWA C110/A21.10, Section 1011, American National Standard

for Ductile and Gray Iron Fittings, 3-48” for water and other liquids.

Mechanical Joint sleeve seal is designed, manufactured, and tested in

strict accordance with the applicable provisions of ANSI/AWWA C111/

A21.11, American National Standard for Rubber Gasket Joints for Cast

OMNI SLEEVE with sleeve Iron and Ductile Iron Pressure Pipe and Fittings.

pipe as installed

Drilling and Tapping conform to ANSI B1.11960, Unified Screw Threads,

and to B1.2-1966, Screw Thread Gages and Gaging. Threads conform

to standards and dimensions of the Coarse Thread Series, Class 2B

Limits. OMNI-SLEEVE™ Hub and Sleeve Pipe are assembled and

sealed with an exclusive OMNI-SEAL™ gasket.

OMNI-SEAL ‘A’ GASKET:

Material conforms to the applicable provisions of CSA B 620M90,

Mechanical Couplings for Drain, Waste, Vent Pipe, and Sewer Pipe.

SIGMA Corporation 700 Goldman Drive 800 999 2550 p www.sigmaco.com

Cream Ridge, NJ 08514 609 758 1163 f

SIGMA Corporation www.sigmaco.com

crm-sales@sigmaco.com 1

OMNI SLEEVE™ Wall Pipe Penetration Sleeve

Dimensional Chart Dimensions in Inches

Weights in Pounds

Carrier Pipe OD Sleeve Distance Bolt Holes

Carrier Waterstop MJ Bolt Circle

Part No. Pipe Waterstop to

Pipe Size Diameter Diameter

DI Steel OD Wall No Size

3 OSL63 3.96 3.5 6.9 11 3/4 4 3/16 6.19 4 5/8 x 3

4 OSL64 4.8 4.5 6.9 11 3/4 4 3/16 7.5 4 3/4 x 4

6 OSL86 6.9 6.625 9.05 14 4 3/16 9.5 6 3/4 x 4

8 OSL108 9.05 8.625 11.1 16 4 3/16 11.75 6 3/4 x 4

10 OSL1210 11.1 10.75 13.2 18 1/4 4 3/16 14 8 3/4 x 4

12 OSL1412 13.2 12.75 15.3 20 1/4 4 3/16 16.25 8 3/4 x 4

14 OSL1614 15.3 N/A 17.4 22 3/8 4 5/16 18.75 10 3/4 x 5

16 OSL1816 17.4 N/A 19.5 24 1/2 4 5/16 21 12 3/4 x 5

18 OSL2018 19.5 N/A 21.6 26 5/8 4 5/16 23.25 12 3/4 x 5

20 OSL2420 21.6 N/A 25.8 30 3/4 4 5/16 25.5 14 3/4 x 5

24 OSL3024 25.8 N/A 32 37 4 5/16 30 16 3/4 x 5

30 OSL3630 32 N/A 38.3 43 3/8 5 9/16 36.88 20 1x6

ALTERNATIVE GASKETS:

EPDM: (ethylene propylene) suitable for water and wastewater, ozones, and strong

oxidizing chemicals. Temperature Range 65-250 degrees Fahrenheit.

CR: (neoprene) suitable for moderate chemicals and acids, oil fats, greases, and

many solvents. Temperature Range 65-200 degrees Fahrenheit.

NBR: (Buna-N, Nytril, Hycar) suitable for gasoline, petroleum products, hydrocarbons,

acids, animal and vegetable oils. Temperature Range: 65-150 degrees Fahrenheit.

OMNI SLEEVE installs accurately

as it can be secured to the FPM: (Viton) ideal for all aliphatic, aromatic, and halogenated hydrocarbons, acids,

formwork with 2 bolts, which animal, and vegetable oils. Temperature Range 50-450 degrees Fahrenheit.

prevents slippage or dislocation

during the concrete pour.

PRESSURE RATING:

Standard mechanical joint pressure pipe seal rated to 350psi.

2 SIGMA Corporation www.sigmaco.com

Suggested Specification

Wall and/or floor pipe penetrations shall be made by a means of a sleeve capable of being bolted directly to the formwork to

prevent misalignment. Seal of the annular space between the carrier pipe and the sleeve shall be by means of a confined

rubber gasket an capable of withstanding 350psi. Sleeve shall be manufactured from ASTM A536 Ductile Iron with an

integrally cast waterstop of 1/2” minimum thickness and 2-1/2” minimum height. Wall sleeves shall be OMNI-SLEEVE™ as

manufactured by SIGMA Corporation or prior approved equal.

Restraint Option

OMNI-SLEEVE’s standard mechanical joint also provides restraint options for your

carrier pipe. Shown at left is a typical installation utilizing SIGMA’s ONE-LOK Wedge

Action Restraint Gland. Using a ONE-LOK or alternatively, using tie-rods from the OMNI-

SLEEVE to the next flange will provide additional restraint to the assembly.

Vibration Absorption

OMNI-SLEEVE’s unique design adapts to settling and seismic movement and

also allows deflection of the carrier pipe system.

Other Features

•Integrally cast-in waterstop

•Ribbed Anchor Ring to provide more positive seal with concrete

•AWWA/ANSI Standardized Bolt Hole Spacing

•Cam Locks rotate into place to secure the carrier pipe

SIGMA Corporation www.sigmaco.com 3

™

Products

AWWA Ductile Iron Fittings

LOCATIONS

• 2-48” mechanical joint fittings (AWWA C153 & C110)

• 2-48” C110 / 54-64” C153 flanged fittings (cast iron also available)

North Region • 3-48” MJ and 3-48” Flanged AWWA Fittings, Domestic Manufacture

• 4-24” TRIM TYTON® C153 / 14-24” TYTON® push on fittings

Cream Ridge, New Jersey (HQ) • 4-24” C110 push on fittings

Phone (800) 999-2550 • C116 fusion bonded epoxy lining available

• PROTECTO 401® ceramic epoxy lining available

Fax (609) 758-1158

crm-sales@sigmaco.com Mechanical Joint Accessories

• Prepackaged and loose mechanical joint accessories

Sauk Village, Illinois • SIGMASEAL™ improved mechanical joint gasket

Phone (888) 999-0420 • Snap-on multi-purpose gasket for ductile iron or PVC pressure pipes

• Ductile iron set screw retainer glands

Fax (708) 758-6790 • OMNI-SLEEVE™ improved wall penetration sleeve

chi-sales@sigmaco.com • Specialty bolts and nuts for mechanical joint assemblies

ONE-LOK™ Wedge Action Restraints

• 3-48” ONE-LOK SLDE restraint for ductile iron pipe (import or domestic)

South Region • 3-36” ONE-LOK SLCE restraint for PVC pipe (import or domestic)

Alexander City, Alabama • 3-36” ONE-LOK SLDEH bell joint harness for ductile iron pipe

• 4-12” / 20” ONE-LOK SLDM restraint for oversized cast iron pipe

Phone (800) 824-4513 • 4-36” ONE-LOK SSLD split restraint for existing ductile iron pipe

Fax (256) 234-4956 • 4-36” ONE-LOK SSLDH split restraint harness for existing ductile iron pipe

rps-sales@sigmaco.com • 4-12” ONE-LOK SLCEH bell joint harness for PVC pipe

PV-LOK™ Serration Lock Restraints

Houston, Texas

• 4-48” PV-LOK PWM Restraint for MJ Fitting to PVC pipe

Phone (800) 999-0109 • 4-48” PV-LOK PWP Restraint for PVC bell joint restraint

Fax (281) 987-0200 • 4-48” PV-LOK PWPF Restraint for PVC fitting to PVC pipe

htn-sales@sigmaco.com • 4-12” PV-LOK PWH PVC bell joint harness

• 2-12” PV-LOK PVM Restraint for MJ Fitting to IPS PVC pipe

• 2-12” PV-LOK PVP Restraint for IPS PVC pipe bell joint

West Region & Canada • 4-8” PV-LOK PVPF Restraints for IPS PVC pressure fitting

Ontario, California Flange Adapters

Phone (800) 688-6230

Fax (909) 391-2033

ont-sales@sigmaco.com • 3-36” SIGMAFLANGE SFA flange adapter sleeve for PVC and DIP

• 2-48” ZIP FLANGE set screw style flange adapter

Auburn, Washington

Phone (800) 688- 6230

Fax (909) 391-2033

Municipal Construction Castings

ont-sales@sigmaco.com • Manhole Rings and Covers

• Curb and Meter Boxes

• Frames and Grates

Victoriaville, Quebec, Canada

• Storm Inlets

Phone (888) 744-6262 • Valve Boxes, Risers, and Extensions

Fax (819) 758-1153

crm-sales@sigmaco.com Products for the Ductile Iron Fabricator

• 3-64” High Hub Threaded Flanges

Innisfil, Ontario, Canada • 3-48” Tapped High Hub Threaded Flanges

Phone (877) 436-3800 • 3-36” Extra Heavy 250lb Drilled Threaded Flanges

Fax (705) 436-6338 • 3-48” Threaded MJ Bell Adapters

• 3-48” MJ x PE Bell adapter (2ft)

crm-sales@sigmaco.com • 3-48” Anchor Flanges

• 3-16” Filler Flanges

Extended Range Products

• FLANGE-PAK™ prepackaged flange accessory sets

• Polyethylene encasement for ductile iron pipe

• Copper tubing products

• Tracer wire & detectable/non-detectable marking tape

• Pipe joint lubricant & hydraulic cement

• Socket clamps and tie rod accessories

www.sigmaco.com • BOXLOK Valve Box Alignment Device

Terms and Conditions of Sales available at our website.

• Cast Iron Companion Flanges

TRIM-TYTON and TYTON are registered trademarks of the United States Pipe and Foundry Company

PROTECTO 401 is a registered trademark of Induron, Inc.

4 SIGMA Corporation ©2011 SIGMA Corporation. All rights reserved. omni/11-11

You might also like

- 9 - Aerial Lifts and Scissor Lifts THA-AHADocument5 pages9 - Aerial Lifts and Scissor Lifts THA-AHAJojolas100% (2)

- DN Tanks: Step1: Review Each "Hazard" With Identified Safety "Controls" and Determine RAC (See Above)Document6 pagesDN Tanks: Step1: Review Each "Hazard" With Identified Safety "Controls" and Determine RAC (See Above)JojolasNo ratings yet

- 18 - Confined Space THA-AHADocument7 pages18 - Confined Space THA-AHAJojolas50% (2)

- 1 - Construction Mobilization THA-AHADocument5 pages1 - Construction Mobilization THA-AHAJojolas0% (1)

- Abhar Low Voltage Cables PDFDocument119 pagesAbhar Low Voltage Cables PDFamirhajianNo ratings yet

- Pipeline Rules of Thumb Handbook: A Manual of Quick, Accurate Solutions to Everyday Pipeline Engineering ProblemsFrom EverandPipeline Rules of Thumb Handbook: A Manual of Quick, Accurate Solutions to Everyday Pipeline Engineering ProblemsRating: 4.5 out of 5 stars4.5/5 (10)

- Company Profile (ACE VALVE)Document20 pagesCompany Profile (ACE VALVE)DDFSFNo ratings yet

- Look Ahead ScheduleDocument9 pagesLook Ahead ScheduleJojolasNo ratings yet

- Catalog Mud Pump 25864Document24 pagesCatalog Mud Pump 25864agus100% (1)

- Mercer 9100Document16 pagesMercer 9100dtmgoNo ratings yet

- A TextBook of Fluid Mechanics and Hydraulic Machines - Dr. R. K. Bansal PDFDocument287 pagesA TextBook of Fluid Mechanics and Hydraulic Machines - Dr. R. K. Bansal PDFPullavartisrikanthChowdaryNo ratings yet

- Taking Body MeasurementsDocument86 pagesTaking Body MeasurementsMariel Liza HernandezNo ratings yet

- Project Deployment Plan TemplateDocument42 pagesProject Deployment Plan TemplateJojolasNo ratings yet

- A319/A320/A321 Transit CheckDocument2 pagesA319/A320/A321 Transit CheckHiram ThomasNo ratings yet

- New NORMAL PUERPERIUMDocument21 pagesNew NORMAL PUERPERIUMvarshaNo ratings yet

- Air Distribution For Large Spaces PDFDocument7 pagesAir Distribution For Large Spaces PDFJojolasNo ratings yet

- 3 - Pipe Blocks & Sumps THA-AHADocument6 pages3 - Pipe Blocks & Sumps THA-AHAJojolasNo ratings yet

- Subarctic Survival Situation - Student VersionDocument5 pagesSubarctic Survival Situation - Student VersionNhật Phương Hoàng NguyễnNo ratings yet

- Resilient Seated: CommercialDocument25 pagesResilient Seated: Commercialagung wijayaNo ratings yet

- Valvulas de Compuerta Hi-AlloyDocument2 pagesValvulas de Compuerta Hi-AlloyQuintin FedabNo ratings yet

- Wo Space Valve CatalogDocument30 pagesWo Space Valve CatalogGilbert MejulioNo ratings yet

- Dembla Gate ValvesDocument20 pagesDembla Gate ValvesMohit AroraNo ratings yet

- AVK Gate Valve Maintenance-Free Design ConceptDocument8 pagesAVK Gate Valve Maintenance-Free Design ConceptRakesh Sasidharan PillaiNo ratings yet

- Descarga 1er Paso Mercer 91-52j11t84u1Document16 pagesDescarga 1er Paso Mercer 91-52j11t84u1Alberto Esau Reyes CruzNo ratings yet

- MAR - GI Pipes & Fittings - 02.08.22Document107 pagesMAR - GI Pipes & Fittings - 02.08.22Ansaf AskyNo ratings yet

- DPCVDocument4 pagesDPCVjamil voraNo ratings yet

- SPO Webversion HighDocument6 pagesSPO Webversion HighchadNo ratings yet

- Butter Mueller 5bt520e0015wf00g1000Document2 pagesButter Mueller 5bt520e0015wf00g1000Manusawin PinsongNo ratings yet

- Klamflexproduct BrochureDocument24 pagesKlamflexproduct BrochureblindjaxxNo ratings yet

- Product BrochureDocument16 pagesProduct Brochurevishnu300022No ratings yet

- 601-A-006 - Avk021 - en 2232 - 471287Document2 pages601-A-006 - Avk021 - en 2232 - 471287bre brilianNo ratings yet

- 621-41-001 - Avk130 - en 2206 - 478821Document2 pages621-41-001 - Avk130 - en 2206 - 478821bre brilianNo ratings yet

- Instrumentation Cable BSDocument42 pagesInstrumentation Cable BSShivaniNo ratings yet

- Series 7600 Triple Offset Butterfly ValveDocument13 pagesSeries 7600 Triple Offset Butterfly ValveAmro AmerNo ratings yet

- AbDex - Hammer UnionsDocument12 pagesAbDex - Hammer UnionsWilliam EvansNo ratings yet

- Transparent Level Gauge Series 2000: Product Data Sheet No. 7Document1 pageTransparent Level Gauge Series 2000: Product Data Sheet No. 7Alfonso BlancoNo ratings yet

- (LR) - Rainwater Drainage System - 04062015Document28 pages(LR) - Rainwater Drainage System - 04062015Tarique ZiyadNo ratings yet

- Victaulic Flexible Hose Connecting To Dry Barrel SprinklerDocument27 pagesVictaulic Flexible Hose Connecting To Dry Barrel SprinklerOwais AhmedNo ratings yet

- Clarkson - Knife Gate Valves - KS3 - Install Manual - 2022-11 - r00Document18 pagesClarkson - Knife Gate Valves - KS3 - Install Manual - 2022-11 - r00Vitor BandeiraNo ratings yet

- Norm Ex ValvesDocument6 pagesNorm Ex Valvesapi-3712612No ratings yet

- Victaulic Flexible Hose Connecting To Regular Reliable SprinklerDocument27 pagesVictaulic Flexible Hose Connecting To Regular Reliable SprinklerOwais AhmedNo ratings yet

- Waterstop PVC BalbeckDocument7 pagesWaterstop PVC BalbeckLuis Carlos EsquivelNo ratings yet

- DemblaDocument12 pagesDemblaISHAN VERMANo ratings yet

- MODELS: C8-300 & C7-300: 300 Lb. Cast Carbon Steel Flanged & Buttweld "Y" StrainersDocument1 pageMODELS: C8-300 & C7-300: 300 Lb. Cast Carbon Steel Flanged & Buttweld "Y" Strainersanugrah_dimas5441No ratings yet

- Bore-Well Pipes PDFDocument6 pagesBore-Well Pipes PDFNikita KadamNo ratings yet

- TERA Joint BrochureDocument16 pagesTERA Joint BrochureraigoukiNo ratings yet

- 10.83 S 766 by Pass Valve PRV SetDocument7 pages10.83 S 766 by Pass Valve PRV SethernantoNo ratings yet

- Wafer Style Twin Disc Ductile Iron Check ValveDocument1 pageWafer Style Twin Disc Ductile Iron Check ValveAlbeiro LeivaNo ratings yet

- A Series 7500 Eccentric Disc Butterfly Valve - 2022Document20 pagesA Series 7500 Eccentric Disc Butterfly Valve - 2022Ali Altoukhy100% (1)

- Series 2200 TechBro 041812Document8 pagesSeries 2200 TechBro 041812GianniNo ratings yet

- 3.3 Valvula Os&y - SanfloDocument2 pages3.3 Valvula Os&y - SanfloYhonny ValenzuelaNo ratings yet

- ProValve Knife Gate ValveDocument12 pagesProValve Knife Gate ValveHarry HonchoNo ratings yet

- Dresser Style 63 Expansion JointDocument1 pageDresser Style 63 Expansion JointAnthonyNo ratings yet

- Ancon 25-14 Restraint SystemDocument4 pagesAncon 25-14 Restraint SystemmcbluedNo ratings yet

- Reg 600XLDocument2 pagesReg 600XLChris PalmerNo ratings yet

- LDWD3510C8FPDocument1 pageLDWD3510C8FPanuarsgNo ratings yet

- Weflow F6001Document1 pageWeflow F6001residente electricistaNo ratings yet

- Detector de Flujo-F6001Document1 pageDetector de Flujo-F6001Julio VizacarraNo ratings yet

- SpecificationDocument2 pagesSpecificationToxic ToucanNo ratings yet

- Filtro de Gas - MUELLERDocument2 pagesFiltro de Gas - MUELLERCarlos BaezaNo ratings yet

- Mercer Valve 9100 Relief Valve Flanged AEDocument16 pagesMercer Valve 9100 Relief Valve Flanged AEChristopher Kenneth ChoaNo ratings yet

- Firelock Butterfly Valve: Series 705 With Weatherproof ActuatorDocument7 pagesFirelock Butterfly Valve: Series 705 With Weatherproof ActuatorDefy BbalNo ratings yet

- Pipe CatalogueDocument6 pagesPipe CatalogueirfanNo ratings yet

- Resilient Seat Gate Valve SolutionsDocument24 pagesResilient Seat Gate Valve SolutionsMohamed shehataNo ratings yet

- STASTO Penstock Serie MR enDocument13 pagesSTASTO Penstock Serie MR envinston.s1949No ratings yet

- 3.2. Flowstrong Yellowbox - Product SpecsDocument16 pages3.2. Flowstrong Yellowbox - Product SpecsHussain Al SanonaNo ratings yet

- E300 Globe ValvesDocument24 pagesE300 Globe ValvesBOUZAIDANo ratings yet

- POLIM-S To 245kV - 2GNM110077 - 7-11 PDFDocument14 pagesPOLIM-S To 245kV - 2GNM110077 - 7-11 PDFByron David MoralesNo ratings yet

- Series 1000 Hinged ClosureDocument3 pagesSeries 1000 Hinged ClosureMurli RamchandranNo ratings yet

- Pool Fittings LeafletDocument20 pagesPool Fittings LeafletmohammudaphNo ratings yet

- Nibco 609Document1 pageNibco 609juanbcarrizales08No ratings yet

- 4 - Powered Industrial Truck THA-AHADocument5 pages4 - Powered Industrial Truck THA-AHAJojolasNo ratings yet

- Constant Velocity Duct DesignDocument5 pagesConstant Velocity Duct DesignJojolasNo ratings yet

- 47 - Hand Blasting THA-AHADocument5 pages47 - Hand Blasting THA-AHAJojolasNo ratings yet

- Project Management Project PlanDocument6 pagesProject Management Project PlanJojolasNo ratings yet

- 014 Water Reticulation System 2016 - 04 - 01Document10 pages014 Water Reticulation System 2016 - 04 - 01JojolasNo ratings yet

- Horizontal End Suction Pumps: Flowmore LimitedDocument36 pagesHorizontal End Suction Pumps: Flowmore LimitedJojolasNo ratings yet

- Fire Hydrant BrochureDocument2 pagesFire Hydrant BrochureJojolasNo ratings yet

- Temperature Measuring DeviceDocument1 pageTemperature Measuring DeviceJojolasNo ratings yet

- The Following Text Is For Questions Number 1 - 4!: Exercise On Greeting CardDocument2 pagesThe Following Text Is For Questions Number 1 - 4!: Exercise On Greeting CardnagaNo ratings yet

- Automatic Clinical Chemistry Analyzer: Technical SpecificationDocument2 pagesAutomatic Clinical Chemistry Analyzer: Technical SpecificationDharmesh PatelNo ratings yet

- Distillation of Alcoholic BeveragesDocument8 pagesDistillation of Alcoholic BeveragesDaennielle PerezNo ratings yet

- Technical Study On The Design and Construction of A Pedal Powered Hacksaw Cutting MachineDocument5 pagesTechnical Study On The Design and Construction of A Pedal Powered Hacksaw Cutting MachineIOSRjournalNo ratings yet

- Evidence-Based ManagementDocument17 pagesEvidence-Based ManagementShruthiNo ratings yet

- Chopard IssuuDocument7 pagesChopard IssuuMarco TeixeiraNo ratings yet

- Case ScenarioDocument4 pagesCase ScenarioAl TheóNo ratings yet

- Marijuana LegalizationDocument10 pagesMarijuana Legalizationapi-253373502No ratings yet

- Imran Et Al 2022 Development Molecular Docking and in Silico Adme Evaluation of Selective Alr2 Inhibitors For TheDocument12 pagesImran Et Al 2022 Development Molecular Docking and in Silico Adme Evaluation of Selective Alr2 Inhibitors For TheBudi AbutNo ratings yet

- Soal Tenses 1Document7 pagesSoal Tenses 1Noviwi HalenciNo ratings yet

- Phyllodes Tumors of The Breast UpToDateDocument22 pagesPhyllodes Tumors of The Breast UpToDateSean SialanaNo ratings yet

- h17 - Cognos ROI Case Study - Trillium Health CenterDocument5 pagesh17 - Cognos ROI Case Study - Trillium Health CenterMike__RobertsNo ratings yet

- SOAL-EBS-2 BASING-X-2012-sentosaDocument4 pagesSOAL-EBS-2 BASING-X-2012-sentosaAnthon KurniadiNo ratings yet

- Juvenile Justice in South AsiaDocument148 pagesJuvenile Justice in South AsiasukirteeeroNo ratings yet

- Tarea 3 de Ingles IIDocument6 pagesTarea 3 de Ingles IINelly SalcedoNo ratings yet

- Roofing 101 BUR Vs Modified BitumenDocument20 pagesRoofing 101 BUR Vs Modified Bitumenchristopher PaulinNo ratings yet

- Wedeco TAK55 UV DesinfectationDocument12 pagesWedeco TAK55 UV DesinfectationCarlos RamírezNo ratings yet

- Coping Mechanisms of Physicians Who Routinely Work With Dying PatientsDocument12 pagesCoping Mechanisms of Physicians Who Routinely Work With Dying PatientsAddie EspirituNo ratings yet

- Labor Cases 5Document131 pagesLabor Cases 5Franz Henri de GuzmanNo ratings yet

- Intake InterviewDocument2 pagesIntake InterviewMarky Laury GameplaysNo ratings yet

- Development Agreement: Former Macy's HQDocument10 pagesDevelopment Agreement: Former Macy's HQWVXU NewsNo ratings yet

- 2 Chemistry Exam ReviewDocument5 pages2 Chemistry Exam ReviewDA RATNo ratings yet

- Interpersonal Relationship:: Raja Abdul Rehman FA19-BBA-199Document3 pagesInterpersonal Relationship:: Raja Abdul Rehman FA19-BBA-199Raja RehmanNo ratings yet

- Earthquake Seismology & Plate Tectonic by Dr. Zulfiqar Ahmad NCPDocument75 pagesEarthquake Seismology & Plate Tectonic by Dr. Zulfiqar Ahmad NCPkazimmehdiNo ratings yet

- Assignment Pad370 Task 1Document14 pagesAssignment Pad370 Task 1Elyka TaiNo ratings yet