Professional Documents

Culture Documents

Cat Electronic Technician 2014A v1.0 Product Status Report

Uploaded by

George ZormpasOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Cat Electronic Technician 2014A v1.0 Product Status Report

Uploaded by

George ZormpasCopyright:

Available Formats

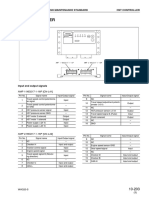

Cat Electronic Technician 2014A v1.

0

Product Status Report

6/3/2020 2:58 PM

Product Status Report

Parameter Value

Product ID CAT00000

Equipment ID WAP00535

Comments

VIMS Main Module

Parameter Value

Machine Serial Number Unavailable

Product ID CAT00000

Equipment ID

ECM Part Number 3402413-04

ECM Serial Number 26129060RN

Software Group Part Number 4345160-00

Software Group Release Date DEC12

Software Group Description PLGSM 2012 Q1 PROD 3.0

Application Software Part Number Unavailable

Telematic Device Software Group Part Number Unavailable

Telematic Device Software Group Release Date Unavailable

Telematic Device Software Group Description Unavailable

Logged Diagnostic Codes [Diagnostic Clock = 20141.4661 hours] - VIMS Main Module

Code Description Occ. First Last

No Logged

Diagnostic

Codes

Logged Event Codes [Diagnostic Clock = 20141.4661 hours] - VIMS Main Module

Code Description Occ. First Last

No Logged

Events

Active Diagnostic Codes - VIMS Main Module

Code Description

No Active

Codes

Active Event Codes - VIMS Main Module

Code Description

No Active

Events

Current Totals - VIMS Main Module

Description Value Unit

Total Operating Hours 20141 hours

Configuration - VIMS Main Module

Description Value Unit

Data Acquisition System Installation Status Unavailable

Data Acquisition System Temporary Not Installed

Installation Status

Data Acquisition System Temporary 15000 min

Installation Time Remaining

Customer Password #1 ********

Customer Password #2 ********

Product ID CAT00000

Equipment ID

External Service Lamp Installation Unavailable

Configuration

External Service Lamp Display Mode Unavailable

Setting

Telemetry Port Selection Unavailable

TMAC Protocol Port Selection Unavailable

Ethernet Media Access Control (MAC) 000A7502A455

Address

Internet Protocol Host Name VIMS3G

Internet Protocol (IPv4) Address 165.26.79.218

Internet Protocol (IPv4) Network Mask 255.255.255.252

Network Default Gateway Internet Protocol 165.26.79.216

(IPv4) Address

Web Server Administrator Password admin

Dynamic Host Configuration Protocol Disabled

(DHCP) Enable Status

Fleet Management System (FMS) Not Installed

Installation Status

Fleet Management System (FMS) Enable Unavailable

Status

Maintenance Mode Off

Machine Serial Number Unavailable

C18 385C/390D (TXH03759)

Parameter Value

Equipment ID WAP00535

Engine Serial Number TXH03759

ECM Part Number 3722906-00

ECM Serial Number 20226195JM

Personality Module Part Number 3802431-00

Personality Module Release Date JUN11

Personality Module Description HEX-385C-TNM-LRC

Logged Diagnostic Codes [Diagnostic Clock = 21775.6074 hours] - C18 385C/390D (TXH03759)

Code Description Occ. First Last

No Logged

Diagnostic

Codes

Logged Event Codes [Diagnostic Clock = 21775.6074 hours] - C18 385C/390D (TXH03759)

Code Description Occ. First Last

No Logged

Events

Active Diagnostic Codes - C18 385C/390D (TXH03759)

Code Description

No Active

Codes

Active Event Codes - C18 385C/390D (TXH03759)

Code Description

No Active

Events

Current Totals - C18 385C/390D (TXH03759)

Description Value Unit

Engine Lifetime Hours Unavailable hours

Total Operating Hours 21776 hours

Total Fuel 202370 gal

Engine Starts 10235

Lifetime Total Engine 2019835548 rev

Revolutions

Total Idle Time 5307:30 hours

Total Idle Fuel 10706 gal

Total Max Fuel 722959 gal

Average Load Factor 26 %

Overall Load Factor 27 %

Configuration - C18 385C/390D (TXH03759)

Description Value Unit

Equipment ID WAP00535

Engine Serial Number TXH03759

ECM Part Number 3722906-00

ECM Serial Number 20226195JM

Personality Module Part Number 3802431-00

Personality Module Release Date JUN11

Personality Module Description HEX-385C-TNM-LRC

Rated Power 553 hp at 1800 rpm

Rated Peak Torque 1934 lb-ft at 1400 rpm

Test Spec 0K6290

Top Engine Speed Range 1980 - 1980 rpm

Ether Solenoid Configuration Continuous Flow Solenoid

FLS -60

FTS 73

Total Tattletale 0

Injector Trim Calibration - C18 385C/390D (TXH03759)

Injector Serial Number File Version

Injector1 000000005A52596008B8 0

Injector2 000000005A52596062F0 0

Injector3 000000005A52596067EB 0

Injector4 000000005A5259598810 0

Injector5 000000005A5259598434 0

Injector6 000000005A525960049C 0

Machine Control 390D/385D

Parameter Value

Product ID WAP00535

ECM Part Number 3668822-00

ECM Serial Number 01502681ER

Software Group Part Number 3668720-00

Software Group Description 390D HEX CONTROL

Software Group Release Date SEP2011

Active Event Codes Present Unavailable

Logged Diagnostic Codes [Diagnostic Clock = 21782 hours] - Machine Control 390D/385D

Code Description Occ. First Last

1118- 5 Neutral Flow Bypass Solenoid : Current Below 255 21550 21782

Normal

96- 4 Fuel Level Sensor : Voltage Below Normal 255 21550 21779

167-12 Alternator Charging Voltage Sensor : Failure 61 21550 21774

295-12 Large Hydraulic Excavator Control Module : 1 21704 21704

Failure

Logged Event Codes [Diagnostic Clock = 21782 hours] - Machine Control 390D/385D

Code Description Occ. First Last

E600 (2) High Hydraulic Oil Temperature Warning 95 21556 21782

Active Diagnostic Codes - Machine Control 390D/385D

Code Description

167-12 Alternator Charging Voltage Sensor : Failure

1118- 5 Neutral Flow Bypass Solenoid : Current Below Normal

Current Totals - Machine Control 390D/385D

Description Value Unit

Total Operating Hours 21783 hours

Engine Maintenance Hours 21782 hours

Engine Oil Hours 6916 hours

Engine Oil Filter Hours 6916 hours

Engine Coolant Hours 6916 hours

Fuel/ Water Separator Hours 6916 hours

Fuel Filter Hours 6916 hours

Hydraulic Pump Hours 21782 hours

Hydraulic Pilot Oil Filter Hours 6916 hours

Hydraulic Case Drain Oil Filter 6916 hours

Hours

Return Hydraulic Oil Filter 6916 hours

Hours

Hydraulic Oil Hours 6916 hours

Attachment Hydraulic Oil Filter 0 hours

Hours

Final Drive Oil Hours 6916 hours

Swing Drive Oil Hours 6916 hours

Swing Motor Hours 8171 hours

Travel Motor Hours 1345 hours

Tool #1 Hours 0 hours

Tool #2 Hours 0 hours

Tool #3 Hours 0 hours

Tool #4 Hours 0 hours

Return Hydraulic Oil Filter 91.5 hours

Bypass Hours

Return Hydraulic Oil Filter 91.5 hours

Bypass at Cold Temperature

Hours

Hours of Operation at High 1436.0 hours

Hydraulic Pressure

Hours of Operation at Relief 663.7 hours

Hydraulic Pressure

Configuration - Machine Control 390D/385D

Description Value Unit

Product ID WAP00535

Fuel Economy Mode Enable Status Enabled

Economy Mode Off

Hydraulic Pump High Pressure Cut Off Unavailable

Enable Status

Straight Travel Pedal Installation Status Not Installed

Travel Alarm Installation Status Installed

Engine Cooling Fan Map Standard

Top Engine Fan Speed 900 rpm

High Power Auxiliary Circuit Flow Rate 42 gal/min

Machine Overload Pressure Sensor Not Installed

Installation

Engine Fan Reversing Feature Installation Not Installed

Status

Water Separator Level Switch Normally Closed (to Ground)

Configuration

Fuel Filter Differential Pressure Switch Normally Open

Config

Secondary Fuel Filter Differential Pressure Not Installed

Switch Config

Attachment Hydraulic Oil Filter Switch Not Installed

Configuration

Boom Lower Check Valve Installation Not Installed

Status

Stick Lower Check Valve Installation Status Not Installed

Smart Boom Installation Status Not Installed

Main Pump Initial Maximum Working 56.0 %

Torque Percentage Configuration

Bucket Configuration Mass Excavation

Excavator Operating Mode Standard

Auxiliary Pedal Installation Status Not Installed

Medium Pressure Hydraulic Circuit Not Installed

Configuration

Auxiliary Hydraulic Circuit #1 Configuration Not Installed

Joystick Handle Configuration Joystick Switch

Auxiliary Flow Reduction Mode Enable Disabled

Status

Joystick Mapping Group Selection Disabled

Joystick Mapping Configuration SAE Mapping

Travel Speed Shift Low Delay 0.4 sec

Travel Speed Shift High Delay 0.4 sec

Travel Speed Shift Low Pres 3481 psi

Travel Speed Shift High Pressure 4786 psi

Throttle Dial Position 1 Engine Speed 1000 rpm

Throttle Dial Position 2 Engine Speed 1100 rpm

Throttle Dial Position 3 Engine Speed 1200 rpm

Throttle Dial Position 4 Engine Speed 1300 rpm

Throttle Dial Position 5 Engine Speed 1470 rpm

Throttle Dial Position 6 Engine Speed 1590 rpm

Throttle Dial Position 7 Engine Speed 1700 rpm

Throttle Dial Position 8 Engine Speed 1800 rpm

Throttle Dial Position 9 Engine Speed 1900 rpm

Throttle Dial Position 10 Engine Speed 1980 rpm

One Touch Engine Speed Setting 1100 rpm

AESC Setting 1300 rpm

AESC Delay Time 5.0 sec

Throttle Dial Position 1 Hydraulic System 50.0 %

Torque Percentage

Throttle Dial Position 2 Hydraulic System 55.0 %

Torque Percentage

Throttle Dial Position 3 Hydraulic System 61.0 %

Torque Percentage

Throttle Dial Position 4 Hydraulic System 69.0 %

Torque Percentage

Throttle Dial Position 5 Hydraulic System 78.0 %

Torque Percentage

Throttle Dial Position 6 Hydraulic System 85.0 %

Torque Percentage

Throttle Dial Position 7 Hydraulic System 92.0 %

Torque Percentage

Throttle Dial Position 8 Hydraulic System 92.0 %

Torque Percentage

Throttle Dial Position 9 Hydraulic System 92.0 %

Torque Percentage

Throttle Dial Position 10 Hydraulic System 100.0 %

Torque Percentage

Engine Oil Recommended Maintenance 500 hours

Interval

Engine Oil Filter Recommended 500 hours

Maintenance Interval

Engine Coolant Recommended 3000 hours

Maintenance Interval

Fuel/ Water Separator Recommended 500 hours

Maint Interval

Fuel Filter Recommended Maintenance 500 hours

Interval

Hydraulic Pilot Oil Filter Recommended 1000 hours

Maintenance Interval

Hydraulic Case Drain Oil Filter 1000 hours

Recommended MI

Return Hyd Oil Filter Recommended Maint 2000 hours

Interval

Final Drive Oil Recommended 2000 hours

Maintenance Interval

Hydraulic Oil Recommended Maintenance 3000 hours

Interval

Swing Drive Oil Recommended 1000 hours

Maintenance Interval

Attachment Hydraulic Oil Filter 0 hours

Recommended Maintenance Interval

Soft Mode Gain Selection Gain Index 1

Soft Mode Response Selection Slow

Normal Mode Gain Selection Gain Index 4

Normal Mode Response Selection Fast

Quick Mode Gain Selection Gain Index 5

Quick Mode Response Selection Fast

AccuGrade System Installation Status Not Installed

Tool Configuration - Machine Control 390D/385D

Description Value Unit

Tool Program Name HAMMER1

Description Selected Tool 1

Program Index Number

Maximum Throttle Dial 9

Initial Tool Program Medium 5 %

Pressure Circuit Main Pump

Torque Reduction

Total Tool Program Medium 20 %

Pressure Circuit Main Pump

Torque Reduction

Auxiliary Minimum Hydraulic 85 gal/min

Extend Flow

Auxiliary Hydraulic Extend Flow 0 psi

Reduction Pressure

Auxiliary Hydraulic Extend 5802 psi

Relief Pressure

Auxiliary Minimum Hydraulic 0 gal/min

Retract Flow

Auxiliary Hydraulic Retract Flow 0 psi

Reduction Pressure

Auxiliary Hydraulic Retract 0 psi

Relief Pressure

Bucket Lever Control Mode Bucket Valve - Direct

Proportional Control

Left Joystick Switch #1 Control No valve controlled

Mode

Left Joystick Switch #2 Control No valve controlled

Mode

Right Joystick Switch #1 No valve controlled

Control Mode

Right Joystick Switch #2 No valve controlled

Control Mode

Tool Program Left Joystick No valve controlled

Switch #4 Control Mode

Tool Program Right Joystick No valve controlled

Switch #4 Control Mode

Tool Configuration - Machine Control 390D/385D

Description Value Unit

Tool Program Name HAMMER2

Description Selected Tool 2

Program Index Number

Maximum Throttle Dial 9

Initial Tool Program Medium 5 %

Pressure Circuit Main Pump

Torque Reduction

Total Tool Program Medium 20 %

Pressure Circuit Main Pump

Torque Reduction

Auxiliary Minimum Hydraulic 85 gal/min

Extend Flow

Auxiliary Hydraulic Extend Flow 0 psi

Reduction Pressure

Auxiliary Hydraulic Extend 5802 psi

Relief Pressure

Auxiliary Minimum Hydraulic 0 gal/min

Retract Flow

Auxiliary Hydraulic Retract Flow 0 psi

Reduction Pressure

Auxiliary Hydraulic Retract 0 psi

Relief Pressure

Bucket Lever Control Mode Bucket Valve - Direct

Proportional Control

Left Joystick Switch #1 Control No valve controlled

Mode

Left Joystick Switch #2 Control No valve controlled

Mode

Right Joystick Switch #1 No valve controlled

Control Mode

Right Joystick Switch #2 No valve controlled

Control Mode

Tool Program Left Joystick No valve controlled

Switch #4 Control Mode

Tool Program Right Joystick No valve controlled

Switch #4 Control Mode

Tool Configuration - Machine Control 390D/385D

Description Value Unit

Tool Program Name HAMMER3

Description Selected Tool 3

Program Index Number

Maximum Throttle Dial 9

Initial Tool Program Medium 5 %

Pressure Circuit Main Pump

Torque Reduction

Total Tool Program Medium 20 %

Pressure Circuit Main Pump

Torque Reduction

Auxiliary Minimum Hydraulic 106 gal/min

Extend Flow

Auxiliary Hydraulic Extend Flow 0 psi

Reduction Pressure

Auxiliary Hydraulic Extend 5802 psi

Relief Pressure

Auxiliary Minimum Hydraulic 106 gal/min

Retract Flow

Auxiliary Hydraulic Retract Flow 0 psi

Reduction Pressure

Auxiliary Hydraulic Retract 5802 psi

Relief Pressure

Bucket Lever Control Mode Bucket Valve - Direct

Proportional Control

Left Joystick Switch #1 Control No valve controlled

Mode

Left Joystick Switch #2 Control No valve controlled

Mode

Right Joystick Switch #1 No valve controlled

Control Mode

Right Joystick Switch #2 No valve controlled

Control Mode

Tool Program Left Joystick No valve controlled

Switch #4 Control Mode

Tool Program Right Joystick No valve controlled

Switch #4 Control Mode

Tool Configuration - Machine Control 390D/385D

Description Value Unit

Tool Program Name HAMMER4

Description Selected Tool 4

Program Index Number

Maximum Throttle Dial 9

Initial Tool Program Medium 5 %

Pressure Circuit Main Pump

Torque Reduction

Total Tool Program Medium 20 %

Pressure Circuit Main Pump

Torque Reduction

Auxiliary Minimum Hydraulic 106 gal/min

Extend Flow

Auxiliary Hydraulic Extend Flow 0 psi

Reduction Pressure

Auxiliary Hydraulic Extend 5802 psi

Relief Pressure

Auxiliary Minimum Hydraulic 106 gal/min

Retract Flow

Auxiliary Hydraulic Retract Flow 0 psi

Reduction Pressure

Auxiliary Hydraulic Retract 5802 psi

Relief Pressure

Bucket Lever Control Mode Bucket Valve - Direct

Proportional Control

Left Joystick Switch #1 Control No valve controlled

Mode

Left Joystick Switch #2 Control No valve controlled

Mode

Right Joystick Switch #1 No valve controlled

Control Mode

Right Joystick Switch #2 No valve controlled

Control Mode

Tool Program Left Joystick No valve controlled

Switch #4 Control Mode

Tool Program Right Joystick No valve controlled

Switch #4 Control Mode

Monitor

Parameter Value

ECM Serial Number 117J0402AJ

Personality Module Part Number 3668810-00

You might also like

- Cat Electronic Technician 2014A v1.0 Product Status ReportDocument6 pagesCat Electronic Technician 2014A v1.0 Product Status ReportGeorge ZormpasNo ratings yet

- Cat Electronic Technician 2014A v1.0 Product Status ReportDocument6 pagesCat Electronic Technician 2014A v1.0 Product Status ReportGeorge ZormpasNo ratings yet

- Cat Electronic Technician 2019A v1.0 Configuration: Parameter ValueDocument5 pagesCat Electronic Technician 2019A v1.0 Configuration: Parameter ValueSteven Y.MNo ratings yet

- Status Report Fruytier 972K Pem00444 DPF A Plus de 140% Soot - PSRPT - 2021-07-28 - 09.36.43Document13 pagesStatus Report Fruytier 972K Pem00444 DPF A Plus de 140% Soot - PSRPT - 2021-07-28 - 09.36.43Jean DiscretNo ratings yet

- Electronic Service Tool 2015A v1.0 Product Status ReportDocument3 pagesElectronic Service Tool 2015A v1.0 Product Status ReportNacer Zehani0% (1)

- Down Load Data - TTT00414 - PSRPT - 2018-12-07 - 10.34.42Document5 pagesDown Load Data - TTT00414 - PSRPT - 2018-12-07 - 10.34.42Hendra MonoNo ratings yet

- Diagnostic Codes: Shutdown SISDocument3 pagesDiagnostic Codes: Shutdown SISNovakurniawanNo ratings yet

- Kit Prise HitachiDocument45 pagesKit Prise HitachiMartinezNo ratings yet

- BZP01346 PSRPT 2017-08-25 13.50.49Document9 pagesBZP01346 PSRPT 2017-08-25 13.50.49S Eko AnangNo ratings yet

- CAT ELECTRONIC TECHNICIAN REPORTDocument17 pagesCAT ELECTRONIC TECHNICIAN REPORTJalel SaidiNo ratings yet

- CAT C9 Oil Pan InstslationDocument4 pagesCAT C9 Oil Pan InstslationEwgenyNo ratings yet

- Ether Injection Control SolenoidDocument3 pagesEther Injection Control SolenoidBlowby HighNo ratings yet

- Troubleshooting Cat 14M Steering IssuesDocument14 pagesTroubleshooting Cat 14M Steering IssuesKhaled KamelNo ratings yet

- Bolt On Turbo Kit for Honda Fit GD3Document4 pagesBolt On Turbo Kit for Honda Fit GD3GHow LeeNo ratings yet

- C32 Syc03519 - PSRPT - 2019-11-06 - 17.53.14 PDFDocument4 pagesC32 Syc03519 - PSRPT - 2019-11-06 - 17.53.14 PDFiprahim202066100% (1)

- Flash 336d2l Engine c9Document5 pagesFlash 336d2l Engine c9Mhmd AlwanNo ratings yet

- Throttle Position Sensor Circuit TestDocument8 pagesThrottle Position Sensor Circuit TestDaniel AmanorNo ratings yet

- d9n - Plano ElectricoDocument2 pagesd9n - Plano ElectricoJorge Calderon Rojas100% (1)

- 3412E Engine Speedsensor PDFDocument2 pages3412E Engine Speedsensor PDFmohammed mostafa100% (1)

- List of Parts and Connectors for Industrial VehicleDocument11 pagesList of Parts and Connectors for Industrial VehicleonrabiNo ratings yet

- Cat Electronic Technician 2018C v1.0 Product Status ReportDocument7 pagesCat Electronic Technician 2018C v1.0 Product Status ReportRodolft RodolftNo ratings yet

- Búsqueda Del Medio - SEBU7898 - C18 Generator Set Cat Digital Voltage Regulator (Cat DVR)Document4 pagesBúsqueda Del Medio - SEBU7898 - C18 Generator Set Cat Digital Voltage Regulator (Cat DVR)CEVegaONo ratings yet

- Thursday, July 9, 2015: Main Electrical SystemDocument3 pagesThursday, July 9, 2015: Main Electrical Systemjohn ayengahNo ratings yet

- SectionC 15Document1 pageSectionC 15veshatNo ratings yet

- C18 Generator Set Electrical System With EMCP3: Harness and Wire Electrical Schematic SymbolsDocument4 pagesC18 Generator Set Electrical System With EMCP3: Harness and Wire Electrical Schematic SymbolsImtiaz AhmedNo ratings yet

- Main Menu: EC21OB/240B/290B PRIME UpdateDocument26 pagesMain Menu: EC21OB/240B/290B PRIME UpdateMuhammad JafariNo ratings yet

- Electronic Control ModuleDocument7 pagesElectronic Control ModuleBroCactusNo ratings yet

- 740B EJ Tier 2 Maintenance Parts ListDocument3 pages740B EJ Tier 2 Maintenance Parts ListMónica Rada UrbinaNo ratings yet

- Cat - Dcs.sis - Controller Cs-663e AefDocument2 pagesCat - Dcs.sis - Controller Cs-663e AefLhsan Rajawi0% (1)

- Dozer CAT D6K Controllers PDFDocument2 pagesDozer CAT D6K Controllers PDFIrfan SaeedNo ratings yet

- Kubota 05 Series v1505 E3b SpecificationsDocument2 pagesKubota 05 Series v1505 E3b SpecificationsVol VasylkevychNo ratings yet

- Caterpillar Customer ETDocument2 pagesCaterpillar Customer ETAnthony graciano leyvaNo ratings yet

- Sensor Signal (PWM) - Test: TroubleshootingDocument6 pagesSensor Signal (PWM) - Test: Troubleshootingronald0% (1)

- HST Pines Komatsu Wa320Document1 pageHST Pines Komatsu Wa320Victor Rodrigo Cortes YañezNo ratings yet

- File 20191211 103211 C9.3 CG9 Emcp4.2 Uenr7508uenr7508 SisDocument2 pagesFile 20191211 103211 C9.3 CG9 Emcp4.2 Uenr7508uenr7508 SisPhanNamNo ratings yet

- Diagnostics SwitchDocument2 pagesDiagnostics SwitchGioalrizki GioalrizkiNo ratings yet

- Cat Electronic Technician 2020B v1.0 Product Status ReportDocument34 pagesCat Electronic Technician 2020B v1.0 Product Status ReportFrancisco LópezNo ratings yet

- Engine Cranks But Will Not Start: Shutdown SIS Previous ScreenDocument8 pagesEngine Cranks But Will Not Start: Shutdown SIS Previous ScreenAHMED2ALINo ratings yet

- Interactive Schematic: This Document Is Best Viewed at A Screen Resolution of 1024 X 768Document8 pagesInteractive Schematic: This Document Is Best Viewed at A Screen Resolution of 1024 X 768Rashid MahmoodNo ratings yet

- Section K: Service Manual - JS200, JS140 & JS205Document6 pagesSection K: Service Manual - JS200, JS140 & JS205Naing Min HtunNo ratings yet

- MSC JQ1165 ElectricsDocument18 pagesMSC JQ1165 ElectricsEnrique Ramirez100% (2)

- Using The Diagnostic Indicator To Determine Diagnostic CodesDocument4 pagesUsing The Diagnostic Indicator To Determine Diagnostic CodesRocko CallejasNo ratings yet

- Tata Truck Service Manual PDF - : PinterestDocument2 pagesTata Truck Service Manual PDF - : PinterestAnbarasanNo ratings yet

- Throttle BulletinDocument6 pagesThrottle BulletinRussell WhearNo ratings yet

- SG72 PDFDocument6 pagesSG72 PDFnhocti007No ratings yet

- Diagrama 323D3Document2 pagesDiagrama 323D3Plstina RamsNo ratings yet

- Philips (Funai) PL10.4 40PFL5705Document59 pagesPhilips (Funai) PL10.4 40PFL5705Israel B ChavezNo ratings yet

- Fault Code 387 Accelerator Pedal or Lever Position Sensor Supply Voltage Circuit - Voltage Above Normal or Shorted To High SourceDocument9 pagesFault Code 387 Accelerator Pedal or Lever Position Sensor Supply Voltage Circuit - Voltage Above Normal or Shorted To High SourceAhmedmah100% (1)

- 330C Plano Electrico PDFDocument2 pages330C Plano Electrico PDFRICHARDNo ratings yet

- Plano Eléctrico - TRACTOR D10T PDFDocument4 pagesPlano Eléctrico - TRACTOR D10T PDFHéctorReyesPinedaNo ratings yet

- Esquema Eletrico Compaquitador cs533Document17 pagesEsquema Eletrico Compaquitador cs533Rodrigo GomesNo ratings yet

- Configuration ModeDocument44 pagesConfiguration ModeNay Soe100% (1)

- Dokumen - Tips 3412 Generator Set 4bz00001 Upsebp2785 48 DocumentationDocument15 pagesDokumen - Tips 3412 Generator Set 4bz00001 Upsebp2785 48 Documentationluis blancoNo ratings yet

- CAT 3408E 3412E EngineDocument11 pagesCAT 3408E 3412E EngineNasser AyoubNo ratings yet

- 08 MGS1000B 50Hz HC6JDocument4 pages08 MGS1000B 50Hz HC6JTuan Kien KieuNo ratings yet

- Solenoid Valves: Systems OperationDocument6 pagesSolenoid Valves: Systems OperationMbahdiro KolenxNo ratings yet

- Status Report Tralux 323e Rap01030 Low Voltage - PSRPT - 2021-07-23 - 08.19.56Document40 pagesStatus Report Tralux 323e Rap01030 Low Voltage - PSRPT - 2021-07-23 - 08.19.56Jean DiscretNo ratings yet

- DWJ00348 PSRPT 2022-01-29 10.04.32Document6 pagesDWJ00348 PSRPT 2022-01-29 10.04.32Tupai PanderNo ratings yet

- 8051 Microcontroller: An Applications Based IntroductionFrom Everand8051 Microcontroller: An Applications Based IntroductionRating: 5 out of 5 stars5/5 (6)

- Hensley Full Catalogue GZDocument161 pagesHensley Full Catalogue GZGeorge ZormpasNo ratings yet

- Cooling Systems LEBW4978-08 PDFDocument144 pagesCooling Systems LEBW4978-08 PDFingcalderonNo ratings yet

- UntitledDocument147 pagesUntitledGeorge Zormpas100% (1)

- HITACHI 850, 850LC, 870H, 870LCH Components Parts Catalog (151-419) Page RecognitionDocument138 pagesHITACHI 850, 850LC, 870H, 870LCH Components Parts Catalog (151-419) Page RecognitionGeorge ZormpasNo ratings yet

- Distributor parts diagram for BMW E12 Saloon 1976Document54 pagesDistributor parts diagram for BMW E12 Saloon 1976George ZormpasNo ratings yet

- Capacity ChartDocument33 pagesCapacity ChartGeorge ZormpasNo ratings yet

- 51 - 0217 Glazing 4641147 3611 5' E12 Saloon 518 ECE L M 1976/06Document130 pages51 - 0217 Glazing 4641147 3611 5' E12 Saloon 518 ECE L M 1976/06George ZormpasNo ratings yet

- Fuel Preparation SystemDocument30 pagesFuel Preparation SystemGeorge ZormpasNo ratings yet

- EngineDocument68 pagesEngineGeorge ZormpasNo ratings yet

- The BMW Carburetor: - :::::: : I:::::: :: !: J L I I: : IDocument32 pagesThe BMW Carburetor: - :::::: : I:::::: :: !: J L I I: : IGeorge ZormpasNo ratings yet

- Chapter 3 SCC1500C Load ChartsDocument34 pagesChapter 3 SCC1500C Load ChartsGeorge ZormpasNo ratings yet

- IHC SC-150 - Details and Specifications (Complete)Document4 pagesIHC SC-150 - Details and Specifications (Complete)George ZormpasNo ratings yet

- Kobelco 6D24-TLU2D - Parts Manual PDFDocument172 pagesKobelco 6D24-TLU2D - Parts Manual PDFGeorge Zormpas100% (1)

- Kobelco Cke2500 SpecDocument8 pagesKobelco Cke2500 SpecAthox QhurienNo ratings yet

- Kobelco Cke2500 SpecDocument8 pagesKobelco Cke2500 SpecAthox QhurienNo ratings yet

- Kobelco 6D24-TLU2D - Parts Manual PDFDocument172 pagesKobelco 6D24-TLU2D - Parts Manual PDFGeorge Zormpas100% (1)

- Kobelco 6D24-TLU2D - Parts Manual PDFDocument172 pagesKobelco 6D24-TLU2D - Parts Manual PDFGeorge Zormpas100% (1)

- CKE2500 - Parts ManualDocument666 pagesCKE2500 - Parts ManualGeorge Zormpas100% (1)

- Saudi Aramco Port and Terminal Booklet 2020 PDFDocument384 pagesSaudi Aramco Port and Terminal Booklet 2020 PDFmersail100% (1)

- General Instruction ManualDocument1 pageGeneral Instruction ManualGeorge ZormpasNo ratings yet

- Cat Electronic Technician 2014A v1.0 Product Status ReportDocument6 pagesCat Electronic Technician 2014A v1.0 Product Status ReportGeorge ZormpasNo ratings yet

- Cylinder Liner: SpecificationsDocument2 pagesCylinder Liner: SpecificationsGeorge Zormpas100% (1)

- CamshaftDocument2 pagesCamshaftGeorge Zormpas100% (1)

- Connecting Rod: SpecificationsDocument3 pagesConnecting Rod: SpecificationsGeorge Zormpas100% (1)

- Cat Electronic Technician 2014A v1.0 Product Status ReportDocument12 pagesCat Electronic Technician 2014A v1.0 Product Status ReportGeorge ZormpasNo ratings yet

- Connecting Rod and Main Bearing Journals: SpecificationsDocument2 pagesConnecting Rod and Main Bearing Journals: SpecificationsGeorge Zormpas100% (1)

- Connecting Rod and Main Bearing Journals: SpecificationsDocument2 pagesConnecting Rod and Main Bearing Journals: SpecificationsGeorge Zormpas100% (1)

- Troubleshoot WLAN IssuesDocument4 pagesTroubleshoot WLAN IssuesIvan Herrera CoronaNo ratings yet

- 1734UserManual Um011 en PDocument156 pages1734UserManual Um011 en Pclebeson_pontalNo ratings yet

- BE-800793.07-Network Clocks-MOBA NMS SNMP NTP DescriptionDocument36 pagesBE-800793.07-Network Clocks-MOBA NMS SNMP NTP DescriptionmohammadNo ratings yet

- UM1709 User Manual: STM32Cube Ethernet IAP ExampleDocument22 pagesUM1709 User Manual: STM32Cube Ethernet IAP ExampleTameClaudioNo ratings yet

- Linux DNS Apache DHCP NFS Roll 12 Yash KaralkarDocument23 pagesLinux DNS Apache DHCP NFS Roll 12 Yash Karalkaryash karalkarNo ratings yet

- Ltrsec 1000 LGDocument394 pagesLtrsec 1000 LGВладимир ЗайнулинNo ratings yet

- Data Domain Student GuideDocument288 pagesData Domain Student GuideNitesh RoyNo ratings yet

- Versa Sd-Wan LabDocument38 pagesVersa Sd-Wan Labbuda.mabulayaNo ratings yet

- FortiGate Admin GuideDocument798 pagesFortiGate Admin GuideSven ČičakNo ratings yet

- 01-22 FAQsDocument410 pages01-22 FAQsDanielNo ratings yet

- EG8145X6 Datasheet 01: Huawei Intelligent GPON and Wi-Fi 6 Routing-Type ONTDocument3 pagesEG8145X6 Datasheet 01: Huawei Intelligent GPON and Wi-Fi 6 Routing-Type ONTxin chenNo ratings yet

- ZTE NODE-B ConnectivityDocument19 pagesZTE NODE-B ConnectivitySanjeet Doodi100% (7)

- NSx700 Manual (1.0)Document157 pagesNSx700 Manual (1.0)afeeshNo ratings yet

- User Guide: FX9500 RFID ReaderDocument75 pagesUser Guide: FX9500 RFID ReaderGonzalo AvNo ratings yet

- ISCOM S5600-EI (A) Series Product Description (Rel - 07)Document92 pagesISCOM S5600-EI (A) Series Product Description (Rel - 07)qwertyNo ratings yet

- SmartAX MT800u T ADSL Router User Manual 2Document83 pagesSmartAX MT800u T ADSL Router User Manual 2dchardwareNo ratings yet

- LDALI User Manual 6 1Document199 pagesLDALI User Manual 6 1Guillermo Andres García MoraNo ratings yet

- Cnpilot Enterprise AP User Guide - PMP 2677 - 001v002Document176 pagesCnpilot Enterprise AP User Guide - PMP 2677 - 001v002tiokcekNo ratings yet

- PXGX Ups Card UgDocument71 pagesPXGX Ups Card UgAndré Luiz Fraga de OliveiraNo ratings yet

- U User Manual: AC1200 MU-MIMO Wi-Fi RouterDocument53 pagesU User Manual: AC1200 MU-MIMO Wi-Fi RouterMilner GranadosNo ratings yet

- EM-SGS-6341 Series Configuration Guide - v2.0Document691 pagesEM-SGS-6341 Series Configuration Guide - v2.0Vinay VermaNo ratings yet

- BRKEWN-2021-How To Setup An SD-Access Fabric From ScratchDocument21 pagesBRKEWN-2021-How To Setup An SD-Access Fabric From Scratchhabib kamaieNo ratings yet

- CCNA1 v7 ITN – IP Addressing Exam AnswersDocument21 pagesCCNA1 v7 ITN – IP Addressing Exam Answersrania stellNo ratings yet

- E300 Electronic Overload RelayDocument44 pagesE300 Electronic Overload Relayvõ cườngNo ratings yet

- Is61276152 Project1718Document25 pagesIs61276152 Project1718John O'ReganNo ratings yet

- Pro Tools - MTRX Studio Installation GuideDocument48 pagesPro Tools - MTRX Studio Installation GuideDavid BonillaNo ratings yet

- Quick Configuration Tool User's ManualDocument15 pagesQuick Configuration Tool User's ManualcastnhNo ratings yet

- Soal Soal Mikrotik MTCNA 2017Document3 pagesSoal Soal Mikrotik MTCNA 2017Novita MulyasariNo ratings yet

- Paperless Graphic Recorders: Specification SheetDocument8 pagesPaperless Graphic Recorders: Specification SheetKarla CalderónNo ratings yet

- Xerox 550 Sys Admin Guide enDocument314 pagesXerox 550 Sys Admin Guide enla34No ratings yet