Professional Documents

Culture Documents

Seminar Assignments - Assignment 5 Questions + Answers Seminar Assignments - Assignment 5 Questions + Answers

Uploaded by

Henry KimOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Seminar Assignments - Assignment 5 Questions + Answers Seminar Assignments - Assignment 5 Questions + Answers

Uploaded by

Henry KimCopyright:

Available Formats

lOMoARcPSD|4496474

Seminar assignments - Assignment 5 questions + answers

Oil Refining and Processing (The University of Western Ontario)

StuDocu is not sponsored or endorsed by any college or university

Downloaded by Henry Kim (ktghenry@gmail.com)

lOMoARcPSD|4496474

The University of Western Ontario

Faculty of Engineering

DEPARTMENT OF CHEMICAL AND BIOCHEMICAL ENGINEERING

CBE 4432B/9132B –Oil Refining and Processing

Assignment # 5

Due Date: Friday, March 28, 2014 by 5 p.m.

Problem 5.1

Part a

A petroleum refinery is planning regeneration schedule for reformer catalyst. The catalyst

deactivates after processing 200 barrels of feed per kg of catalyst. Calculate the length of

time between regeneration given the following conditions: (15)

Feed rate = 6000 BPSD

Feed API gravity = 54.5o

Catalyst bulk density = 810 kg/m3

Liquid hourly space velocity (LHSV) = 3.0 v/hr/v

Part b

A reforming reactor operates at 20 atm, it is desired to achieve 95% conversion of

heptane (C7H16) in the reactor feed to toluene as shown by the following reaction:

C7H16 ↔ C7H8 + 4H2

The equilibrium constant (Keq) for the reaction can be estimated by the following equation

ln Keq = a/T + b

where a = -31.24x103; b = 53.36; T is temperature in oK

Calculate reactor operating temperature. (25)

Problem 5.2

Part a

Discuss role of alkylation in a petroleum refinery with a simple block flow diagram and

examples of chemical reaction. (20)

Part b

Compare sulphuric acid and hydrofluoric acid catalysts for alkylation based on

considerations of safety, energy efficiency and cost. (20)

Downloaded by Henry Kim (ktghenry@gmail.com)

lOMoARcPSD|4496474

Part c

Feed to an alkylation unit is C4= at 3000 BPD and Isobutane to olefins (I/O) ratio of 8.

Olefins residence time in the reactor is 40 min., calculate the following.

a) Reactor volume (10)

b) Alkylate yield based on equation by Edgar and Himmelblau (1988) given below.

(10)

Valk = Volf (1.12 + 0.13167 (I/O)F – 0.0067(I/O)F )

2

Where V is volumetric flow BPD.

Solution to Problem 5.1

Part a

Reformer Feed rate = 6000 BPSD

= 6000 (barrels/d)x(159 liters/barrel)x (1 m3/1000 liter)(d/24h)

= 39.75 m3/h

Weight of catalyst calc.:

LHSV = 3. 0 (Feed rate, m3/h)/(vol. of catalyst, m3)

Vol. of catalyst = (39.75 m3/h)/(3 h-1) = 13.25 m3

Catalyst deactivation rate = 200 barrels of feed/ kg of catalyst

Total feed that can be processed by catalyst:

= 200 (barrel/kg cat)x(13.25 m3)x(810 kg/m3)

= 2.146x106 barrels

Length of time between regenerations:

= 2.146x106 (barrels) /6000 (barrels/d)

= 357.8 days

Downloaded by Henry Kim (ktghenry@gmail.com)

lOMoARcPSD|4496474

Part b

Desired conversion of heptanes (X) = 0. 95

C7H16 ↔ C7H8 + 4H2

(1-X) X 4X

Total moles at a given time = 1- X + X + 4X = 1+4X

From definition of chemical equilibrium constant based on partial pressures:

Thus pT = 20.(X/(1+4X)) pH2 = 20.(4X/(1+4X)) pHp = 20.(1-X)/(1+4X)

Since X = 0.95 Keq = 3.958x(15.8)4/0.208 = 11.859x105

Since ln Keq = a/T + b

where a = -31.24x103; b = 53.36; T in oK

Solving for T:

= 793.4 oK or 520.4 oC

Solution to Problem 5.2

Part a and b

Please refer to lecture notes on alkylation.

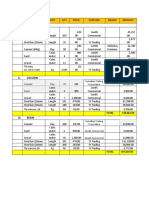

Part c

Feed to an alkylation unit (C4= ) = 3000 BPD

Isobutane to olefins (I/O) ratio = 8.

Olefins residence time in the reactor = 40 min.

Downloaded by Henry Kim (ktghenry@gmail.com)

lOMoARcPSD|4496474

Reactor volume calculation:

Reformer Feed rate = 3000 BPD

= 3000 (barrels/d)x(159 liters/barrel)x (1 m3/1000 liter)(d/24h)x(h/60 min)

= 0.331 m3/min

Reactor volume = 40x0.331 = 13.24 m3

Alkylate yield (Valk ) = Volf (1.12 + 0.13167 (I/O)F – 0.0067(I/O)F2)

= 3000 (1.12 + 0.13167(8) – 0.0067(8)2)

= 5233.68 BPD

References

Edgar, T.F., and D.M. Himmelblau, `Optimization of Chemical Processes`, McGraw Hill,

New York (1988).

Fahim, M.A., T.A. Alsahhaf, and A. Elkilani, “ Fundamentals of Petroleum Refining”,

Elsevier (2010).

Furimsky, E., ‘Selection of Catalysts and Reactors for Hydroprocessing”, Applied

CatalysisA: General 171, pp. 177-206 (1998).

Gary, J.H. and G.E. Hardwerk,”Petroleum Refining”, 4th ed., M.Dekker Inc., New York,

(2001).

Perry, R.H. and D.W. Green, “Perry’s Chemical Engineering Handbook”, 8th Ed., McGraw

Hill, N. York (2008).

Riazi, M.R., and Al-Sahhaf, T.A.. “Physical properties of heavy petroleum fractions and

crude oils”, Fluid Phase Equilib., Vol. 117, pp. 217-224 (1996).

Downloaded by Henry Kim (ktghenry@gmail.com)

You might also like

- A Modern Course in Statistical PhysicsFrom EverandA Modern Course in Statistical PhysicsRating: 3.5 out of 5 stars3.5/5 (2)

- Combustion of Pulverised Coal in a Mixture of Oxygen and Recycled Flue GasFrom EverandCombustion of Pulverised Coal in a Mixture of Oxygen and Recycled Flue GasNo ratings yet

- 2018l19 Final Exam With SolutionDocument13 pages2018l19 Final Exam With SolutionGAMERS OF KUWAITNo ratings yet

- Seminar Assignments - Assignment 4 Questions + Answers Seminar Assignments - Assignment 4 Questions + AnswersDocument6 pagesSeminar Assignments - Assignment 4 Questions + Answers Seminar Assignments - Assignment 4 Questions + AnswersHenry KimNo ratings yet

- B 3 FFDocument3 pagesB 3 FFanhNo ratings yet

- FinalAcetic Anhydride ProductionDocument15 pagesFinalAcetic Anhydride ProductionSwarnim Raj100% (2)

- 1. Set A Final Exam QuestionDocument8 pages1. Set A Final Exam QuestionDhayalan RamachandranNo ratings yet

- CHE 304 (Spring 2010) Problem Set SolutionsDocument6 pagesCHE 304 (Spring 2010) Problem Set SolutionsAman SrivastavaNo ratings yet

- Vapor Absorption Refrigeration SystemDocument17 pagesVapor Absorption Refrigeration Systemmariane.riane01No ratings yet

- Seminar Assignments - Assignment 3 Questions + Answers Seminar Assignments - Assignment 3 Questions + AnswersDocument7 pagesSeminar Assignments - Assignment 3 Questions + Answers Seminar Assignments - Assignment 3 Questions + AnswersHenry KimNo ratings yet

- Temperature, °C: SolutionDocument18 pagesTemperature, °C: Solutionمحمد حلمي هاريريNo ratings yet

- Homework 5 - 2020 - 01 - v3 - YH (v3) - ALV (v2)Document5 pagesHomework 5 - 2020 - 01 - v3 - YH (v3) - ALV (v2)CARLOS DIDIER GÓMEZ ARCOSNo ratings yet

- Tutorial Problems (Set 5)Document2 pagesTutorial Problems (Set 5)Manishaa Varatha RajuNo ratings yet

- 4.0 Preliminary Design of Equipment HeuristicsDocument10 pages4.0 Preliminary Design of Equipment Heuristicssolehah misniNo ratings yet

- Assignment CreDocument16 pagesAssignment CreAli Sabri BaharumNo ratings yet

- Resit Exam-CHEM4005-2015-2016Document4 pagesResit Exam-CHEM4005-2015-2016ajali1957No ratings yet

- CHE3044F Reactor Design 1 Tutorial 7 Equilibrium Calculations and Reactor SelectionDocument2 pagesCHE3044F Reactor Design 1 Tutorial 7 Equilibrium Calculations and Reactor SelectionnmhatityeNo ratings yet

- Set3ans 10Document5 pagesSet3ans 10amalinaishahNo ratings yet

- Fogler, H. S., Elements of Chemical Reaction Engineering, Prentice Hall, 1999Document5 pagesFogler, H. S., Elements of Chemical Reaction Engineering, Prentice Hall, 1999Zulaikha AinaNo ratings yet

- Tut1 2016 QDocument5 pagesTut1 2016 QAbhishek SardaNo ratings yet

- NAME: Vincent Rey Olario: Bsme - 5Document11 pagesNAME: Vincent Rey Olario: Bsme - 5Pryce YurongNo ratings yet

- Assignment 6Document3 pagesAssignment 6Yi Hong LowNo ratings yet

- CalculationDocument4 pagesCalculationaoauaz2000No ratings yet

- Exercise Chapter 2Document22 pagesExercise Chapter 2yewhouNo ratings yet

- New - OOI CHEL GEE - 005093 (RED2&3)Document17 pagesNew - OOI CHEL GEE - 005093 (RED2&3)Choo Shyan LeeNo ratings yet

- CHEM311 182 Major2 SolvedDocument10 pagesCHEM311 182 Major2 SolvedhussainNo ratings yet

- Environmental Fate EstimationDocument41 pagesEnvironmental Fate EstimationdhikaNo ratings yet

- rr220802 Chemical Engineering Thermodynamics IDocument8 pagesrr220802 Chemical Engineering Thermodynamics ISRINIVASA RAO GANTANo ratings yet

- CHE411 Fall 2010-Chemical Reaction Engineeirng-Ahmed A AbdalaDocument206 pagesCHE411 Fall 2010-Chemical Reaction Engineeirng-Ahmed A AbdalaYayan IndrayaniNo ratings yet

- rr320802 Chemical Reaction Engineering IDocument8 pagesrr320802 Chemical Reaction Engineering ISRINIVASA RAO GANTANo ratings yet

- Vinyl Acetate - Mass and Energy BalanceDocument26 pagesVinyl Acetate - Mass and Energy Balanceفيصل الغامدي100% (2)

- TakeHomeR - Kimia UAS AnwarJundiy011200306Document9 pagesTakeHomeR - Kimia UAS AnwarJundiy011200306Akbar YulandraNo ratings yet

- Pro2reactor PDFDocument29 pagesPro2reactor PDFJoy DasNo ratings yet

- JNTU Old Question Papers 2007Document8 pagesJNTU Old Question Papers 2007Srinivasa Rao GNo ratings yet

- Rajiv Gandhi University of Knowledge Technologies, Basar Mechanical EngineeringDocument7 pagesRajiv Gandhi University of Knowledge Technologies, Basar Mechanical EngineeringPunith YadavNo ratings yet

- PHY232 TEST2- October_2014_V001.docDocument2 pagesPHY232 TEST2- October_2014_V001.docTsitsi BasimaneNo ratings yet

- Reactor Design Guide1Document3 pagesReactor Design Guide1Muhammad NaqviNo ratings yet

- Tutorial Chemical Energetics Part I SolutionsDocument20 pagesTutorial Chemical Energetics Part I SolutionsDarren LimNo ratings yet

- Tutorial 6Document1 pageTutorial 6Aiman FadzilNo ratings yet

- CHEMICAL THERMODYNAMICS EXAM FOR BSC AND BED SCI DEGREESDocument3 pagesCHEMICAL THERMODYNAMICS EXAM FOR BSC AND BED SCI DEGREESjipson olooNo ratings yet

- CSTR ExampleDocument8 pagesCSTR Examplenatalia_campelo100% (2)

- Revision QuestionsDocument12 pagesRevision QuestionsLiew Wen Xuan0% (2)

- Reactor Design II-Fourth Year DR - Ali N.Khalaf: Chemical Engineering Department - University of BasrahDocument11 pagesReactor Design II-Fourth Year DR - Ali N.Khalaf: Chemical Engineering Department - University of BasrahKORAMA KIEN100% (1)

- Brayton cycle analysis with compressor and turbine efficienciesThe title "TITLE Brayton cycle analysis with compressor and turbine efficienciesDocument52 pagesBrayton cycle analysis with compressor and turbine efficienciesThe title "TITLE Brayton cycle analysis with compressor and turbine efficienciesGiuseppe TestarossaNo ratings yet

- Solution: For A First-Order Reaction, The Following Rate Coefficients Were FoundDocument16 pagesSolution: For A First-Order Reaction, The Following Rate Coefficients Were FoundDeepak SharmaNo ratings yet

- Final 04 SolDocument6 pagesFinal 04 SolHungDo0% (1)

- Reactoon Eng CRSWRK 2Document18 pagesReactoon Eng CRSWRK 2Ibrahim Aliyu100% (1)

- Chemcad Batch ReactorsDocument26 pagesChemcad Batch ReactorsCüneyt Gökhan Tosun0% (1)

- PP 106-110 Modeling & Simulation of Water Gas Shift Reaction JALPADocument5 pagesPP 106-110 Modeling & Simulation of Water Gas Shift Reaction JALPAEditorijset IjsetNo ratings yet

- TUGAS ATK KELOMPOK 8 Anggota: Anton, Dian, HendriadiDocument4 pagesTUGAS ATK KELOMPOK 8 Anggota: Anton, Dian, Hendriadisongjihyo16111994No ratings yet

- Tugas TRK 2 - Kelompok 7 PDFDocument37 pagesTugas TRK 2 - Kelompok 7 PDFRahmanto Ikhlas SejatiNo ratings yet

- Student 4 Stage 2Document9 pagesStudent 4 Stage 2Meck LotfiNo ratings yet

- Ch.8 - Exhaust Flow Elements and ProblemsDocument1 pageCh.8 - Exhaust Flow Elements and ProblemsJohn Joseph AmoresNo ratings yet

- Ryerson CHE 312 assignment on reactor engineeringDocument2 pagesRyerson CHE 312 assignment on reactor engineeringAbdi AhmedNo ratings yet

- Air Pollution Control Technologies: VOC IncineratorsDocument51 pagesAir Pollution Control Technologies: VOC IncineratorsRay CNo ratings yet

- JEE Main Physics Previous Year Questions With Solutions On ThermodynamicsDocument5 pagesJEE Main Physics Previous Year Questions With Solutions On ThermodynamicsDipra BiswasNo ratings yet

- Soft Computing in the Design and Manufacturing of Composite Materials: Applications to Brake Friction and Thermoset Matrix CompositesFrom EverandSoft Computing in the Design and Manufacturing of Composite Materials: Applications to Brake Friction and Thermoset Matrix CompositesNo ratings yet

- Glenn's Glue Stick Inc. Income Statement and FinancialsDocument5 pagesGlenn's Glue Stick Inc. Income Statement and FinancialsHenry KimNo ratings yet

- Projected Income Statement for Maple Leaf Hardware Ltd 2013-2014Document1 pageProjected Income Statement for Maple Leaf Hardware Ltd 2013-2014Henry KimNo ratings yet

- Glenn's Glue Stick Inc. Income Statement and FinancialsDocument5 pagesGlenn's Glue Stick Inc. Income Statement and FinancialsHenry KimNo ratings yet

- ABC Distribution Company LTDDocument2 pagesABC Distribution Company LTDHenry KimNo ratings yet

- Cash Flow AnalysisDocument10 pagesCash Flow AnalysisHenry KimNo ratings yet

- ABC Distribution Company LTDDocument2 pagesABC Distribution Company LTDHenry KimNo ratings yet

- Seminar Assignments - Assignment 3 Questions + Answers Seminar Assignments - Assignment 3 Questions + AnswersDocument7 pagesSeminar Assignments - Assignment 3 Questions + Answers Seminar Assignments - Assignment 3 Questions + AnswersHenry KimNo ratings yet

- Cash Flow AnalysisDocument10 pagesCash Flow AnalysisHenry KimNo ratings yet

- Seminar Assignments - Assignment 2 Questions + Answers Seminar Assignments - Assignment 2 Questions + AnswersDocument6 pagesSeminar Assignments - Assignment 2 Questions + Answers Seminar Assignments - Assignment 2 Questions + AnswersHenry KimNo ratings yet

- Seminar Assignments - Assignment 1 Questions + Answers Seminar Assignments - Assignment 1 Questions + AnswersDocument7 pagesSeminar Assignments - Assignment 1 Questions + Answers Seminar Assignments - Assignment 1 Questions + AnswersHenry KimNo ratings yet

- Hitachi Data Instance Director: Quick Start GuideDocument35 pagesHitachi Data Instance Director: Quick Start GuideJugal ProhitNo ratings yet

- Mark DarcoDocument48 pagesMark DarcoMohammad QasimNo ratings yet

- Guía de Firewall FortinetDocument102 pagesGuía de Firewall FortinetFederico ParalachiNo ratings yet

- Construction materials and supplies itemizationDocument7 pagesConstruction materials and supplies itemizationGintokiNo ratings yet

- Hazop Sil Study Report For 6 Buy Back Gas PipelineDocument32 pagesHazop Sil Study Report For 6 Buy Back Gas Pipelinealinor_tn100% (1)

- How To Size A ThickenerDocument5 pagesHow To Size A ThickenerRodrigo GarcíaNo ratings yet

- NIQ For Barbed WireDocument5 pagesNIQ For Barbed WireIrshad KhanNo ratings yet

- Re 29929Document4 pagesRe 29929Ahmed Abd ElhakeemNo ratings yet

- Hubungan Derajat Merokok Dengan Nilai Arus Puncak Ekspirasi Pada Pria Dewasa Awal (20-40 Tahun) Di Desa Tampaksiring, Kecamatan TampaksiringDocument8 pagesHubungan Derajat Merokok Dengan Nilai Arus Puncak Ekspirasi Pada Pria Dewasa Awal (20-40 Tahun) Di Desa Tampaksiring, Kecamatan TampaksiringBima SorayaNo ratings yet

- Catalog EnglezaDocument16 pagesCatalog EnglezaRamesh AnanthanarayananNo ratings yet

- Control System Module 2 NotesDocument133 pagesControl System Module 2 NotesRaghunath B H100% (6)

- Simpson Rule PDFDocument29 pagesSimpson Rule PDFBrajesh Narayan100% (1)

- Figure 1 Synthesis of DilantinDocument9 pagesFigure 1 Synthesis of Dilantinstepkim92No ratings yet

- Force Notes (Class 10)Document16 pagesForce Notes (Class 10)kumarardash86No ratings yet

- RainbowCrack tutorial guide for password crackingDocument5 pagesRainbowCrack tutorial guide for password crackingJunior SanzNo ratings yet

- Carbon Steel Plates TDCDocument3 pagesCarbon Steel Plates TDCshazanNo ratings yet

- Tilt-Up Construction GuideDocument147 pagesTilt-Up Construction GuideTiago Castelani100% (1)

- Complete Hci Question BankDocument21 pagesComplete Hci Question BankPurushothama Reddy100% (1)

- CHENNAI PORT AUCTION DETAILSDocument4 pagesCHENNAI PORT AUCTION DETAILSAjit ChauhanNo ratings yet

- HES2125 10S2 Revision01Document4 pagesHES2125 10S2 Revision01Roberto RizzoNo ratings yet

- How To Write A Killer Software Testing QA Resume That Will Turn Into An Interview Call - Software Testing HelpDocument27 pagesHow To Write A Killer Software Testing QA Resume That Will Turn Into An Interview Call - Software Testing HelpSyedMadar100% (1)

- Manual Electrico Kobelco SK 330-8Document6 pagesManual Electrico Kobelco SK 330-8sanach041275% (4)

- Netzcsh Screw PumpDocument4 pagesNetzcsh Screw Pumpaconibet9040No ratings yet

- Hafod Arch, Brynmawr, Blaenau Gwent. Watching BriefDocument28 pagesHafod Arch, Brynmawr, Blaenau Gwent. Watching BriefAPAC LtdNo ratings yet

- Propylene, Propylene Oxide and Isopropanol: Course: Chemical Technology (Organic) Module VIIDocument12 pagesPropylene, Propylene Oxide and Isopropanol: Course: Chemical Technology (Organic) Module VIImaheshNo ratings yet

- Chapter 8Document44 pagesChapter 8Syukri ZainuddinNo ratings yet

- Atom Incu I Service Manual & Parts List P2Document54 pagesAtom Incu I Service Manual & Parts List P2Diego DiazNo ratings yet

- NetApp Cluster Mode CDOT 8Document10 pagesNetApp Cluster Mode CDOT 8rahulchaudhry007No ratings yet