Professional Documents

Culture Documents

4.1.4contr A35-Section VI SOW-substation

Uploaded by

Hossam AlzubairyOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

4.1.4contr A35-Section VI SOW-substation

Uploaded by

Hossam AlzubairyCopyright:

Available Formats

SCOPE OF WORK - SUBSTATION

4.1.4Contr A35-Section VI SOW-substation May 2014 KPLC

VI - i

TABLE OF CONTENTS

4.2 SCOPE OF WORK - SUBSTATIONS .......................................................................................... 1

4.2.1 General ................................................................................................................................ 1

4.2.2 Standard Substation ............................................................................................................... 2

4.2.3 33 kV Switchgear GIS Type ..................................................................................................... 2

4.2.3.1 Transformer Bay......................................................................................................................... 2

4.2.3.2 Feeder Bay ................................................................................................................................ 3

4.2.3.3 33kv Bus Bar Protection ........................................................................................................... 3

4.2.5 Auxiliary transformer for 33/11kV Substation ............................. Error! Bookmark not defined.

4.2.6 MV Power Cables from Transformer to Indoor Switchgear ........... Error! Bookmark not defined.

4.2.7 MV Power Cables from Indoor Switchgear to line termination tower ........... Error! Bookmark not

defined.

4.2.8 Control, Protection, Metering and Signalling............................................................................ 5

4.2.8.1 Substation Automation System ..................................................................................................... 5

4.2.8.2 Control and Measuring Cables ...................................................................................................... 7

4.2.8.3 Telecommunications ................................................................................................................... 7

4.2.9 Auxiliary AC Supply Equipment .............................................................................................. 9

4.2.9.1 Main AC Distribution Board ........................................................................................................ 9

4.2.9.2 Sub-distribution Boards and Panels ............................................................................................... 9

4.2.9.3 Cables ....................................................................................................................................... 9

4.2.10 DC Supply System.............................................................................................................. 9

4.2.10.1 Battery ...................................................................................................................................... 9

4.2.10.2 Charger ..................................................................................................................................... 9

4.2.10.3 Switchboard ............................................................................................................................. 10

4.2.10.4 Battery Conductors and Fuses ..................................................................................................... 10

4.2.10.5 Sub-distribution Boards and Panels ............................................................................................. 10

4.2.10.6 Cables ..................................................................................................................................... 10

4.2.11 Earthing System .............................................................................................................. 10

4.2.12 Ancillary Equipment ........................................................................................................ 11

4.2.12.1 Station Equipment .................................................................................................................... 11

4.2.12.2 Earthing Devices ...................................................................................................................... 11

4.2.12.3 Cable Accessories ..................................................................................................................... 11

4.2.12.4 Racks, Conduits, Ducts, etc ........................................................................................................ 11

4.2.13 Power transformers .............................................................. Error! Bookmark not defined.

4.2.13.1 Type of transformers ..................................................................... Error! Bookmark not defined.

4.2.13.2 CTs for Power Transformers .......................................................... Error! Bookmark not defined.

4.2.14 Civil Works ..................................................................................................................... 11

4.2.14.1 Platform works ............................................................................. Error! Bookmark not defined.

4.2.14.2 Switchgear buildings ................................................................................................................. 11

4.2.14.3 Transformer foundations ................................................................ Error! Bookmark not defined.

4.2.14.4 Cable Trenches ........................................................................................................................ 11

4.2.15 Training in control (SAS), Telecommunication and protection system .................................... 11

4.2.16 Factory Acceptance Test................................................................................................... 12

4.2.17 Test Equipment (TS –001) ................................................................................................. 12

4.2.18 Final documentation ........................................................................................................ 12

4.2.19 Site Offices and site facilities(LS-010, -011) ....................................................................... 12

4.2.20 KIPEVU ............................................................................. Error! Bookmark not defined.

4.2.21 Mandatory Spare Parts and Tools ...................................................................................... 13

4.2.21.1 For Transformers ...................................................................................................................... 14

4.2.21.2 For Substations ........................................................................................................................ 14

4.2.22 Recommended Spare Parts and Tools ................................................................................. 14

4.1.4Contr A35-Section VI SOW-substation May 2014 KPLC

Kenya Power and Lighting Company VI 4.2 - 1 Contract A35

KENYA POWER Funded Project Technical Specifications and Drawings

4.2 SCOPE OF WORK - SUBSTATIONS

4.2.1 General

The Bidder shall examine the scope of works in this section in close connection with the other

documents and particulars forming these Bidding Documents.

Special attention shall be paid to General Specifications and Particular Technical

Specifications, in which the general technical requirements are specified. The drawings

enclosed in are for bidding purposes only.

If the Specifications and/or Drawings do not contain particulars of materials or goods, which

are necessary for the proper and safe completion, operation, and maintenance of the

equipment in question, all such materials shall be deemed to be included in the supply.

In the event of any conflict between the Drawings and the Specifications, the latter shall

prevail.

In the event of any conflict between scaled dimensions and figures on the Drawings, the

figures shall prevail.

Should the Bidder find discrepancies in or omissions from these Specifications or from the

other Documents, or should he be in doubt as to their meaning, he should immediately contact

the Project Manager for interpretation, clarification or correction thereof before submitting his

Bid. Such action shall, however, in no case be considered as a cause for altering the closing

date of the Bid.

The scope of work for equipment shall cover engineering design, manufacture, testing before

shipment and packing sea worthy or otherwise as required, delivery CIP site, of all equipment

as specified in the preceding chapters.

For substations contracted on turnkey basis the substation contractor shall be responsible for

design, material supply, transport, erection, and installation and commissioning as well as

having the full responsibility for civil works including design and construction of transformer

foundations and control building.

The Contractor shall install double bus bar gas insulated with the following bays feeders,

incomers and a bus coupler. The contractor shall interface the 33kV switch gear to the

existing 132/33 kV transformers and 33/11kv transformers.

The existing 33kV feeders interface connections, support structures shall be designed by the

contractor and approved by the project manager. The design shall meet the requirements for

highly saline environment and shall minimize outages for interface.

The existing building shall be used for the switch gear and its recommended that the

contractor shall familiarize himself with all the building design and status and carry out

necessary modifications and reinforcement.

Loose equipment for the Employer’s rehabilitation shall be complete with documentation and

ancillaries like programs, licences and programming tools.

4.1.4Contr A35-Section VI SOW-substation May 2014 KPLC

Kenya Power and Lighting Company VI 4.2 - 2 Contract A35

KENYA POWER Funded Project Technical Specifications and Drawings

Equipment that is to be dismantled and removed from existing substations is to be recovered

by the Contractor and deposited to sites within or in the immediate vicinity of each substation.

Such sites are to be designated by the Employer. The recovered equipment is to be taken over

by the Employer at these sites.

KPLC has a SCADA (Supervisory, Control & Data Acquisition) system that is controlled

from the Regional Control Centres& the National Control Centre. The National Control

Centre (NCC) is at Juja Rd and controls the entire transmission network & substations (ie

some 66kV, all 132kV, all 220kV & soon to be introduced 400kV stations.)

There are 4 regional control centres in total. These are located in the following locations; Juja

Rd (Nairobi region), Rabai (Coast region), Lessos (West Kenya region) & Kiganjo (Mt

Kenya region). These Regional Control Centres monitor & control the 11KV, 33kV & 66kV

Distribution networks &substations in their specific regions.

The Control Centres all run ABB’s Network Manager WS500 which is the software used for

monitoring & Control of all the incorporated substations. The Communication protocol

currently supported by KPLCs front end servers is ABBs PCU 400, for data telegram

exchange with Remote Terminal Units (RTUs). Whereas, the Station Control Management

Systems (SCMS) in the substations in its SCADA system are IEC 60870-5-101&IEC

60870-5-104.

The automated 33kV Distribution substation will be required to communicate with the front

end server (ABB’s PCU400) via communication protocols outlined above. The automated

sub-Station must communicate with the Regional Control Centre under which it shall be

monitored & controlled.

The interconnected KPLC’s telecommunications system is based on a backbone of SDH

STM1/4 terminal equipment, FOX 515 from ABB. A network management system (NMS)

for the telecommunication system has been installed at NCC.

4.2.2 Standard Substation

This section defines the standard substation components.

4.2.3 33 kV Switchgear GIS Type

4.2.3.1 33kV incomer Bay

1 (one) complete bay shall be equipped with:

a. 1 (one) set of GIS for 33kV incomer bay with circuit breaker, disconnectors,

earthing switch, fast acting earthing switch, current transformers, 3 phase voltage

transformers, busbars and busbars connections. Outdoor bushings, transition bus and

surge diverters.

b. 1 (one) set of control/protection panel

c. 1 (one) bay control unit with proper display, for measurements (V,I,MVAR,MW)

d. 1 (one) multifunctional protection unit as per 4.1.2.9.2. Section VI Particular

Technical specifications substations control, and Protection

e. overcurrent protection relay.

f. 1 (one) lock-out trip relay with electrical/hand reset facilities/ scada rest.

4.1.4Contr A35-Section VI SOW-substation May 2014 KPLC

Kenya Power and Lighting Company VI 4.2 - 3 Contract A35

KENYA POWER Funded Project Technical Specifications and Drawings

g. 1 (one) lot of necessary interposing relays, MCB’s, terminal blocks and wiring to

form a complete operative bay control. The control scheme shall be prepared for

SCADA operation

h. 33kV Incomer copper cable 1000mm2

4.2.3.2 33kV Feeder Bay

1(one) complete bay shall be equipped with:

a. 1 (one) set of GIS for line bay with circuit breaker, disconnectors, earthing

switch, fast acting earthing switch, current transformers, 3 phase voltage

transformers, busbars and busbar connections. Outdoor bushings, transition bus and

surge diverters

b. 1 (one) set of control/protection panel

c. 1 (one) bay control unit with display and measuring functions

d. 1 (one) multifunctional protection unit as per 4.1.2.9.2

e. 1 (one) lock-out trip relay with electrical/hand reset facilities/scada reset.

f. 1 (one) lot of necessary interposing relays, MCB’s, terminal blocks and wiring to

form a complete operative bay control. The control scheme shall be prepared for

SCADA operation.

g. Feeder copper cable 800mm2(GIS to transition structure)

4.2.3.3 33kv Bus Bar Protection

1 (one) bus bar protection unit included in the control panel for 33 kV double busbars.

4.2.4 11 kV Switchgear Outdoor Type

4.2.4.1 11 kV Transformer Bay

1 (one) complete bay shall be equipped with:

(a) 1 (one) Autorecloser/circuit breaker

(b) 1 (one) earthing switch

(c) 1 (one) set of busbars

(d) 1 (one) set of current transformers

(e) 1 (one) set of surge diverters

(f) 3 (three) sets of air break switches

(g) 1 (one) neutral current transformer

(h) 1 (one) bay control unit with display and measuring functions

(i) 1 (one) restricted fault relay function

(j) 1 (one) neutral point earth fault relay function

(k) 1 (one) lock-out trip relay with electrical/hand reset facilities/scada reset

(l) 1 (one) lot of necessary interposing relays, MCB’s, terminal blocks and wiring to

form a complete operative bay control. The control scheme shall be prepared for

SCADA operation.

(m) 1 (one) set of voltage transformers (with a facility for primary isolation)

4.2.4.2 11 kV Feeder Bay

1 (one) complete bay shall be equipped with:

(a) 1 (one) Autorecloser/circuit breaker

4.1.4Contr A35-Section VI SOW-substation May 2014 KPLC

Kenya Power and Lighting Company VI 4.2 - 4 Contract A35

KENYA POWER Funded Project Technical Specifications and Drawings

(b) 1 (one) earthing switch

(c) 1 (one) set of busbars

(d) 1 (one) set of current transformers

(e) 1 (one) set of surge diverters

(f) 1 (one) bay control unit with display and measuring functions

(g) 1 (one) 3-phase over current relay function with auto re-close function. The auto-

reclose function must be selectable with an external switch

(h) 1 (one) Earth fault relay function

(i) 1 (one) sensitive Earth fault function

(j) 1 (one) restricted fault relay function (if not provided on the HV transformer bay

panel)

(k) 1 (one) lot of necessary interposing relays, MCB’s, terminal blocks and wiring to

form a complete operative bay control. The control scheme shall be prepared for

SCADA operation.

Note: 11KV Capacitor bank switchgear shall be equipped with the necessary protection and

control relays for Capacitor banks. .

4.2.4.3 Auxiliary Transformer bay

1 (one) complete bay equipped with:

(a) 1 (one) set of expulsion fuses

(b) 1 (one) set of busbars jumpers

4.2.5 11 kV Switchgear Indoor Type

4.2.5.1 Switch Board Panel for 11 kV Transformer Bay

1 (one) complete bay shall be equipped with:

a) 1 (one) Withdrawable circuit breaker

b) 1 (one) earthing switch

c) 1 (one) set of busbars

d) 1 (one) set of current transformers

e) 1 (one) bay control unit with display and measuring functions

f) 1 (one) restricted fault relay function

g) 1 (one) neutral point earth fault relay function

h) 1 (one) lock-out trip relay with electrical/hand reset facilities

i) 1 (one) lot of necessary interposing relays, MCB’s, terminal blocks and wiring to form a

complete operative bay control. The control scheme shall be prepared for SCADA

operation.

j) 1 (one) set of voltage transformers (with a facility for primary isolation)

4.2.5.2 Switch Board Panel for 11 kV Feeder Indoor panel

1 (one) complete bay shall be equipped with:

a) 1 (one) circuit breaker

b) 1 (one) earthing switch

c) 1 (one) set of busbars

d) 1 (one) set of current transformers

e) 1 (one) bay control unit with display and measuring functions

4.1.4Contr A35-Section VI SOW-substation May 2014 KPLC

Kenya Power and Lighting Company VI 4.2 - 5 Contract A35

KENYA POWER Funded Project Technical Specifications and Drawings

f) 1 (one) 3-phase over current relay function with auto re-close function. The auto-reclose

function must be selectable with an external switch

g) 1 (one) Earth fault relay function

h) 1 (one) sensitive Earth fault function

i) 1 (one) lot of necessary interposing relays, MCB’s, terminal blocks and wiring to form a

complete operative bay control. The control scheme shall be prepared for SCADA

operation.

4.2.5.3 Switch Board Panel for Indoor Bus- Sectionaliser

1 (one) complete bay shall be equipped with:

(a) 1 (one) circuit breaker

(b) 1 (one) set of protection current transformers.

(c) 2 (two) earthing switches (one on each busbar section if not located elsewhere)

(d) 1 (one) set of busbars including droppers and risers

(e) 2 (two) set of voltage transformers (one on each busbar section if not located elsewhere)

(f) 1 (one) bay control unit with display

(g) 1 (one) overcurrent function and 1 (one) relay function

(h) 1 (one) lot of necessary interposing relays, MCB’s, terminal blocks and wiring to form a

complete operative bay control. The control scheme shall be prepared for remote

operation.

4.2.5.4 Switch Board Panel for Auxiliary Transformer

1 (one) complete bay equipped with:

a) 1 (one) fuse switch disconnector, manual

b) 1 (one) set of fuses

c) 1 (one) earthing switch

d) 1 (one) bay control unit

e) 1 (one) set of busbars

f) 1 (one) set of wiring, terminal blocks, etc. to form a complete bay control.

4.2.6 Control, Protection, Metering and Signalling

4.2.6.1 Substation Automation System

General

1 (one) lot complete system (equipment and software) for substation control.

To the extent the internal control and interlocking system for the equipment supplied is not

included for that particular equipment, it shall be included herein. All interconnections needed

to form a complete installation shall also be included herein.

The control system specified hereunder shall include all necessary equipment for control,

protection, metering and signalling. The system shall include all instruments, meters,

switches, position indicators, inscriptions and mimic diagrams, protective and auxiliary

relays, terminal blocks, internal wiring and any other equipment required to form a complete

installation.

4.1.4Contr A35-Section VI SOW-substation May 2014 KPLC

Kenya Power and Lighting Company VI 4.2 - 6 Contract A35

KENYA POWER Funded Project Technical Specifications and Drawings

Drawings showing the control system, protection units and the boards as they are proposed

shall be supplied with the Bid.

The space needed for the boards should not exceed the available space.

Information defining the internal local control communication protocol shall be submitted with

the Bid.

Complete sets of schematic diagrams for control, protection, indication, metering, signalling,

alarms, etc. shall be supplied as part of the project and shall be subject to the Project

Manager's approval.

The requirements as to submission of diagrams, drawings and other documents with the Bid

and after award of Contract are stated in the standard form of contract.

4.2.6.1.1 Scope SCADA/SAS.

The scope of work for the SCADA portion shall include but not limited to

Complete supply, installation and commissioning of SAS as described in specifications including

UPS.

Supply of one time licences for SAS Application, Data Engineering application, system

configuration, modification and extensions software.

Integration of substation to existing SCADA/EMS Central system.

Complete Control and Protection system as described in specifications

Spares and Training and other Services as described in this detailed specifications;

Base Radio as described in the specifications

The supply and services to be performed by the Contractor shall comprise the design, manufacture,

factory testing, packing, transport, insurance, unloading, storage on Site, construction works and

erection, corrosion protection, site testing, submission of documentation, commissioning, training of

KPLC’s personnel and warranty of the works.

The proposed SA system for the above work should offer at least the following functionality:

Full operational control, reporting, alarm and indication facilities for the substation from

the RCC’s (Supervisory level).

Full operational control, alarm and indication facilities for the substation from the Human

Machine interface (HMI) workstations in the substation control room (Substation Level).

Operational control of each new circuit/bay from the protection relay panel using the bay

control unit LCD display (Bay level).

Control of each item of plant from the Local Control Cubicle (LCC) (Local Level)

The control facilities from each control point are to be interlocked (hardwired) to prevent

operation of any device simultaneously from more than one control point.

At least one fully operational control point shall remain available in the event of a single

equipment or communications failure.

Complete facilities must exist for the proper lockout and maintenance tagging of circuits

and plant items to ensure the safety of personnel and the security of the system

The SA system shall use open communication protocols and be readily interfaced with

third part devices operating on open protocols. The Tenderer shall describe such interfaces

and provide an experience list of devices with which the offered control system has

previously been interfaced.

4.1.4Contr A35-Section VI SOW-substation May 2014 KPLC

Kenya Power and Lighting Company VI 4.2 - 7 Contract A35

KENYA POWER Funded Project Technical Specifications and Drawings

The SCMS shall typically include:

Station Level:

2 independent Gateway (Main and Hot-standby) for communications to the SCADA

system.

1 Operator Workstation/HMI, and the complete workplace (desk, chair).

Color printer. To print screen shots

Operator log printer

Satellite clock, complete with GPS Receiver, Antenna and necessary time synchronization

ports.

Interface for laptop computer for maintenance, information transfer and emergency HMI

Laptop Computer for maintenance, information transfer and emergency HMI

UPS system for SCMS.

Communication network equipment [station (system) LAN, Field Communication

Network, Various optical couplers, etc.].

interface for control and monitoring of the circuit/bay

Interface for protection devices that cannot directly interface with the substation LAN

4.2.6.2 Control and Measuring Cables

(a) All external cables, conventional or fibre optical, for control, protection, measuring,

indication, etc., for the complete plant. Wiring between the switchyard apparatus,

transformers, the board(s) and the control system in the control building and the

interconnections between the various apparatus in the switchyard shall be included.

4.2.6.3 Telecommunications

a) In order for the SCADA data to be transferred to the Regional control centres, the

bidder shall design and commission an appropriate communication system based on

Fibre or other approved communication media for data and speech requirement.

Equipment supplied shall be digital and latest technology and shall comply to the latest

ITU-T, IEC, ITU-R, IEEE and ETSI standards.

It is required that one remote subscriber be implemented in each substation.

Interface for data transmission shall be according to ITU-T recommendation V.24 or

V.35

Bit error rates of 1x10-6 shall not be exceeded.

b) It is the responsibility of the contractor to interconnect with existing SCADA and

Telecommunications system. However use and extension of existing infrastructure

where possible shall be encouraged.

c) The Tenderer shall acquaint himself with all the sites and determine the requirements for

towers or masts to suit his design. When a new tower or mast is necessary, the Tenderer

shall supply drawings for the proposed installation. All towers shall be 36 m and self

supporting. The tenderer shall provide details of loading and guy stresses for masts or

towers to be erected on buildings. All antennae mounting components including wave-

guides, cables, cable clamps and external cable connectors shall be specified.

d) Where PLCs are to used or where the T-offs affect existing PLC communication links,

blocking line-traps including support strucures shall be in scope of supply.

e) All communications equipment installed in the country must be type approved by the

Communications Commission of Kenya (CCK). The Contractor will obtain the type

approval.

4.1.4Contr A35-Section VI SOW-substation May 2014 KPLC

Kenya Power and Lighting Company VI 4.2 - 8 Contract A35

KENYA POWER Funded Project Technical Specifications and Drawings

The CCK has to be consulted and give approval for each new project and an application

has to be submitted stating the location of the sites and request for the frequencies to be

used. Unless otherwise stated this application for frequencies is normally done by

KPLC.

The radio frequency plan shall be prepared by the Contractor and closely coordinated

with KPLC during the project design stage. All path surveys shall be carried out by

contractor.

f) The Contractor shall provide a list of recommended spares, the quantities and prices to

last for a period of five (5) years after expiry of guarantee period.

g) The contractor shall offer training for four (4) technical appointees of the employer for 2

weeks at manufacturer’s premises. Terms and conditions similar to 4.2.15

h) The contractor shall provide necessary configuration software pre-installed on a

maintenance laptop with a onetime software license.

4.2.6.3.1 Scope of works - Telecommunication

The scope as described shall include detailed system design, manufacture, and supply, installation,

testing, commissioning, remedying of defects, and maintaining the works during the defects liability

period and any incidental work necessary for the proper completion of the work in accordance with this

contract. Scope shall include integration of STM-4, to the existing KPLC Network Management

System. In some cases there shall be need to upgrade existing Telecommunication equipment in order to

achieve data and speech routing to Regional and National control centres. Survey and necessary

preparation works on existing systems, Equipment and substations to achieve specified functionality

shall be in the scope of supply. Contractors shall be required to submit for approval detailed design of

system before manufacture.

The STM 4 equipment shall include Tele-protection modules (4 Command), High Speed Ethernet

modules and 1+1 protection.

Necessary upgrade of communication and SCADA Front Ends (PCUs) equipment at terminal stations

and at Control centres shall achieve complete Data and Speech to RCC/NCC shall be included in scope.

In addition all substations (irrespective of whether SCADA functionality to control centre is

established) shall be equipped with a Base Radio capable of communicating with the ASTRO trunking

radio system for use during switching operations. Where OLTEs are the terminal equipment, additional

Ethernet capability shall be established to cater for other corporate data. All stations shall be equipped

with two (2N0.) telephone extensions originating from existing PAXes in Regional control centres.

All communication equipment supplied under this project shall be type approved by the regulator,

Communication Commission of Kenya (CCK) and the Kenya Bureau of Standards (KBS) where

applicable. It is the responsibility of the contractor to obtain these necessary approvals.

The type of required communication link shall be detailed in scope of supply for individual stations.

The links to be established include the following;

New Substation Terminal station Proposed Existing Control Centre

communication Equipment in substation

media Terminal reports to

station

1 kipevu Rabai OPGW Existing FOX 515 RCC

4.1.4Contr A35-Section VI SOW-substation May 2014 KPLC

Kenya Power and Lighting Company VI 4.2 - 9 Contract A35

KENYA POWER Funded Project Technical Specifications and Drawings

4.2.7 Auxiliary AC Supply Equipment

4.2.7.1 Main AC Distribution Board

1 (one) main distribution board designed for minimum 200 A with the necessary number of

panels for:

(a) 1 (one) circuit breaker, manual operated, minimum 200 A, for the feeder from the station

supply transformer.

(b) 2 (two) current transformers 200/1/1 A with two cores, one core for measuring and one

for protection.

(c) 1 (one) constant time overcurrent relay.

(d) 1 (one) earth fault relay.

(e) 1 (one) A-meter function with selector switch.

(f) 1 (one) V-meter function with selector switch.

(g) 1 (one) lot of feeder circuit breakers with electro-magnetic and thermal releases. The

breaker ratings shall be chosen to suit the different consumers to be connected. 20% of

the breakers of each size shall be spare and readily mounted.

4.2.7.2 Sub-distribution Boards and Panels

(a) 1 (one) lot of all necessary sub-distribution boards and panels (including the distribution

panel for lighting and small power of the control building).

The boards shall be completely equipped with busbars, circuit breakers, miniature circuit

breakers etc. Contactors, motor starters, instruments, operating switches, push buttons,

indicating lamps, etc., shall be included whenever required. 20% of the breakers of each size

shall be spare and readily mounted.

4.2.7.3 Cables

(a) 1 (one) lot of all necessary armoured power and control cables for supply to the main

distribution board and to the sub-distribution boards, panels and equipment except for

the cables for lighting and small power which are included in the civil Goods under

separate contract.

4.2.8 DC Supply System

4.2.8.1 Battery

i. 1 (one) 110 V battery. Capacity at least 200 Ah/10h for substations with more than 10

MVA installation of transformer capacity

ii. The 48V batteries shall be included in the bid for communication equipment and the

RTU. The battery shall be at least 100A/10Ah

The capacities to be recommended by the Bidder, based upon the calculated consumption

considering a fully developed substation.

Batteries shall be installed in separate room with EX proof ventilation fan (for 110 V batteries

only).

4.2.8.2 Charger

(a) 1 (one) DC charger for the 110 V battery.

4.1.4Contr A35-Section VI SOW-substation May 2014 KPLC

Kenya Power and Lighting Company VI 4.2 - 10 Contract A35

KENYA POWER Funded Project Technical Specifications and Drawings

(b) 1 (one) DC charger for the 48 V Battery.

The chargers shall be complete with instruments, breakers on AC and DC side, and

protection.

4.2.8.3 Switchboard

1 (one) switchboard 110 V DC.

The board shall have:

(a) 1 (one) circuit breaker with magnetic and thermal release for the feeder from earache

charger and battery.

(b) 1 (one) A-meter with shunt for each battery.

(c) 1 (one) V-meter with selector switch for the voltage between the poles and between poles

and earth for each battery.

(d) 1 (one) set of contacts on the front for banana jacks for the battery voltage and earth.

(e) 1 (one) battery monitoring devices with alarm contacts.

(f) 1 (one) lot of all necessary circuit breakers and miniature circuit breakers for the outgoing

feeders and circuits.

20% of the breakers of any size shall be spare and readily mounted.

4.2.8.4 Battery Conductors and Fuses

(a) 1 (one) set of conductors for the battery in the battery room.

(b) 2 (two) single pole fuse boxes with main fuses for the battery, placed on the wall outside

of the battery room, and two fuses for the battery monitoring device.

4.2.8.5 Sub-distribution Boards and Panels

(a) 1 (one) lot of all necessary sub-distribution boards and panels.

The boards shall be completely equipped with busbars, miniature circuit breakers, fuses, etc.

Contactors, motor starters, instruments, operating switches, push buttons, indicating lamps,

under-voltage relays with alarm contact, etc., shall be included whenever needed.

4.2.8.6 Cables

(a) 1 (one) lot of all necessary DC power supply cables, including wiring to the apparatus in

the switchyard.

4.2.9 Earthing System

An earthing network shall be installed comprising the following:

(a) 1 (one) lot of underground earthing system covering the platform and control building

with risers

(b) 1 (one) complete set of "above-floor" earthing system for the control building, as

applicable, with connections to the risers from the under-ground system.

4.1.4Contr A35-Section VI SOW-substation May 2014 KPLC

Kenya Power and Lighting Company VI 4.2 - 11 Contract A35

KENYA POWER Funded Project Technical Specifications and Drawings

4.2.10 Ancillary Equipment

4.2.10.1 Station Equipment

(a) 2 (two) self-contained, rechargeable, portable hand-held lights.

(b) 1 (one) audible alarm system with the necessary wiring.

4.2.10.2 Earthing Devices

(a) 1 (one) set of three phase portable earthing devices for 33kv with operating rods suitable

for earthing of the bay conductors and busbars.

(b) 1 (one) set of voltage indicator for 33kV with audible and visual indication for voltage

4.2.10.3 Cable Accessories

(a) 1 (one) lot of all connecting material, cable boxes and material for fixing the cables.

Terminals and terminal labels to the extent that this is not included in other sections.

4.2.10.4 Racks, Conduits, Ducts, etc

(a) 1 (one) lot of all cables, racks and trays to the extent necessary for the proper

distribution of cables.

All the conduits and protection tubes, wherever cables may deteriorate or where cable laying

may otherwise present difficulties.

4.2.11 Civil Works

4.2.11.1 Switchgear buildings

Switchgear building has been constructed.

Control Panels and medium voltage indoor switchgears of different Voltage levels shall be

installed in separate rooms

4.2.11.2 Cable Trenches

Cable trenches shall be constructed as specified in particular specifications and in scope of

work.

4.2.12 Training in control (SAS), Telecommunication and protection system

The training includes travel for the 4 (four) KPLC engineers as well as all course material and

other expenses shall be catered by the Contractor. The training shall be held at the

manufacturer's place. The training shall cover design, application, testing, commissioning and

maintenance of the relevant digital control and protection systems. The training course shall

have a minimum of 2 (two) weeks duration for SAS and Protection and one week for

communication. The cost of per diem and accommodation shall be met by KPLC.

4.1.4Contr A35-Section VI SOW-substation May 2014 KPLC

Kenya Power and Lighting Company VI 4.2 - 12 Contract A35

KENYA POWER Funded Project Technical Specifications and Drawings

4.2.13 Factory Acceptance Test

The Contractor shall arrange for 2 participants from KPLC and the Project Manager to

witness tests of major equipment listed below in the manufacturer’s plant. All routine tests

shall be carried out in the presence of the Employer’s representatives. The representatives

shall approve shipment of the equipment if they are satisfied that the requirements of the

specification are fully met

The Contractor shall arrange and meet the full cost of the air tickets and local transportation

33kV GIS switch gears disconnectors,earth switch, CTs, VTs and CBs

Protection and control system

Power cables

SAS

Telecommunications Equipment

FAT shall be carried out as prescribed in the particular technical specifications of the

equipment. The cost of per diem and accommodation shall be met by KPLC.

4.2.14 Test Equipment (TS –001)

Lap top computers: Two units set up with comprehensive software. The pc shall be

supplied with all the necessary accessories and ports and loaded with latest operating

system. The Lap top must be able to run all the relay and equipment software’s

supplied under the contract. The lap top specifications shall be approved by the

project manager. The Test equipment for Telecommunications shall be as described

in 4.1.6

4.2.15 Final documentation

As built drawings: 5 paper copies delivered in binders

3 CD-ROM copy (all drawings in auto cad)

1 set of transparencies

Operation and maintenance manuals: 2 copies per equipment

4.2.16 Site Offices and site facilities(LS-010, -011)

At the location where the Contractor will establish his main site administration:

At the location where the Contractor will establish his main site administration, an

office for site supervisors from the Project Manager with basic office furniture,

internet, telephone and access/use of fax and copier shall be provided by the

contractor for the implementation period

The contractor shall provide mobile phone for coordination of activities with project

manager and KES 10,000(ten thousand) monthly.

4.2.17 KIPEVU

Kipevu: New substation,

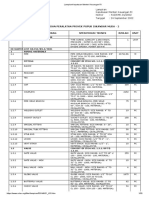

Item no. Item Description Unit Quantity

KIPEVU, 33KV GIS S/S

KIPEVU-001 Nineteen(19) bay Gas insulated 33KV

switchgear ( forteen(14) 33KV outgoing lines

and three(3) 33KV transformers incomers and

two(2) bus coupler ) double busbar

configuration. With current transformers, Lot 1

4.1.4Contr A35-Section VI SOW-substation May 2014 KPLC

Kenya Power and Lighting Company VI 4.2 - 13 Contract A35

KENYA POWER Funded Project Technical Specifications and Drawings

Item no. Item Description Unit Quantity

voltage transformers, circuit breakers,

disconnectors, earth switch, fast acting earth

switch, busbar materials and steel structures

for support

KIPEVU-002 33/11kV Transformer control and protection

panel pc 2

KIPEVU-003 33kv line protection and control panel pc 12

KIPEVU-004 33kv Incomer protection and control panel pc 3

KIPEVU-005 33kv bus coupler and busbar protection panel pc 2

KIPEVU-006 Fourteen(14) panel 11 kV switchboard (with 2

Incomer panels, 1 bus coupler, 8feeder panels,

2 bus PT panels, 2 auxiliary Tx panels) lot 1

KIPEVU-007 Substation Automation System (SAS) LOT 1

KIPEVU-008 Control and measuring cables lot 1

KIPEVU-009 Auxiliary AC supply lot 1

KIPEVU-010 DC supply System lot 1

KIPEVU-011 Earthing system lot 1

KIPEVU-012 11/0.415kV 100KVA station transformers pc 2

KIPEVU-013 Ancillary Equipment lot 1

KIPEVU-014 Lightning protection system lot 1

KIPEVU-015 Optical terminal equipment type SDH STM-4

and associated materials for kipevu lot 1

KIPEVU-016 33KV incomer cables in 1000mmsq s/c Cu

2.5

including their termination kits KM

KIPEVU-017 33KV Feeder cables in 800mmsq s/c Cu

10

including their termination kits KM

KIPEVU- 018 Telecommunication system and associated

1

accessories(radio/fiber based communication) Lot

KIPEVU-019 33 kv surge arresters pc 50

KIPEVU-020 Transition buses with support structures Lot 1

KIPEVU-021 33KV line cables in 630mmsq s/c Cu including

20

their termination kits KM

KIPEVU-022 11KV incomer cables in 630mmsq s/c Cu

3

including their termination kits KM

KIPEVU-023 11KV line cables in 300mmsq 3/c Cu including

4

their termination kits KM

KIPEVU-019 11 kv surge arresters pc 40

Works:

KIPEVU-201 Civil works (cables) and switchgear building

1

rehabilitation & reinforcement. lot

4.2.18 Mandatory Spare Parts and Tools

All spares and tools specified below are to be of makes and types that match with the

equipment in the scope of works, to the extent possible. Spares and Tools are to be delivered

to KPLC's central stores in Nairobi.

4.1.4Contr A35-Section VI SOW-substation May 2014 KPLC

Kenya Power and Lighting Company VI 4.2 - 14 Contract A35

KENYA POWER Funded Project Technical Specifications and Drawings

4.2.18.1 For 33KV GIS

The following spares and tools are to be provided for the GIS:

Item no. Item Description Quantity

Tools

TT-001 Gantry crane 1 pc

TT-002 Gas filling equipment 1pc

TT-003 Gas vacuuming equipment 1pc

TT-004 SF6 Gas processing unit 1pc

TT-005 SF6 spare Gas 10 cylinders

4.2.18.2 For Substations

Item no. Item Description Quantity

Spares

SS-001 33kV GIS Breaker 2

SS-002 33kv main and backup line protection units 2

SS-003 33kV GIS dis-connector 2

SS-004 33kV GIS Current Transformer 2

SS-005 33kV GIS Voltage Transformers 2

SS-006 Transformer Protection unit for 33/11 kV transformer bay 1

SS-007 Bay control unit 2

SS-008 SCADA and Telecommunications interface unit of each type 1 lot

as described in 4.1.6

SS-009 Auxiliary relays of matching type to ones used in offered 5

equipment, assorted

SS-010 (Control) contactors of matching type to ones used in 5

offered equipment, assorted

SS-011 Assorted MCB's for AC and DC distribution boards 10

SS-012 Trip coils for each type of Circuit Breaker 5

SS-013 Close coils for each type of Circuit Breaker 5

SS-014 Indicating lamps 10

SS-015 Interlocking coils for circuit breakers 4

SS-016 Earth switch interlocking coils 4

SS-017 33KV cable termination kit 3

SS-018 SAS and telecommunication tools 1 set

SS-019 Ten(10) 11kV tripping coils 10

SS-020 Ten(10) 11kV closing coils 10

SS-021 Four(4) 11kV earth switch interlocking coils 4

SS-022 Ten(10) 11kV indication lamps of each type 10

Tools for substations

TS-001 Lap tops 2

4.2.19 Recommended Spare Parts and Tools

The Bidder shall recommend additional spares and tools suitable for the offered equipment.

The prices are to be entered in Price schedule No. 6, which shall not be added to the Grand

4.1.4Contr A35-Section VI SOW-substation May 2014 KPLC

Kenya Power and Lighting Company VI 4.2 - 15 Contract A35

KENYA POWER Funded Project Technical Specifications and Drawings

Summary Prices. The recommended spares and tools are to be specifically discussed and

agreed on during contract negotiations

4.1.4Contr A35-Section VI SOW-substation May 2014 KPLC

You might also like

- Enquiry 33404 - Part 4 - Engineering Documents ListDocument98 pagesEnquiry 33404 - Part 4 - Engineering Documents ListRamahNo ratings yet

- (PCM) - Aplng Upstream Phase 1 - Custody Metering Skids - Technical SpecificationDocument37 pages(PCM) - Aplng Upstream Phase 1 - Custody Metering Skids - Technical SpecificationChrisNo ratings yet

- Appendix A - Scope of Work - A4J8F3Document19 pagesAppendix A - Scope of Work - A4J8F3Donald JabagatNo ratings yet

- OCTO-DC-Net Standards and Practices For Comms Environments v1.4Document87 pagesOCTO-DC-Net Standards and Practices For Comms Environments v1.4satheeskrsnaNo ratings yet

- Newfoundland Power Service and Metering Guide: Date Rev. DescriptionDocument53 pagesNewfoundland Power Service and Metering Guide: Date Rev. Descriptionparallax1957No ratings yet

- Hunter Water Elect Design SpecDocument82 pagesHunter Water Elect Design SpecnitinrajuNo ratings yet

- Planning Requirements For Underground Residential DevelopmentsDocument26 pagesPlanning Requirements For Underground Residential DevelopmentsRickNo ratings yet

- Electrical Design CriteriaDocument533 pagesElectrical Design CriteriaHimdad Bahri100% (3)

- Vessels Operating in Low Temperature Environments: Guide ForDocument248 pagesVessels Operating in Low Temperature Environments: Guide ForramkumarNo ratings yet

- PNOC Project 2023-06-165-SpecificationDocument307 pagesPNOC Project 2023-06-165-SpecificationelciNo ratings yet

- Technical Standards Manual2010 PDFDocument72 pagesTechnical Standards Manual2010 PDFFilip StojkovskiNo ratings yet

- Wärtsilä Propac Project GuideDocument186 pagesWärtsilä Propac Project Guideannabogatyreva27No ratings yet

- Installation Guide: RADWIN 5000Document72 pagesInstallation Guide: RADWIN 5000DicksonNo ratings yet

- ABS Vessels Operating in Very Low Temperatures GuideDocument246 pagesABS Vessels Operating in Very Low Temperatures GuideCharalampos ChatzivasileiouNo ratings yet

- Solar PV Connection Guidelines For Customers and InstallersDocument42 pagesSolar PV Connection Guidelines For Customers and Installersabdulla100% (1)

- Hardware Manual: A50-031170-001 GE ISSUE 3.0 November 2012Document150 pagesHardware Manual: A50-031170-001 GE ISSUE 3.0 November 2012atilacezarNo ratings yet

- S-LV-SWG-Outdoor Ds - 00Document51 pagesS-LV-SWG-Outdoor Ds - 00Sachin PrakashNo ratings yet

- PlumbingDocument115 pagesPlumbingLance Rallione FariñasNo ratings yet

- DF-2 User ManualDocument120 pagesDF-2 User ManualAmir hosain AsadiNo ratings yet

- SL1000 Hardware Manual 5 0 GEDocument154 pagesSL1000 Hardware Manual 5 0 GEpeponetasNo ratings yet

- 6 Volume Technical SpecificationsDocument120 pages6 Volume Technical SpecificationssaratNo ratings yet

- DIVISION 26 - ElectricalDocument283 pagesDIVISION 26 - ElectricalsadoonNo ratings yet

- Substation Construction ManualDocument63 pagesSubstation Construction ManualAnicet VincentNo ratings yet

- Planning Guide Line Sep 2003Document171 pagesPlanning Guide Line Sep 2003Engr AHmed Ali DallNo ratings yet

- Structures Design ManualDocument171 pagesStructures Design ManualAshebir AjemaNo ratings yet

- Pipeline Transportation Systems For Liquids and Slurries: ASME B31.4-2016Document6 pagesPipeline Transportation Systems For Liquids and Slurries: ASME B31.4-2016gembulflow815350% (2)

- Electrical Equipment CodeDocument3 pagesElectrical Equipment CodemmshtNo ratings yet

- Siemens SAS61.03U User GuideDocument50 pagesSiemens SAS61.03U User GuideSaulo TrejoNo ratings yet

- LWUA Vol2. Reformat PDFDocument274 pagesLWUA Vol2. Reformat PDFKenny Wong100% (6)

- NES 769 Approval System For Welding Consumables For Structural Steels Category 2Document74 pagesNES 769 Approval System For Welding Consumables For Structural Steels Category 2JEORJENo ratings yet

- A7670 ESE Installation ManualDocument42 pagesA7670 ESE Installation ManualTran Tuan NghiaNo ratings yet

- SOW-subst R1Document40 pagesSOW-subst R1cherif yahyaouiNo ratings yet

- Tech Spec 11kV Indoor Metal Enclosed Switch GearDocument46 pagesTech Spec 11kV Indoor Metal Enclosed Switch Gearravi23454No ratings yet

- ADB-401.A Volume-II PDFDocument173 pagesADB-401.A Volume-II PDFbladdeeNo ratings yet

- B23-11 - TERMPOL Surveys and Studies - Section 3.10 - Site Plans and Technical Data A1Z6J5Document95 pagesB23-11 - TERMPOL Surveys and Studies - Section 3.10 - Site Plans and Technical Data A1Z6J5odongo johnNo ratings yet

- Draft Morka - Gircha - Chencha Quality Audit ReportDocument45 pagesDraft Morka - Gircha - Chencha Quality Audit ReportYosef BrukNo ratings yet

- NEC SL1100 Hardware ManualDocument158 pagesNEC SL1100 Hardware ManualsandakanNo ratings yet

- 5 Volume Technical SpecificationsDocument434 pages5 Volume Technical Specificationssaravanan jNo ratings yet

- 003 SD 01Document176 pages003 SD 01Rishikesh GunjalNo ratings yet

- CX1100-00xx: Hardware DocumentationDocument78 pagesCX1100-00xx: Hardware DocumentationThiago FernandesNo ratings yet

- Technical Standards AND Specification Manual FOR Gas Distribution SystemsDocument25 pagesTechnical Standards AND Specification Manual FOR Gas Distribution SystemsTiffany DavisNo ratings yet

- EHV Handbook ENG PDFDocument46 pagesEHV Handbook ENG PDFAbhinav SinhaNo ratings yet

- Pipelines Design PhilosophyDocument29 pagesPipelines Design PhilosophyDaniel Dambo100% (4)

- Design Req Gas Service InstallationDocument51 pagesDesign Req Gas Service InstallationShijo PodiyanNo ratings yet

- 6 HLD For Ran v10 PDFDocument167 pages6 HLD For Ran v10 PDFyasirNo ratings yet

- 2.2 - TS - Technical SpecificationDocument71 pages2.2 - TS - Technical SpecificationMahendra TrianugrahNo ratings yet

- Q2118121 01 El CRT 00001Document25 pagesQ2118121 01 El CRT 00001haitam terribleNo ratings yet

- Neca 331 - First DraftDocument83 pagesNeca 331 - First DraftMohammed IrfanNo ratings yet

- MoC Specification #4 01 Dec 13Document66 pagesMoC Specification #4 01 Dec 13Prashanth Gopinath44% (9)

- Department of Defense Interface StandardDocument272 pagesDepartment of Defense Interface StandardaparnaNo ratings yet

- SEWA-E-C-001 Fiber Optic CableDocument34 pagesSEWA-E-C-001 Fiber Optic Cablezaheer2931100% (1)

- Hardware - 3ADR010278, 3, en - US, CAA-Merger-2 - V3Document1,029 pagesHardware - 3ADR010278, 3, en - US, CAA-Merger-2 - V3MocaNo ratings yet

- RP30 1Document132 pagesRP30 1mohamedfirozNo ratings yet

- RFPPrecision AC020418Document57 pagesRFPPrecision AC020418ShazmanNo ratings yet

- Engineering Docummentation CI1145 008727 B en PDFDocument100 pagesEngineering Docummentation CI1145 008727 B en PDFEl KhanNo ratings yet

- Ml11180a100 PDFDocument828 pagesMl11180a100 PDFmuhammad AmjadNo ratings yet

- Basic of Train NingDocument39 pagesBasic of Train NingHossam AlzubairyNo ratings yet

- Corrigendum 18 Totenderno 6522Document1 pageCorrigendum 18 Totenderno 6522Hossam AlzubairyNo ratings yet

- Protection Manual For Precommissioning-6Document26 pagesProtection Manual For Precommissioning-6supermannon100% (1)

- How To Apply Capacitors To Low Voltage Power Systems.Document13 pagesHow To Apply Capacitors To Low Voltage Power Systems.Ahmed Reda Abdou MohamedNo ratings yet

- Substation Grounding Study Specification: Name of Station Name of Location Number of Lines Number of CircuitsDocument7 pagesSubstation Grounding Study Specification: Name of Station Name of Location Number of Lines Number of CircuitsDony SaputraNo ratings yet

- REC GST Registration Details 01092020Document2 pagesREC GST Registration Details 01092020Hossam AlzubairyNo ratings yet

- Doctor of Osteopathic Medicine, Expected May 2008: Studentdoctor@umdnj - EduDocument3 pagesDoctor of Osteopathic Medicine, Expected May 2008: Studentdoctor@umdnj - EduHosam AlzubairyNo ratings yet

- ASEAN Scholarship For Nalanda University 2021 - SSDocument3 pagesASEAN Scholarship For Nalanda University 2021 - SSnurul qamariahNo ratings yet

- ABB Drives - Software Manual C PDFDocument0 pagesABB Drives - Software Manual C PDFvasilev_darkoNo ratings yet

- Corp Taxation GST Helpdesk DT 08-09-2020Document1 pageCorp Taxation GST Helpdesk DT 08-09-2020Hossam AlzubairyNo ratings yet

- Spaj 135 C Combined Overcurrent and Earth-Fault Relay: User S Manual and Technical DescriptionDocument56 pagesSpaj 135 C Combined Overcurrent and Earth-Fault Relay: User S Manual and Technical DescriptionHossam AlzubairyNo ratings yet

- Nuclear Power Corporation of India LimitedDocument9 pagesNuclear Power Corporation of India LimitedChandan KumarNo ratings yet

- Fowler Westrup India PVT LTD: Initiatives Through Namma HalliDocument2 pagesFowler Westrup India PVT LTD: Initiatives Through Namma HalliHossam AlzubairyNo ratings yet

- ASEAN Scholarship For Nalanda University 2021 - SSDocument3 pagesASEAN Scholarship For Nalanda University 2021 - SSnurul qamariahNo ratings yet

- Eswatini Electricity Company: Request For Expression of Interest (REOI)Document24 pagesEswatini Electricity Company: Request For Expression of Interest (REOI)Hossam AlzubairyNo ratings yet

- 3M 92 EB64!1!11kV Cold Shrink Cable Termination Copper Wire Screen 300 630sqmmDocument2 pages3M 92 EB64!1!11kV Cold Shrink Cable Termination Copper Wire Screen 300 630sqmmHossam AlzubairyNo ratings yet

- Analysis of Transmission Tower Using ANSYS: International Research Journal of Engineering and Technology (IRJET)Document6 pagesAnalysis of Transmission Tower Using ANSYS: International Research Journal of Engineering and Technology (IRJET)Hossam AlzubairyNo ratings yet

- Annexure E - SBD 6.1 (PPR 2017) - 5Document5 pagesAnnexure E - SBD 6.1 (PPR 2017) - 5Andile NtuliNo ratings yet

- Optimization of Transmission Line Tower: Nternational Ournal of Nnovative Esearch in Cience, Ngineering and EchnologyDocument8 pagesOptimization of Transmission Line Tower: Nternational Ournal of Nnovative Esearch in Cience, Ngineering and EchnologyHossam AlzubairyNo ratings yet

- SBD 6.2 Local Content in Terms of PPR 2017 - 130Document4 pagesSBD 6.2 Local Content in Terms of PPR 2017 - 130Hossam AlzubairyNo ratings yet

- Vol 4 - Bill of Material - Swallows LILO132 R1Document15 pagesVol 4 - Bill of Material - Swallows LILO132 R1Hossam AlzubairyNo ratings yet

- Vol 3 - Detailed Scope of Work - Swallows LILO132 Part A R1Document33 pagesVol 3 - Detailed Scope of Work - Swallows LILO132 Part A R1Hossam AlzubairyNo ratings yet

- Annexure-A Technical Specifications For Heat Shrinkable Cable Terminations and Joints For 6.6kV, XLPE CablesDocument4 pagesAnnexure-A Technical Specifications For Heat Shrinkable Cable Terminations and Joints For 6.6kV, XLPE CablesHossam AlzubairyNo ratings yet

- Testing of Transformer Diff - RelayDocument25 pagesTesting of Transformer Diff - Relaydeepak2628No ratings yet

- 6Document14 pages6Hossam AlzubairyNo ratings yet

- 11kV Terminations Single Core XLPE EPR Heat Shrink Cable Terminations Nexans SREIDocument1 page11kV Terminations Single Core XLPE EPR Heat Shrink Cable Terminations Nexans SREIHossam AlzubairyNo ratings yet

- Annexure-A Technical Specifications For Heat Shrinkable Cable Terminations and Joints For 6.6kV, XLPE CablesDocument4 pagesAnnexure-A Technical Specifications For Heat Shrinkable Cable Terminations and Joints For 6.6kV, XLPE CablesHossam AlzubairyNo ratings yet

- Request For Quotation Local Purchase Section: RFQ NumberDocument2 pagesRequest For Quotation Local Purchase Section: RFQ NumberHossam AlzubairyNo ratings yet

- 11kV Terminations Single Core XLPE EPR Heat Shrink Cable Terminations Nexans SREIDocument1 page11kV Terminations Single Core XLPE EPR Heat Shrink Cable Terminations Nexans SREIHossam AlzubairyNo ratings yet

- 6Document14 pages6Hossam AlzubairyNo ratings yet

- Acustica Ruby EbonyDocument1 pageAcustica Ruby EbonyZizja TurtleNo ratings yet

- Green14 Snaith PerovskiteSolarCells ReviewDocument9 pagesGreen14 Snaith PerovskiteSolarCells ReviewjonbilbaoNo ratings yet

- Week1 LecA 2024Document45 pagesWeek1 LecA 2024yoyolamlyy0511No ratings yet

- HMI GOT1000 Discontinued & ReplacementDocument16 pagesHMI GOT1000 Discontinued & Replacementkurakura langitNo ratings yet

- What Is ESP32 SIM800L BoardDocument14 pagesWhat Is ESP32 SIM800L BoardjackNo ratings yet

- Motoman XRC Concurrent IO and Parameter ManualDocument340 pagesMotoman XRC Concurrent IO and Parameter ManualsunhuynhNo ratings yet

- 300G CONTEC ECG - 3 Channel With 12-Leads Monitor: User ManualDocument42 pages300G CONTEC ECG - 3 Channel With 12-Leads Monitor: User ManualRicky Maulana FirdausNo ratings yet

- Solar Panel Umbrella - PresentationDocument25 pagesSolar Panel Umbrella - PresentationFAISAL ALBALAWINo ratings yet

- How To Test Circuit Board With MultimeterDocument9 pagesHow To Test Circuit Board With MultimeterjackNo ratings yet

- Columbus Fitness S900 Treadmill Manual GuideDocument14 pagesColumbus Fitness S900 Treadmill Manual GuideChong JetNo ratings yet

- Selection PDFDocument494 pagesSelection PDFjonny david martinez perez100% (1)

- Omron G6H 2 DC24 DatasheetDocument10 pagesOmron G6H 2 DC24 DatasheetRoy y Pau Zavala GnecchiNo ratings yet

- MAX44267 +15V Single-Supply, Dual Op Amp With 10V Output RangeDocument19 pagesMAX44267 +15V Single-Supply, Dual Op Amp With 10V Output RangegirimooliNo ratings yet

- SN74LVC1G97 Configurable Multiple-Function Gate: 1 Features 3 DescriptionDocument38 pagesSN74LVC1G97 Configurable Multiple-Function Gate: 1 Features 3 DescriptioncutoNo ratings yet

- Frigorífico Daewoo fr2701 y fr2702Document18 pagesFrigorífico Daewoo fr2701 y fr2702Markos MXNo ratings yet

- Electronics: A Review On Small Power Rating PV Inverter Topologies and Smart PV InvertersDocument26 pagesElectronics: A Review On Small Power Rating PV Inverter Topologies and Smart PV InvertersPadmavathi RNo ratings yet

- PowerShield 8 Solution Overview - 3.0 - 19Document4 pagesPowerShield 8 Solution Overview - 3.0 - 19Sudharsan KingNo ratings yet

- Bob Beck Protocol - Blood PurifierDocument6 pagesBob Beck Protocol - Blood PurifierWb Warnabrother HatchetNo ratings yet

- Lukas Kaul - Practical Arduino Robotics - A Hands-On Guide To Bringing Your Robotics Ideas To Life Using Arduino-Packt Publishing (2023)Document334 pagesLukas Kaul - Practical Arduino Robotics - A Hands-On Guide To Bringing Your Robotics Ideas To Life Using Arduino-Packt Publishing (2023)gaby21marian3712100% (1)

- Pantalla Info Completa Claa150xg-01-ChunghwapicturetubesDocument17 pagesPantalla Info Completa Claa150xg-01-ChunghwapicturetubesYessenia PerezNo ratings yet

- XR2206 104 020808Document16 pagesXR2206 104 020808Khaleel MohammadNo ratings yet

- LampiranKeputusan Menteri Keuangan RI Data PIM PDFDocument33 pagesLampiranKeputusan Menteri Keuangan RI Data PIM PDFkhomeinitjNo ratings yet

- DM900 - 9.00 kVA: ModelDocument3 pagesDM900 - 9.00 kVA: ModelMohamed HusseinNo ratings yet

- Operating InstructionsDocument72 pagesOperating InstructionsCLAVOTNo ratings yet

- Index For Checklist of ElectricalDocument16 pagesIndex For Checklist of ElectricalKamranNo ratings yet

- Top 10 High Frequency PCB Manufacturers in The WorldDocument14 pagesTop 10 High Frequency PCB Manufacturers in The WorldjackNo ratings yet

- DC Ac MidtermDocument81 pagesDC Ac MidtermaaronjameseviscaynoNo ratings yet

- Saudi Arabian Oil Company: NotesDocument1 pageSaudi Arabian Oil Company: Notesmahesh reddy mNo ratings yet

- Solar Charger INV 1-4KW AC Charger: MPPT OPS (HF&1p) CSBDocument2 pagesSolar Charger INV 1-4KW AC Charger: MPPT OPS (HF&1p) CSBEku EmmanuelNo ratings yet

- Synthesis and Design of Dual-Wideband Bandpass Filters With Internally-Coupled Microstrip LinesDocument15 pagesSynthesis and Design of Dual-Wideband Bandpass Filters With Internally-Coupled Microstrip LinesAllam Naveen Kumar 21MCE0006No ratings yet

- FreeCAD | Step by Step: Learn how to easily create 3D objects, assemblies, and technical drawingsFrom EverandFreeCAD | Step by Step: Learn how to easily create 3D objects, assemblies, and technical drawingsRating: 5 out of 5 stars5/5 (1)

- Certified Solidworks Professional Advanced Weldments Exam PreparationFrom EverandCertified Solidworks Professional Advanced Weldments Exam PreparationRating: 5 out of 5 stars5/5 (1)

- CATIA V5-6R2015 Basics - Part I : Getting Started and Sketcher WorkbenchFrom EverandCATIA V5-6R2015 Basics - Part I : Getting Started and Sketcher WorkbenchRating: 4 out of 5 stars4/5 (10)

- Autodesk Fusion 360: A Power Guide for Beginners and Intermediate Users (3rd Edition)From EverandAutodesk Fusion 360: A Power Guide for Beginners and Intermediate Users (3rd Edition)Rating: 5 out of 5 stars5/5 (2)

- Beginning AutoCAD® 2020 Exercise WorkbookFrom EverandBeginning AutoCAD® 2020 Exercise WorkbookRating: 2.5 out of 5 stars2.5/5 (3)

- SketchUp Success for Woodworkers: Four Simple Rules to Create 3D Drawings Quickly and AccuratelyFrom EverandSketchUp Success for Woodworkers: Four Simple Rules to Create 3D Drawings Quickly and AccuratelyRating: 1.5 out of 5 stars1.5/5 (2)

- Autodesk Inventor 2020: A Power Guide for Beginners and Intermediate UsersFrom EverandAutodesk Inventor 2020: A Power Guide for Beginners and Intermediate UsersNo ratings yet

- Certified Solidworks Professional Advanced Surface Modeling Exam PreparationFrom EverandCertified Solidworks Professional Advanced Surface Modeling Exam PreparationRating: 5 out of 5 stars5/5 (1)

- Product Manufacturing and Cost Estimating using CAD/CAE: The Computer Aided Engineering Design SeriesFrom EverandProduct Manufacturing and Cost Estimating using CAD/CAE: The Computer Aided Engineering Design SeriesRating: 4 out of 5 stars4/5 (4)

- Contactless Vital Signs MonitoringFrom EverandContactless Vital Signs MonitoringWenjin WangNo ratings yet

- FreeCAD | Design Projects: Design advanced CAD models step by stepFrom EverandFreeCAD | Design Projects: Design advanced CAD models step by stepRating: 5 out of 5 stars5/5 (1)