Professional Documents

Culture Documents

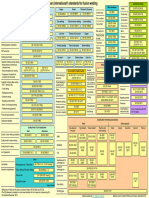

Nylon Materials Chart

Uploaded by

Prabhat SharmaOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Nylon Materials Chart

Uploaded by

Prabhat SharmaCopyright:

Available Formats

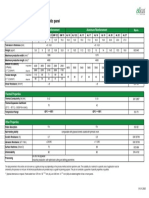

NYLON MATERIALS Polypenco Nylatron GS Nylatron NS Nylatron Nylatron Nylatron MC 901 MC 904 MC 907 ST801 Hydlar ZF 30% Glass-

Nylon 101 Filled Nylon Filled Nylon GSM Nylon GSM-Blue NSM Nylon Blue Blue Natural Nylon Nylon Filled Black

Nylon Nylon Nylon Nylon Nylon

NYLATRON - ZYTEL - MC901 Units ASTM Type 6/6 MoSc Filled Lubricated MoS2 Filled Lubricated Lubricated Monocast Heat Plasticized Heat Monocast FDA Impact Aramid Filled 30% Glass Filled

Test Polyamide Type 6/6 Type 6/6 Type 6 Type 6 Type 6 Stabilized Type 6 Stabilized Type 6 Type 6 Modified Type Type 6/6 Black Type 6/6

Method Polyamide Polyamide Polyamide Polyamide Polyamide Polyamide Polyamide Polyamide 6/6 Polyamide Polyamide Polyamide

1 Strength to Weight Ratio ksi - 10.0 10.8 8.9 9.1 8.7 9.6 10.4 8.3 10.4 5.6 14.5 9.8

2 Specific Gravity @ 73 F - D792 1.15 1.16 1.18 1.16 1.15 1.15 1.15 1.15 1.15 1.08 1.19 1.36

3 Tensile Strength @73 F, (ult/yld) psi D638 11500 (ult) 12500 (ult 10500 (ult) 10500 (ult) 10000 (ult) 11000 (ult) 12000 (ult) 9500 (ult) 12000 (ult) 6000 (yld) 17300 (yld) 13388 (ult)

4 Tensile Modulus of Elasticity @ 73 F psi D638 425000 480000 410000 400000 500000 410000 400000 275000 400000 - 802000 654620

5 Tensile Elongation at Break @ 73 F % D638 50 25 10 30 35 20 20 50 20 210 4 7

6

MECHANICAL

Flexural Strength @73 F psi D790 15000 17000 14000 16000 15000 16000 16000 - 16000 - 21300 20550

7 Flexural Modulus of Elasticity @ 73 F psi D790 450000 460000 400000 500000 500000 475000 500000 - 500000 245000 664000 723500

8 Shear Strength @ 73 F psi D732 10000 10500 9000 10500 - 10000 11000 - 11000 8400 - -

9 Compressive Strength, (%Deformation) @ 73 F psi D695 12500 (10) 16000 (10) 12000 (10) 14000 (10) 13000 (10) 14000 (10) 15000 (10) - 15000 (10) - 19300 (10) 18070 (10)

10 Compressive Modulus of Elasticity @ 73 F psi D695 420000 420000 400000 400000 425000 400000 400000 - 400000 - - 589800

11 Hardness, Rockwell, Scale as noted @ 73 F - D785 M85 (R115) M85 (R115) M85 (R115) M80 (R110) M80 (R117) M80 (R110) M85 (R115) M70 M85 (R115) (R112) M80 (R121) M65 (R121)

12 Hardness, Durometer, Shore D @ 73 F - D2240 D80 D85 D85 D85 - D85 D85 D85 D85 - - -

13 Izod Impact, (Notched) @ 73 F ft-lb/in of notch D256 TypeA 0.6 0.5 0.4 0.5 0.9 0.5 0.4 - 0.4 17.0 1.2 2.3

14 Coefficient of Friction, (Dry vs. Steel) Dynamic - - 0.25 0.20 0.16 0.20 0.18 0.18 0.20 - 0.20 0.28 0.32 -

15 Limiting PV, with 4 to 1 factor of safety applied psi-ft/min - 2700 3000 10000 3000 5500 15000 3000 - 3000 - - -

16 Coefficient of Linear Thermal Expansion @ 73 F in/in/F E-831 (TMA) 5.5E-05 4.0E-05 5.5E-05 3.5E-05 5.9E-05 5.0E-05 3.5E-05 3.5E-05 3.5E-05 6.7E-05 3.5E-05 1.7E-05

17 Heat Deflection Temperature @ 264 psi F D648 200 200 200 200 - 200 200 200 200 160 - 413

THERMAL

18 Tg-Glass transition temperature, (Amorphous) F D3418 - - - - - - - - - - - -

19 Melting Point, (VS= Vicat Softening Temp.) F D3418 500 500 500 420 420 420 420 420 420 491 491 420

20 Continuous Service Temperature in Air, (Max.) F - 210 220 220 200 200 200 260 - 200 - 300 -

21 Thermal Conductivity BTU-in/hr-ft2F - 1.70 1.70 - - - - 1.70 - 1.70 - - -

22 Dielectric Strength, Short Term Volts/ mil D149 400 350 350 400 - 400 500 - 500 - 350 -

ELECTRICAL

23 Volume Resistivity ohm-cm D257 >E13 >E13 >E13 >E13 >E13 >E13 >E13 >E13 >E13 >E13 >E13 >E13

24 Dielectric Constant @ 10E6Hz - D150 3.6 - - 3.7 - - 3.7 - 3.7 2.9 3.4 -

25 Dissipation Factor @ 10E6Hz - D150 0.020 - - - - - - - - 0.020 0.010 -

26 Flammability @ 3.1 mm unless noted - UL94 V-2 V-2 HB HB HB HB HB HB HB HB (.81mm) - -

27 Water Absorbtion, Immersion, 24 Hrs. % by wt D570(7) 0.30 0.30 0.30 0.30 0.22 0.25 0.30 0.30 0.30 1.20 1.20 -

H2O

28 Water Absorbtion, Saturation % by wt D570(7) 7.00 7.00 7.00 7.00 - 7.00 7.00 7.00 7.00 6.70 8.50 -

You might also like

- The Mechanical Behaviour of Engineering Materials: The Commonwealth and International Library: Structures and Solid Body Mechanics DivisionFrom EverandThe Mechanical Behaviour of Engineering Materials: The Commonwealth and International Library: Structures and Solid Body Mechanics DivisionNo ratings yet

- PSG Epoxy Glass PhenolicsDocument1 pagePSG Epoxy Glass PhenolicsmadhunnadigNo ratings yet

- Technical Data Sheet Nylon: (Polyamide)Document3 pagesTechnical Data Sheet Nylon: (Polyamide)Dharmendra DubeyNo ratings yet

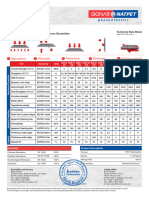

- Property of Polyfelt TS Nonwoven GeotextilesDocument1 pageProperty of Polyfelt TS Nonwoven GeotextilesAgis Satryo Falck100% (1)

- 01.03.03.101 Spesifikasi-BPM HDPE SmoothDocument1 page01.03.03.101 Spesifikasi-BPM HDPE SmoothRezky BaskoroNo ratings yet

- PP Geotextile Data SheetDocument1 pagePP Geotextile Data SheetAnonymous MAQrYFQDzVNo ratings yet

- Technical Data Sheet G-10: General DescriptionDocument1 pageTechnical Data Sheet G-10: General Descriptionbahtiar affandyNo ratings yet

- Elastollan® 1100 SeriesDocument1 pageElastollan® 1100 Serieskorma5No ratings yet

- UHMW Mechanical Properties: Comparison of Dynamic Coefficient of Friction On Polished SteelDocument4 pagesUHMW Mechanical Properties: Comparison of Dynamic Coefficient of Friction On Polished SteeldangdinhthyNo ratings yet

- Techgeo Nonwoven Geotextiles Technical Data SheetDocument1 pageTechgeo Nonwoven Geotextiles Technical Data Sheetakkieuap100% (1)

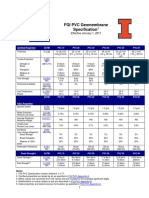

- FGI PVC Geomembrane Specification: Effective January 1, 2017Document3 pagesFGI PVC Geomembrane Specification: Effective January 1, 2017Paul Alex Quiroz BarrionuevoNo ratings yet

- Technical Data Sheet Polyimide: Benefits ApplicationsDocument3 pagesTechnical Data Sheet Polyimide: Benefits Applicationssanthosha rkNo ratings yet

- Material ZirconiaDocument1 pageMaterial ZirconiaCpc Comercializadora CubillosNo ratings yet

- Rowad HDSDocument1 pageRowad HDSsellami walidNo ratings yet

- Geotextiles DatasheetDocument1 pageGeotextiles DatasheetMohammad TalalNo ratings yet

- Bontec Non-Woven Geotextiles - TDSDocument11 pagesBontec Non-Woven Geotextiles - TDSAnang BagusNo ratings yet

- Zeus Inc. Properties Of Extruded FluoropolymersDocument1 pageZeus Inc. Properties Of Extruded FluoropolymersAmir KhanNo ratings yet

- PET Geogrid SeriesDocument1 pagePET Geogrid Seriessundra0No ratings yet

- Tecothane TPU ClearDocument3 pagesTecothane TPU ClearKhoa HuynhdangNo ratings yet

- Technical Information: (A) (SF) (ST) (F)Document1 pageTechnical Information: (A) (SF) (ST) (F)johnNo ratings yet

- TecamidDocument2 pagesTecamidTejas HuddarNo ratings yet

- Geotextiles VTDocument28 pagesGeotextiles VTSumit GuptaNo ratings yet

- Technical Characteristics 2020 ENDocument1 pageTechnical Characteristics 2020 ENezzularabNo ratings yet

- Tabla Compartiva Fluidos Hidraulicos - FormexDocument4 pagesTabla Compartiva Fluidos Hidraulicos - Formexirvingsr91No ratings yet

- Durolon HFR 1910Document2 pagesDurolon HFR 1910elrolo3000No ratings yet

- Pet Non-Woven Geo Textile Data SheetDocument2 pagesPet Non-Woven Geo Textile Data SheetAnonymous MAQrYFQDzVNo ratings yet

- Titanpro 6531 MDocument1 pageTitanpro 6531 MErnesto CheguavaraNo ratings yet

- Optigear 1100 RangeDocument3 pagesOptigear 1100 RangeResistenciaDisidenteNo ratings yet

- Daikin Ducable Unit 5 5tr To 16 7trDocument2 pagesDaikin Ducable Unit 5 5tr To 16 7trరాజా రావు చామర్తిNo ratings yet

- Teslin TableDocument1 pageTeslin TableEzequiel FernandezNo ratings yet

- The PE4710 - PE 100 Is A Special Black Polyethylene Material For The Pipe IndustryDocument2 pagesThe PE4710 - PE 100 Is A Special Black Polyethylene Material For The Pipe IndustrysreeNo ratings yet

- ADPL718 Catalog Page 25 - Yellow B AckDocument1 pageADPL718 Catalog Page 25 - Yellow B AckSugeng DarmintoNo ratings yet

- Data Sheet - Polyfelt® TS HD (100 600-td-02-19)Document1 pageData Sheet - Polyfelt® TS HD (100 600-td-02-19)andriarisetiawanNo ratings yet

- Acrylic Sheet Fabrication GuideDocument44 pagesAcrylic Sheet Fabrication GuideBa BagymkyzyNo ratings yet

- Resumen SuperpaveDocument60 pagesResumen SuperpaveFranklinNo ratings yet

- PolycarbonateDocument2 pagesPolycarbonatepuvitta sudeshilaNo ratings yet

- PolycarbonateDocument2 pagesPolycarbonateROHIT SHARMANo ratings yet

- PolycarbonateDocument2 pagesPolycarbonateAdnan KhanNo ratings yet

- Technical Data: GeosyntheticsDocument2 pagesTechnical Data: GeosyntheticsAdrian CorralesNo ratings yet

- UPVC Pipe DIN 8062 TdsDocument3 pagesUPVC Pipe DIN 8062 TdsAdany AdenNo ratings yet

- Corys Geosynthetics Data Sheet HDPE Smooth Geomembrane: Metric UnitsDocument1 pageCorys Geosynthetics Data Sheet HDPE Smooth Geomembrane: Metric UnitsVenkadesh PeriathambiNo ratings yet

- FRPC Properties EN-RUDocument1 pageFRPC Properties EN-RUVahNo ratings yet

- Tecoflex TPU - 40% Barium Sulfate: Technical Data SheetDocument4 pagesTecoflex TPU - 40% Barium Sulfate: Technical Data SheetJoseph ShingNo ratings yet

- Data Sheet - Mirafi® HPa (200 613-td-05-15)Document1 pageData Sheet - Mirafi® HPa (200 613-td-05-15)khairul umamNo ratings yet

- Premier Series Piston Pumps Technical SpecificationsDocument40 pagesPremier Series Piston Pumps Technical SpecificationsDamNo ratings yet

- TenCate Polyfelt TS Nonwoven GeotextilesDocument6 pagesTenCate Polyfelt TS Nonwoven GeotextilesChee Soon LeeNo ratings yet

- 203-010 Griswold 6100 Family Product Data SheetDocument1 page203-010 Griswold 6100 Family Product Data Sheetjuan davidNo ratings yet

- Synthetic Gear Oil Data SheetDocument2 pagesSynthetic Gear Oil Data SheetDiegoNo ratings yet

- Physical and Piezoelectric Properties of APC Materials ChartDocument2 pagesPhysical and Piezoelectric Properties of APC Materials ChartTrương Anh DuyNo ratings yet

- TDS BOPP Clear LSA47 TaghleefDocument2 pagesTDS BOPP Clear LSA47 TaghleefEmmanuel AlvarezNo ratings yet

- Technical Information: (BR) (WR-2) (Special F)Document1 pageTechnical Information: (BR) (WR-2) (Special F)johnNo ratings yet

- 1 Wa-Catalog9Document1 page1 Wa-Catalog9johnNo ratings yet

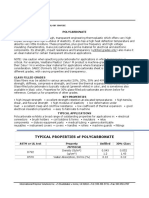

- Polyurethane Properties PDFDocument1 pagePolyurethane Properties PDFdestroNo ratings yet

- Couplant Comparison and Specification ChartDocument1 pageCouplant Comparison and Specification ChartdantegimenezNo ratings yet

- Mechanical Properties ASTM Test Method Units Nylon 6/6 Nylon 6/6 GF30Document1 pageMechanical Properties ASTM Test Method Units Nylon 6/6 Nylon 6/6 GF30Mai Huong Bui ThiNo ratings yet

- Standard and reinforced PA grades overviewDocument2 pagesStandard and reinforced PA grades overviewabhishek_negi_41No ratings yet

- Thebault Dop01 Teboply Ext GBDocument2 pagesThebault Dop01 Teboply Ext GBDumitrache IulianNo ratings yet

- 630 (17-4) Precipitation Hardening Stainless Steel BarDocument4 pages630 (17-4) Precipitation Hardening Stainless Steel Barehudingram6535No ratings yet

- Pt. Gunung: Ragat MandiriDocument40 pagesPt. Gunung: Ragat MandirirachmanNo ratings yet

- Co-Efficient of Friction Test Report: Test SR - No. Test Date Test Time Customer Name Customer Code Operator NameDocument11 pagesCo-Efficient of Friction Test Report: Test SR - No. Test Date Test Time Customer Name Customer Code Operator NameAshish PatelNo ratings yet

- Design and Analysis of Automotive Serpentine Belt Drive Systems For Steady State PerformanceDocument8 pagesDesign and Analysis of Automotive Serpentine Belt Drive Systems For Steady State PerformancePrabhat SharmaNo ratings yet

- A Definitive Guide To DFM Success Issue IIDocument11 pagesA Definitive Guide To DFM Success Issue IIarenasjoseNo ratings yet

- Front and Rear Swing Arm Design of An Electric Racing MotorcycleDocument10 pagesFront and Rear Swing Arm Design of An Electric Racing MotorcycleSai KrishnaNo ratings yet

- India Poltical Map PDFDocument1 pageIndia Poltical Map PDFPrabhat SharmaNo ratings yet

- Catr 2001 eDocument126 pagesCatr 2001 eSaeedAkbarzadehNo ratings yet

- An Assessment of Bicycle Frame Behaviour Under VarDocument7 pagesAn Assessment of Bicycle Frame Behaviour Under VarPrabhat SharmaNo ratings yet

- Motorcycle Frame DesignDocument5 pagesMotorcycle Frame DesignKomang Priatna SuardiNo ratings yet

- Its09 World Maps eDocument6 pagesIts09 World Maps evarunkksdNo ratings yet

- BIS LIST OF IS CERTIFIED PRODUCT STANDARDSDocument27 pagesBIS LIST OF IS CERTIFIED PRODUCT STANDARDSMayank AgrawalNo ratings yet

- Motorcycle Frame DesignDocument5 pagesMotorcycle Frame DesignKomang Priatna SuardiNo ratings yet

- Bolt Tightening Methods and Torque-Tension RelationshipsDocument12 pagesBolt Tightening Methods and Torque-Tension RelationshipsJuanGómezNo ratings yet

- Motorcycle Frame DesignDocument5 pagesMotorcycle Frame DesignKomang Priatna SuardiNo ratings yet

- An Assessment of Bicycle Frame Behaviour Under VarDocument7 pagesAn Assessment of Bicycle Frame Behaviour Under VarPrabhat SharmaNo ratings yet

- Motorcycle Frame DesignDocument5 pagesMotorcycle Frame DesignKomang Priatna SuardiNo ratings yet

- An Assessment of Bicycle Frame Behaviour Under VarDocument7 pagesAn Assessment of Bicycle Frame Behaviour Under VarPrabhat SharmaNo ratings yet

- Mechanical Design Professional: Ashok KumarDocument3 pagesMechanical Design Professional: Ashok KumarPrabhat SharmaNo ratings yet

- Motorcycle Frame DesignDocument5 pagesMotorcycle Frame DesignKomang Priatna SuardiNo ratings yet

- An Assessment of Bicycle Frame Behaviour Under VarDocument7 pagesAn Assessment of Bicycle Frame Behaviour Under VarPrabhat SharmaNo ratings yet

- Ecowasher PDFDocument16 pagesEcowasher PDFPrabhat SharmaNo ratings yet

- Mechanical Design Professional: Ashok KumarDocument3 pagesMechanical Design Professional: Ashok KumarPrabhat SharmaNo ratings yet

- Mechanical Design Professional: Ashok KumarDocument3 pagesMechanical Design Professional: Ashok KumarPrabhat SharmaNo ratings yet

- Mechanical Design Professional: Ashok KumarDocument3 pagesMechanical Design Professional: Ashok KumarPrabhat SharmaNo ratings yet

- PMP 6 EditionDocument12 pagesPMP 6 EditionDeepak Sharma0% (3)

- 29 Auto 11 Changed SDDocument10 pages29 Auto 11 Changed SDPrabhat SharmaNo ratings yet

- Overview of Materials For Nylon 66/6, 40% Glass Fiber ReinforcedDocument2 pagesOverview of Materials For Nylon 66/6, 40% Glass Fiber ReinforcedPrabhat SharmaNo ratings yet

- HSSC Application LinkDocument1 pageHSSC Application LinkPrabhat SharmaNo ratings yet

- PMP 6 EditionDocument12 pagesPMP 6 EditionDeepak Sharma0% (3)

- Dryness FractionDocument3 pagesDryness FractionJigme Lama100% (2)

- Determining Hardenability of Steel: Standard Test Methods ForDocument26 pagesDetermining Hardenability of Steel: Standard Test Methods ForJuan Diego Palacio VelasquezNo ratings yet

- Jarissa Banner Nitration of Bromobnzene LabDocument15 pagesJarissa Banner Nitration of Bromobnzene LabJuiloNo ratings yet

- Importance of ProteinsDocument30 pagesImportance of ProteinsJUSTIN VICTOR ANGNo ratings yet

- IR Absorption Table PDFDocument3 pagesIR Absorption Table PDFDavid QuinteroNo ratings yet

- An Introduction To Cavitation FundamentalsDocument18 pagesAn Introduction To Cavitation FundamentalsJaqueline GontijoNo ratings yet

- Euronorme SuduraDocument1 pageEuronorme SuduragulieionutNo ratings yet

- Astm A 370 PDFDocument52 pagesAstm A 370 PDFBez SofNo ratings yet

- STERIS - 6 Hydrogen Peroxide WFI Sterile Solution - TDS - 420 100 0202ADocument2 pagesSTERIS - 6 Hydrogen Peroxide WFI Sterile Solution - TDS - 420 100 0202AJoffrey AntonNo ratings yet

- Mega BlueDocument9 pagesMega Bluepollito AmarilloNo ratings yet

- CLEANING VALIDATION & ANALYTICAL METHOD VALIDATIONDocument50 pagesCLEANING VALIDATION & ANALYTICAL METHOD VALIDATIONDarlenis RodriguezNo ratings yet

- Corrosion On AircraftDocument59 pagesCorrosion On Aircraftprakash100% (2)

- Mollier Hs Diagram PDFDocument1 pageMollier Hs Diagram PDFArluky Novandy0% (1)

- Drying Methods Impact on Steviol Glycosides and Antioxidants in Stevia LeavesDocument6 pagesDrying Methods Impact on Steviol Glycosides and Antioxidants in Stevia LeavesMaría Eugenia OlivaresNo ratings yet

- Alucobond ContemporaryColorChart Jan 2016 PDFDocument2 pagesAlucobond ContemporaryColorChart Jan 2016 PDFcathes231No ratings yet

- ANT Stabilizer 28-04-2022Document8 pagesANT Stabilizer 28-04-2022Manoj AhirwarNo ratings yet

- WTTC9 Proceedings 2002 Comor COSTIS Solid Target p59Document186 pagesWTTC9 Proceedings 2002 Comor COSTIS Solid Target p59Juan CarlosNo ratings yet

- Acceptance Criteria Boiler (API 573)Document1 pageAcceptance Criteria Boiler (API 573)Nur Achmad BusairiNo ratings yet

- Degradation of Sugarcane Vinasse in A Full-Scale Methanogenic UASBDocument11 pagesDegradation of Sugarcane Vinasse in A Full-Scale Methanogenic UASBProyectos Plantas De Tratamiento De AguaNo ratings yet

- Physical and Chemical PrinciplesDocument4 pagesPhysical and Chemical PrinciplesAriel Raye RicaNo ratings yet

- 100 Physics One Liner For WBCS 2020Document2 pages100 Physics One Liner For WBCS 2020Saurav BandyopadhyayNo ratings yet

- Horse Construction's Unidirectional Carbon Fiber FabricDocument36 pagesHorse Construction's Unidirectional Carbon Fiber FabricArok ANo ratings yet

- Basic concepts of thermodynamics and energy transferDocument2 pagesBasic concepts of thermodynamics and energy transferHasrul Reza100% (1)

- Calculating A PH Slope Percentage Hanna Instruments PDFDocument2 pagesCalculating A PH Slope Percentage Hanna Instruments PDFamerican_guy10No ratings yet

- Microscope Lab GuideDocument10 pagesMicroscope Lab GuideBrian Luo67% (3)

- DDS Duct Deluge System For The Protection of Ventilation Ductwork Handling Corrosive Gases General DescriptionDocument6 pagesDDS Duct Deluge System For The Protection of Ventilation Ductwork Handling Corrosive Gases General DescriptionhungNo ratings yet

- Prorox SL 580 PDFDocument1 pageProrox SL 580 PDFgowtham_venkat_4No ratings yet

- Method Development and Validation of Esomeprazole Magnesium Trihydrate in Bulk and Formulation by UV Spectroscopic MethodDocument29 pagesMethod Development and Validation of Esomeprazole Magnesium Trihydrate in Bulk and Formulation by UV Spectroscopic MethodSantoshNo ratings yet

- Skoog - Solucionário Capítulo 10 PDFDocument20 pagesSkoog - Solucionário Capítulo 10 PDFThais Dos SantosNo ratings yet

- Secondary Beam - BM and Shear ForceDocument11 pagesSecondary Beam - BM and Shear ForcerameshkaaNo ratings yet