Professional Documents

Culture Documents

Technical Information: (BR) (WR-2) (Special F)

Uploaded by

johnOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Technical Information: (BR) (WR-2) (Special F)

Uploaded by

johnCopyright:

Available Formats

Technical Information

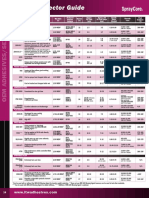

Devcon® Devcon® Wear Resistant Devcon® Underwater Devcon® HVAC Repair

Physical Properties Devcon® FasMetal™

Bronze Putty (BR) Putty (WR-2) Repair Putty (UW) (Special F)

Color Bronze Dark Grey Grey Grey Grey

Mix ratio by weight / volume

9:1 / 3:1 9:1 / 4:1 1.4:1 / 1:1 1.07:1 / 1:1 0.9:1 / 1:1

resin:hardener

Mixed viscosity cP Putty Putty Putty Putty 40,000

Functional cure hours 16 16 24 1 16

Pot life minutes @ 75˚F 35 45 45 4 60

Specific volume inches 3/pound 12.4 13.9 17.0 17.2 16.1

Coverage per pound inches 2

50 56 68 69 64

@ 1⁄4" thickness

Cured hardness

85 85 82 90 85

(ASTM D2240) Shore D

Cured shrinkage

0.0010 0.0005 0.0020 0.0093 0.0008

(ASTM D2566) inch/inch

Adhesive tensile shear

2,680 2,200 2,685 2,000 2,500

(ASTM D1002) psi

Compressive strength

8,540 9,800 5,625 12,700 8,420

(ASTM D695) psi

Flexural strength

6,180 6,500 4,990 7,700 6,260

(ASTM D790) psi

Modulus of elasticity

8.0 7.5 7.5 8.5 7.8

(ASTM D638) psi x 10 5

Coefficient of thermal expansion

(ASTM D696) 33 32 18 32 29

[(in)/(in x ˚F)] x 10 -6

Thermal conductivity (ASTM C177)

1.57 1.67 1.41 2.04 1.73

[(cal x cm)/(sec x cm 2 x ˚C)] x 10 -3

Dielectric constant

75.0 6.3 8.6 18.6 21.4

(ASTM D150 ) 1 kHz

Dielectric strength

25 400 150 370 100

(ASTM D149 ) volts/mil

Maximum continuous dry

250 250 250 250 250

service temperature ˚F

Maximum continuous wet

120 120 120 N/A 110

service temperature ˚F

Devcon® Devcon® Wear Resistant Devcon® Underwater Devcon® HVAC Repair

Chemical Resistance Devcon® FasMetal™

Bronze Putty (BR) Putty (WR-2) Repair Putty (UW) (Special F)

ACIDS

Acetic 10%

Hydrochloric 10%

Sulfuric 10%

ALCOHOLS

Methanol

Isopropanol

KETONES

Acetone

Methyl ethyl ketone

ALKALIS

Ammonium hydroxide 20%

Sodium hydroxide 10%

HYDROCARBONS

Gasoline (unleaded)

Mineral spirits

CHLORINATED

HYDROCARBONS

1-1-1 Trichloroethane

SALTS

Sodium chloride

Trisodium phosphate

Key: Excellent Very Good Fair Poor

17

You might also like

- Organic Chemistry, Second Edition Janice Gorzynski Smith, ch1Document40 pagesOrganic Chemistry, Second Edition Janice Gorzynski Smith, ch1sungyeon heoNo ratings yet

- Latest Biology Ss1Document163 pagesLatest Biology Ss1chidimma AnyaboluNo ratings yet

- Using Plastic Waste in ConcreteDocument90 pagesUsing Plastic Waste in ConcretejosephfelixNo ratings yet

- The Mechanical Behaviour of Engineering Materials: The Commonwealth and International Library: Structures and Solid Body Mechanics DivisionFrom EverandThe Mechanical Behaviour of Engineering Materials: The Commonwealth and International Library: Structures and Solid Body Mechanics DivisionNo ratings yet

- Microbial Enhanced Oil RecoveryDocument24 pagesMicrobial Enhanced Oil RecoverySayed Afg HashimiNo ratings yet

- Devcon Catalog PDFDocument24 pagesDevcon Catalog PDFSergio MarchettiNo ratings yet

- Technical Information: (A) (SF) (ST) (F)Document1 pageTechnical Information: (A) (SF) (ST) (F)johnNo ratings yet

- 1 Wa-Catalog13Document1 page1 Wa-Catalog13johnNo ratings yet

- 1 Wa-Catalog7Document1 page1 Wa-Catalog7johnNo ratings yet

- ITW Product Catalog23Document1 pageITW Product Catalog23johnNo ratings yet

- 1 Wa-Catalog9Document1 page1 Wa-Catalog9johnNo ratings yet

- 1 Wa-Catalog5Document1 page1 Wa-Catalog5johnNo ratings yet

- ITW Product Catalog21 PDFDocument1 pageITW Product Catalog21 PDFjohnNo ratings yet

- ITW Product Catalog30 PDFDocument1 pageITW Product Catalog30 PDFjohnNo ratings yet

- UHMW Mechanical Properties: Comparison of Dynamic Coefficient of Friction On Polished SteelDocument4 pagesUHMW Mechanical Properties: Comparison of Dynamic Coefficient of Friction On Polished SteeldangdinhthyNo ratings yet

- Bergquist Gap Pad Comparison TableDocument1 pageBergquist Gap Pad Comparison TableMaike SongNo ratings yet

- LdpeDocument1 pageLdpeArdy WiyogoNo ratings yet

- Devcon Plastic Steel Putty ADocument3 pagesDevcon Plastic Steel Putty AAZLAN ABDULLAINo ratings yet

- Datasheet SD Ferralium 255 SD50 BarDocument4 pagesDatasheet SD Ferralium 255 SD50 Barpranav kariaNo ratings yet

- General PropertiesDocument2 pagesGeneral PropertiesIsrael ExporterNo ratings yet

- Kocetal K700 Property DataDocument1 pageKocetal K700 Property DataRanjan GnanaoliNo ratings yet

- PolycarbonateDocument2 pagesPolycarbonateAdnan KhanNo ratings yet

- PolycarbonateDocument2 pagesPolycarbonatepuvitta sudeshilaNo ratings yet

- PolycarbonateDocument2 pagesPolycarbonateROHIT SHARMANo ratings yet

- HojaTecnica Heat Flex Hi Temp 1200Document4 pagesHojaTecnica Heat Flex Hi Temp 1200NANCY JASMIN MORENONo ratings yet

- Nominal Engineering Properties of Ryton R-4: Data SheetDocument4 pagesNominal Engineering Properties of Ryton R-4: Data SheetRakeshNo ratings yet

- DEVCON® Fasmetal 10 HVAC Repair (Special F)Document2 pagesDEVCON® Fasmetal 10 HVAC Repair (Special F)mohamed hamedNo ratings yet

- PVC and CPVC properties referenceDocument2 pagesPVC and CPVC properties referenceAdnan KhanNo ratings yet

- Technical Data Sheet Uhmw Polyethelyne (Uhmw Pe) : (Ultra High Molecular Weight Polyethylene)Document1 pageTechnical Data Sheet Uhmw Polyethelyne (Uhmw Pe) : (Ultra High Molecular Weight Polyethylene)HARSHA PNo ratings yet

- Technical Data Sheet PVC: (Polyvinyl Chloride)Document1 pageTechnical Data Sheet PVC: (Polyvinyl Chloride)Adnan KhanNo ratings yet

- Plastic Steel Putty A v3Document2 pagesPlastic Steel Putty A v3feri.ferdianto02No ratings yet

- TDS Nylon101Document2 pagesTDS Nylon101wilderness_666No ratings yet

- Technical Data Sheet High Density Polyethylene: Typical Properties of PolyethyleneDocument1 pageTechnical Data Sheet High Density Polyethylene: Typical Properties of PolyethyleneQuality teamNo ratings yet

- Technical Data Sheet Teflon (Ptfe) : (Polytetrafluoroethylene Resin)Document1 pageTechnical Data Sheet Teflon (Ptfe) : (Polytetrafluoroethylene Resin)Dharmendra DubeyNo ratings yet

- PTFE Technical Data Sheet Highlights Chemical Resistance and Wide Temperature RangeDocument1 pagePTFE Technical Data Sheet Highlights Chemical Resistance and Wide Temperature RangeMarisa Yuni Nur AzizaNo ratings yet

- Poly-Cote 110 (Aug'22)Document4 pagesPoly-Cote 110 (Aug'22)David cNo ratings yet

- Technical Data Sheet Peek: Typical Properties of Virgin (Unfilled) PeekDocument2 pagesTechnical Data Sheet Peek: Typical Properties of Virgin (Unfilled) PeekSyed MoinNo ratings yet

- Technical Data Sheet CPVC: (Chlorinated Polyvinyl Chloride)Document1 pageTechnical Data Sheet CPVC: (Chlorinated Polyvinyl Chloride)Nam NguyenNo ratings yet

- Zeus Inc. Properties Of Extruded FluoropolymersDocument1 pageZeus Inc. Properties Of Extruded FluoropolymersAmir KhanNo ratings yet

- Protective & Marine Coatings: Polysiloxane 1KDocument4 pagesProtective & Marine Coatings: Polysiloxane 1KAna CabreraNo ratings yet

- PolystyreneDocument1 pagePolystyrenejoshkajasmineNo ratings yet

- Corys Geosynthetics Data Sheet HDPE Smooth Geomembrane: Metric UnitsDocument1 pageCorys Geosynthetics Data Sheet HDPE Smooth Geomembrane: Metric UnitsVenkadesh PeriathambiNo ratings yet

- Technical Data Sheet G-10: General DescriptionDocument1 pageTechnical Data Sheet G-10: General Descriptionbahtiar affandyNo ratings yet

- Protective & Marine Coatings: DTM Acrylic Primer/FinishDocument4 pagesProtective & Marine Coatings: DTM Acrylic Primer/FinishAna CabreraNo ratings yet

- Sherwin Williams - Heatflex Hi-Temp 1200 DatasheetDocument4 pagesSherwin Williams - Heatflex Hi-Temp 1200 DatasheetAce AceNo ratings yet

- Mitsubishi Chemical Advanced Materials Acetron ® LSG POM-C Copolymer Acetal, Porosity-Free, Unfilled, ExtrudedDocument2 pagesMitsubishi Chemical Advanced Materials Acetron ® LSG POM-C Copolymer Acetal, Porosity-Free, Unfilled, ExtrudedJuan Orlando Loaiza MurilloNo ratings yet

- Pultruded Composites Material Property ComparisonDocument5 pagesPultruded Composites Material Property ComparisonJohn WycliffeNo ratings yet

- PSG Epoxy Glass PhenolicsDocument1 pagePSG Epoxy Glass PhenolicsmadhunnadigNo ratings yet

- 4114A042 TestingDocument10 pages4114A042 TestingmuratNo ratings yet

- Protective DTM Acrylic Primer/Finish Product DescriptionDocument4 pagesProtective DTM Acrylic Primer/Finish Product DescriptionVernon Jiménez FonsecaNo ratings yet

- Bronze Putty: Technical Data SheetDocument2 pagesBronze Putty: Technical Data SheetSharad ShahNo ratings yet

- 0001 - POLYFOAM Super (Gen) 09-30.11.2020Document1 page0001 - POLYFOAM Super (Gen) 09-30.11.2020Meeran MohamedNo ratings yet

- Tairilac ABS Resin: Properties (1/3)Document3 pagesTairilac ABS Resin: Properties (1/3)DiegoTierradentroNo ratings yet

- Tairilac ABS Resin Properties and CharacteristicsDocument3 pagesTairilac ABS Resin Properties and CharacteristicsDiegoTierradentroNo ratings yet

- Nap-Gard 7-2500 PDFDocument2 pagesNap-Gard 7-2500 PDFPietro ViganNo ratings yet

- Technical Data Sheet Polyfoam Normal: Extruded Polystyrene Insulation (Non Fire R Etardant)Document1 pageTechnical Data Sheet Polyfoam Normal: Extruded Polystyrene Insulation (Non Fire R Etardant)Raha Trading and ContactingNo ratings yet

- Spur Gear Spec Some Manufactures Dimension PDFDocument52 pagesSpur Gear Spec Some Manufactures Dimension PDFagus wahyudiNo ratings yet

- Lexan 9034 Data SheetDocument2 pagesLexan 9034 Data SheetAdrián PonceNo ratings yet

- Heat exchanger specification sheetDocument1 pageHeat exchanger specification sheetIdil Fitri100% (1)

- KWER 1001-55BR (TDS)Document4 pagesKWER 1001-55BR (TDS)NganNo ratings yet

- Dfense Blok™: Technical Data SheetDocument1 pageDfense Blok™: Technical Data SheetjohnNo ratings yet

- PolycarbonateDocument1 pagePolycarbonatezainudinNo ratings yet

- Dokumen - Tips - Waterborne CNSL Curing Agent For Grout and Adhesive Curing Agent Dry ConcreteDocument16 pagesDokumen - Tips - Waterborne CNSL Curing Agent For Grout and Adhesive Curing Agent Dry Concretem_shahbaghiNo ratings yet

- ITW Product Catalog33 PDFDocument1 pageITW Product Catalog33 PDFjohnNo ratings yet

- ITW Product Catalog41 PDFDocument1 pageITW Product Catalog41 PDFjohnNo ratings yet

- ITW Product Catalog31 PDFDocument1 pageITW Product Catalog31 PDFjohnNo ratings yet

- ITW Product Catalog40 PDFDocument1 pageITW Product Catalog40 PDFjohnNo ratings yet

- Floor Repair and Surfacing: AcidsDocument1 pageFloor Repair and Surfacing: AcidsjohnNo ratings yet

- ITW Product Catalog32 PDFDocument1 pageITW Product Catalog32 PDFjohnNo ratings yet

- ITW Product Catalog39 PDFDocument1 pageITW Product Catalog39 PDFjohnNo ratings yet

- ITW Product Catalog29 PDFDocument1 pageITW Product Catalog29 PDFjohnNo ratings yet

- ITW Product Catalog33 PDFDocument1 pageITW Product Catalog33 PDFjohnNo ratings yet

- ITW Product Catalog30 PDFDocument1 pageITW Product Catalog30 PDFjohnNo ratings yet

- ITW Product Catalog29 PDFDocument1 pageITW Product Catalog29 PDFjohnNo ratings yet

- ITW Product Catalog31 PDFDocument1 pageITW Product Catalog31 PDFjohnNo ratings yet

- ITW Product Catalog33 PDFDocument1 pageITW Product Catalog33 PDFjohnNo ratings yet

- ITW Product Catalog32 PDFDocument1 pageITW Product Catalog32 PDFjohnNo ratings yet

- ITW Product Catalog27Document1 pageITW Product Catalog27johnNo ratings yet

- ITW Product Catalog30 PDFDocument1 pageITW Product Catalog30 PDFjohnNo ratings yet

- ITW Product Catalog30 PDFDocument1 pageITW Product Catalog30 PDFjohnNo ratings yet

- ITW Product Catalog32 PDFDocument1 pageITW Product Catalog32 PDFjohnNo ratings yet

- ITW Product Catalog26Document1 pageITW Product Catalog26johnNo ratings yet

- ITW Product Catalog31 PDFDocument1 pageITW Product Catalog31 PDFjohnNo ratings yet

- ITW Product Catalog28Document1 pageITW Product Catalog28johnNo ratings yet

- ITW Product Catalog22Document1 pageITW Product Catalog22johnNo ratings yet

- ITW Product Catalog17Document1 pageITW Product Catalog17johnNo ratings yet

- Dfense BLO: Wearing CompoundsDocument1 pageDfense BLO: Wearing CompoundsjohnNo ratings yet

- ITW Product Catalog21 PDFDocument1 pageITW Product Catalog21 PDFjohnNo ratings yet

- MRO Product Selector GuideDocument1 pageMRO Product Selector GuidejohnNo ratings yet

- ITW Product Catalog16 PDFDocument1 pageITW Product Catalog16 PDFjohnNo ratings yet

- General Surface Preparation Concrete RubberDocument1 pageGeneral Surface Preparation Concrete RubberjohnNo ratings yet

- MODULE 2 IUPAC System NomenclatureDocument18 pagesMODULE 2 IUPAC System NomenclatureJude's TimeNo ratings yet

- Brochure Celdas EWDocument5 pagesBrochure Celdas EWPablo HurtubiaNo ratings yet

- Stereo ChemistryDocument135 pagesStereo ChemistryAntoni Budhi PrasetyoNo ratings yet

- Uv-Visible Spectroscopy: Presented By: Gabriel Engonga and Flora DikeDocument61 pagesUv-Visible Spectroscopy: Presented By: Gabriel Engonga and Flora DikeGabriel EngongaNo ratings yet

- TDS Nitoproof Damp Protect India2Document2 pagesTDS Nitoproof Damp Protect India2hitesh315No ratings yet

- Compressive Strength of Fly Ash-Based Geopolymer Concrete With A Variable of Sodium Hydroxide (Naoh) Solution MolarityDocument5 pagesCompressive Strength of Fly Ash-Based Geopolymer Concrete With A Variable of Sodium Hydroxide (Naoh) Solution Molarityjahremade jahremadeNo ratings yet

- Sample Question Paper Term IIDocument3 pagesSample Question Paper Term IIKafeel ShahNo ratings yet

- In Uence of Coatings On Tensile Properties of Glass Fiber: Materials Science April 2014Document6 pagesIn Uence of Coatings On Tensile Properties of Glass Fiber: Materials Science April 2014MorkizgaNo ratings yet

- Fragmentations PaternDocument22 pagesFragmentations PaternkhadijahhannahNo ratings yet

- The Design of Microbial Fuel Cell (MFC) : Author 1:Mrs. Saee Harshad ThakurDocument6 pagesThe Design of Microbial Fuel Cell (MFC) : Author 1:Mrs. Saee Harshad ThakurmNo ratings yet

- Diffusion Through Solids: Types and MechanismsDocument55 pagesDiffusion Through Solids: Types and MechanismsDivyamNo ratings yet

- Past Paper - Acids and Alkalis - LQDocument10 pagesPast Paper - Acids and Alkalis - LQapi-3739994100% (2)

- MBC 201 Nature of Biomolecules, Basic Concept of Metabolism, Integration of Intermediary Metabolism and Energy Generation.Document13 pagesMBC 201 Nature of Biomolecules, Basic Concept of Metabolism, Integration of Intermediary Metabolism and Energy Generation.Aina AdesolaNo ratings yet

- Cambridge O Level: CHEMISTRY 5070/22Document20 pagesCambridge O Level: CHEMISTRY 5070/22Saim QadriNo ratings yet

- Chemistry Unit 2 Part 2 ReallyacademicsDocument26 pagesChemistry Unit 2 Part 2 ReallyacademicsWill Andy100% (1)

- Chem Ch-10 DPPDocument36 pagesChem Ch-10 DPPDummy dumNo ratings yet

- 214 Lab-Exp 3 2021Document19 pages214 Lab-Exp 3 2021Rahaf ZaitounNo ratings yet

- Mono103 006 Bitumens PDFDocument182 pagesMono103 006 Bitumens PDFtariq wazedNo ratings yet

- Anjum 2016Document54 pagesAnjum 2016Dileepa NeranjanaNo ratings yet

- Chemical Engineer Resume Seeking New OpportunityDocument3 pagesChemical Engineer Resume Seeking New OpportunitypratikNo ratings yet

- AP Chemistry - Calorimetry Online LabDocument5 pagesAP Chemistry - Calorimetry Online LabJoseph SaccoNo ratings yet

- The Sintering Temperature Effect On Electrochemical Properties of Limn ODocument7 pagesThe Sintering Temperature Effect On Electrochemical Properties of Limn OSalsa NisaNo ratings yet

- 10 1021@acs Iecr 9b02077Document14 pages10 1021@acs Iecr 9b02077dipen royNo ratings yet

- 096723-Resinous Floor SpecsDocument7 pages096723-Resinous Floor SpecsGhayas JawedNo ratings yet

- Addition of CPP-ACP To Yogurt Inhibits Enamel SubsurfaceDocument24 pagesAddition of CPP-ACP To Yogurt Inhibits Enamel SubsurfaceSan SanNo ratings yet

- Organic Chemistry Midterm Activity 3Document2 pagesOrganic Chemistry Midterm Activity 3Frances May MagalonaNo ratings yet