Professional Documents

Culture Documents

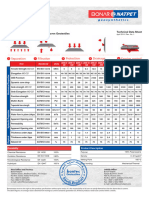

1 Wa-Catalog9

Uploaded by

johnOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

1 Wa-Catalog9

Uploaded by

johnCopyright:

Available Formats

Technical Information

Devcon® Flexane® Devcon® Flexane® Devcon® Flexane® Devcon® Flexane® Devcon® Flexane®

Physical Properties Devcon® R-Flex®

80 Putty Brushable High Performance Putty Fast Cure Putty Fast Cure Liquid

Color Black Black Black Black Black Grey

Mix ratio by weight resin:hardener 88:12 72:28 80:20 94:6 80:20 80:20

Mixed viscosity cP Putty Putty 40,000 Putty Putty 5,800

Pot life minutes @ 75˚F 4 20 45 10 8 8

Specific volume inches3/pound 27.4 23.5 26.0 23.5 23.5 26.5

Coverage per pound inches2

440 (4lb)/110 (1.5lb) 94 104 94 94 106

@ 1/4" thickness

Functional cure hours 1 1/2 12 18 16 3 2

Demolding time hours N/A N/A N/A N/A N/A N/A

Cured hardness

92 87 86 78 88 94

(ASTM D2240) Shore A

Cured shrinkage

NA 0.0014 0.232 0.122 0.0014 0.0018

(ASTM D2566) inch/inch

Tensile strength

1,462 1,700 3,500 4,500 2,400 3,300

(ASTM D412) psi

Tear resistance

270 300 400 400 275 430

(ASTM D624) pli

Abrasion resistance

270 280 90 140 220 330

weight loss1

Maximum elongation

421 300 600 600 500 450

(ASTM D412) %

Dielectric strength

350 350 340 350 350 350

(ASTM D149 ) volts/mil

Maximum continuous wet

120 120 120 120 120 120

service temperature ˚F

Maximum continuous dry

180 180 180 180 180 180

service temperature ˚F

Maximum continuous wet

120 120 120 120 120 120

service temperature ˚F

NOTES: 1 Taber H-18 wheel (mg/1,000 revolutions @ 1,000 gram load) 2 Due to solvent loss

Devcon® Flexane® Devcon® Flexane® Devcon® Flexane® Devcon® Flexane® Devcon® Flexane®

Chemical Resistance Devcon® R-Flex®

80 Putty Brushable High Performance Putty Fast Cure Putty Fast Cure Liquid

ACIDS

Acetic 10%

Hydrochloric 10%

Sulfuric 10%

Sulfuric 50%

Phosphoric 10%

ALCOHOLS

Methanol

Isopropanol

KETONES

Acetone

Methyl ethyl ketone

ALKALIS

Ammonium hydroxide 20%

Sodium hydroxide 10%

HYDROCARBONS

Gasoline (unleaded)

Mineral spirits

SALTS

Sodium chloride

Trisodium phosphate

Aluminum sulfate 10%

Sodium carbonate 10%

Key: Excellent Very Good Fair Poor

You might also like

- Mcqs of Family LawDocument24 pagesMcqs of Family LawVenugopal Mantraratnam32% (19)

- Inr Si47 1038g e PDFDocument107 pagesInr Si47 1038g e PDFsd23No ratings yet

- Life Wealth Mastery EnglishDocument12 pagesLife Wealth Mastery EnglishD.j. Ralmm100% (1)

- Medical Power PointDocument124 pagesMedical Power PointPhysiology by Dr Raghuveer75% (4)

- Traits and BehaviorDocument8 pagesTraits and BehaviorNorwafa Cariga EspinosaNo ratings yet

- DCM601A51 - Technical DataDocument405 pagesDCM601A51 - Technical Datathanhthuan100% (1)

- TDI - Full Cave Diver Course: TDI Instructor Manual Part 2 - Diver Standards Date: 12/31/2009 Revision: 10.0Document5 pagesTDI - Full Cave Diver Course: TDI Instructor Manual Part 2 - Diver Standards Date: 12/31/2009 Revision: 10.0BraulioNo ratings yet

- Product Specification BS-4449Document2 pagesProduct Specification BS-4449Cyprian Cypu100% (2)

- Epofine 740 - Finehard 5200Document4 pagesEpofine 740 - Finehard 5200Karishma PrabhuNo ratings yet

- 1 Wa-Catalog7Document1 page1 Wa-Catalog7johnNo ratings yet

- Technical Information: (BR) (WR-2) (Special F)Document1 pageTechnical Information: (BR) (WR-2) (Special F)johnNo ratings yet

- 1 Wa-Catalog13Document1 page1 Wa-Catalog13johnNo ratings yet

- Technical Information: (A) (SF) (ST) (F)Document1 pageTechnical Information: (A) (SF) (ST) (F)johnNo ratings yet

- ITW Product Catalog23Document1 pageITW Product Catalog23johnNo ratings yet

- 1 Wa-Catalog5Document1 page1 Wa-Catalog5johnNo ratings yet

- Datasheet SD Ferralium 255 SD50 BarDocument4 pagesDatasheet SD Ferralium 255 SD50 Barpranav kariaNo ratings yet

- 01.03.03.101 Spesifikasi-BPM HDPE SmoothDocument1 page01.03.03.101 Spesifikasi-BPM HDPE SmoothRezky BaskoroNo ratings yet

- Foodmax Grease CAS S 2 LS - TDS - 263701301 - ENDocument2 pagesFoodmax Grease CAS S 2 LS - TDS - 263701301 - ENDeath Heart100% (1)

- LdpeDocument1 pageLdpeArdy WiyogoNo ratings yet

- Dokumen - Tips - Castables and Refractories For Cement Dri Sponge Iron Kiln CoolerDocument8 pagesDokumen - Tips - Castables and Refractories For Cement Dri Sponge Iron Kiln CoolerjulianoducaNo ratings yet

- Devcon Plastic Steel Putty ADocument3 pagesDevcon Plastic Steel Putty AAZLAN ABDULLAINo ratings yet

- Nominal Engineering Properties of Ryton R-4: Data SheetDocument4 pagesNominal Engineering Properties of Ryton R-4: Data SheetRakeshNo ratings yet

- Foodmax Grease CAS S 2 HS - TDS - 263701201 - ENDocument2 pagesFoodmax Grease CAS S 2 HS - TDS - 263701201 - ENDeath HeartNo ratings yet

- Technical Data Sheet Uhmw Polyethelyne (Uhmw Pe) : (Ultra High Molecular Weight Polyethylene)Document1 pageTechnical Data Sheet Uhmw Polyethelyne (Uhmw Pe) : (Ultra High Molecular Weight Polyethylene)HARSHA PNo ratings yet

- Materialdatasheet 80 NBR 709 6Document3 pagesMaterialdatasheet 80 NBR 709 6Miguel ContrerasNo ratings yet

- Tairilac ABS Resin: Properties (1/3)Document3 pagesTairilac ABS Resin: Properties (1/3)DiegoTierradentroNo ratings yet

- Tairilac ABS Resin Properties and CharacteristicsDocument3 pagesTairilac ABS Resin Properties and CharacteristicsDiegoTierradentroNo ratings yet

- UHMW Mechanical Properties: Comparison of Dynamic Coefficient of Friction On Polished SteelDocument4 pagesUHMW Mechanical Properties: Comparison of Dynamic Coefficient of Friction On Polished SteeldangdinhthyNo ratings yet

- Couplant Comparison and Specification ChartDocument1 pageCouplant Comparison and Specification ChartdantegimenezNo ratings yet

- Technical Data Sheet High Density Polyethylene: Typical Properties of PolyethyleneDocument1 pageTechnical Data Sheet High Density Polyethylene: Typical Properties of PolyethyleneQuality teamNo ratings yet

- Technical Data of Adtech Fluoroplastic Polymers: Servicios E Importaciones Especializadas S.A. de C.VDocument1 pageTechnical Data of Adtech Fluoroplastic Polymers: Servicios E Importaciones Especializadas S.A. de C.VEdgar LucianoNo ratings yet

- Corys Geosynthetics Data Sheet HDPE Smooth Geomembrane: Metric UnitsDocument1 pageCorys Geosynthetics Data Sheet HDPE Smooth Geomembrane: Metric UnitsVenkadesh PeriathambiNo ratings yet

- 4070-4072 Product InfoDocument2 pages4070-4072 Product InfoCesar Marcello Cordova GuerreroNo ratings yet

- HojaTecnica Heat Flex Hi Temp 1200Document4 pagesHojaTecnica Heat Flex Hi Temp 1200NANCY JASMIN MORENONo ratings yet

- Plastic Steel Putty A v3Document2 pagesPlastic Steel Putty A v3feri.ferdianto02No ratings yet

- Maker Tauro enDocument2 pagesMaker Tauro enibrahim maulanaNo ratings yet

- MetaCeram-25040.. Castollin EutecticDocument2 pagesMetaCeram-25040.. Castollin EutecticAndrés MolinaNo ratings yet

- The PE4710 - PE 100 Is A Special Black Polyethylene Material For The Pipe IndustryDocument2 pagesThe PE4710 - PE 100 Is A Special Black Polyethylene Material For The Pipe IndustrysreeNo ratings yet

- Rigid 10k DatasheetDocument2 pagesRigid 10k DatasheetAna Maria RodrigoNo ratings yet

- Protective DTM Acrylic Primer/Finish Product DescriptionDocument4 pagesProtective DTM Acrylic Primer/Finish Product DescriptionVernon Jiménez FonsecaNo ratings yet

- Fluteck P7500 CA v01.19Document2 pagesFluteck P7500 CA v01.19fprovitaliNo ratings yet

- Lcy 6733Document1 pageLcy 6733quangga10091986No ratings yet

- TecamidDocument2 pagesTecamidTejas HuddarNo ratings yet

- DS Mold 4140Document3 pagesDS Mold 4140reza prasetiaNo ratings yet

- TDS - 7-0008 - Internal Pipe Coating - EngDocument3 pagesTDS - 7-0008 - Internal Pipe Coating - Englong chanNo ratings yet

- Optigear 1100 RangeDocument3 pagesOptigear 1100 RangeResistenciaDisidenteNo ratings yet

- Geotextiles DatasheetDocument1 pageGeotextiles DatasheetMohammad TalalNo ratings yet

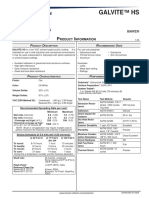

- Protective & Marine Coatings: Galvite™ HsDocument4 pagesProtective & Marine Coatings: Galvite™ HsAna CabreraNo ratings yet

- Bronze Putty: Technical Data SheetDocument2 pagesBronze Putty: Technical Data SheetSharad ShahNo ratings yet

- HT Swancor 901-Pt-Ve-30Document3 pagesHT Swancor 901-Pt-Ve-30Fernando Cesar PérezNo ratings yet

- SAF 2205 DatasheetDocument11 pagesSAF 2205 DatasheetNitinNo ratings yet

- Castrol Tribol GR 4020 220-460 PD Tds-EnDocument3 pagesCastrol Tribol GR 4020 220-460 PD Tds-EnIulian BarbuNo ratings yet

- 1125 (Eng)Document1 page1125 (Eng)Sarthak AggarwalNo ratings yet

- Brushable CeramicDocument2 pagesBrushable CeramicDivyanshu GuptaNo ratings yet

- Aw Hydraulic Oil: Applications Selection GuideDocument2 pagesAw Hydraulic Oil: Applications Selection GuideMassimiliano VolaNo ratings yet

- LCP Ueno A5000 MSDSDocument1 pageLCP Ueno A5000 MSDSEvertNo ratings yet

- 4622 Monolec® Multiplex Lubricant - TDSDocument4 pages4622 Monolec® Multiplex Lubricant - TDSEngineering MP CikupaNo ratings yet

- Nap-Gard 7-2500 PDFDocument2 pagesNap-Gard 7-2500 PDFPietro ViganNo ratings yet

- Bontec Non-Woven Geotextiles - TDSDocument11 pagesBontec Non-Woven Geotextiles - TDSAnang BagusNo ratings yet

- Protective & Marine Coatings: Polysiloxane 1KDocument4 pagesProtective & Marine Coatings: Polysiloxane 1KAna CabreraNo ratings yet

- Desmodur TD6xx Based SystemsDocument2 pagesDesmodur TD6xx Based SystemsKris SzongNo ratings yet

- Bel Ray Molylube Ultra Open Gear Lubricant PDS 12june2023 1Document2 pagesBel Ray Molylube Ultra Open Gear Lubricant PDS 12june2023 1xxx yyyNo ratings yet

- Product Data Sheet: 100 Gear Oil Extreme Pressure Gear OilDocument3 pagesProduct Data Sheet: 100 Gear Oil Extreme Pressure Gear OilDiegoNo ratings yet

- Ceramic Repair Putty: Technical Data SheetDocument2 pagesCeramic Repair Putty: Technical Data SheetNiku SamarthNo ratings yet

- Technical Data Sheet Polyfoam Normal: Extruded Polystyrene Insulation (Non Fire R Etardant)Document1 pageTechnical Data Sheet Polyfoam Normal: Extruded Polystyrene Insulation (Non Fire R Etardant)Raha Trading and ContactingNo ratings yet

- Floor Repair and Surfacing: AcidsDocument1 pageFloor Repair and Surfacing: AcidsjohnNo ratings yet

- ITW Product Catalog40 PDFDocument1 pageITW Product Catalog40 PDFjohnNo ratings yet

- ITW Product Catalog39 PDFDocument1 pageITW Product Catalog39 PDFjohnNo ratings yet

- ITW Product Catalog33 PDFDocument1 pageITW Product Catalog33 PDFjohnNo ratings yet

- ITW Product Catalog41 PDFDocument1 pageITW Product Catalog41 PDFjohnNo ratings yet

- ITW Product Catalog33 PDFDocument1 pageITW Product Catalog33 PDFjohnNo ratings yet

- ITW Product Catalog30 PDFDocument1 pageITW Product Catalog30 PDFjohnNo ratings yet

- ITW Product Catalog32 PDFDocument1 pageITW Product Catalog32 PDFjohnNo ratings yet

- ITW Product Catalog32 PDFDocument1 pageITW Product Catalog32 PDFjohnNo ratings yet

- ITW Product Catalog30 PDFDocument1 pageITW Product Catalog30 PDFjohnNo ratings yet

- ITW Product Catalog29 PDFDocument1 pageITW Product Catalog29 PDFjohnNo ratings yet

- ITW Product Catalog31 PDFDocument1 pageITW Product Catalog31 PDFjohnNo ratings yet

- ITW Product Catalog28Document1 pageITW Product Catalog28johnNo ratings yet

- ITW Product Catalog30 PDFDocument1 pageITW Product Catalog30 PDFjohnNo ratings yet

- ITW Product Catalog33 PDFDocument1 pageITW Product Catalog33 PDFjohnNo ratings yet

- ITW Product Catalog29 PDFDocument1 pageITW Product Catalog29 PDFjohnNo ratings yet

- ITW Product Catalog31 PDFDocument1 pageITW Product Catalog31 PDFjohnNo ratings yet

- ITW Product Catalog27Document1 pageITW Product Catalog27johnNo ratings yet

- ITW Product Catalog26Document1 pageITW Product Catalog26johnNo ratings yet

- ITW Product Catalog31 PDFDocument1 pageITW Product Catalog31 PDFjohnNo ratings yet

- ITW Product Catalog17Document1 pageITW Product Catalog17johnNo ratings yet

- ITW Product Catalog32 PDFDocument1 pageITW Product Catalog32 PDFjohnNo ratings yet

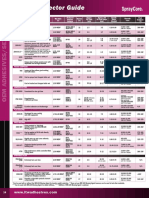

- MRO Product Selector GuideDocument1 pageMRO Product Selector GuidejohnNo ratings yet

- ITW Product Catalog22Document1 pageITW Product Catalog22johnNo ratings yet

- General Surface Preparation Concrete RubberDocument1 pageGeneral Surface Preparation Concrete RubberjohnNo ratings yet

- ITW Product Catalog21 PDFDocument1 pageITW Product Catalog21 PDFjohnNo ratings yet

- Dfense BLO: Wearing CompoundsDocument1 pageDfense BLO: Wearing CompoundsjohnNo ratings yet

- ITW Product Catalog16 PDFDocument1 pageITW Product Catalog16 PDFjohnNo ratings yet

- Sorogon Medical Mission Group Hospital Operation RecordDocument3 pagesSorogon Medical Mission Group Hospital Operation RecordRoden BerdinNo ratings yet

- Manual Book IOG ConventionDocument17 pagesManual Book IOG ConventionTaufiq MaulanaNo ratings yet

- ZinkPower Batam - Company BrochureDocument6 pagesZinkPower Batam - Company BrochureansarALLAAHNo ratings yet

- EMBRYOLOGYDocument4 pagesEMBRYOLOGYbhagavan prasadNo ratings yet

- Counter Argument Against Euthanasia (40Document4 pagesCounter Argument Against Euthanasia (40Daphniee PosingNo ratings yet

- Work Immersion PortfolioDocument15 pagesWork Immersion PortfolioKaye Irish RosauroNo ratings yet

- Subway 2009Document12 pagesSubway 2009sparklers_mNo ratings yet

- Sedimentation Tank Design NptelDocument7 pagesSedimentation Tank Design NptelNayan HalderNo ratings yet

- Cronidur 30: Maximum Demand by Maximum Demand by Corrosive Stress WearDocument24 pagesCronidur 30: Maximum Demand by Maximum Demand by Corrosive Stress WearVlad PopescuNo ratings yet

- ZavzpretDocument21 pagesZavzpretNeethu Anna StephenNo ratings yet

- Online Medicine Industry Competitor AnalysisDocument14 pagesOnline Medicine Industry Competitor Analysispawangadiya1210No ratings yet

- Blood Bank Case Study 5bDocument2 pagesBlood Bank Case Study 5bbalqis jaberNo ratings yet

- Honey & Bee Product Recipes: November 2007Document29 pagesHoney & Bee Product Recipes: November 2007Kyra ThomasNo ratings yet

- Ecl7000 enDocument2 pagesEcl7000 ensuchaya tupyangNo ratings yet

- Hyperfunctional Voice DisordersDocument11 pagesHyperfunctional Voice DisordersJam PNo ratings yet

- M 200Document3 pagesM 200Rafael Capunpon VallejosNo ratings yet

- PEDH ReviewerDocument10 pagesPEDH ReviewerMaki Orejola de LeonNo ratings yet

- WordsDocument11 pagesWordsAref HoseyniNo ratings yet

- DC532: 16 Digital Inputs and 16 Digital Outputs Module for S500 PLCDocument3 pagesDC532: 16 Digital Inputs and 16 Digital Outputs Module for S500 PLCVinay SaiNo ratings yet

- Broken Access ControlDocument3 pagesBroken Access ControlGlady GladsonNo ratings yet

- Personal LetterDocument4 pagesPersonal LetterAskme AzmyNo ratings yet

- WP Stratasys TopFiveReasonsDocument7 pagesWP Stratasys TopFiveReasonscititorulturmentatNo ratings yet

- Refrigeration and Air Conditioning Laboratory: Lab Session 3 Absorption Refrigeration Demonstrator 816 ObjectivesDocument10 pagesRefrigeration and Air Conditioning Laboratory: Lab Session 3 Absorption Refrigeration Demonstrator 816 Objectivesjhon milliNo ratings yet