Professional Documents

Culture Documents

1 Wa-Catalog7

Uploaded by

johnOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

1 Wa-Catalog7

Uploaded by

johnCopyright:

Available Formats

Technical Information

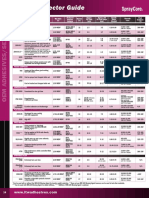

Devcon® Devcon® Devcon® Devcon® Devcon® Devcon® Devcon®

Physical Devcon® Devcon®

Wear Guard™ Wear Guard™ Wear Guard™ Wear Guard™ Wear Guard™ Combo Wear FC HV Tile

Properties Tile Adhesive Carbide Putty

Fine Load High Load High Temp High Impact Ultra (Fast Cure) Adhesive

Color Grey Grey Grey Dark Grey Grey Grey White Grey Grey

Mix ratio by weight /volume

resin:hardener

2:1 / 2:1 2:1 / 2:1 13.7:1 / 6:1 2.5:1 / 2.5:1 2.15:1:5.65 2 2:1 / 2:1 1.1:1 / 1:1 1.1:1 / 1:1 8:1 / 4:1

Mixed viscosity cP Putty Putty Putty Putty Putty Putty Putty Putty Putty

Functional cure hours 6-8 6-8 Heat Cured 6-8 16 2-3 12 8 16

Pot life minutes @ 75˚F 30 30 120 30 20 7 240 35 50

Specific volume inches1/pound 12.4 12.9 14.3 12.4 11.4 12.4 19.2 19 15.9

Coverage per pound

inches2 @ 1⁄4" thickness

50 50 60 50 46 50 76.8 76 64

Cured hardness

(ASTM D2240) Shore D

87 87 87 85 87 87 81 81 85

Cured shrinkage

(ASTM D2566) inch/inch

0.0006 0.0006 0.0010 0.0006 0.0004 0.0008 0.0010 0.0010 0.0009

Adhesive tensile shear

(ASTM D1002) psi

1,375 1,474 2,300 2,567 1,425 1,450 2,890 1,825 1,350

Compressive strength

(ASTM D695) psi

11,000 11,000 13,200 7,250 13,910 11,000 9,620 11,800 8,160

Flexural strength

(ASTM D790) psi

7,190 7,140 8,220 6,144 7,220 7,140 5,480 5,400 5,480

Coefficient of thermal

expansion (ASTM D696) 34 32 27 34 26 34 14 14 14

[(in)/(in x ˚F)] x 10-6

Dielectric constant

(ASTM D150) 1 kHz

46.0 41.0 38.0 46.0 40.0 41.0 46.0 45.0 25.0

Maximum continuous dry

service temperature ˚F

300 300 450 300 300 300 200 200 250

Maximum continuous wet

140 140 150 140 140 140 N/A N/A 120

service temperature ˚F

NOTES: 2 Three-part system, beads separate

Chemical Devcon® Devcon® Devcon® Devcon® Devcon® Devcon®

Devcon® Devcon® Devcon®

Wear Guard™ Wear Guard™ Wear Guard™ Wear Guard™ Wear Guard™ Combo Wear FC

Resistance Tile Adhesive HV Tile Adhesive Carbide Putty

Fine Load High Load High Temp High Impact Ultra (Fast Cure)

ACIDS

Acetic 10%

Hydrochloric 10%

Sulfuric 10%

ALCOHOLS

Methanol

Isopropanol

KETONES

Acetone

Methyl ethyl ketone

ALKALIS

Ammonium hydroxide 20%

Sodium hydroxide 10%

HYDROCARBONS

Gasoline (unleaded)

Mineral spirits

CHLORINATED

HYDROCARBONS

1-1-1 Trichloroethane

SALTS

Sodium chloride

Trisodium phosphate

Key: Excellent Very Good Fair Poor

You might also like

- Sigma Fluid PDFDocument2 pagesSigma Fluid PDFHubertt Chacon AntonioNo ratings yet

- Service Manual Repair Parts: Size 03 To 20 Posidyne Clutch/Brake DrivesDocument45 pagesService Manual Repair Parts: Size 03 To 20 Posidyne Clutch/Brake DrivesAnibal RodriguezNo ratings yet

- ITW Product Catalog23Document1 pageITW Product Catalog23johnNo ratings yet

- Technical Information: (BR) (WR-2) (Special F)Document1 pageTechnical Information: (BR) (WR-2) (Special F)johnNo ratings yet

- 1 Wa-Catalog13Document1 page1 Wa-Catalog13johnNo ratings yet

- 1 Wa-Catalog9Document1 page1 Wa-Catalog9johnNo ratings yet

- 1 Wa-Catalog5Document1 page1 Wa-Catalog5johnNo ratings yet

- Technical Information: (A) (SF) (ST) (F)Document1 pageTechnical Information: (A) (SF) (ST) (F)johnNo ratings yet

- ITW Product Catalog21 PDFDocument1 pageITW Product Catalog21 PDFjohnNo ratings yet

- ITW Product Catalog30 PDFDocument1 pageITW Product Catalog30 PDFjohnNo ratings yet

- Devcon Catalog PDFDocument24 pagesDevcon Catalog PDFSergio MarchettiNo ratings yet

- UHMW Mechanical Properties: Comparison of Dynamic Coefficient of Friction On Polished SteelDocument4 pagesUHMW Mechanical Properties: Comparison of Dynamic Coefficient of Friction On Polished SteeldangdinhthyNo ratings yet

- NEISCO Technical Catalog 2020 Features UPVC Pressure FittingsDocument66 pagesNEISCO Technical Catalog 2020 Features UPVC Pressure FittingsKadiri El MoustaphaNo ratings yet

- Bergquist Gap Pad Comparison TableDocument1 pageBergquist Gap Pad Comparison TableMaike SongNo ratings yet

- LdpeDocument1 pageLdpeArdy WiyogoNo ratings yet

- Bpxe B6ctalDocument2 pagesBpxe B6ctalVusal HasanovNo ratings yet

- Technical Data Sheet Uhmw Polyethelyne (Uhmw Pe) : (Ultra High Molecular Weight Polyethylene)Document1 pageTechnical Data Sheet Uhmw Polyethelyne (Uhmw Pe) : (Ultra High Molecular Weight Polyethylene)HARSHA PNo ratings yet

- Technical Data Sheet PVC: (Polyvinyl Chloride)Document1 pageTechnical Data Sheet PVC: (Polyvinyl Chloride)Adnan KhanNo ratings yet

- PVC and CPVC properties referenceDocument2 pagesPVC and CPVC properties referenceAdnan KhanNo ratings yet

- Epoxy Adhesives: Devcon 10 Minute Epoxy Devcon HP 250Document1 pageEpoxy Adhesives: Devcon 10 Minute Epoxy Devcon HP 250johnNo ratings yet

- Zeus Inc. Properties Of Extruded FluoropolymersDocument1 pageZeus Inc. Properties Of Extruded FluoropolymersAmir KhanNo ratings yet

- Hex Bonde A 9394 Structi L PDFDocument2 pagesHex Bonde A 9394 Structi L PDFFlorian Le MaoNo ratings yet

- Tairilac ABS Resin Properties and CharacteristicsDocument3 pagesTairilac ABS Resin Properties and CharacteristicsDiegoTierradentroNo ratings yet

- Tairilac ABS Resin: Properties (1/3)Document3 pagesTairilac ABS Resin: Properties (1/3)DiegoTierradentroNo ratings yet

- Plastic Steel Putty A v3Document2 pagesPlastic Steel Putty A v3feri.ferdianto02No ratings yet

- Prefabricated Vertical Drain For Soft Ground Improvement: Verti-Drain Is DAEHAN's Registered TrademarkDocument6 pagesPrefabricated Vertical Drain For Soft Ground Improvement: Verti-Drain Is DAEHAN's Registered Trademark김경모No ratings yet

- Devcon Plastic Steel Putty ADocument3 pagesDevcon Plastic Steel Putty AAZLAN ABDULLAINo ratings yet

- 01.03.03.101 Spesifikasi-BPM HDPE SmoothDocument1 page01.03.03.101 Spesifikasi-BPM HDPE SmoothRezky BaskoroNo ratings yet

- Thermalbond v2200 Foam Tape Tds 1067 PDFDocument2 pagesThermalbond v2200 Foam Tape Tds 1067 PDFDario DiazNo ratings yet

- Scotchweld EC 2216BADocument8 pagesScotchweld EC 2216BAbenNo ratings yet

- Ceramic Repair Putty: Technical Data SheetDocument2 pagesCeramic Repair Putty: Technical Data SheetNiku SamarthNo ratings yet

- WD-40 Multi-Use Product: Technical Data SheetDocument3 pagesWD-40 Multi-Use Product: Technical Data SheetKatsukiDaito100% (1)

- Corys Geosynthetics Data Sheet HDPE Smooth Geomembrane: Metric UnitsDocument1 pageCorys Geosynthetics Data Sheet HDPE Smooth Geomembrane: Metric UnitsVenkadesh PeriathambiNo ratings yet

- Elite NG 5401BDocument3 pagesElite NG 5401BAbdo WalidNo ratings yet

- 1125 (Eng)Document1 page1125 (Eng)Sarthak AggarwalNo ratings yet

- Technical Data Sheet Peek: Typical Properties of Virgin (Unfilled) PeekDocument2 pagesTechnical Data Sheet Peek: Typical Properties of Virgin (Unfilled) PeekSyed MoinNo ratings yet

- Epoxy Curing With INVISTA DiaminesDocument5 pagesEpoxy Curing With INVISTA DiaminesUnknownNo ratings yet

- Fluoropolymer Tubing (MS 02 196)Document2 pagesFluoropolymer Tubing (MS 02 196)herysyam1980No ratings yet

- PolycarbonateDocument2 pagesPolycarbonateROHIT SHARMANo ratings yet

- PolycarbonateDocument2 pagesPolycarbonatepuvitta sudeshilaNo ratings yet

- PolycarbonateDocument2 pagesPolycarbonateAdnan KhanNo ratings yet

- Technical Data Sheet High Density Polyethylene: Typical Properties of PolyethyleneDocument1 pageTechnical Data Sheet High Density Polyethylene: Typical Properties of PolyethyleneQuality teamNo ratings yet

- Techtron PPS HPV & Ketron PEEK HPV SpecificationsDocument3 pagesTechtron PPS HPV & Ketron PEEK HPV SpecificationsPeterWayNo ratings yet

- Technical Data Sheet CPVC: (Chlorinated Polyvinyl Chloride)Document1 pageTechnical Data Sheet CPVC: (Chlorinated Polyvinyl Chloride)Nam NguyenNo ratings yet

- Technical Data Sheet G-10: General DescriptionDocument1 pageTechnical Data Sheet G-10: General Descriptionbahtiar affandyNo ratings yet

- Technical Data Sheet Ultem (Pei) : (Polyetherimide)Document3 pagesTechnical Data Sheet Ultem (Pei) : (Polyetherimide)Dynamic SaravananNo ratings yet

- Optigear EP 150Document3 pagesOptigear EP 150Franklin JprstNo ratings yet

- Datasheet SD Ferralium 255 SD50 BarDocument4 pagesDatasheet SD Ferralium 255 SD50 Barpranav kariaNo ratings yet

- Brosur EPS ISULATION SPECIFICATIONDocument2 pagesBrosur EPS ISULATION SPECIFICATIONtitaNo ratings yet

- PSG Epoxy Glass PhenolicsDocument1 pagePSG Epoxy Glass PhenolicsmadhunnadigNo ratings yet

- Thebault Dop01 Teboply Ext GBDocument2 pagesThebault Dop01 Teboply Ext GBDumitrache IulianNo ratings yet

- Technical Data Sheet: Page 1 of 6 HCD-10307 (Rev. 2011-11-03 2:00 PM)Document6 pagesTechnical Data Sheet: Page 1 of 6 HCD-10307 (Rev. 2011-11-03 2:00 PM)Pedro NavarroNo ratings yet

- CASTROL PERFECTO XDocument3 pagesCASTROL PERFECTO XHector Martin BarajasNo ratings yet

- Technical Data of Adtech Fluoroplastic Polymers: Servicios E Importaciones Especializadas S.A. de C.VDocument1 pageTechnical Data of Adtech Fluoroplastic Polymers: Servicios E Importaciones Especializadas S.A. de C.VEdgar LucianoNo ratings yet

- High Performance Stretch Film ResinDocument3 pagesHigh Performance Stretch Film Resinujang sukartaNo ratings yet

- DEVCON® Fasmetal 10 HVAC Repair (Special F)Document2 pagesDEVCON® Fasmetal 10 HVAC Repair (Special F)mohamed hamedNo ratings yet

- Ficha Tecnica Castrol Perfecto X RangeDocument3 pagesFicha Tecnica Castrol Perfecto X Rangeel pro jajaja GonzalezNo ratings yet

- Bronze Putty: Technical Data SheetDocument2 pagesBronze Putty: Technical Data SheetSharad ShahNo ratings yet

- Titanium Putty HPDocument2 pagesTitanium Putty HPDivyanshu GuptaNo ratings yet

- Geotextiles and Geomembranes HandbookFrom EverandGeotextiles and Geomembranes HandbookT.S. IngoldRating: 5 out of 5 stars5/5 (1)

- Floor Repair and Surfacing: AcidsDocument1 pageFloor Repair and Surfacing: AcidsjohnNo ratings yet

- ITW Product Catalog32 PDFDocument1 pageITW Product Catalog32 PDFjohnNo ratings yet

- ITW Product Catalog29 PDFDocument1 pageITW Product Catalog29 PDFjohnNo ratings yet

- ITW Product Catalog33 PDFDocument1 pageITW Product Catalog33 PDFjohnNo ratings yet

- ITW Product Catalog39 PDFDocument1 pageITW Product Catalog39 PDFjohnNo ratings yet

- ITW Product Catalog41 PDFDocument1 pageITW Product Catalog41 PDFjohnNo ratings yet

- ITW Product Catalog33 PDFDocument1 pageITW Product Catalog33 PDFjohnNo ratings yet

- ITW Product Catalog40 PDFDocument1 pageITW Product Catalog40 PDFjohnNo ratings yet

- ITW Product Catalog31 PDFDocument1 pageITW Product Catalog31 PDFjohnNo ratings yet

- ITW Product Catalog31 PDFDocument1 pageITW Product Catalog31 PDFjohnNo ratings yet

- ITW Product Catalog30 PDFDocument1 pageITW Product Catalog30 PDFjohnNo ratings yet

- ITW Product Catalog31 PDFDocument1 pageITW Product Catalog31 PDFjohnNo ratings yet

- ITW Product Catalog32 PDFDocument1 pageITW Product Catalog32 PDFjohnNo ratings yet

- ITW Product Catalog30 PDFDocument1 pageITW Product Catalog30 PDFjohnNo ratings yet

- ITW Product Catalog29 PDFDocument1 pageITW Product Catalog29 PDFjohnNo ratings yet

- ITW Product Catalog33 PDFDocument1 pageITW Product Catalog33 PDFjohnNo ratings yet

- ITW Product Catalog28Document1 pageITW Product Catalog28johnNo ratings yet

- ITW Product Catalog21 PDFDocument1 pageITW Product Catalog21 PDFjohnNo ratings yet

- ITW Product Catalog32 PDFDocument1 pageITW Product Catalog32 PDFjohnNo ratings yet

- ITW Product Catalog30 PDFDocument1 pageITW Product Catalog30 PDFjohnNo ratings yet

- ITW Product Catalog26Document1 pageITW Product Catalog26johnNo ratings yet

- ITW Product Catalog27Document1 pageITW Product Catalog27johnNo ratings yet

- ITW Product Catalog17Document1 pageITW Product Catalog17johnNo ratings yet

- General Surface Preparation Concrete RubberDocument1 pageGeneral Surface Preparation Concrete RubberjohnNo ratings yet

- Dfense BLO: Wearing CompoundsDocument1 pageDfense BLO: Wearing CompoundsjohnNo ratings yet

- ITW Product Catalog22Document1 pageITW Product Catalog22johnNo ratings yet

- ITW Product Catalog16 PDFDocument1 pageITW Product Catalog16 PDFjohnNo ratings yet

- MRO Product Selector GuideDocument1 pageMRO Product Selector GuidejohnNo ratings yet

- Antioxidants - MELROB - RubberDocument6 pagesAntioxidants - MELROB - RubberMarcos ROSSINo ratings yet

- DS PGM Using CPPDocument18 pagesDS PGM Using CPPanand5703No ratings yet

- Chapter 1 - Systems of Linear Equations and InequalitiesDocument7 pagesChapter 1 - Systems of Linear Equations and InequalitiesRonald AlmagroNo ratings yet

- Modeling, Simulation & Performance Analysis of BluetoothDocument4 pagesModeling, Simulation & Performance Analysis of BluetoothInternational Journal of Application or Innovation in Engineering & ManagementNo ratings yet

- Big-M Two Phase MethodsDocument51 pagesBig-M Two Phase Methodsbits_who_am_iNo ratings yet

- Biochem Laboratory ReviewerDocument6 pagesBiochem Laboratory Reviewer202370092No ratings yet

- T1 SeriesDocument1 pageT1 SeriesFabricio GonçalvesNo ratings yet

- Executive Summary by Dr. Eugene Brigham and Dr. Joel HoustonDocument12 pagesExecutive Summary by Dr. Eugene Brigham and Dr. Joel HoustonCharisseMaeM.CarreonNo ratings yet

- s67 Rosen Thermo - Hi.pvc Iz 2018 enDocument34 pagess67 Rosen Thermo - Hi.pvc Iz 2018 enSomea NoneaNo ratings yet

- 17-7 PHDocument48 pages17-7 PHsunsirNo ratings yet

- History and Working Principles of Tunnel DiodesDocument15 pagesHistory and Working Principles of Tunnel DiodesMahy MagdyNo ratings yet

- Experiment No.1 CalorimetryDocument6 pagesExperiment No.1 Calorimetrytintindlr100% (1)

- WL 80250 4 EA 0510 MainCat Equipment and ServicesDocument116 pagesWL 80250 4 EA 0510 MainCat Equipment and ServicesApetrei Ioan CristianNo ratings yet

- ME:5160 Fluid Flow HW6 SolutionDocument6 pagesME:5160 Fluid Flow HW6 SolutionDiki AgungNo ratings yet

- BNS-TCC Basler Time CurvesDocument8 pagesBNS-TCC Basler Time CurvesFelipeMoriNo ratings yet

- Química de CoordinacionDocument107 pagesQuímica de CoordinacionEMMANUEL ALEJANDRO FERNANDEZ GAVIRIANo ratings yet

- Assigment1 Jan30-2023Document4 pagesAssigment1 Jan30-2023Vaquas aloNo ratings yet

- P3 Light and Sound QuestionsDocument21 pagesP3 Light and Sound Questionslelon81No ratings yet

- Data Sartocon X-Cap15 SPC2065-eDocument2 pagesData Sartocon X-Cap15 SPC2065-eJosé Ramón Devan DevanNo ratings yet

- Is Structure AnswerDocument2 pagesIs Structure AnswerJay JayNo ratings yet

- IT MAth QuestionsDocument24 pagesIT MAth QuestionsTechnicianccna100% (2)

- Rubrics Vital Signs TakingDocument6 pagesRubrics Vital Signs TakingRichard SluderNo ratings yet

- Integration Iit KanpurDocument5 pagesIntegration Iit KanpurAnsh KapoorNo ratings yet

- Telecom-02-00022-V2Document21 pagesTelecom-02-00022-V2husam hamidNo ratings yet

- Energy Efficiency MotorCatalogue - Eff1Document2 pagesEnergy Efficiency MotorCatalogue - Eff1matealoredana8015No ratings yet

- Angular - A Popular JavaScript FrameworkDocument4 pagesAngular - A Popular JavaScript FrameworkAlbano FuttaNo ratings yet

- SimulationDocument56 pagesSimulationErica SalasNo ratings yet

- ASTM B 280-20 STD Spec For Seamless Copper Tubing For Air Conditioning and Refrigeration Field ServiceDocument9 pagesASTM B 280-20 STD Spec For Seamless Copper Tubing For Air Conditioning and Refrigeration Field Servicetomhansen935No ratings yet

- Tutorial 6Document5 pagesTutorial 6Nixon GamingNo ratings yet