Professional Documents

Culture Documents

Synthesis of Flowsheets For Extractive Distillation of Azeotropic Mixtures

Uploaded by

DiegoOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Synthesis of Flowsheets For Extractive Distillation of Azeotropic Mixtures

Uploaded by

DiegoCopyright:

Available Formats

Theoretical Foundations of Chemical Engineering, Vol. 39, No. 1, 2005, pp. 16–23.

Translated from Teoreticheskie Osnovy Khimicheskoi Tekhnologii, Vol. 39, No. 1, 2005, pp. 19–26.

Original Russian Text Copyright © 2005 by Ivanova, Timoshenko, Timofeev.

Synthesis of Flowsheets for Extractive Distillation

of Azeotropic Mixtures

L. V. Ivanova, A. V. Timoshenko, and V. S. Timofeev

Lomonosov State Academy of Fine Chemical Technology, pr. Vernadskogo 86, Moscow, 117571 Russia

E-mail: ilv79@mail.ru

Received April 23, 2004

Abstract—An algorithm for synthesizing extractive distillation flowsheets for separation of complex ternary

azeotropic mixtures with different vapor–liquid equilibrium patterns is proposed.

Separation of end fractions of given compositions single binary azeotrope were proposed, which use sep-

from azeotropic mixtures is complicated by thermody- aration of an azeotropic mixture at different pressures.

namic and topological constraints, which can be sur- Note that, in practice, thermodynamic and topolog-

mounted using the principle of redistribution of con- ical constraints on separation of end fractions of given

centration fields between separation regions [1–3]. This compositions are most often surmounted by using

principle can be implemented using homogeneous and extractive distillation. However, conventional extrac-

heterogeneous (involving extraction, adsorption, tive distillation methods are highly energy-intensive.

absorption, and chemical and other separation tech- Therefore, it is topical to develop and use optimal

niques) separation systems. In homogeneous systems, energy-saving technologies. This problem is solved in

distillation can be designed so that, at one of the steps, several steps:

an azeotropic fraction is isolated, which is then sepa- structural optimization of a flowsheet,

rated by special methods. If this fraction contains two optimization of the operating parameters of distilla-

or more components, one can use extractive distillation tion columns,

or separation of the azeotropic mixture at different design optimization of flowsheet elements.

pressures. If the fraction contains more than two com- Since distillation is irreversible, its thermodynamic

ponents, separation can be performed by methods using efficiency depends on the process path—a set of flow-

the curvature of the separating manifold [3, 4]. Previ- sheets or distillation trajectories. To date, approaches to

ously [2, 5], a general approach to synthesizing flow- synthesizing extractive distillation flowsheets have

sheets for distillation of multicomponent nonideal been developed obviously insufficiently. This question

(including azeotropic) mixtures was put forward, which was considered only in few works. For example, a num-

is based on the concept of a distillation region. Later ber of systems of different structures for separation of

[6–8], some approaches to synthesizing flowsheets for multicomponent azeotropic mixtures were proposed

distillation of multicomponent mixtures containing a [9]. Certain technological solutions for distillation of an

(‡) (b)

A B A

F F

S

S B

(c) (d) (e) (f) (j)

A B C A B

A B A A C

F F

F F F

S C B B S

S S C

S C

Fig. 1. Flowsheets for separation of (a, b) ternary and (c–g) quaternary zeotropic mixtures: A, B, C are components of a mixture; S

is a low-volatile extractant; F is feed (a, b) ABS and (c–g) ABCS.

0040-5795/05/3901-0016 © 2005 MAIK “Nauka /Interperiodica”

SYNTHESIS OF FLOWSHEETS FOR EXTRACTIVE DISTILLATION 17

A B C A B C

F S

Fn

S

S

Fig. 2. Representation of the distillation flowsheet in Fig. 1c

as the orgraph L. The nodes represent columns (empty cir- Fig. 3. Graph M obtained by splitting the node F of the

cles) and fractions (filled circles). graph L.

(‡) (b) (‡) (b)

A B C A B C

A B A

Fn Fn

S S Fn Fn

S

S B

Fig. 4. Graph U obtained by merging two nodes S (repre- Fig. 5. Graphs corresponding to flowsheets for extractive

senting fractions) of the graph M. distillation of an A–B binary azeotropic mixture.

ethanol–water mixture were presented [10]. However, concentration space can be used as elements of separa-

thermodynamic and topological constraints on the tion of mixtures in the second class of flowsheets for

compositions of the products were not always taken mixtures of higher dimensionality.

into account and the proposed solutions are inoperable.

Thus, structural optimization of extractive distillation Let us consider an algorithm for synthesizing flow-

currently remains virtually beyond the scope of consid- sheets of the first class. Introduction of an extractant

eration. Solving this problem is expediently begun lifts the thermodynamic and topological constraints on

from developing general algorithms for synthesizing the compositions of the product flows; therefore, as

flowsheets of this class. Within such a problem formu- prototypes for synthesis, we use sets of flowsheets for

lation, one can analyze not only distillation systems distillation of zeotropic mixtures in simple two-section

involving columns from which the products are with- columns. Let the object of separation be an (n + 1)-

drawn from two points, but also more complex struc- component mixture consisting of an n-component ini-

tures with partially coupled heat and material flows. tial azeotropic mixture and an extractant. Let us assume

However, early in our consideration, we restrict our- that the extractant is the least volatile component of the

selves to synthesizing a flowsheet for distillation of ter- mixture.

nary azeotropic mixtures in systems of two-point with- Figure 1 presents the flowsheets for distillation of

drawal columns. ternary and quaternary zeotropic mixtures. For further

By now, extractive distillation flowsheets have been analysis, we represent them as oriented graphs in which

classified. All the possible variants of separation can be nodes characterize columns and fractions, and edges

divided into two large classes [9]. The first class describe flow relationships between them. Let the

includes flowsheets in which an extractant is used as far nodes that characterize the fractions be labeled with the

upstream as the first column of a distillation system corresponding letters. For example, the flowsheet in

and, consequently, thermodynamic and topological Fig. 1c is represented by the graph in Fig. 2. The graph

constraints on the compositions of the product fractions in Fig. 2 describes the separation sequence. The next

are lifted. In flowsheets of the second class, the initial step of the synthesis is to split the flow F of the (n + 1)-

multicomponent mixture is predistilled until a fraction component mixture into two individual flows: the

of azeotrope-forming components is isolated, which is n-component mixture Fn and the extractant S. Formally,

then separated by extractive distillation. Taken if we start from the graph L in Fig. 2, we will obtain the

together, the two classes encompass all the possible graph M in Fig. 3. This structure already almost fully

variants of separation. Flowsheets of the first class for represents the extractive distillation flowsheet. It is only

distillation of mixtures with low dimensionality of the necessary to create a cycle for the extractant S by merg-

THEORETICAL FOUNDATIONS OF CHEMICAL ENGINEERING Vol. 39 No. 1 2005

18 IVANOVA et al.

(a) (b) (c) (d) (e)

A B C A S C S A B S C A A

F F F F F C

S B C B S

(f) (j) (h) (i) (g)

A B C A S C S A B S C A A

F F F F F C

S B C B S

(k) (l) (m) (n) (o)

A B C A S C S A B S C A A

B

Fn C

Fn Fn Fn Fn

S B C B S

Fig. 6. Synthesis of graphs corresponding to extractive distillation flowsheets.

ing two nodes (characterizing the fractions) labeled Fig. 5 presents only such variants. It is seen that the first

with S. We will obtain the graph U in Fig. 4. operability condition is satisfied only by the graph in

Note that, depending on the vapor–liquid equilib- Fig. 5a. The structure of this graph fully corresponds to

rium pattern, more than one edge may leave the node S the classical flowsheet for extractive distillation of a

(the extractant may also be necessary for separating the binary azeotropic mixture with a low-volatile extract-

mixture in the second column of the system) (Fig. 4b). ant.

The extractant S is assumed to ensure separation of the The example considered is trivial. Therefore, let us

entire n-component mixture into pure components. present our algorithm and illustrate it by the example of

Since the extractive distillation system has a closed separation of a ternary azeotropic mixture.

(without taking into account losses) cycle for the

extractant, one of the conditions of operability of flow- (1) Choose a vapor–liquid equilibrium pattern

sheets synthesized using the proposed algorithm is the according to Serafimov’s classification (Table 1) [11].

presence of a cycle in the orgraph. By a cycle, we mean As an example, we consider a pattern of type 3.1.1 t1a

the possibility of passing through a number of graph with direct orientation of distillation lines.

nodes and returning to the starting node with allowance

for the orientation of edges. A cycle must include at (2) Synthesize flowsheets for distillation of a quater-

least two nodes representing columns. A second condi- nary zeotropic mixture (Figs. 1c–1g) and represent

tion of operability of the proposed flowsheets is the them as orgraphs of the L type (Figs. 6a–6e).

introduction of the extractant into the column in which (3) In flowsheets of the set obtained (Figs. 6a–6e),

an azeotropic pair of components is separated. select and label nodes to which an edge from the node

Let us consider the simplest example, namely, sepa- S (representing the extraction column) should be

ration of an A–B binary azeotropic mixture. Obviously, directed. For the selected type of extractive distillation

for the given type of flowsheets, the extractant must be flowsheets, these nodes describe the columns that are

introduced into the first separation column; therefore, the first in the separation sequence (filled circles).

THEORETICAL FOUNDATIONS OF CHEMICAL ENGINEERING Vol. 39 No. 1 2005

SYNTHESIS OF FLOWSHEETS FOR EXTRACTIVE DISTILLATION 19

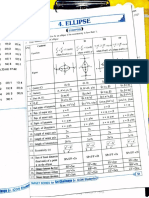

Table 1. Types of phase diagrams of ternary azeotropic mixtures with direct and reverse orientation of distillation lines

Diagram type Direct Reverse Diagram type Direct Reverse

A C A

3.1.0 t1a 3.2.1 t3a

B C B A B C

A C A C

3.1.0 t1b 3.2.1 t3b

B C B A B C B A

C A C A

3.1.0 t2 3.3.0 t1a

B A B C B A B C

A C A A

3.1.1 t1a 3.3.0 t1b

B C B A B C B C

C A C A

3.1.1 t1b 3.3.0 t2

B A B C B A B C

A A A

3.2.0 t1 3.3.1 t1b

B C B C B C

A C A A

3.2.0 t2a 3.3.1 t1c

B C B A B C B C

A C A A

3.2.0 t2b 3.3.1 t2

B C B A B C B C

THEORETICAL FOUNDATIONS OF CHEMICAL ENGINEERING Vol. 39 No. 1 2005

20 IVANOVA et al.

Table 1. (Contd.)

Diagram type Direct Reverse Diagram type Direct Reverse

A C A A

3.2.0 t2c 3.3.1 t3a

B C B A B C B C

C A A A

3.2.1 t1 3.3.1 t3b

B A B C B C B C

A C A A

3.2.1 t2a 3.3.1 t4

B C B A B C B C

A C

3.2.1 t2b

B C B A

(4) Split the node F into nodes Fn and S and remove the corresponding flowsheets, there is extractant recir-

the node S incident to the incoming edge. This opera- culation, and their applicability is determined by the

tion is equivalent to replacement of the node F by Fn. vapor–liquid equilibrium pattern. Therefore, when ana-

(5) Connect the node S to the labeled node (repre- lyzing structures for phase diagrams of different types,

senting the extraction column) with an oriented edge we further consider only these variants. In the flow-

leaving the node S and check the obtained structures sheets corresponding to the graphs in Figs. 6m and 6n,

(Figs. 6k–6o) for operability. there is no extractant recirculation, and these flowsheets

do not meet the operability conditions.

Of five graphs obtained, only two (Figs. 6k, 6l) meet

the operability conditions. They correspond to quite Let us consider an algorithm for synthesizing

trivial flowsheets in Fig. 7. extractive distillation flowsheets of the second class. In

Analyzing the graphs in Fig. 6, one can reveal a cer- this case, the first step is the distillation of the initial

tain set of flowsheets whose operability depends only mixture; therefore, for all the flowsheets of this class,

on the phase portraits of the corresponding distillation the extractant is used at any separation step other than

systems. These are the graphs in Figs. 6k, 6l, and 6o. In the first. Below are the main steps of the algorithm.

(1) Determine the type of the phase diagram. As an

example, we will consider the same vapor–liquid equi-

librium pattern of type 3.1.1 t1a with direct orientation

A B C A B of distillation lines.

ABC ABC (2) Synthesize flowsheets for distillation of a quater-

nary zeotropic mixture. When determining the

S S C sequence of separation of components, it is necessary

to consider the possibility of distilling the initial mix-

ture into an azeotropic constituent and a zeotropic con-

Fig. 7. Operable flowsheets for the vapor–liquid equilib- stituent. It is seen that the component C can also be iso-

rium pattern of type 3.1.1 t1a. lated without using extractive distillation. Of the five

THEORETICAL FOUNDATIONS OF CHEMICAL ENGINEERING Vol. 39 No. 1 2005

SYNTHESIS OF FLOWSHEETS FOR EXTRACTIVE DISTILLATION 21

(‡) (b) (c) (d)

F1 A B F1n A B F1 A B

A B

ABC

F F

F S

S

C S

C S C S C

Fig. 8. (a–c) Graphs and (d) flowsheet for extractive distillation.

possible separation variants proposed, only one flow- Two of them belong to the first class of flowsheets, in

sheet (Fig. 8) meets this condition. which azeotrope-forming components are separated in

(3) Determine and label graph nodes to which an the first column and extractive distillation is used start-

edge from the node S (representing the extraction col- ing with the first column; the third flowsheet belongs to

umn) should be directed. For the selected type of the second class of flowsheets, in which the initial mix-

extractive distillation flowsheets, these nodes describe ture is predistilled.

the columns where azeotrope-forming components are Let us consider the same vapor–liquid equilibrium

separated. pattern of type 3.1.1 t1a but with reverse orientation of

(4) Design extractant recirculation. In this case, add distillation lines. We will not dwell on algorithm steps

a node corresponding to the introduction of the extrac- in detail but will consider its results. It is seen that, in

tant into the column of separation of an azeotropic pair this case, the algorithm leads to other operable flow-

of components. In Fig. 8b, such a node is labeled by S. sheets (Fig. 9). The flowsheet in Fig. 9a belongs to the

first class of extractive distillation flowsheets and has

(5) Check the obtained structures for operability. quite an unconventional structure, and the flowsheet in

Among extractive distillation flowsheets of the sec- Fig. 9b belongs to the second class of flowsheets, in

ond class, some variants of process design can also be which the zeotropic constituent is preseparated.

a priori discarded. These are the flowsheets in Figs. 1d,

1f, and 1g. In the flowsheets in Figs. 1d and 1f, with Thus, the selection of flowsheets for separation of

allowance for the separation of the zeotropic constitu- azeotropic mixtures is a complex problem, which

ent of the mixture in the first column, the extractant is involves the investigation of the vapor–liquid equilib-

withdrawn upstream of the point of separation of the rium pattern and the analysis of all the possible variants

azeotropic pair of components. To implement the flow- of flowsheets. Therefore, we further consider the possi-

sheet in Fig. 1g, in the case of precise distillation, the bility of applying some flowsheets or others by the

initial mixture must contain at least four components. example of known types of phase diagrams of ternary

Thus, using the algorithm proposed, for separation

of the ternary mixture described by the vapor–liquid (‡) (b) (c)

equilibrium pattern of type 3.1.1 t1a with direct orien-

A B C A B

tation of distillation lines, we synthesized three opera- A C

ble extractive distillation flowsheets (Fig. 7, Fig. 8d).

F F F

B S

(‡) (b) S S

C

A ë A B ë (d) (e)

A B C A B

ABC ABC

B F F

S S

S C S

Fig. 9. Flowsheets for the vapor–liquid equilibrium pattern

of type 3.1.1 t1a with reverse orientation of distillation Fig. 10. Flowsheets of the (a–c) first and (d, e) second class

lines. of extractive distillation flowsheets.

THEORETICAL FOUNDATIONS OF CHEMICAL ENGINEERING Vol. 39 No. 1 2005

22 IVANOVA et al.

A B C A B C

ABC ABC

S S S

Fig. 11. Separation flowsheets for complex vapor–liquid equilibrium patterns.

mixtures. Earlier, we determined the flowsheets that out using an extractant. These are types 3.1.2 t1b and

can be implemented, depending on the type of phase 3.1.1 t1b. Within the concentration simplexes corre-

diagram of a mixture being separated (Fig. 10). The sponding to these types, a single bundle of distillation

results of analyzing these variants are presented in lines develops. This makes possible the separation of

Table 2. In addition, there are two types of phase dia- the pure components A, B, and C in a sequence of two

grams for which separation can also be performed with- distillation columns.

Note that, in each particular case, it is necessary to

carefully study the applicability of a separation variant.

Table 2. Operability of flowsheets in Figs. 10a–10e for var- For example, for a number of vapor–liquid equilibrium

ious types of phase diagrams with direct/reverse orientation patterns (3.2.0 t2b, 3.2.0 t2c, 3.2.1 t2b, 3.2.1 t3b,

of distillation lines when, in the first column, (I) an extractant

is used and (II) the initial mixture is distilled 3.3.0 t2, 3.3.1 t3b), flowsheets of the second class are

implementable only when the initial feed composition

I II belongs to a certain distillation region of the concentra-

Diagram

type tion simplex. For example, for the system characterized

10a 10b 10c 10d 10e by the vapor–liquid equilibrium pattern of type

3.1.0 t1a +/+ +/– –/+ –/+ +/– 3.2.0 t2b with direct orientation of distillation lines,

distillation of the initial mixture (isolation of the com-

3.1.0 t1b +/+ +/+ +/+ –/+ +/– ponent C) is possible if the initial feed composition

3.1.0 t2 +/+ +/– –/+ –/+ +/– belongs to the region AzÄÇ–B–C–AzÄë and the compo-

3.1.1 t1a +/+ +/– –/+ –/+ +/– sition of the distillate of this column corresponds to the

3.1.1 t1b +/+ +/+ +/+ +/– –/+

segment B–AzÄÇ.

3.1.1 t2 +/+ +/– –/+ –/– –/– As noted above, the operability of a flowsheet is

3.2.0 t1 + + – – – determined by the presence of a cycle in the corre-

sponding orgraph. The direction of the edge represent-

3.2.0 t2a +/+ +/– –/+ –/+ +/– ing the extractant recirculation is determined by the

3.2.0 t2b +/+ +/+ –/– –/+ +/– vapor–liquid equilibrium pattern of the initial mixture.

3.2.0 t2c +/+ +/+ –/– –/+ +/– The extractant must be directed only to the column

3.2.1 t1 +/+ –/+ +/– –/– –/–

(columns) in which the extractant is necessary for sep-

aration of the mixture. In the case of a complex vapor–

3.2.1 t2a +/+ +/– –/+ –/+ +/– liquid equilibrium pattern (3.1.1 t2, 3.2.1 t1, 3.2.1 t2b,

3.2.1 t2b +/+ +/– –/+ –/+ +/– 3.3.0 t1a, 3.3.0 t1b, 3.3.0 t2, and also all the subtypes of

3.2.1 t3a + + – – – 3.3.1), the extractant must be introduced simulta-

neously into two columns of the distillation system.

3.2.1 t3b +/+ +/+ –/– –/– +/– Therefore, such process design should always be com-

3.3.0 t1a +/+ –/– –/– –/+ +/– pared with two consecutive extractive distillation sys-

3.3.0 t1b +/+ –/– –/– –/– –/– tems for revealing the most efficient solution (Fig. 11).

3.3.0 t2 +/+ –/– –/– –/+ +/– Thus, we have developed a universal algorithm for

3.3.1 t1a +/+ –/– –/– –/+ +/– synthesizing flowsheets for extractive distillation of

3.3.1 t1b +/+ –/– –/– –/– –/– multicomponent azeotropic mixtures, which is based

on the use of flowsheets for distillation of zeotropic

3.3.1 t1c +/+ –/– –/– –/– –/– mixtures in simple two-section columns as prototypes

3.3.1 t2 +/+ –/– –/– –/– –/– of extractive distillation flowsheets. This algorithm

3.3.1 t3a +/+ –/– –/– –/– –/– should be applied at the step of structural optimization

of distillation flowsheets for reducing the energy con-

3.3.1 t3b +/+ –/– –/– –/– +/–

sumption for separation. It was noted that the operable

3.3.1 t4 +/+ –/– –/– –/– –/– flowsheets thus obtained should be subjected to further

THEORETICAL FOUNDATIONS OF CHEMICAL ENGINEERING Vol. 39 No. 1 2005

SYNTHESIS OF FLOWSHEETS FOR EXTRACTIVE DISTILLATION 23

analysis and discrimination for applicability to a partic- Distillation: Theory and Design), Moscow: Khimiya,

ular separation problem. 1983.

6. Timoshenko, A.V. and Serafimov, L.A., Flowsheet Syn-

thesis for Distillation of Multicomponent Mixtures with

ACKNOWLEDGMENTS One Binary Azeotrope, Teor. Osn. Khim. Tekhnol., 1999,

This work was supported by the Russian Foundation vol. 33, no. 1, pp. 47–53 [Theor. Found. Chem. Eng.

for Basic Research, project no. 04-03-32987. (Engl. Transl.), vol. 33, no. 1, pp. 41–47].

7. Timoshenko, A.V. and Serafimov, L.A., Synthesis and

Discrimination of Distillation Separation Flowsheets

REFERENCES Using an Energy Consumption Criterion, III Mezhdunar.

1. Serafimov, L.A., Technology of Separation of Azeotro- konf. “Naukoemkie khimicheskie tekhnologii” (III Int.

pic Mixtures, suppl. ch. in Swietoslawski, W., Azeotro- Conf. on Science-Intensive Chemical Technologies),

pia i poliazeotropia, Warszawa: Panstwowe Wydaw- Tver, 1995, p. 65.

nictwo Naukowe, 1957. Translated under the title 8. Timoshenko, A.V., Serafimov, L.A., Timofeev, V.S., and

Azeotropiya i poliazeotropiya, Moscow: Khimiya, 1968. Glushachenkova, E.A., Synthesis and Analysis of Flow-

2. Zharov, V.T. and Serafimov, L.A., Fiziko-khimicheskie sheets for Separation of Ternary Azeotropic Mixtures, IV

osnovy distillyatsii i rektifikatsii (Physicochemical Foun- Mezhdunar. konf. “Naukoemkie khimicheskie tekh-

dations of Distillation and Rectification), Leningrad: nologii” (IV Int. Conf. on Science-Intensive Chemical

Khimiya, 1975. Technologies), Volgograd, 1996, p. 84.

3. Serafimov, L.A. and Frolkova, A.K., Fundamental Prin- 9. Frolkova, A.K., Theoretical Foundations of Separation

ciple of Concentration-Field Redistribution between of Multicomponent Multiphase Systems Using Func-

Separation Regions as a Basis for the Design of Techno- tional Complexes, Doctoral (Tech.) Dissertation, Mos-

logical Systems, Teor. Osn. Khim. Tekhnol., 1997, cow: Lomonosov State Acad. Fine Chem. Technol.,

vol. 31, no. 2, pp. 184–193 [Theor. Found. Chem. Eng. 2000.

(Engl. Transl.), vol. 31, no. 2, pp. 159–166]. 10. Manan, Z.A. and Banares-Alcantara, R., A New Catalog

4. Grishunin, A.V., Balashov, M.I., and Serafimov, L.A., of the Most Promising Separation Sequences for Homo-

Synthesis of Systems of Distillation Columns for Sepa- geneous Azeotropic Mixtures: I. Systems without

ration of Ternary Azeotropic Mixtures Using the Princi- Boundary Crossing, Ind. Eng. Chem. Res., 2001, vol. 40,

ples of Traversability of Separating Manifolds, in Razde- pp. 5795–5809.

lenie zhidkikh neideal’nykh smesei. Tr. Altaisk. Politekh. 11. Serafimov, L.A., Thermodynamic and Topological Anal-

Inst. (Separation of Liquid Nonideal Mixtures (Proc. ysis of Heterogeneous Equilibrium Diagrams of Multi-

Altai Polytech. Inst.)), Barnaul, 1974, pp. 45–49. component Mixtures, Zh. Fiz. Khim., 2002, vol. 76,

5. Petlyuk, F.B. and Serafimov, L.A., Mnogokomponent- no. 8, p. 1331 [Russ. J. Phys. Chem. (Engl. Transl.),

naya rektifikatsiya. Teoriya i raschet (Multicomponent vol. 76, no. 8, pp. 1211–1224].

THEORETICAL FOUNDATIONS OF CHEMICAL ENGINEERING Vol. 39 No. 1 2005

You might also like

- Review Distillation PDFDocument35 pagesReview Distillation PDFsupercubos1No ratings yet

- CHE-471 Term Final QuestionsDocument18 pagesCHE-471 Term Final QuestionsAjmain ShakibNo ratings yet

- Extractive Distillation PDFDocument12 pagesExtractive Distillation PDFROHAN PATILNo ratings yet

- Ebook Chemistry and Chemical Reactivity 9Th Edition Kotz Solutions Manual Full Chapter PDFDocument44 pagesEbook Chemistry and Chemical Reactivity 9Th Edition Kotz Solutions Manual Full Chapter PDFMrNicolasGuerraJrnsadz100% (12)

- European Journal of Medicinal Chemistry: Channamata Shankara Naveena, Poojary Boja, Nalilu Sucheta KumariDocument12 pagesEuropean Journal of Medicinal Chemistry: Channamata Shankara Naveena, Poojary Boja, Nalilu Sucheta KumariWalid Ebid ElgammalNo ratings yet

- Nso Sample Paper Class-10 PDFDocument2 pagesNso Sample Paper Class-10 PDFShyam khandelwalNo ratings yet

- Che 246 Tuto 4Document8 pagesChe 246 Tuto 4SITI HAJAR ANAZIAH MUHAMADNo ratings yet

- Maximum Overlap Approximation Calculations On Polyato 1978 Journal of MolecuDocument11 pagesMaximum Overlap Approximation Calculations On Polyato 1978 Journal of MolecuFihad LatheefNo ratings yet

- Asphaltene EclipseDocument16 pagesAsphaltene Eclipsenguyenhoangduc82No ratings yet

- Exam Bio-Organic Chemistry (8S140) Thursday November 23, 2008 14.00-17.00 H This Exam Consists of 7 Questions. Explain Your Answers Clearly. Answers May Be Given in English or DutchDocument5 pagesExam Bio-Organic Chemistry (8S140) Thursday November 23, 2008 14.00-17.00 H This Exam Consists of 7 Questions. Explain Your Answers Clearly. Answers May Be Given in English or DutchSergeyNo ratings yet

- Nso Sample Paper Class-7Document2 pagesNso Sample Paper Class-7Adhrit ADHIKARINo ratings yet

- Absorption Spectra of Some Cobalt (III) Coördination CompoundsDocument5 pagesAbsorption Spectra of Some Cobalt (III) Coördination CompoundsHyga ForcarNo ratings yet

- Graphical Absorbance-Ratio Method For RapidDocument4 pagesGraphical Absorbance-Ratio Method For Rapidiabureid7460No ratings yet

- A Chemical Classification of Volcanic Rocks Based On The Total Alkali - Silica DiagramDocument6 pagesA Chemical Classification of Volcanic Rocks Based On The Total Alkali - Silica DiagramJackson Gonzalez BermudezNo ratings yet

- Steiner's Theorems On The Complete Quadrilateral Jean-Pierre EhrmannDocument18 pagesSteiner's Theorems On The Complete Quadrilateral Jean-Pierre EhrmannAltananyNo ratings yet

- 2001 ExamDocument5 pages2001 Examabhi_nishuNo ratings yet

- Liquid Extraction: Phase DiagramDocument3 pagesLiquid Extraction: Phase DiagramTIVIYAH THEVAR 1017No ratings yet

- Düssel, R., & Stichlmair, J. (1995) - Separation of Azeotropic Mixtures by Batch Distillation Using An Entrainer. Computers & Chemical Engineering, 19, 113-118.Document6 pagesDüssel, R., & Stichlmair, J. (1995) - Separation of Azeotropic Mixtures by Batch Distillation Using An Entrainer. Computers & Chemical Engineering, 19, 113-118.Silvio Latini SpahnNo ratings yet

- A Chemical Classification of Volcanic RocksDocument6 pagesA Chemical Classification of Volcanic RocksDavid PastenNo ratings yet

- Meerut Institute of Engineering & Technology Sessional Test I (March, 2015) SET-1Document2 pagesMeerut Institute of Engineering & Technology Sessional Test I (March, 2015) SET-1Kshitiz VaishNo ratings yet

- NSO Class 7 Sample Paper 2023 24Document3 pagesNSO Class 7 Sample Paper 2023 24ishwar shelarNo ratings yet

- Symmetry As Compositional Determinant MethodsDocument11 pagesSymmetry As Compositional Determinant MethodssertimoneNo ratings yet

- Isometric ProjectionDocument38 pagesIsometric ProjectionrahulNo ratings yet

- Challenges and Outlook For Catalytic Direct Amidation ReactionsDocument5 pagesChallenges and Outlook For Catalytic Direct Amidation ReactionsAngélica Andrea SalinasNo ratings yet

- C H BR C H O (1S, 3S) - 3-MethylcyclohexanolDocument3 pagesC H BR C H O (1S, 3S) - 3-MethylcyclohexanolAnh Pham Le NgocNo ratings yet

- Design/Optimization of Ternary Hetero-Geneous Azeotropic Distillation SequencesDocument10 pagesDesign/Optimization of Ternary Hetero-Geneous Azeotropic Distillation SequencesJuan Pablo Polania BNo ratings yet

- Uni/Tersity The Pui/Jab: Llo :'J ' 'J:'JDocument21 pagesUni/Tersity The Pui/Jab: Llo :'J ' 'J:'JJhon EstwoodNo ratings yet

- 2009 O Level Chem Questions With AnswersDocument14 pages2009 O Level Chem Questions With AnswersGertrude Ramsbottom50% (2)

- Full Paper Liquid Liquid Equilibrium For The DesignDocument19 pagesFull Paper Liquid Liquid Equilibrium For The DesignAli aliraqiNo ratings yet

- BALIBASE7REFDocument4 pagesBALIBASE7REFCRISTIAN GABRIEL ZAMBRANO VEGANo ratings yet

- Hydrocarbons & Halogen Derivatives PDFDocument326 pagesHydrocarbons & Halogen Derivatives PDFSuraj panditNo ratings yet

- BD S1e04Document9 pagesBD S1e04BAFSNo ratings yet

- Che 249 - Chapter 3 (Liquid-Liquid Extraction)Document34 pagesChe 249 - Chapter 3 (Liquid-Liquid Extraction)nurul syamimieNo ratings yet

- Eric Wibisono-2nd APIEOM Indonesia-2021Document10 pagesEric Wibisono-2nd APIEOM Indonesia-2021Davey MarbunNo ratings yet

- Adobe Scan 02-Jul-2021Document5 pagesAdobe Scan 02-Jul-2021Uppada LaxmiNo ratings yet

- GOC Question Bank-20200420174037517680 PDFDocument30 pagesGOC Question Bank-20200420174037517680 PDFMadhu BishtNo ratings yet

- Molec Geometry WorksheetsDocument18 pagesMolec Geometry WorksheetschaNo ratings yet

- Extraction and Purification of Caffeine From Tea Leaves ExperimentDocument6 pagesExtraction and Purification of Caffeine From Tea Leaves ExperimentJean Risquez100% (1)

- Cas 556Document2 pagesCas 556rapsjadeNo ratings yet

- Multicomponent Three-Phase Azeotropic Distillation. Extensive Experimental Data and Simulation ResultsDocument15 pagesMulticomponent Three-Phase Azeotropic Distillation. Extensive Experimental Data and Simulation ResultsSilvio Latini SpahnNo ratings yet

- Che 535 PQDocument2 pagesChe 535 PQPromise OkekeNo ratings yet

- Santiuste 2006 CNXDocument12 pagesSantiuste 2006 CNXteddy1967No ratings yet

- Self Consistent Field Molecular Orbital Calculations For Mono and Disubstituted BenzenesDocument3 pagesSelf Consistent Field Molecular Orbital Calculations For Mono and Disubstituted Benzenesmanuel.araya.floresNo ratings yet

- Separation Process ExerciseDocument3 pagesSeparation Process ExerciseSteven LauNo ratings yet

- Plane Geometry (Pentagon, Hexagon Etc.) PDFDocument6 pagesPlane Geometry (Pentagon, Hexagon Etc.) PDFSajedur Rahman MishukNo ratings yet

- Plane Geometry (Pentagon, Hexagon Etc.) PDFDocument6 pagesPlane Geometry (Pentagon, Hexagon Etc.) PDFsignNo ratings yet

- Module 7 KISS Notes (HSC Chemistry)Document15 pagesModule 7 KISS Notes (HSC Chemistry)rsorani8No ratings yet

- POLYGONSDocument6 pagesPOLYGONSMaria Glenda DianoNo ratings yet

- Exam 3 ReviewDocument12 pagesExam 3 ReviewEvan TryonNo ratings yet

- JuvabioneDocument13 pagesJuvabionePreeti Yadav100% (1)

- CHM 102Document4 pagesCHM 102Fumzy AdelakunNo ratings yet

- NR 320801 Mass Transfer Operations IIDocument6 pagesNR 320801 Mass Transfer Operations IISrinivasa Rao G100% (6)

- Eq and Slope FieldsDocument12 pagesEq and Slope FieldsFarida MachhwaNo ratings yet

- Virtual Practical Work in HPLCDocument11 pagesVirtual Practical Work in HPLCsedalatianzNo ratings yet

- ISTEC 2011: Simulation and Optimization of Ethyl Acetate Reactive Packed Distillation Process Using Aspen HysysDocument6 pagesISTEC 2011: Simulation and Optimization of Ethyl Acetate Reactive Packed Distillation Process Using Aspen HysysAbdulwahab GIWANo ratings yet

- Ge Numerical 2014Document8 pagesGe Numerical 2014Ahmed Ali AlsubaihNo ratings yet

- Ioc 11Document5 pagesIoc 11KarthikeyanNo ratings yet

- Structural Snapshots of V, A-ATPase Reveal The Rotary Catalytic Mechanism of Rotary ATPasesDocument11 pagesStructural Snapshots of V, A-ATPase Reveal The Rotary Catalytic Mechanism of Rotary ATPasesFernandoNo ratings yet

- Polymer Diverter Valve Gala 2S EN SDocument2 pagesPolymer Diverter Valve Gala 2S EN SDiegoNo ratings yet

- ts601B ENDocument7 pagests601B ENDiegoNo ratings yet

- Tubi Da fumoGB-Uso EsternoDocument6 pagesTubi Da fumoGB-Uso EsternoDiegoNo ratings yet

- Oven Heat Stability of Poly (Vinyl Chloride) Compositions: Standard Practice ForDocument3 pagesOven Heat Stability of Poly (Vinyl Chloride) Compositions: Standard Practice ForDiego100% (1)

- Selection of Gas CompressorsDocument4 pagesSelection of Gas CompressorsDiegoNo ratings yet

- Emailing 1-S2.0-S0009250901002603-Main PDFDocument7 pagesEmailing 1-S2.0-S0009250901002603-Main PDFDiegoNo ratings yet

- Selecting Appropriate Control Variables For A Heat-Integrated Distillation System With PrefractionatorDocument9 pagesSelecting Appropriate Control Variables For A Heat-Integrated Distillation System With PrefractionatorDiegoNo ratings yet

- Simulation of The Tetrahydrofuran Dehydration Process by Extractive Distillation PDFDocument10 pagesSimulation of The Tetrahydrofuran Dehydration Process by Extractive Distillation PDFDiegoNo ratings yet

- Dynamics and Control of A Heterogeneous Azeotropic Distillation Column: Conventional Control ApproachDocument11 pagesDynamics and Control of A Heterogeneous Azeotropic Distillation Column: Conventional Control ApproachDiegoNo ratings yet

- E9 5711 PDFDocument285 pagesE9 5711 PDFDiegoNo ratings yet

- Chart Title: Boiling-Point Diagram Benzene (A) - Toluen (B) at 101,32 KpaDocument3 pagesChart Title: Boiling-Point Diagram Benzene (A) - Toluen (B) at 101,32 KpaliyaNo ratings yet

- Figure M 39 Ethanol Water MixtureDocument10 pagesFigure M 39 Ethanol Water MixturediegoNo ratings yet

- Figure M 39 Ethanol Water MixtureDocument6 pagesFigure M 39 Ethanol Water MixtureHamza ShafiqNo ratings yet

- Vapor-Liquid Equilibrium (Vle) Water-Ethanol From Bulrush FermentantionDocument10 pagesVapor-Liquid Equilibrium (Vle) Water-Ethanol From Bulrush FermentantionTakdir AnisNo ratings yet

- Butyl Acrylate Azeotrope DataDocument3 pagesButyl Acrylate Azeotrope DataAnuragNo ratings yet

- Chapter 6 Phase Equilibria 1Document17 pagesChapter 6 Phase Equilibria 1Vijeethira RavichandranNo ratings yet

- Phase Diagram For MulticomponentDocument23 pagesPhase Diagram For MulticomponentFaisal MumtazNo ratings yet