Professional Documents

Culture Documents

Cooling System PDF

Cooling System PDF

Uploaded by

German Rosero MOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Cooling System PDF

Cooling System PDF

Uploaded by

German Rosero MCopyright:

Available Formats

DI06-1

SECTION

00 DI06

COOLING SYSTEM

Table of Contents

COOLING SYSTEM .................................................... DI06-3

ENGINE COOLING SYSTEM ...................................... DI06-4

Specifications ........................................................ DI06-10

INSPECTION AND REPAIR ....................................... DI06-14

Inspection .............................................................. DI06-14

REMOVAL AND INSTALLATION ............................... DI06-16

PREHEATING SYSTEM ............................................ DI06-29

Overview ............................................................... DI06-30

Preheating relay ................................................... DI06-30

Preheating system diagram .................................. DI06-31

COOLING SYSTEM CHANGED BY

DI ENG SM - 2004.4 EFFECTIVE DATE

AFFECTED VIN

DI06-3

COOLING SYSTEM

Coolant temperature

Coolant reservoir FFH

sensor

Radiator Water pump Cooling fan

Y220_06001

FFH (Fuel Fired Heater): refer to “FFH System” in this manual.

COOLING SYSTEM CHANGED BY

DI ENG SM - 2004.4 EFFECTIVE DATE

AFFECTED VIN

DI06-4

ENGINE COOLING SYSTEM

Coolant

reservoir

Engine

Cylinder head

Thermostat

Heater

Radiator

Water pump

Cylinder block

Oil cooler

(Heater line)

<PTC Engine Coolant Flows>

Coolant

reservoir

Engine

Cylinder head

Thermostat

Heater

Radiator

Water pump

Cylinder block

EGR cooler

Oil cooler

(henceforth)

<FFH Engine Coolant Flows>

Y220_06002

• Cylinder block side

Block #5 → Oil cooler → Heater → Heater water pump inlet pipe → Water pump

• Cylinder head side

Cylinder head → Coolant outlet port (intake #1) → Radiator → Water pump

CHANGED BY COOLING SYSTEM

EFFECTIVE DATE DI ENG SM - 2004.4

AFFECTED VIN

DI06-5

Function Description

Intake Manifold

Cylinder Head

Coolant Outlet Port

Y220_06003

• Cylinder head coolant outlet port is integrated into intake manifold. (in front of cylinder #1)

: Improved shape and gasket material to prevent coolant from leaking

From cylinder head

From reservoir

4

5

6

From heater

1 2 3

Y220_06004

• In OM 600 engine, coolant inflows through the heater line rear section (cylinder #4 and #5) of cylinder head. However,

in D27DT engine, coolant inflows from cylinder block through oil cooler (refer to coolant flows layout in previous

page).

: It prevents cooling efficiency from decreasing due to coolant separation between cylinder #4 and #5.

• In OM 600 engine, the cooling fan is installed with water pump, however, in case of D27DT engine, it is connected to

water pump with an additional pulley.

COOLING SYSTEM CHANGED BY

DI ENG SM - 2004.4 EFFECTIVE DATE

AFFECTED VIN

DI06-6

Radiator

This vehicle has a lightweight tube-and-fin aluminum radiator.

Be careful not to damage the radiator core when servicing.

Y220_06005

Water pump

The belt-driven centrifugal water pump consists of an impeller,

a drive shaft, and a belt pulley. The impeller is supported by a

completely sealed bearing.

The water pump is serviced as an assembly and, therefore,

cannot be disassembled.

Y220_06006

Coolant reservoir

Notice

Scalding hot coolant and steam could be blown out under

pressure, which could cause serious injury. Never remove

the coolant reservoir cap when the engine and radiator

are hot.

The coolant reservoir is a transparent plastic reservoir, similar

to the windshield washer reservoir. The coolant reservoir is

connected to the radiator by a hose and to the engine cooling

Y220_06007

system by another hose. As the vehicle is driven, the engine

coolant heats and expands. The portion of the engine coolant

displaced by this expansion flows from the radiator and the

engine into the coolant reservoir. The air trapped in the radia-

tor and the engine is degassed into the coolant reservoir.

When the engine stops, the engine coolant cools and

contracts. The displaced engine coolant is then drawn back

into the radiator and the engine. This keeps the radiator filled

with the coolant to the desired level at all times and increases

the cooling efficiency. Maintain the coolant level between the

MIN and MAX marks on the coolant reservoir when the sys-

tem is cold.

CHANGED BY COOLING SYSTEM

EFFECTIVE DATE DI ENG SM - 2004.4

AFFECTED VIN

DI06-7

Thermostat

A wax pellet-type thermostat controls the flow of the engine

coolant through the engine cooling system. The thermostat is

mounted in the thermostat housing to the front of the cylinder

head. The thermostat stops the flow of the engine coolant

from the engine to the radiator to provide faster warm-up, and

to regulate the coolant temperature. The thermostat remains

closed while the engine coolant is cold, preventing circulation

of the engine coolant through the radiator. At this point, the

engine coolant is allowed to circulate only throughout the heater

core to warm it quickly and evenly. As the engine warms, the

thermostat opens. This allows the engine coolant to flow Y220_06008

through the radiator where the heat is dissipated. This open-

ing and closing of the thermostat permits enough engine cool-

ant to enter the radiator to keep the engine within proper en-

gine temperature operating limits. The wax pellet in the ther-

mostat is hermetically sealed in a metal case. The wax ele-

ment of the thermostat expands when it is heated and con-

tracts when it is cooled. As the vehicle is driven and the en-

gine warms, the engine coolant temperature increases. When

the engine coolant reaches a specified temperature, the wax

pellet element in the thermostat expands and exerts pressure

against the metal case, forcing the valve open. This allows the

engine coolant to flow through the engine cooling system and

cool the engine. As the wax pellet cools, the contraction al-

lows a spring to close the valve.

The thermostat begins to open at 85°C and is fully open at

100°C. The thermostat closes at 85°C.

Operating

Thermostat Opening Value (mm)

Temperature (°C)

Begins to open 85°C 0.1 mm

Fully open 100°C 8 mm

COOLING SYSTEM CHANGED BY

DI ENG SM - 2004.4 EFFECTIVE DATE

AFFECTED VIN

DI06-8

When closed (up to 85°C) When partially opened (85°C ~ 100°C)

Y220_06009 Y220_06010

X. from vrankcase

Y. to crankcase

Z. from radiator

When fully opened (above 100°C)

If the cooling system is fully filled with, the coolant is auto-

matically bled through ball valve (arrow) in thermostat.

Y220_06011 Y220_06012

CHANGED BY COOLING SYSTEM

EFFECTIVE DATE DI ENG SM - 2004.4

AFFECTED VIN

DI06-9

Viscous fan clutch

Y220_06014

The cooling fans are mounted behind the radiator in the

engine compartment. The electric cooling fans increase

the flow of air across the radiator fins and across the con-

denser on air conditioner. The fan is 320 mm in diameter

with five blades to aid the airflow through the radiator and

the condenser. An electric motor attached to the radiator

support drives the fan.

1. A/C Off or Non-AC Model

Y220_06013

• The cooling fan operates at low speed when the

1. Clutch housing 9. Pin coolant temperature reaches 95°C and at high

2. Drive disc 10. Bi-metal speed when the coolant temperature reaches

3. Flange 11. Bracket cover 100°C.

4. Seal ring 12. Separator disc • The cooling fan is turned from high speed to low

speed at 97°C and turns off at 90°C.

5. Needle bearing 13. Supply port

6. Cooling fan 14. Lever valve

2. A/C On

7. Oil scraper 15. Oil chamber

• The ECU will turn the cooling fan on at high speed

8. Spring 16. Operating chamber when the A/C system is on.

The cooling speed increases approx. 1,000 rpm with wind Engine coolant temperature sensor

noise when the engine speed is 4,000 to 4,500 rpm and

The Engine Coolant Temperature (ECT) sensor uses a tem-

the coolant temperature is 90 to 95°C.

perature to control the signal voltage to the Engine Control

Unit (ECU).

Notice

Keep hands, tools, and clothing away from the engine

cooling fans to help prevent personal injury. This fan

is electric and can turn on even when the engine is

not running.

Notice

If a fan blade is bent or damaged in any way, no attempt

should be made to repair or reuse the damaged part.

A bent or damaged fan assembly should always be

replaced with a new one to prevent possible injury.

Y220_06015

COOLING SYSTEM CHANGED BY

DI ENG SM - 2004.4 EFFECTIVE DATE

AFFECTED VIN

DI06-10

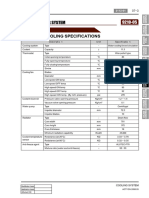

SPECIFICATIONS

Description Unit Specification

Cooling system Type - Water cooling forced circulation

Coolant Capacity 11.3

Thermostat Type - Wax pellet type

Initial opening temperature DI Engine °C 85

IDI Engine °C 80

Fully opening temperature DI Engine °C 100

IDI Engine °C 95

Fully closing temperature DI Engine °C 83

IDI Engine °C 78

Stroke DI Engine mm min. 8

IDI Engine mm min. 8

Cooling fan Type - Electric

Blades 5

Diameter mm 320 (2)

Low speed ON temp °C 91

Low speed OFF temp °C 88

High speed ON temp °C 95

High speed OFF temp °C 92

High speed ON temp. (By A/C pressure) psi 270

Coolant reservoir pressure valve opening pressure Kg/cm2 1.2 ~ 1.5

Vacuum valve opening pressure Kg/cm2 0.1

Water pump Type - Turbo centrifugal

Impeller diameter mm 72.3

Impeller blades 10

Radiator Type - Down-flow

Core width mm 701

Core height mm 372

Core thickness mm 18

Minimum radiation capability Kcal/h 45,000

Coolant tempera- Resistance (at 20°C) KΩ 3.33 ~ 3.78

ture sensor Resistance (at 80°C) KΩ 0.32 ~ 0.35

Anti-freeze agent Type − ALUTEC-P78

Mixture ratio (water and anti-freeze) − 50 : 50

CHANGED BY COOLING SYSTEM

EFFECTIVE DATE DI ENG SM - 2004.4

AFFECTED VIN

DI06-11

Coolant Level Check

Notice

• Scalding hot coolant and steam could be blown out under pressure, which could cause serious injury. Never

remove the coolant reservoir cap when the engine and radiator are hot.

• Take precautions to prevent antifreeze coming in contact with the skin, eyes or vehicle body. If contact

happens, rinse affected areas immediately with plenty of water.

1. Place the vehicle on a level ground and check the coolant level through the coolant reservoir.

2. Add if needed. Change the coolant if necessary.

Y220_06016

COOLING SYSTEM CHANGED BY

DI ENG SM - 2004.4 EFFECTIVE DATE

AFFECTED VIN

DI06-12

Coolant Temperature Sensor

Temp.

Resistance

<Coolant Temperature Sensor> <Output Characteristics of Coolant Temperature Sensor>

Y220_06017

Coolant temperature sensor is a NTC resister that sends coolant temperature to ECU.

NTC resister has characteristics that if the engine temperature rises, the resistance lowers so the ECU detects lowering

signal voltages.

If the fuel injected into the engine through injector has more turbulence, then combusts very well. However, if engine tempera-

ture is too low, the fuel injected as foggy state forms big compounds causing incomplete combustion. So the sensor detects

coolant temperature and changes coolant temperature changes into voltage then sends to ECU to increase the fuel volume

during cold start for better starting. And detects engine overheating for fuel volume reduction to protect the engine.

ECU functions as below with coolant temperature sensor signals.

• When engine is cold, controls fuel volume to correct idle speed

• When engine is overheated, controls electrical fan and A/C compressor to protect the engine

• Sends information for emission control

Temperature NTC 1 Resistance ( Ω ) NTC 2 Resistance ( Ω )

20 2,550 6,062

50 826 1,800

80 321 638

120 123 200

Signal

Auto amp

Ground

<Coolant Temperature Sensor Circuit> Y220_06018

CHANGED BY COOLING SYSTEM

EFFECTIVE DATE DI ENG SM - 2004.4

AFFECTED VIN

DI06-13

Trouble Diagnosis

Symptom Cause Action

Low coolant • Leaks in radiator • Replace radiator

level • Leaks in coolant reservoir • Replace coolant reservoir

• Leaks in heater core • Replace heater

• Leaks in hose connection • Reconnect hose or replace clamp

• Damaged coolant hose • Replace hose

• Leaks in water pump gasket • Replace gasket

• Leaks in water pump internal seal • Replace water pump

• Leaks in coolant inlet cap • Replace water inlet cap gasket

• Leaks in thermostat housing • Replace thermostat sealing

• Improper tightening torque of cylinder head • Retighten

• Damaged cylinder head gasket • Replace cylinder head gasket

Excessively • Coolant leaks (too low coolant level) • Add coolant

high coolant • Improper coolant mixture ratio • Check coolant concentration

temperature

• Kinked coolant hose • Repair or replace hose

• Defective thermostat • Replace thermostat

• Defective water pump • Replace water pump

• Defective radiator • Replace radiator

• Defective coolant reservoir and cap • Replace coolant reservoir or cap

• Cracks on cylinder head or cylinder block • Replace cylinder head or cylinder block

• Clogged coolant passages in cylinder head or cylinder block • Clean coolant passages

• Clogged radiator core • Clean radiator core

• Improper operation of cooling fan • Replace cooling fan or repair related circuit

• Faulty temperature sensor or defective harness • Replace sensor or repair related circuit

Excessively • Stuck thermostat (with open) • Replace thermostat

low coolant • Improper operation of cooling fan • Replace cooling fan or repair related circuit

temperature

• Faulty temperature sensor or defective harness • Replace sensor or repair related circuit

COOLING SYSTEM CHANGED BY

DI ENG SM - 2004.4 EFFECTIVE DATE

AFFECTED VIN

DI06-14

INSPECTION AND REPAIR

INSPECTION

Cooling System

1. Release the pressure from coolant reservoir by loosening

one notch of coolant reservoir cap, and then remove the

cap.

Notice

Scalding hot coolant and steam could be blown out

under pressure, which could cause serious injury.

Never remove the coolant reservoir cap when the

before the temperature goes down below 90°C.

Y220_06019

2. Add the coolant up to upper mark (arrow) on the reservoir.

3. Install the tester to the coolant reservoir and apply the

pressure of 1.4 bar.

4. Check the coolant hoses, pipes and connections for leaks

after the pointer of the tester drops. Replace or retighten

as required.

Y220_06020

Thermostat

Temperature gauge

Immerse the thermostat into the water. Heat the water and

check the valve opening temperature.

Valve opening temperature DI Engine: 85 ± 2°C

Y220_06021

CHANGED BY COOLING SYSTEM

EFFECTIVE DATE DI ENG SM - 2004.4

AFFECTED VIN

DI06-15

Coolant Temperature Gauge Unit

1. Immerse the senor unit into the water. Heat the water

and check the resistance.

Y220_06022

2. If the measured resistance is out of specified value,

replace the gauge unit.

3. Measure the resistance between terminal A and gauge

unit housing, and terminal B and gauge unit housing.

Terminal A

Terminal B

Terminal A 0.4 Ω / 79°C

(for coolant temp.) 23.8 Ω / 115°C

Terminal B 24.8 Ω / -20°C

(for glow plug) 3.25 Ω / 20°C

Y220_06023

Thermostat

1. Immerse the thermostat into the oil. Heat the oil until it

reaches the specified temperature and check if the

coolant temperature switch is turned “OFF”.

Coolant temperature at

113 ± 3°C

point A

Coolant temperature at

point B 116°C

Y220_06024

Notice

Use only engine oil for this inspection. Stir the oil

during heating it. Never heat the oil over required

temperature.

COOLING SYSTEM CHANGED BY

DI ENG SM - 2004.4 EFFECTIVE DATE

AFFECTED VIN

DI06-16

REMOVAL AND INSTALLATION

Coolant Hose (Inlet/Outlet)

Preceding Work: Draining of coolant

1. Loosen the clamp and remove the coolant outlet hose

(engine to radiator).

Y220_06025

2. Disconnect the HFM sensor connector.

3. Remove the air intake duct from the air cleaner.

Y220_06026

4. Loosen the clamp and remove the coolant inlet hose

(radiator to thermostat housing).

Y220_06027

CHANGED BY COOLING SYSTEM

EFFECTIVE DATE DI ENG SM - 2004.4

AFFECTED VIN

DI06-17

5. Lift up the vehicle and remove the skid plate.

6. Loosen the clamp and remove the lower inlet hose.

Y220_06028

Shroud and Cooling Fan/Clutch

Preceding Works:

- Draining of coolant

- Removal of coolant inlet and outlet hose

- Removal of V-belt

1. Remove the radiator grille.

Y220_06029

2. Remove the air intake hoses.

3. Set aside the coolant return pipe.

Y220_06030

4. Unscrew the upper bolts and loosen the shroud.

Y220_06031

COOLING SYSTEM CHANGED BY

DI ENG SM - 2004.4 EFFECTIVE DATE

AFFECTED VIN

DI06-18

5. Unscrew the center bolt and remove the cooling fan clutch

while holding the pulley with counter holder (special tool).

Installation Notice

Tightening torque 45 ± 4.5 Nm

Y220_06033

6. Remove the shroud.

7. Install in the reverse order of removal.

Y220_06034

CHANGED BY COOLING SYSTEM

EFFECTIVE DATE DI ENG SM - 2004.4

AFFECTED VIN

DI06-19

Water Pump - Assembly

Preceding Works:

- Draining of coolant

- Removal of V-belt

- Removal of shroud

- Removal of cooling fan

Y220_06035

1. Thermostat housing 4. Belt pulley

2. Gasket ........................................................... Replace 5. Bolt ................................................................... 10 Nm

3. Bolt ................................................................... 10 Nm 6. Water pump

1. Remove the V-belt while pressing down the auto tensioner

adjusting bolt.

Y220_06036

COOLING SYSTEM CHANGED BY

DI ENG SM - 2004.4 EFFECTIVE DATE

AFFECTED VIN

DI06-20

2. Unscrew the bolts and remove the EGR pipe and bracket.

Installation Notice

Tightening torque 23 ± 2.3 Nm

Y220_06037

3. Unscrew the bolts and remove the belt pulley while

holding the belt pulley with a special tool.

Installation Notice

Tightening torque 10 Nm

Y220_06038

4. Remove the oil dipstick tube.

Notice

• Replace the O-ring in oil dipstick with new one.

• Plug the oil dipstick hole with a cap not to get the

foreign materials into the engine.

Y220_06039

5. Unscrew the bolts and remove the water pump assembly.

Installation Notice

Tightening torque 10 Nm

Notice

Remove the gasket residues from the sealing surface

and replace the gasket with new one.

Y220_06040 6. Install in the reverse order of removal.

CHANGED BY COOLING SYSTEM

EFFECTIVE DATE DI ENG SM - 2004.4

AFFECTED VIN

DI06-21

Thermostat

* Preceding Works:

- Draining of coolant

- Removal of V-belt

- Removal of cooling fan

- Removal of intake duct (air cleaner to turbo charger)

Y220_06041

1. Gasket ...................................................... Replace 5. Thermostat

2. Water pump housing 6. Seal

3. Connector 7. Coolant hose

4. Bolt ............................................................. 10 Nm

COOLING SYSTEM CHANGED BY

DI ENG SM - 2004.4 EFFECTIVE DATE

AFFECTED VIN

DI06-22

1. Unscrew the bolts and remove the thermostat housing.

Installation Notice

Tightening torque 10 ± 1.0 Nm

Y220_06042

2. Remove the thermostat.

3. Install in the reverse order of removal.

Y220_06043

CHANGED BY COOLING SYSTEM

EFFECTIVE DATE DI ENG SM - 2004.4

AFFECTED VIN

DI06-23

Water Pump Housing

Preceding Works:

- Removal of water pump assembly

- Removal of thermostat assembly

1. Remove the heater hose.

Y220_06044

2. Unscrew the bolts and remove the alternator.

Installation Notice

Tightening torque 46 ± 4.6 Nm

Y220_06045

3. Unscrew the bolts and remove the alternator bracket.

Installation Notice

Tightening torque 25 ± 2.5 Nm

Y220_06046

4. Unscrew the bolts and remove the water pump housing.

Installation Notice

Tightening torque 10 ± 1.0 Nm

Notice

• Be careful not to damage the O-ring in coolant outlet

pipe (cylinder head side).

• Remove the gasket residues from the sealing

surface and replace the gasket with new one.

5. Install in the reverse order of removal. Y220_06047

COOLING SYSTEM CHANGED BY

DI ENG SM - 2004.4 EFFECTIVE DATE

AFFECTED VIN

DI06-24

Radiator

Preceding Work: Draining of coolant

1. Lift up the vehicle and remove the skid plate.

Y220_06048

2. Remove the clips and washers from bottom of radiator at

both sides.

Notice

Be careful not to damage the rubber bushing.

Y220_06049

3. Unscrew the bracket mounting bolts under the radiator

condenser.

Installation Notice

Tightening torque 10 ± 1.0 Nm

Y220_06050

4. Disconnect the oil inlet and outlet hoses from bottom of

radiator.

Notice

• Plug the radiator oil holes with caps.

• Replace the hose washers with new ones.

Y220_06051

CHANGED BY COOLING SYSTEM

EFFECTIVE DATE DI ENG SM - 2004.4

AFFECTED VIN

DI06-25

5. Remove the coolant outlet hose.

Y220_06052

6. Remove the radiator grille.

Y220_06053

7. Remove the coolant inlet hose and the cooler inlet hose.

8. Remove the coolant return hose.

Y220_06054

9. Unscrew the bolts and remove the shroud.

Y220_06055

COOLING SYSTEM CHANGED BY

DI ENG SM - 2004.4 EFFECTIVE DATE

AFFECTED VIN

DI06-26

10. Unscrew the bolts and remove the radiator upper plate.

Installation Notice

Tightening torque 10 ± 1.0 Nm

Y220_06056

11. Unscrew the bracket mounting bolts on the radiator

condenser.

Installation Notice

Tightening torque 10 ± 1.0 Nm

Y220_06057

12. Remove the radiator by pulling it up carefully.

Y220_06058

13. Install in the reverse order of removal.

CHANGED BY COOLING SYSTEM

EFFECTIVE DATE DI ENG SM - 2004.4

AFFECTED VIN

DI06-27

Coolant Reservoir

1. Drain the coolant.

2. Remove the hoses.

Y220_06059

3. Unscrew the bolts and remove the coolant reservoir.

Installation Notice

Tightening torque 7 Nm

4. Install in the reverse order of removal. Y220_06060

COOLING SYSTEM CHANGED BY

DI ENG SM - 2004.4 EFFECTIVE DATE

AFFECTED VIN

DI06-28

Draining and Adding of Coolant

1. Release the pressure from coolant reservoir by loosening

one notch of coolant reservoir cap, and then remove the

cap.

Notice

Scalding hot coolant and steam could be blown out

under pressure, which could cause serious injury.

Never remove the coolant reservoir cap when the

before the temperature goes down below 90°C.

Y220_06061

2. Loosen the drain plug in bottom of radiator and drain the

coolant.

Notice

Collect the drained coolant with a proper container.

Y220_06062

3. Remove the drain plug (1) and seal (2) in the cylinder

block and drain the coolant.

4. Replace the seal with new one and install the drain plug.

Installation Notice

Tightening torque 30 Nm

Y220_06063

5. Install the drain plug in bottom of radiator.

6. Add the coolant through the coolant reservoir.

Notice

• Keep the coolant mixture ratio of 50:50 (water : anti-

freezer).

• Add the coolant until the water flows out through

the overflow hose.

7. Warm up the engine until the thermostat begins to open

and check if the coolant level is at “FULL” mark on the

reservoir. Add if necessary.

CHANGED BY COOLING SYSTEM

EFFECTIVE DATE DI ENG SM - 2004.4

AFFECTED VIN

DI06-29

PREHEATING SYSTEM

ECU Glow indicator (meter cluster)

Glow plug Preheating relay

Y220_06068

COOLING SYSTEM CHANGED BY

DI ENG SM - 2004.4 EFFECTIVE DATE

AFFECTED VIN

DI06-30

OVERVIEW

Glow plug is installed on the cylinder head (combustion chamber) in the D27DT preheating control unit system. Cold

starting performance has improved and exhaust gas during cold starting has reduced.

ECU receives coolant temperature and engine speed to control; after monitoring the engine preheating/after heating and

glow plug diagnosis function, the fault contents will be delivered to ECU.

• Engine preheating/after heating functions

• Preheating relay activation by ECU controls

- Senses engine temperature and controls the preheating/after heating time

- Glow indicator

• K-LINE for information exchanges between preheating unit and ECU

- Transmits preheating unit self-diagnosis results to ECU

- Transmits glow plug diagnosis results and operating status to ECU

PREHEATING RELAY

Structure

K-LINE #1 IG1

(ECU 34) Power terminal

Glow plug

control signal

K (ECU 113)

R/Y

Ground terminal

B+main wire

(12V)

STICS terminal

Glow plug (remote start)

terminal

Y220_06069

CHANGED BY COOLING SYSTEM

EFFECTIVE DATE DI ENG SM - 2004.4

AFFECTED VIN

DI06-31

PREHEATING SYSTEM DIAGRAM

STICS(remote start)

Coolant

temperature

sensor

Y220_06070

Specifications

Description Specification

Rated voltage DC 12 V

Operating voltage range DC 8 ~ 15 V

Operating range - 40 ~ + 100°C

Relay operating voltage Over 6.5 V

Relay releasing voltage Over 1.5 V

Relay coil resistance 11.3 Ω

Voltage drop Below 150 mV at each glow plug (at 16A of current)

Parasitic current MAX 1mA

COOLING SYSTEM CHANGED BY

DI ENG SM - 2004.4 EFFECTIVE DATE

AFFECTED VIN

DI06-32

Function

Preheating system controls and checks following functions and operating conditions.

Pre-Heating

• The power will be supplied to the glow plugs by ECU controls when the power is supplied to the IG terminal from

the battery and there are normal communications with ECU within 2 seconds. The surface of glow plug will be

heated up to 850°C very quickly to aid combustion by vaporizing air-fuel mixture during compression stroke.

• Preheating time is controlled by ECU.

After-heating

• When the engine is started, after-heating starts by ECU controls. The idle rpm will be increased to reduce toxic

smoke, pollutants and noises.

• After-heating time is controlled by ECU.

Checking glow plugs

• Check each glow plug for short in circuit

• Check each glow plug for open in circuit due to overvoltage

• Check glow plug for short to ground

Forceful relay shut-down

• When glow plug is shorted to ground

K-Line communication

• ECU sends the results to preheating time control relay through K-Line to start communication.

• Preheating time control relay sends messages including self-diagnosis data for glow plugs to ECU.

• Glow plug makes communication only as response to demand.

• When power is supplied, ECU starts self-diagnosis within 2 seconds.

• Under the following conditions, communication error occurs.

- When there is no response from glow plug module within 2 seconds

- When an error is detected in checksum

- Less byte is received

Error code of “P1720 - Pre heating control communication fail” will be reported.

Operating time

Coolant Temp. -35 °C -25 °C -20 °C -10 °C 0 °C 10 °C 20 °C

Pre- Operating Time 31 sec 22 sec 19 sec 17 sec 14 sec 0 sec 0 sec

heating Operating • IG: “ON” Release • After operating time elapsed

Conditions • B+ : below 15.2V Conditions • IG: “OFF” • When engine cranking

Coolant Temp. -30 °C -20 °C -10 °C 0 °C 10 °C 20 °C 35 °C

Operating Time 115 sec 80 sec 30 sec 19 sec 11 sec 11 sec 0 sec

After-

heating • After engine starting • After operating time elapsed

Operating Release

• Torque : 190/170 Nm

Conditions Conditions

• Speed: 2100/2050 rpm

Coolant Temp. -30 °C -25 °C -20 °C -10 °C 0 °C 10 °C 20 °C

Glow Operating Time 18 sec 16 sec 10 sec 5 sec 2 sec 0 sec 0 sec

Indicator Operating Release

• IG: “ON” • When engine cranking

Conditions Conditions

CHANGED BY COOLING SYSTEM

EFFECTIVE DATE DI ENG SM - 2004.4

AFFECTED VIN

You might also like

- Toyota Engine 1grfe 4 0 Repair ManualDocument7 pagesToyota Engine 1grfe 4 0 Repair Manualjames100% (56)

- J-Serise Engine-USADocument29 pagesJ-Serise Engine-USACristian m VizcainoNo ratings yet

- Automotive Air Conditioning and Climate Control SystemsFrom EverandAutomotive Air Conditioning and Climate Control SystemsRating: 4 out of 5 stars4/5 (6)

- Description: 2009 Dodge Journey SE 2009 Dodge Journey SEDocument129 pagesDescription: 2009 Dodge Journey SE 2009 Dodge Journey SERodrigoAntonioRoblesSantosNo ratings yet

- Donny’S Unauthorized Technical Guide to Harley-Davidson, 1936 to Present: Volume I: the Twin CamFrom EverandDonny’S Unauthorized Technical Guide to Harley-Davidson, 1936 to Present: Volume I: the Twin CamNo ratings yet

- Cooling System OBH KomatsuDocument55 pagesCooling System OBH KomatsuYUDI WAHYUDI 17249No ratings yet

- Engine JS330 PDFDocument82 pagesEngine JS330 PDFabathun100% (2)

- Forklift GuideDocument142 pagesForklift GuideYeison Leon Durango CastañedaNo ratings yet

- Crown Light CommissioningDocument41 pagesCrown Light CommissioningAli AKNo ratings yet

- 1GR-FE CoolingDocument18 pages1GR-FE CoolingJorge Miguel Couto Cabral100% (1)

- Water Cooled Centrifugal Chiller: HTS/HTCDocument16 pagesWater Cooled Centrifugal Chiller: HTS/HTCthu hangNo ratings yet

- P0116 Engine Coolant Temperature Sensor Replacement (Radiator)Document3 pagesP0116 Engine Coolant Temperature Sensor Replacement (Radiator)Andre VPNo ratings yet

- 320D Control Van Schema PDFDocument52 pages320D Control Van Schema PDFAhmad Minangkabau100% (5)

- Leyland HA6ETI Service ManualDocument72 pagesLeyland HA6ETI Service ManualPolavarapu Sreedhar100% (4)

- Fan Clutch PDFDocument20 pagesFan Clutch PDFCuong DinhNo ratings yet

- 1kz-Te Cooling System PDFDocument14 pages1kz-Te Cooling System PDFwill meridith100% (2)

- Refrigeration Guide Book For Marine EngineersDocument9 pagesRefrigeration Guide Book For Marine EngineersGee LongNo ratings yet

- D4204T5 EngineDocument52 pagesD4204T5 EngineCristian100% (7)

- R134a WC DX SCREW CHILLER USER MANUAL USER MANUAL 1 PDFDocument116 pagesR134a WC DX SCREW CHILLER USER MANUAL USER MANUAL 1 PDFSumit DasNo ratings yet

- Composite Pressure Vessel Term PaperDocument35 pagesComposite Pressure Vessel Term PaperNeel NadparaNo ratings yet

- HACCP-Manual ExampleDocument26 pagesHACCP-Manual ExampleRONo ratings yet

- 114 Engine S&FDocument30 pages114 Engine S&Fivan alvesNo ratings yet

- ТНВД 4D88E YANMMARDocument58 pagesТНВД 4D88E YANMMARАлексей100% (2)

- Direct Condensation of Hydrocarbon VaporsDocument10 pagesDirect Condensation of Hydrocarbon VaporsManju Lata Kapur100% (1)

- 2 5415941395045155907 PDFDocument19 pages2 5415941395045155907 PDFAlyelXNo ratings yet

- Parts of A Power TransformerDocument3 pagesParts of A Power TransformerOscar Raymund Cadag100% (1)

- Nle Notes MCNDocument33 pagesNle Notes MCNjosephmary09No ratings yet

- Axillary Node DissectionDocument71 pagesAxillary Node DissectionKartik Kaistha100% (1)

- July PNLE 2011 PreBoard ExamDocument9 pagesJuly PNLE 2011 PreBoard ExamRon KimNo ratings yet

- Motor c13 CatDocument4 pagesMotor c13 CatDiego Vicente50% (2)

- SanyonDocument4 pagesSanyonCristian Cortes diasNo ratings yet

- Engine Cooling - ID4 2.2L Diesel - : Item SpecificationDocument30 pagesEngine Cooling - ID4 2.2L Diesel - : Item SpecificationRichard Andrianjaka LuckyNo ratings yet

- Engine Cooling - INGENIUM I4 2.0L PetrolDocument736 pagesEngine Cooling - INGENIUM I4 2.0L Petrolkhaledserag23No ratings yet

- LSMtron Operating MaintenanceDocument56 pagesLSMtron Operating MaintenanceCơ DungNo ratings yet

- Section 2 EngineDocument6 pagesSection 2 EngineDomingo BravoNo ratings yet

- Engine : General InformationDocument86 pagesEngine : General Informationahmed mNo ratings yet

- D12C Lub CoolDocument12 pagesD12C Lub Coolnainc928No ratings yet

- Liebherr R920 Cooling SystemDocument6 pagesLiebherr R920 Cooling SystemRiza DS100% (1)

- 7.engine Cooling SystemDocument52 pages7.engine Cooling Systemalex generalNo ratings yet

- 3 160428055251Document30 pages3 160428055251arifNo ratings yet

- Cooling SystemDocument16 pagesCooling SystemRavneel ChandNo ratings yet

- CO - 1NZ-FXE CoolingDocument42 pagesCO - 1NZ-FXE CoolingShua HaiderNo ratings yet

- Automobile Cooling System PDFDocument21 pagesAutomobile Cooling System PDFGomathi SankarNo ratings yet

- Proton Arena Engine Cooling 1.5 1.8 Service ManualDocument16 pagesProton Arena Engine Cooling 1.5 1.8 Service ManualchipestNo ratings yet

- 1 Nzfe 9Document11 pages1 Nzfe 9rahmatullahmohammady2002No ratings yet

- Chevy z71 Cooling System Form Service MAnualDocument65 pagesChevy z71 Cooling System Form Service MAnualBush Pilot DudeNo ratings yet

- Engine 4J SeriesDocument16 pagesEngine 4J SeriesImesh SachinthaNo ratings yet

- Section 2 EngineDocument5 pagesSection 2 EngineJuan Felipe Garza GNo ratings yet

- Búsqueda Del Medio - SEBD0518 - Know Your Cooling System (0708, 1Document105 pagesBúsqueda Del Medio - SEBD0518 - Know Your Cooling System (0708, 1Wilder UrtadoNo ratings yet

- D3500MM M03 CoolSys en TXT-ParticipantDocument29 pagesD3500MM M03 CoolSys en TXT-ParticipantGuilherme ChiminelliNo ratings yet

- RLC Eb 16Document8 pagesRLC Eb 16Armando Jesus CedeñoNo ratings yet

- Section 2 Engine: Group 1 Structure and Function 2-1Document5 pagesSection 2 Engine: Group 1 Structure and Function 2-1Manuel PomahualiNo ratings yet

- Engine Cooling SystemDocument21 pagesEngine Cooling SystemDidier ÁlvarezNo ratings yet

- 1998 Sec 6-Engine Cooling & ElectricalDocument156 pages1998 Sec 6-Engine Cooling & ElectricalLuis TomboNo ratings yet

- Cooling System Overview - E70 DieselDocument1 pageCooling System Overview - E70 Dieselzerhan zenunNo ratings yet

- Section 2 EngineDocument7 pagesSection 2 EngineЕвгений СолдатовNo ratings yet

- Sis 2.0Document82 pagesSis 2.0MalindaNo ratings yet

- Hijet CO-Cooling SystemDocument28 pagesHijet CO-Cooling Systemjyzjz6sr65No ratings yet

- 5-1 Steering SystemDocument7 pages5-1 Steering SystemSumitomo Laos Sumitomo LaosNo ratings yet

- E3262 LE202 Technical DataDocument58 pagesE3262 LE202 Technical DatacriveraNo ratings yet

- Calculation and Specification of Engine Cooling System: Design Iv Machinery System Department of Marine EngineeringDocument22 pagesCalculation and Specification of Engine Cooling System: Design Iv Machinery System Department of Marine EngineeringSean Chen GyarinoNo ratings yet

- Cooling Sist - Ford MustangDocument4 pagesCooling Sist - Ford MustangLuis Blanco BandresNo ratings yet

- HL740-9 2-1Document7 pagesHL740-9 2-1REMZONANo ratings yet

- Audi Engines Chain Drives Part 2Document4 pagesAudi Engines Chain Drives Part 2mildred100% (35)

- 303-03A+Engine+CoolingDocument33 pages303-03A+Engine+CoolingP HandokoNo ratings yet

- Know Your Cooling SystemDocument103 pagesKnow Your Cooling SystemgustavoNo ratings yet

- R2 Four Basic Components of A Refrigeration System: #2 CompressorsDocument54 pagesR2 Four Basic Components of A Refrigeration System: #2 CompressorsAhmad NasrudinNo ratings yet

- Diesel CoolingDocument84 pagesDiesel CoolingNA01JTNo ratings yet

- Daddy Wasn't There, Abandonment PoemDocument2 pagesDaddy Wasn't There, Abandonment Poemonejako12No ratings yet

- Probiotics and PrebioticsDocument19 pagesProbiotics and PrebioticsAbdul RehmanNo ratings yet

- Survey On Maggi NoodlesDocument18 pagesSurvey On Maggi NoodlesSiddhesh SawantNo ratings yet

- Plinth Beam and FoundationDocument1 pagePlinth Beam and FoundationSteny AbrahamNo ratings yet

- PH, Buffer, and Dissociation ConstantDocument5 pagesPH, Buffer, and Dissociation ConstantAlisher AbdugalimovNo ratings yet

- D6489 PDFDocument3 pagesD6489 PDFKalindaMadusankaDasanayakaNo ratings yet

- NCP Skills LabDocument6 pagesNCP Skills LabJunnie Rose IsiderioNo ratings yet

- United States Court of Appeals, Eleventh CircuitDocument6 pagesUnited States Court of Appeals, Eleventh CircuitScribd Government DocsNo ratings yet

- Electricity Booklet 2Document7 pagesElectricity Booklet 2Neline Joy P GonzagaNo ratings yet

- CBC AuditDocument4 pagesCBC Auditfrenz2kiranNo ratings yet

- BW - Pe 5Document1 pageBW - Pe 5Leslivar BangbangNo ratings yet

- Corporate Finance: Topic: Amalgamation of HBL and BarclaysDocument8 pagesCorporate Finance: Topic: Amalgamation of HBL and BarclaysNoor-Us-Sabah GilaniNo ratings yet

- Specific Gravity of Soil SolidsDocument7 pagesSpecific Gravity of Soil SolidsChristian CabacunganNo ratings yet

- English Assignment 2Document7 pagesEnglish Assignment 2Zeuss MohamedNo ratings yet

- NABARDDocument10 pagesNABARDYogesh SinghalNo ratings yet

- Srw12U: Smartrack Wall-Mount Rack Enclosure CabinetDocument3 pagesSrw12U: Smartrack Wall-Mount Rack Enclosure CabinetcurdanetNo ratings yet

- Rev - STR-044 AGDocument12 pagesRev - STR-044 AGShiv PandeyNo ratings yet

- MBT-Term Test 1Document45 pagesMBT-Term Test 1lkokodkodNo ratings yet

- C+F-Overview of Supraventriculer Tachycardia in Dogs and CatsDocument11 pagesC+F-Overview of Supraventriculer Tachycardia in Dogs and Catstaner_soysurenNo ratings yet

- Hygiene Monitoring in Support of Food Safety - A Review of Methods and Industry TrendsDocument6 pagesHygiene Monitoring in Support of Food Safety - A Review of Methods and Industry TrendsIvone DominguezNo ratings yet